Patents

Literature

48results about How to "Uniform wall thickness distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of titanium alloy hollow component

ActiveCN101786223AIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

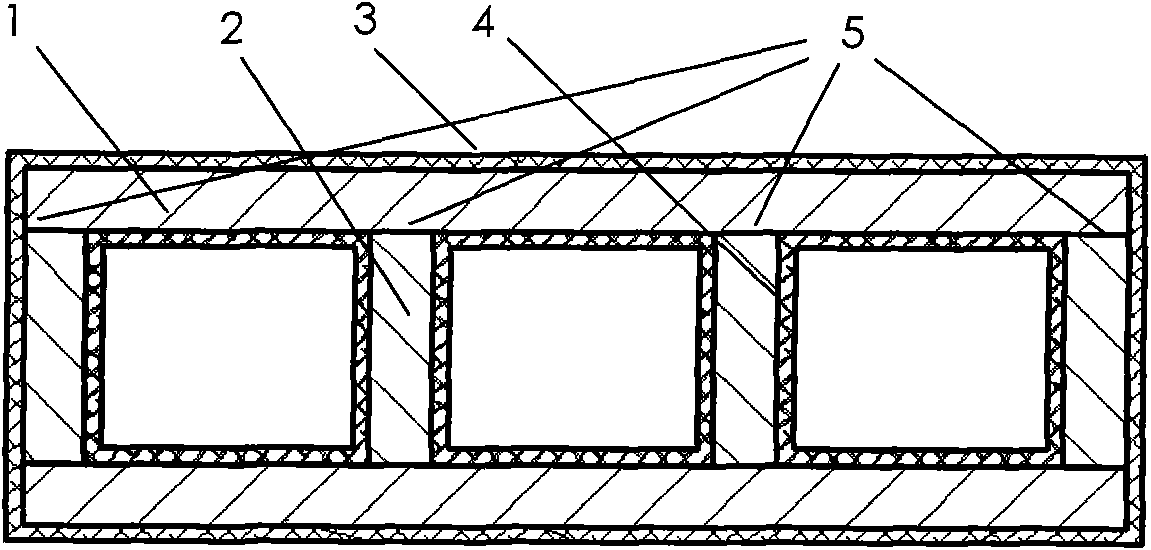

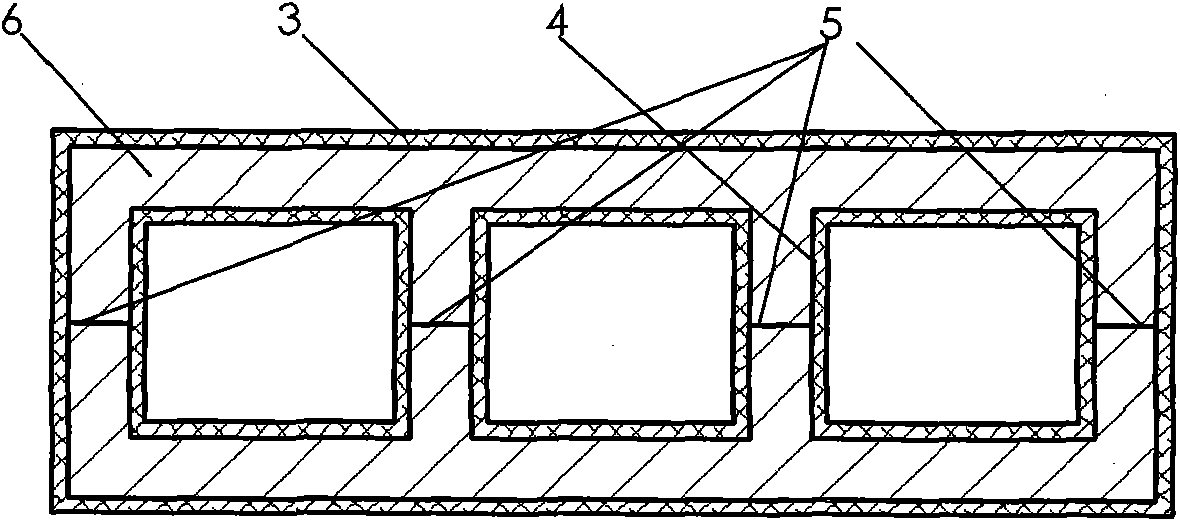

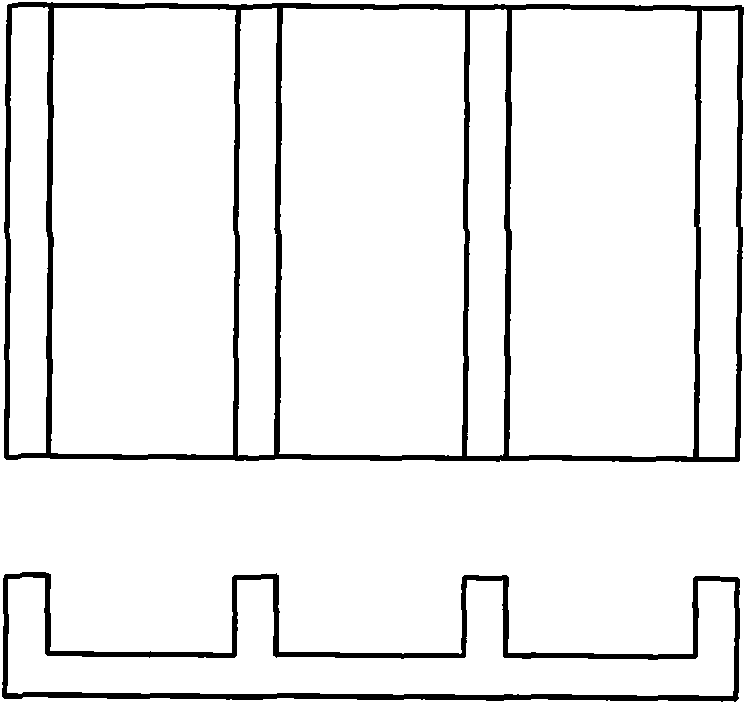

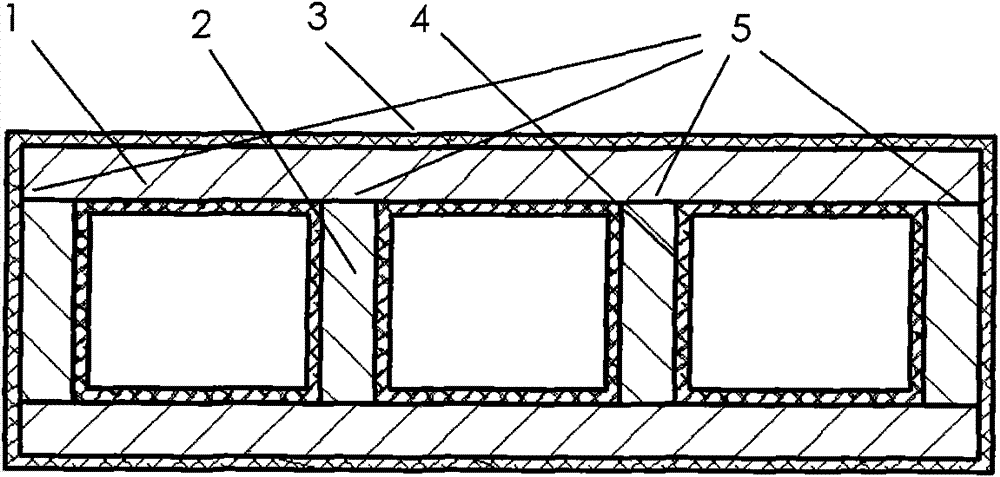

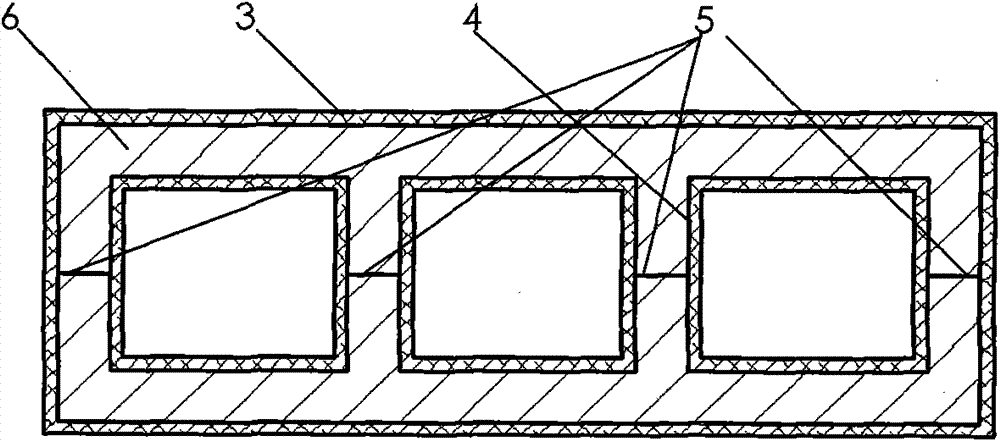

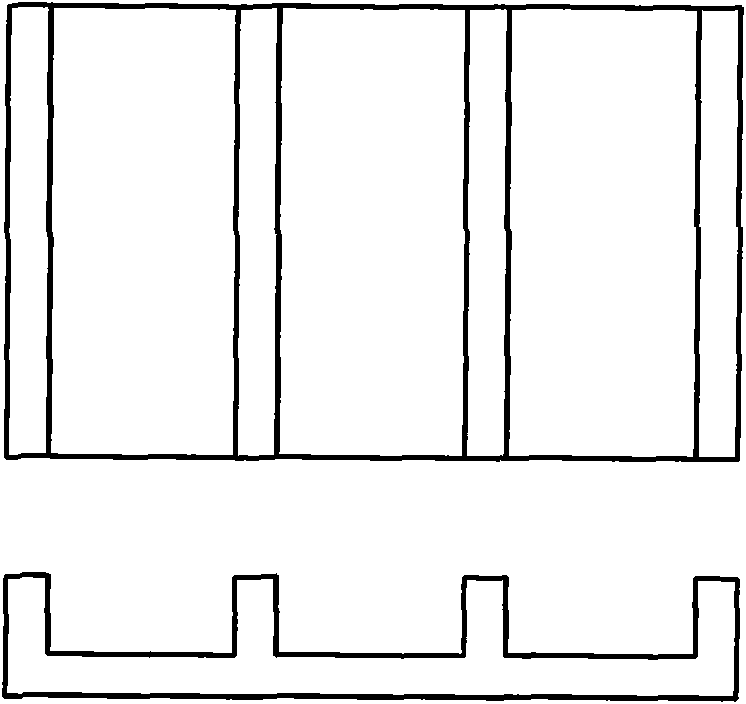

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structure forms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposed structure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structural part is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

