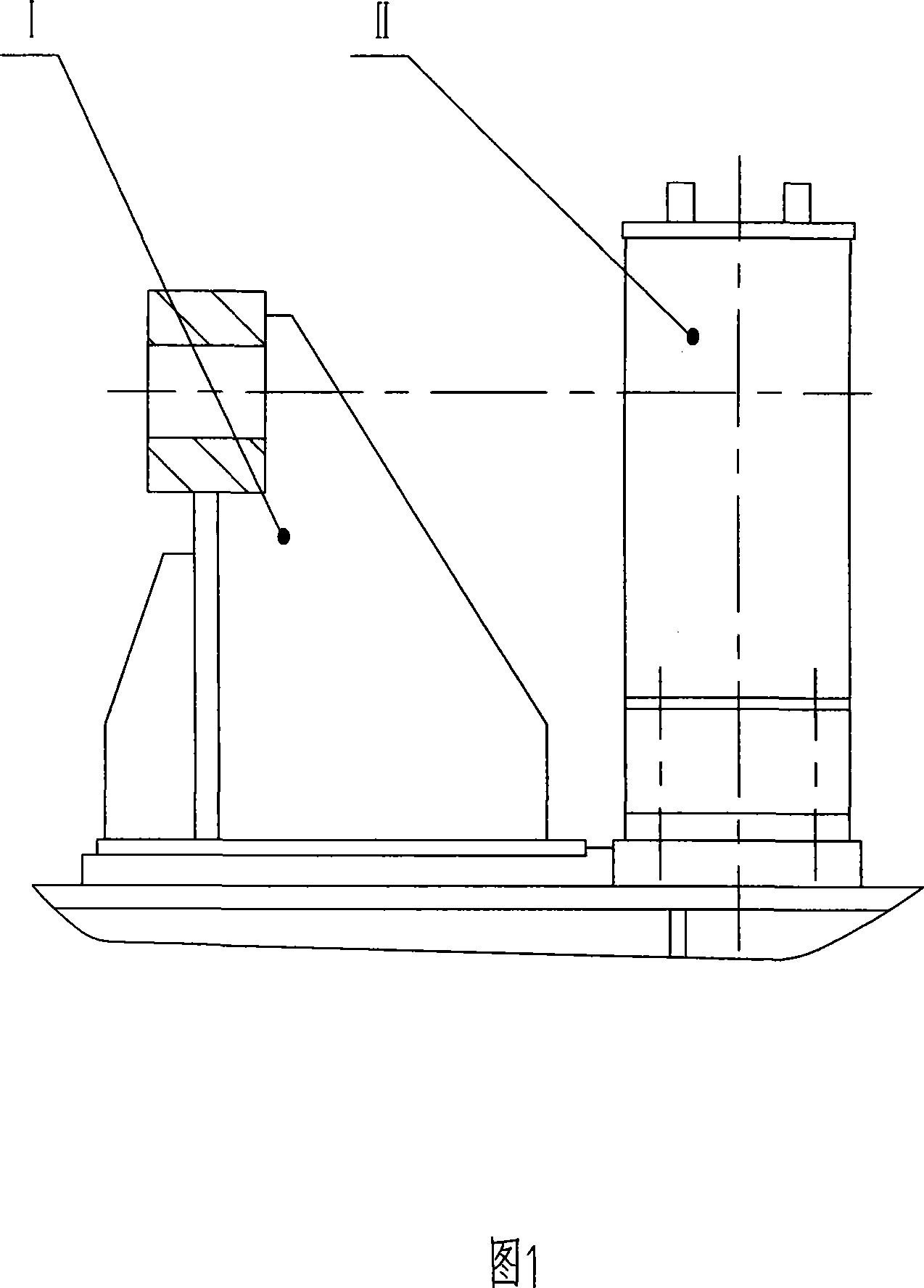

Disconnection device for punch refrigerant top

A technology for piercing and pipe removal, which is applied in the direction of removal of mandrels, metal rolling, manufacturing tools, etc., can solve the problems of poor rigidity, uneven wall thickness of capillaries, and large floor space, and achieves improvement of uniform wall thickness. performance, shortening the length of the ejector rod, and improving the rigidity of the ejector rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

