Useful wrinkle prefabrication method for improving internal high-pressure forming limit in pipe

A technology of internal high pressure forming and wrinkling, which is applied in the field of pipe hydroforming, which can solve problems such as mutual constraints and wrinkle control difficulties, and achieve the effects of high limit expansion rate, improved formability, uniformity of wall thickness, and uniform distribution of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

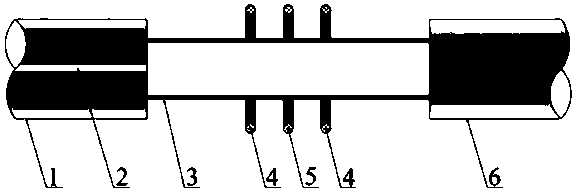

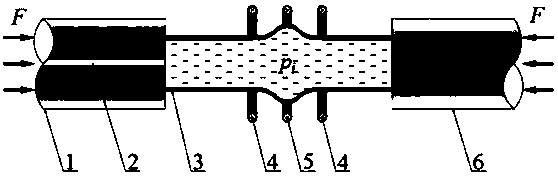

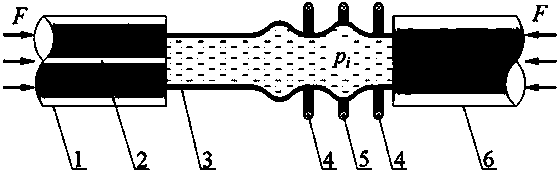

[0032] In the first step, the tube to be wrinkled passes through the induction heating coil and the cooling coil, and then the two ends of the tube are installed between the left punch I and the right punch I, and the tube blank is connected to the left punch I and the right punch Sealing needs to be realized between the punches Ⅰ, the left punch Ⅰ and the right punch Ⅰ can move in the axial direction respectively, so as to apply axial pressure to the tube blank, and the left punch Ⅰ has a channel Ⅰ;

[0033]Prefabrication of beneficial corrugated tube blanks by using selective heating method is mainly to improve the forming limit of low plastic pipes in the internal high pressure forming process and improve the uniformity of pipe wall thickness distribution. Specifically, the corrugated tube blanks are made of aluminum and aluminum alloys, magnesium and magnesium One of alloys, titanium and titanium alloys or other pipes that are prone to rupture during internal high pressure ...

Embodiment 2

[0042] When prefabricating the corrugation of the tube blank, no pressure is applied to the inside of the tube blank, that is, p i =0, after local heating of the tube blank, the tube blank only undergoes plastic instability and wrinkles under the action of axial feeding. Other implementation methods are the same as in Example 1.

Embodiment 3

[0044] When performing local heating, no cooling coil is provided, and the local heating of the tube blank is realized only through the induction heating coil. Other implementation methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com