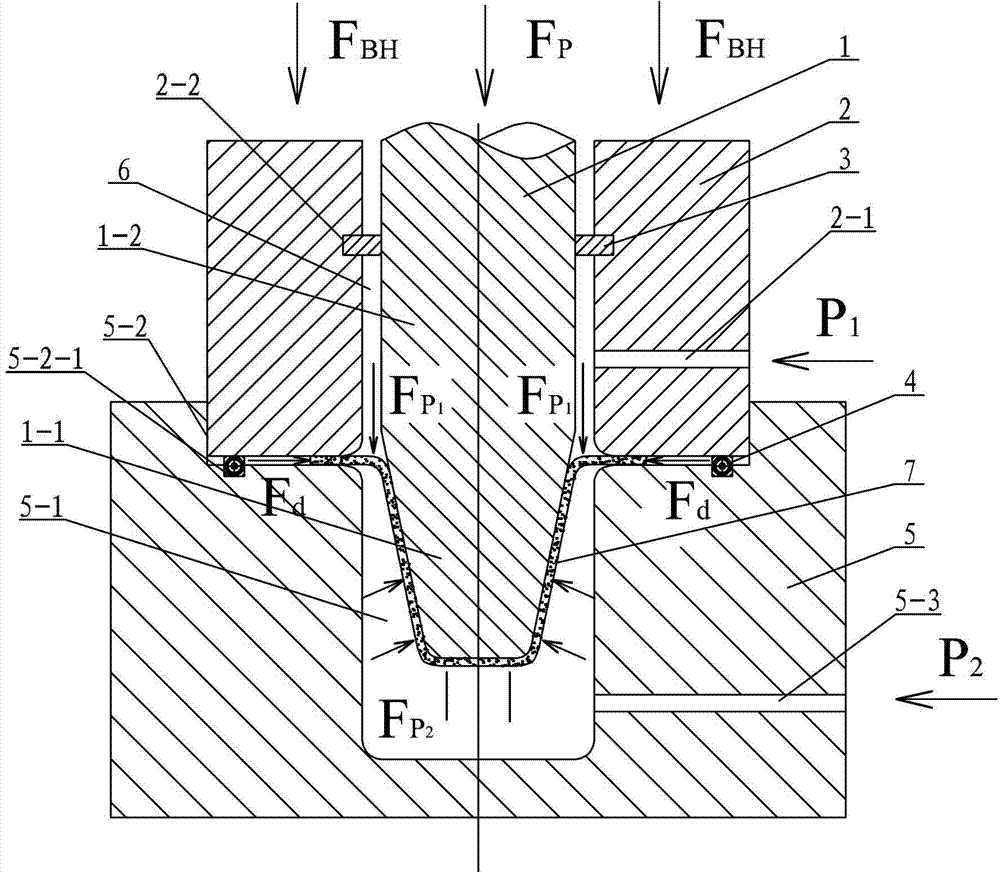

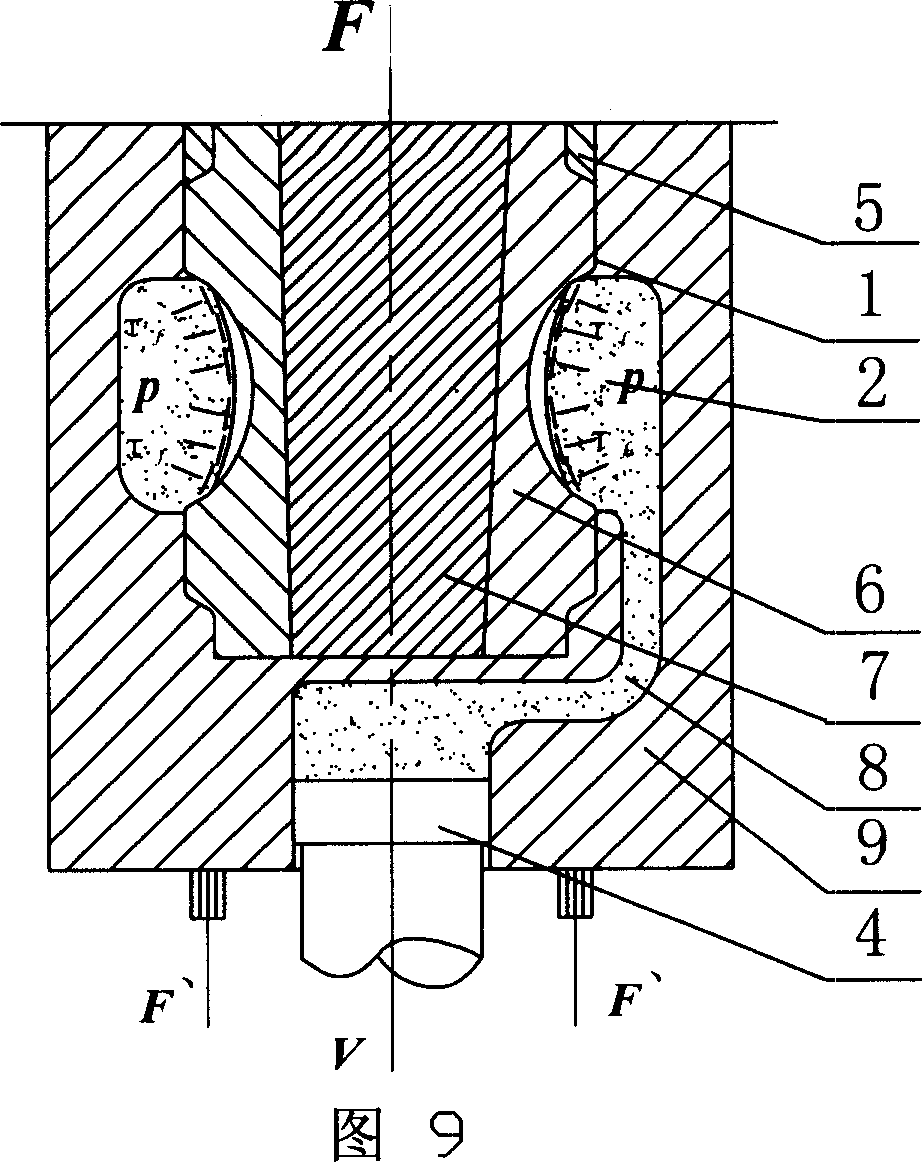

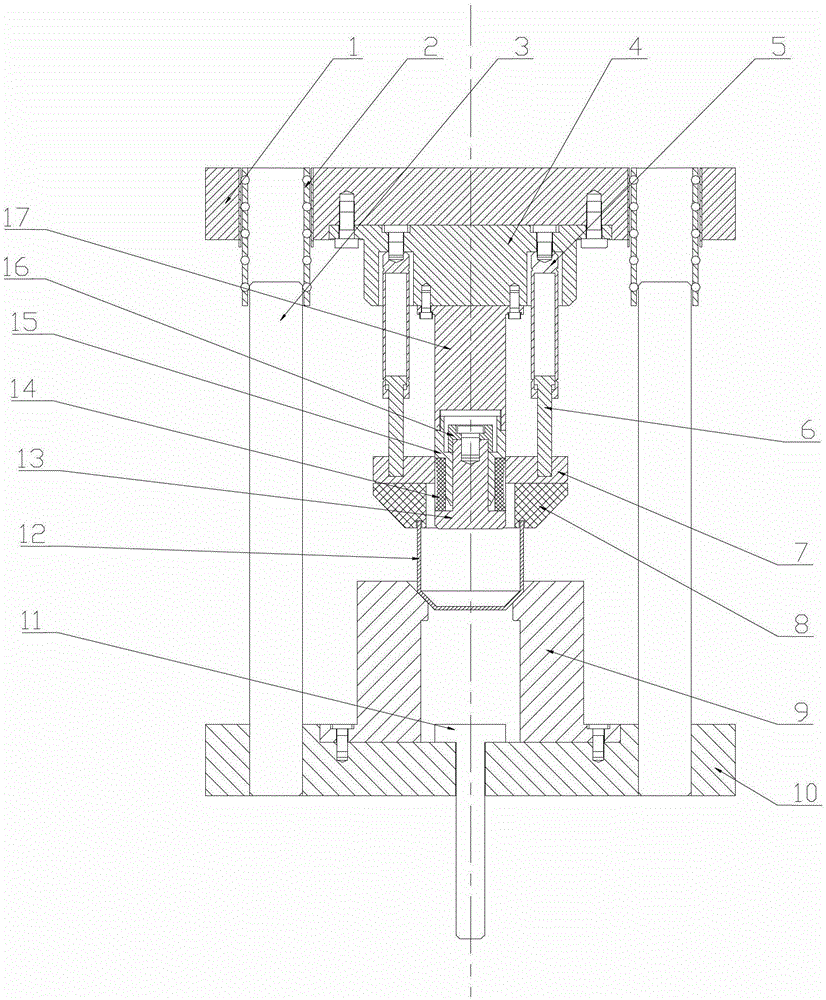

Electromagnetism-assisted forming device and method for dissimilar metal composite boards

The invention relates to an electromagnetism-assisted forming device and method for dissimilar metal composite boards and aims to solve the problem that existing metal composite boards are severely lapped and even broken in a drawing process. According to the forming device, a coil is arranged in an annular coil groove, a liquid channel is disposed between the inner wall of a blank holder and a cylinder, an upper liquid inlet channel is transversely arranged on the side wall of the blank holder, and a lower liquid inlet channel is transversely arranged on the side wall of a female die. The method includes placing the composite boards on the bottom surface of the blank holder; filling forward liquids into the liquid channel, filling reverse liquids into the female die, and exerting radial electromagnetic force Fd on the periphery of a flange of the composite board through the coil; forming the composite board under the combined action of a reverse pressure Fp2, a forward pressure Fp1 and the radial electromagnetic force Fd; and unloading a forward liquid pressure P1 and then a reverse liquid pressure P2, returning a male die and taking the formed part.