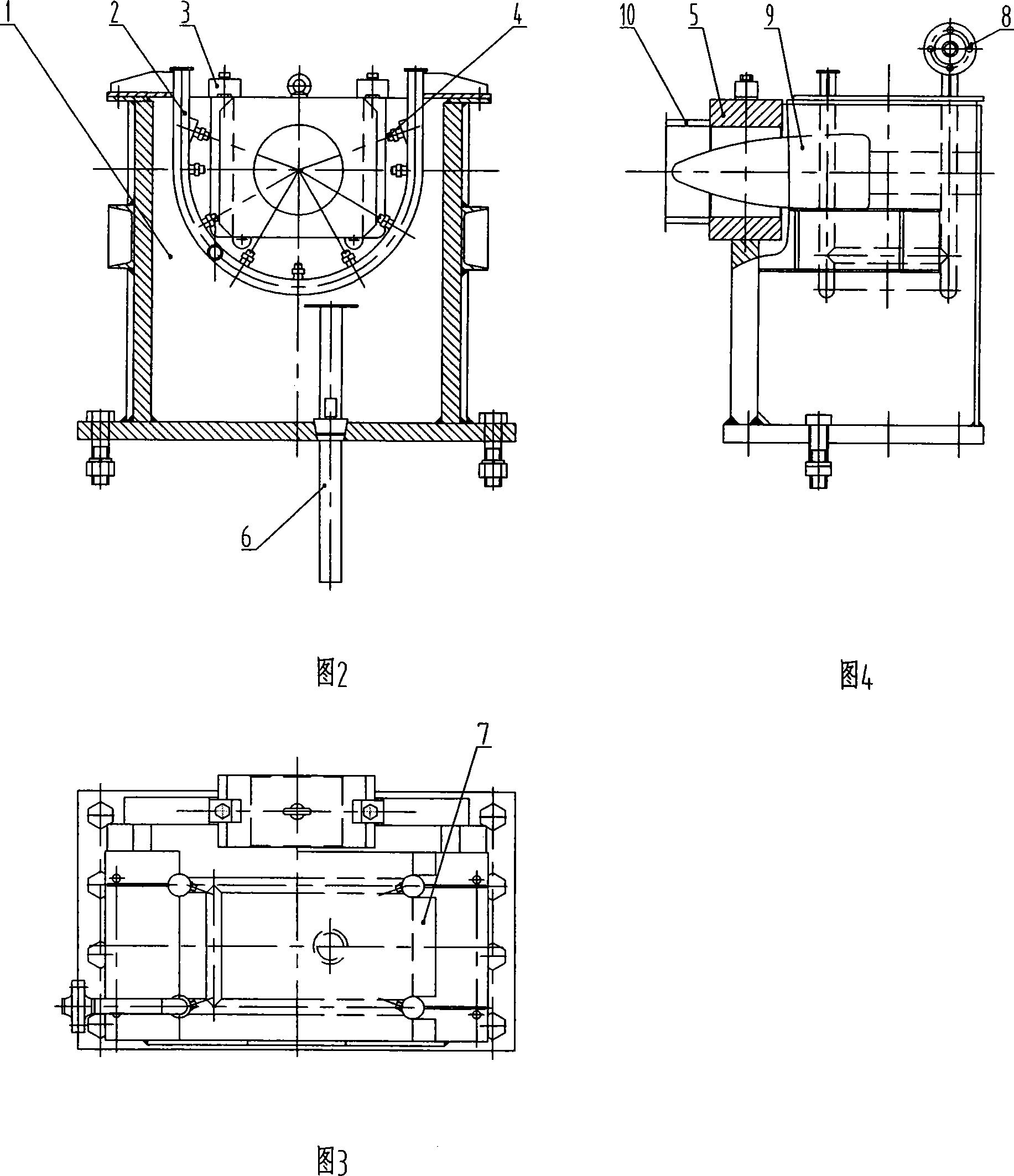

[0018] As shown in Figures 2, 3, and 4, a pipe removal device used for cooling the top of the piercer is to design the front panel of the cooling water tank 1 as a pipe removal mold bracket, and the pipe removal mold 5 is installed on the front panel of the water tank. It is fixed by the pressure block 3. The stripping die is a device that separates the capillary from the plug 9 and the ejector pin after the perforation is completed. Its main function is to block the head of the capillary 10 to position the capillary, allowing the plug and the ejector pin to be drawn out through the die opening. After the plug is pulled out from the die mouth, it enters the water tank. The water spray pipe 2 is installed in the water tank. The water spray pipe is connected with the workshop water supply pipe through the flange 8. The water spray pipe is composed of two semicircular water pipes with nozzles 4. During the intermittent time, spray water from all around to the head to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com