Owner:HARBIN INST OF TECH

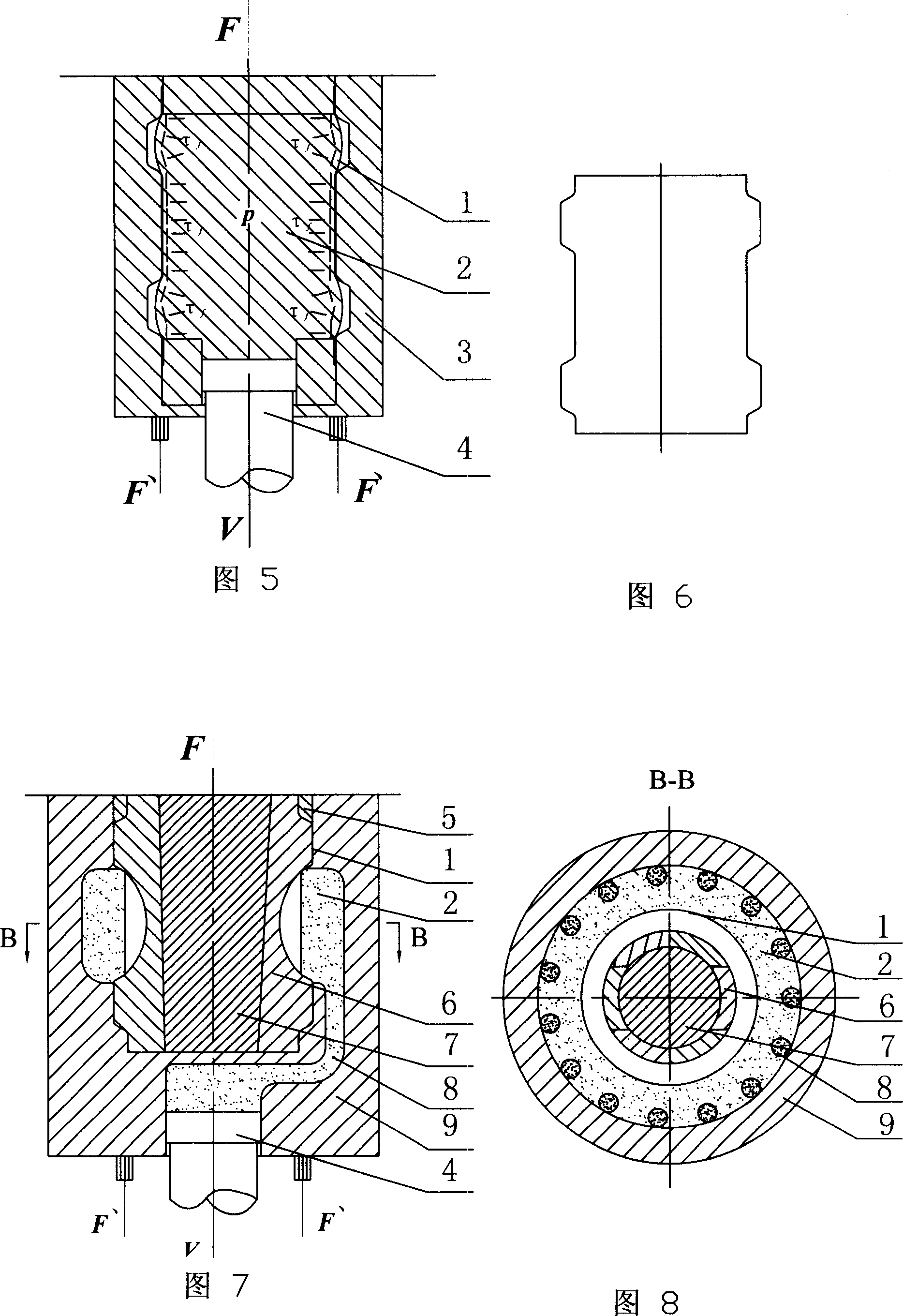

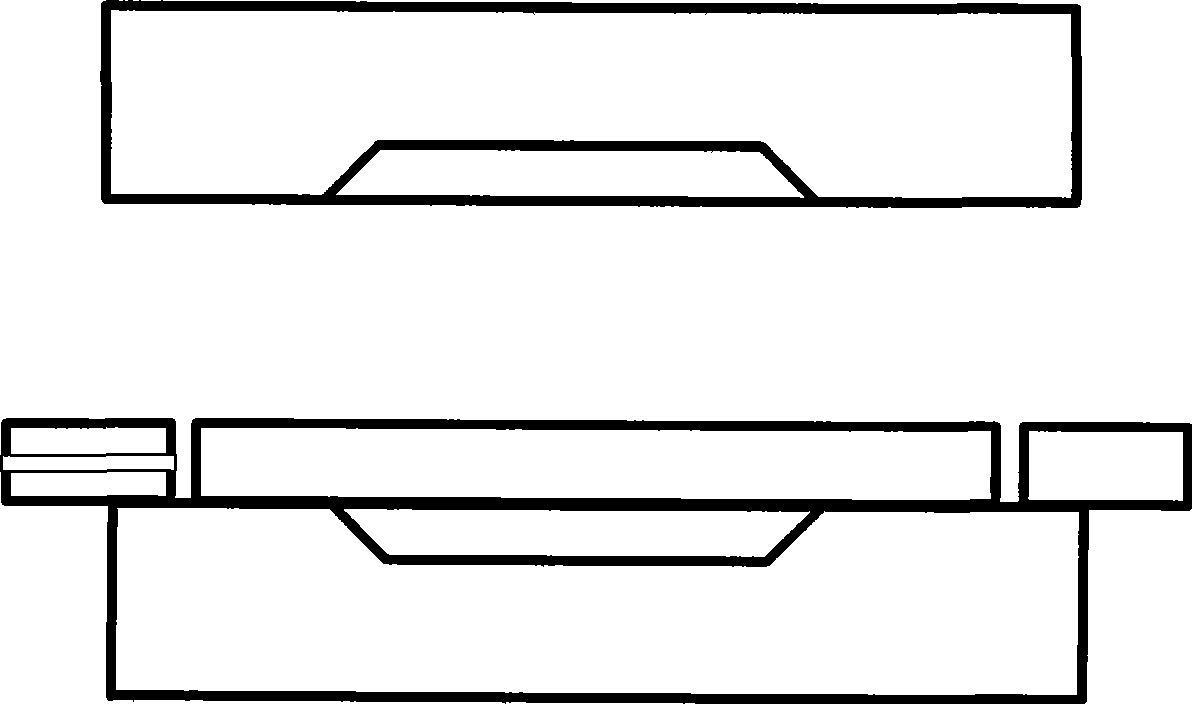

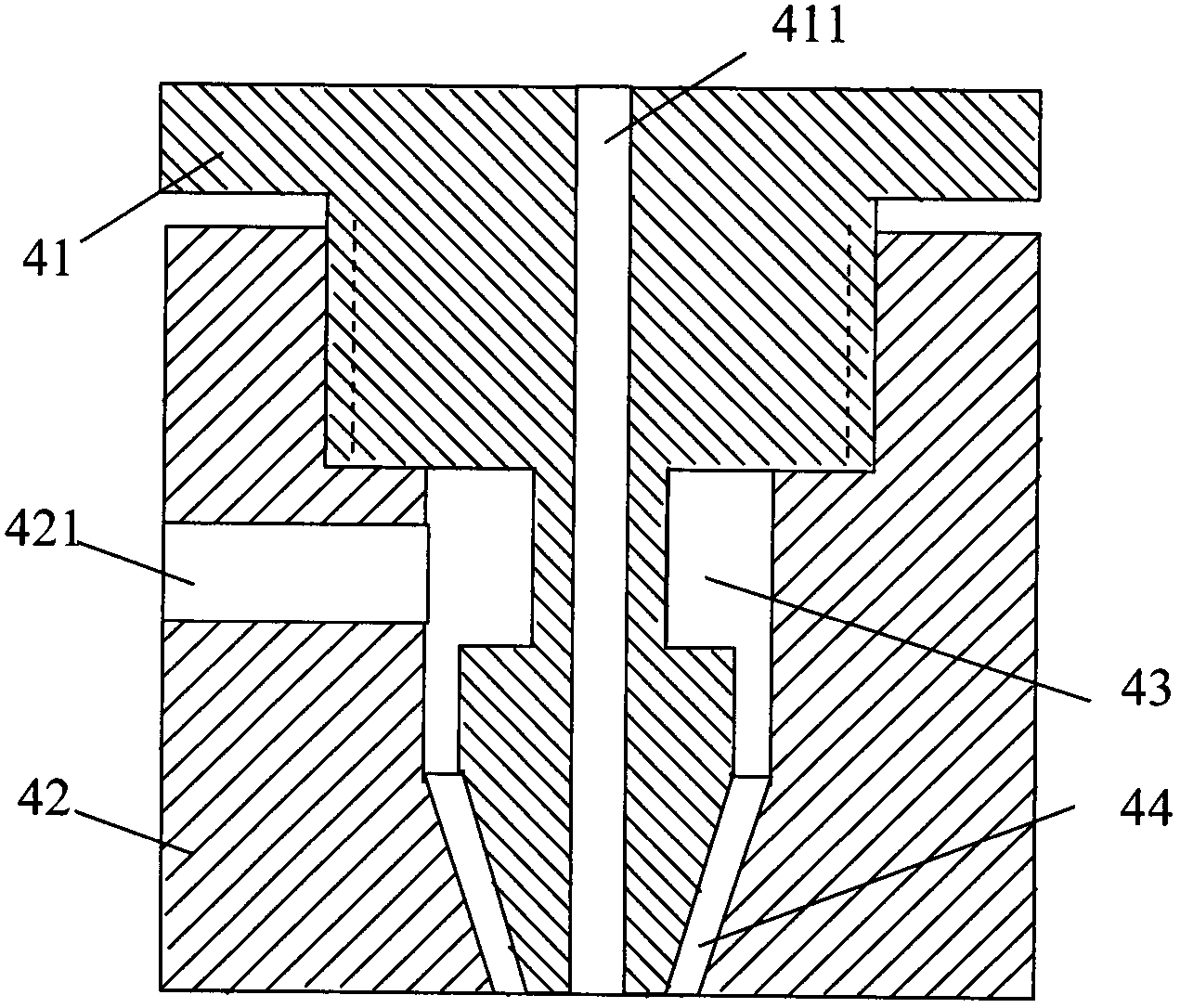

Mold and shaping technique for metal sheet material deep-drawing cup shell

The invention discloses a die assembly of metal plate deep-drawing cup shells and shaping process. The invention comprises an upper die holder and a lower die holder, wherein a punch and a cavity die which are mutually corresponded are respectively arranged on the upper die holder and the lower die holder, a discharging screw which is connected with the upper die holder and a flanging spring which is sleeved on the discharging screw are arranged on the outer side of the punch, a blank holder is arranged on the lower end of the discharging screw, a holding frame which is fixedly connected with the lower die holder is arranged on the outer side of the cavity die, a conical pushing block and a rubber pad are arranged in turn in the holding frame from top to bottom, a conical enclasping element which is matched with the punch is arranged in the conical pushing block, a spring holder is arranged on the lower end of the lower die holder, a material squeezing spring is arranged in the spring holder, and a push rod which is extended through the rubber pat, the conical pushing block, and a conical clamping element is arranged on the upper end of the material squeezing spring. The invention carries out enclasping along the side-wall direction during the deep-drawing process of cup shells, material flowing tendency can be changed flexibly and actively, which enables wall thickness to be changed evenly, maximum thinning-out quantity on a dangerous cross portion during the process for drawing can be minimized and drawing breakage can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

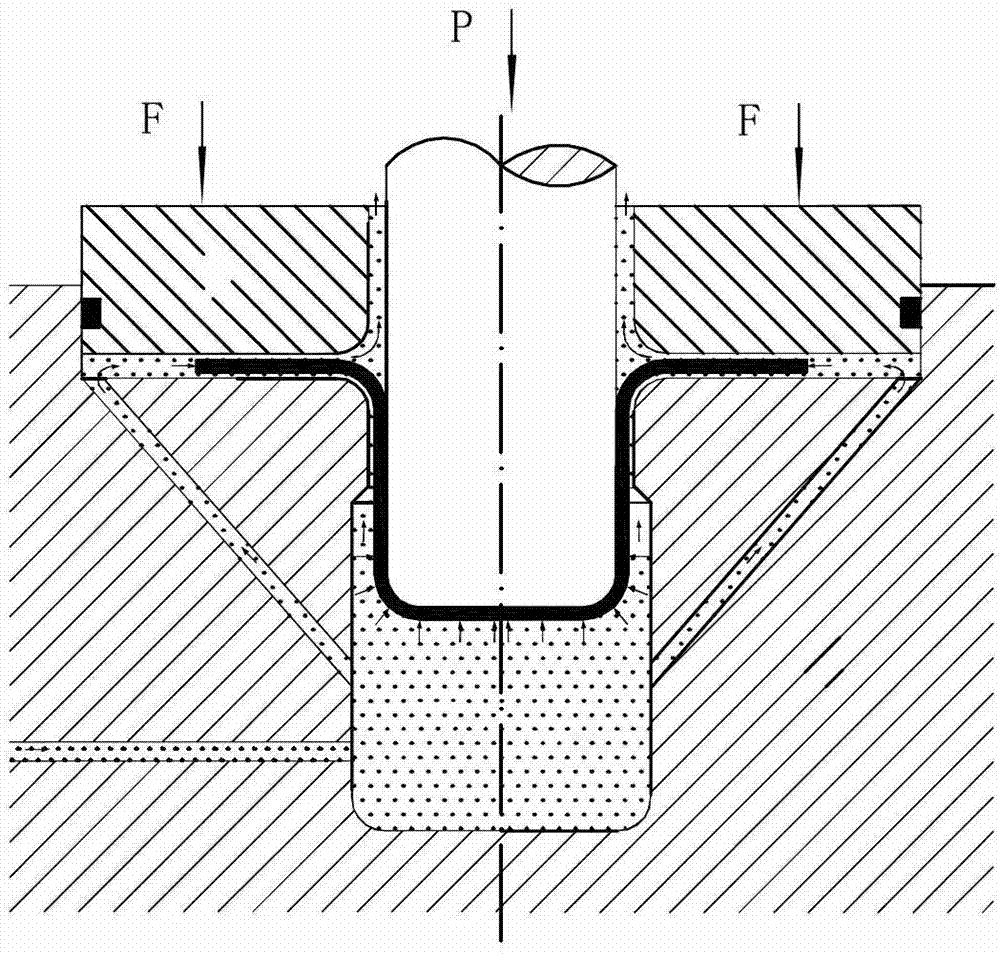

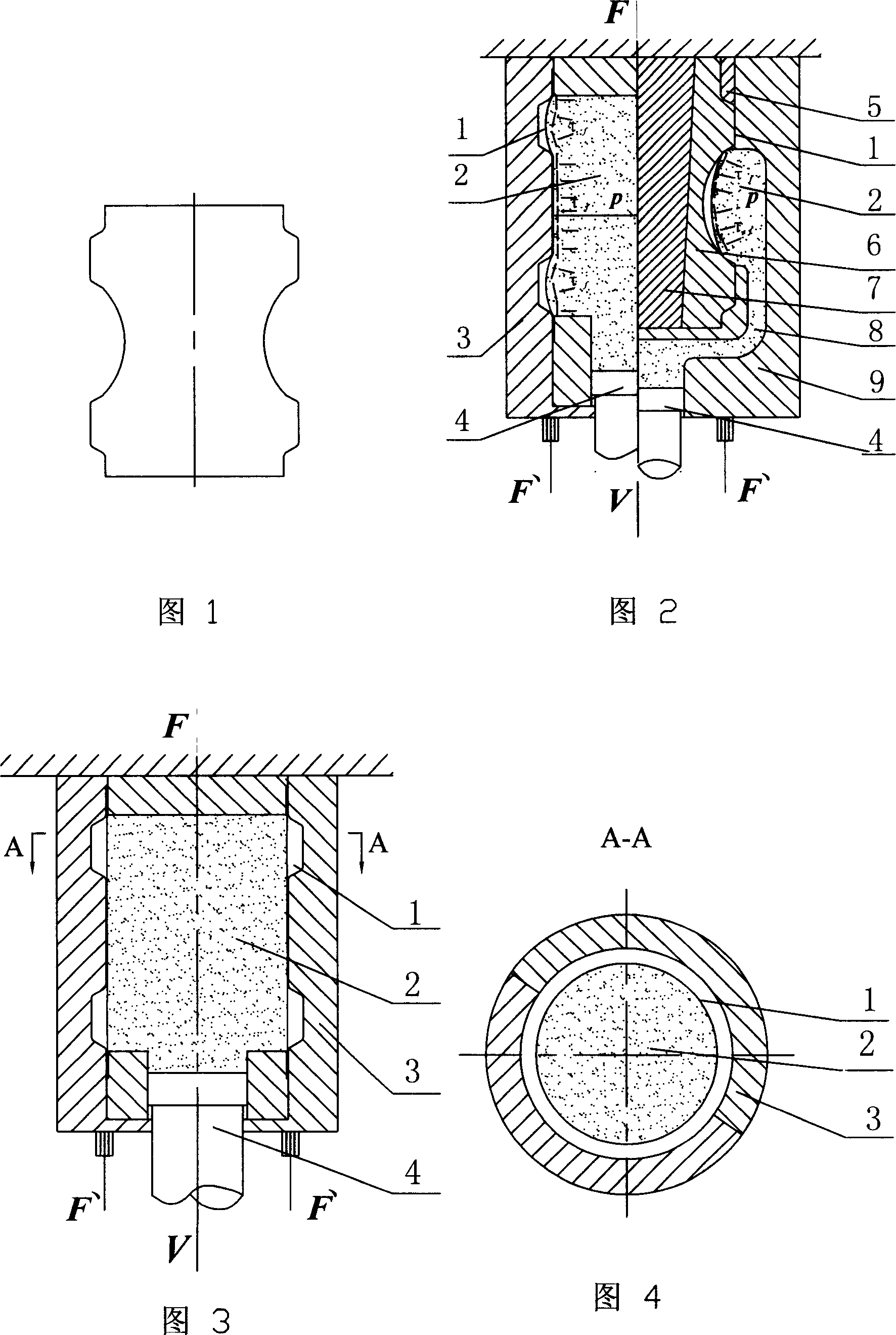

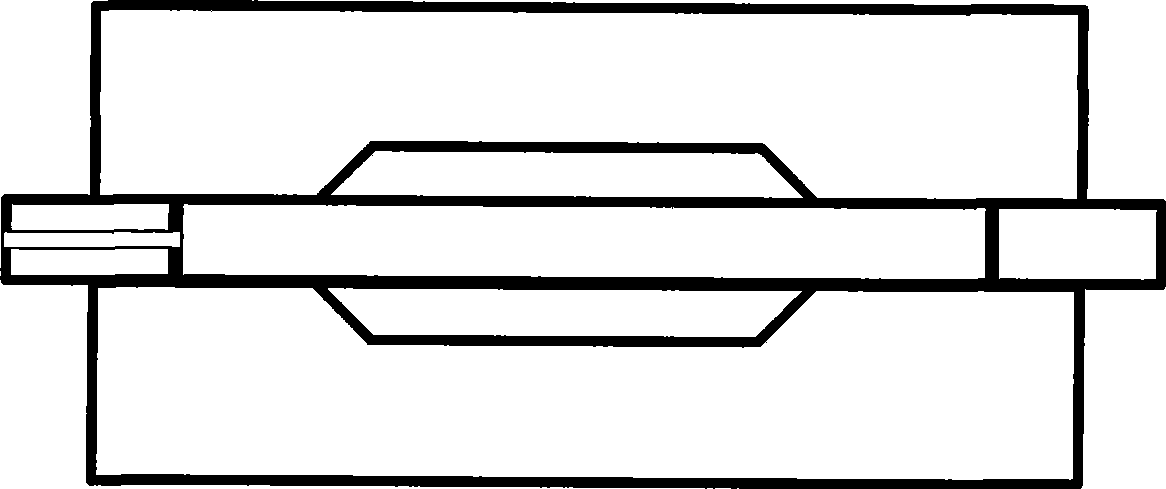

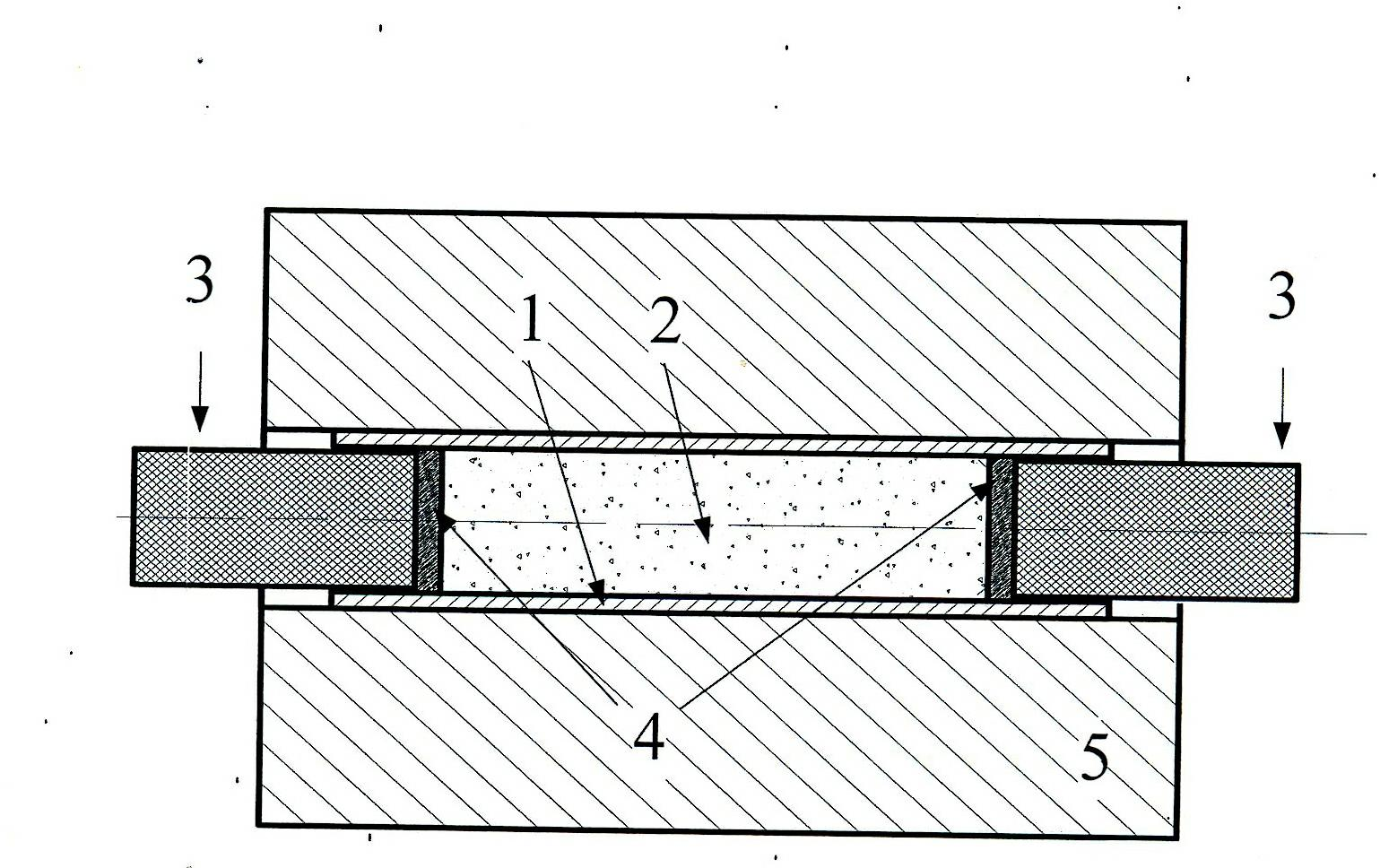

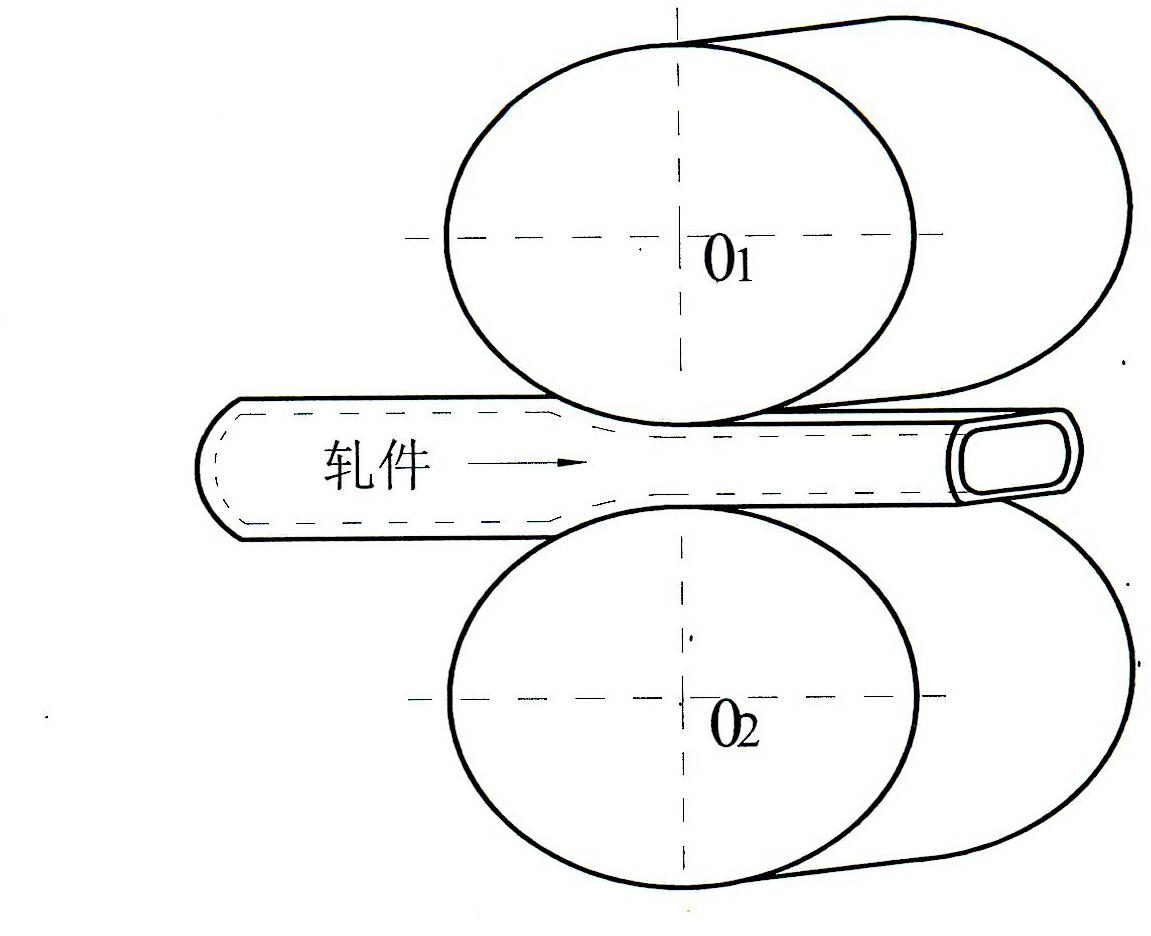

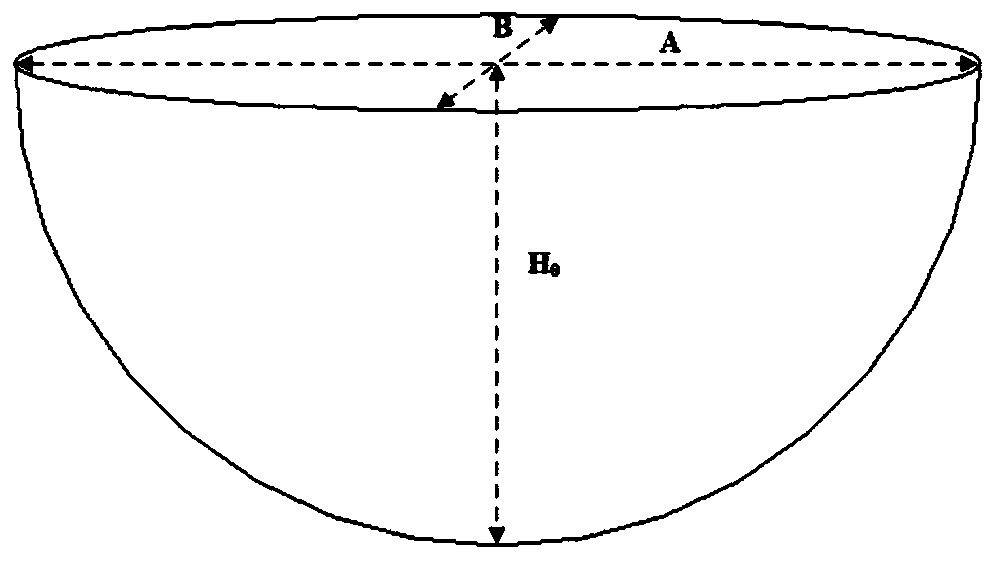

Internal and external pressurization compound forming method for axisymmetric thin-wall special-shaped curved work piece with large section surface

InactiveCN1962107AStrong strain rate sensitivityHigh dimensional accuracyShaping toolsMaterials scienceThin walled

The invention relates to a composite shaping method of symmetry thin large-section special curvature element, wherein it comprises that; selecting cylinder blank; preparing cylinder blank; putting the blank into shaping mould; pouring adhesive soft mould material along the inner side of cylinder, to expand the diameter of blank until contact the mould; opening the mould, taking out shaped element and removing the adhesive soft mould material; then putting the element into compression mould, and pouring the adhesive soft mould material into the outer side of element to reduce the diameter of blank, until contacting the corn mould; opening mould and taking out the element. The inventive product has uniform wall and high accuracy.

Owner:HARBIN INST OF TECH

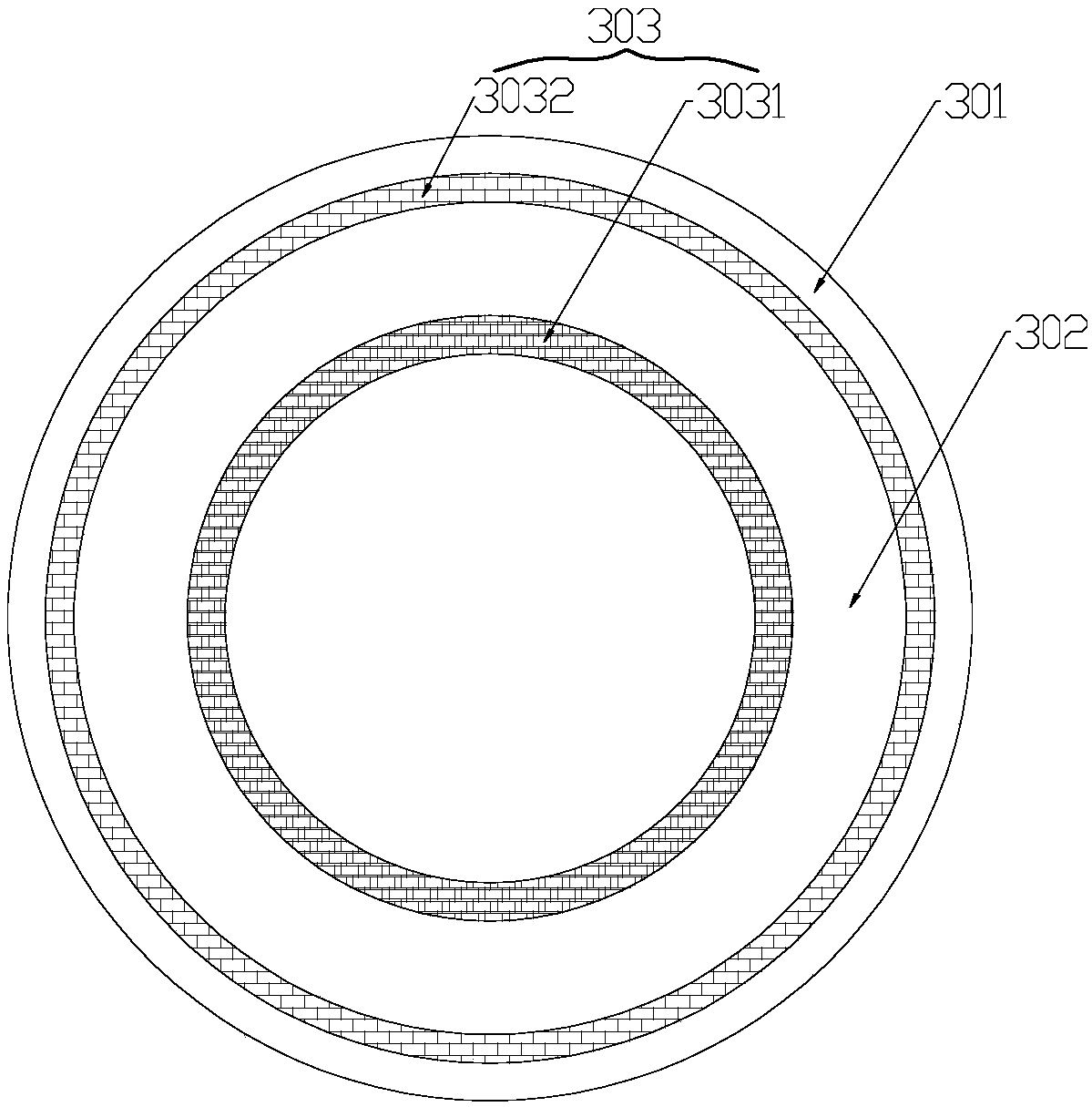

Braided tube-reinforced hollow fiber membrane and preparation apparatus and manufacturing process thereof

ActiveCN107913603AEasy to operateProcess conditions are easy to controlSemi-permeable membranesSustainable biological treatmentHollow fibre membraneFiber

The application relates to a braided tube-reinforced hollow fiber membrane and a preparation apparatus and a manufacturing process thereof, which belong to the technical field of semipermeable membranes characterized by organic materials and used for physical or chemical separation and special preparation methods thereof. The braided tube-reinforced hollow fiber membrane is composed of three layers, i.e. a separating layer, a precoated layer and a braided tube reinforcing layer, the braided tube reinforcing layer is arranged inside, the separating layer is arranged outside, moreover, the precoated layer consists of a first precoated layer and a second precoated layer, the first precoated layer is arranged on the inside of the braided tube reinforcing layer, and the second precoated layer is arranged between the braided tube reinforcing layer and the separating layer. When the application is applied in fields such as braided tube-reinforced hollow fiber membranes, the braided tube-reinforced hollow fiber membrane and preparation apparatus and manufacturing process thereof have the advantages of high bonding strength, low stripping rate and the like.

Owner:李亮

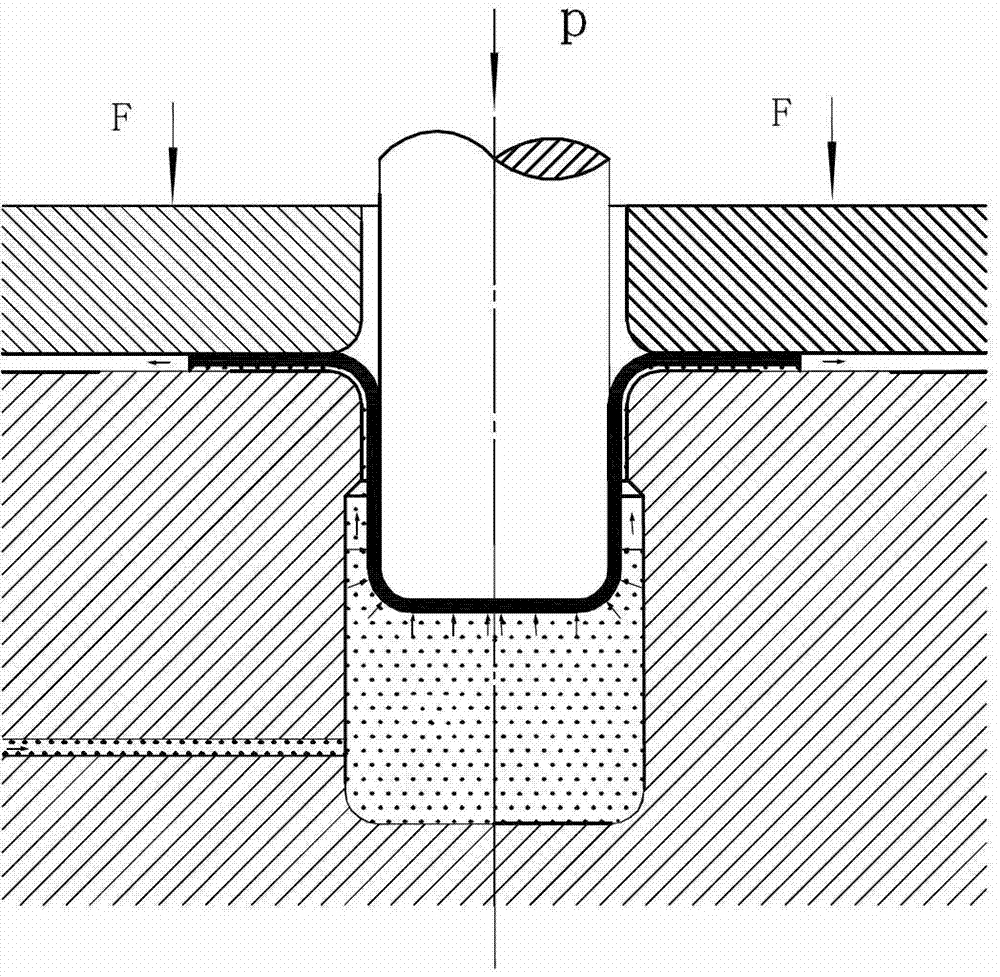

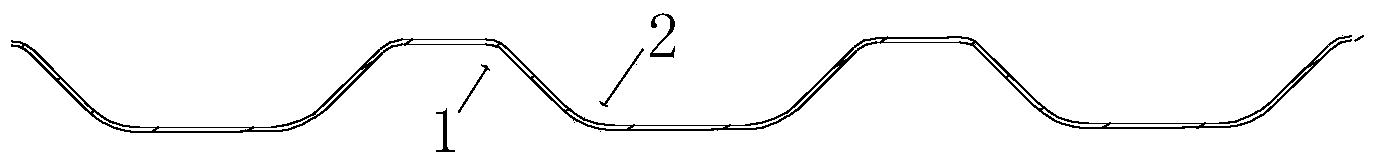

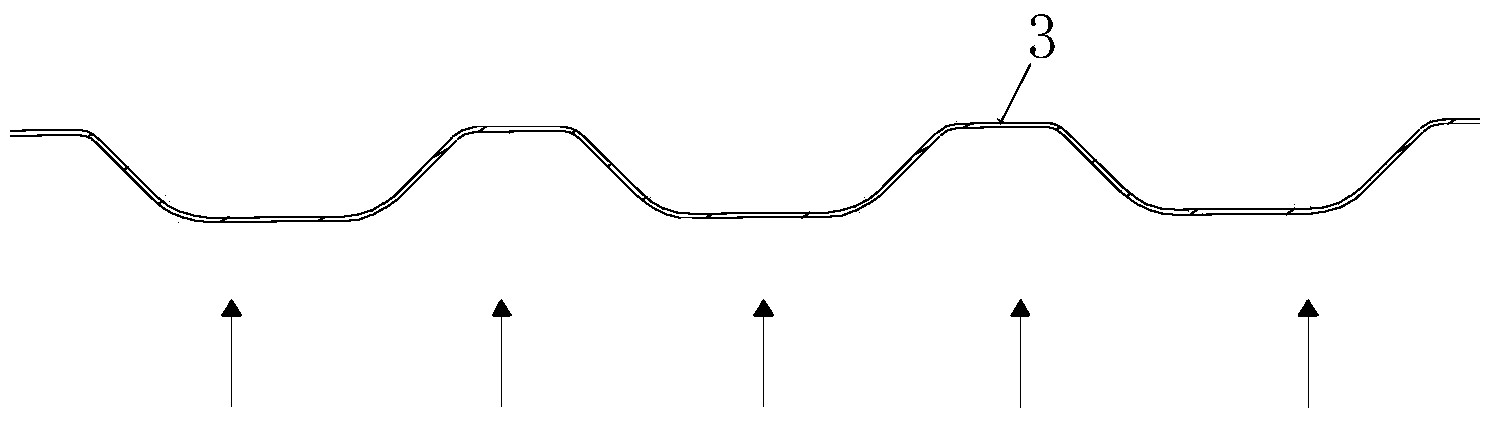

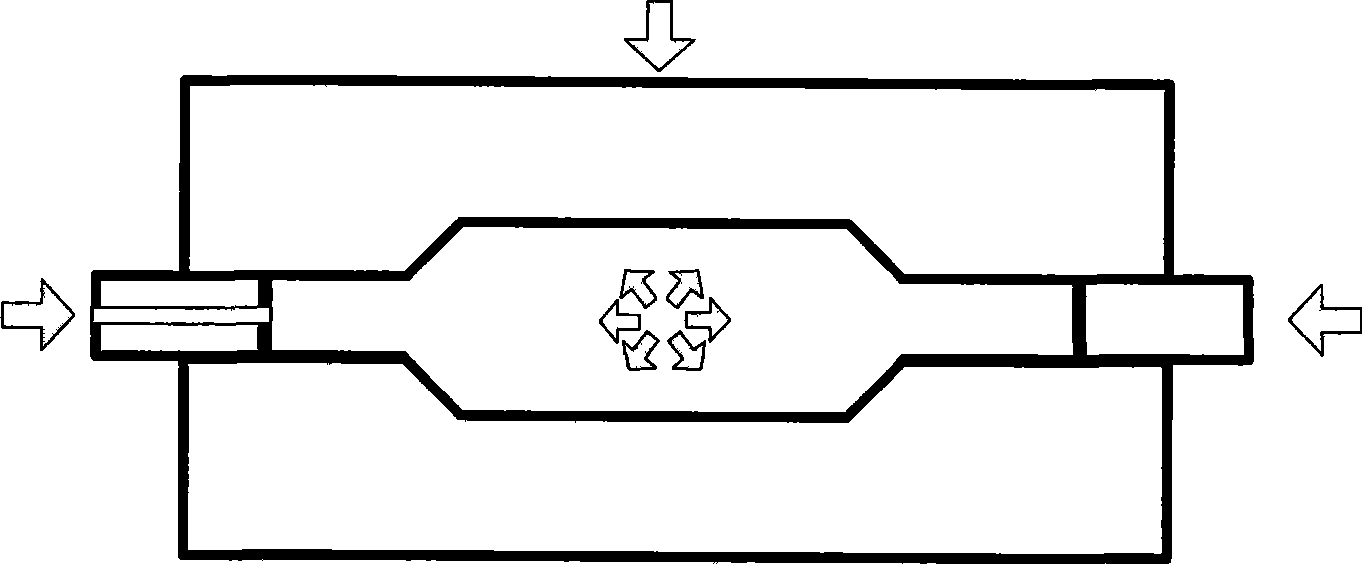

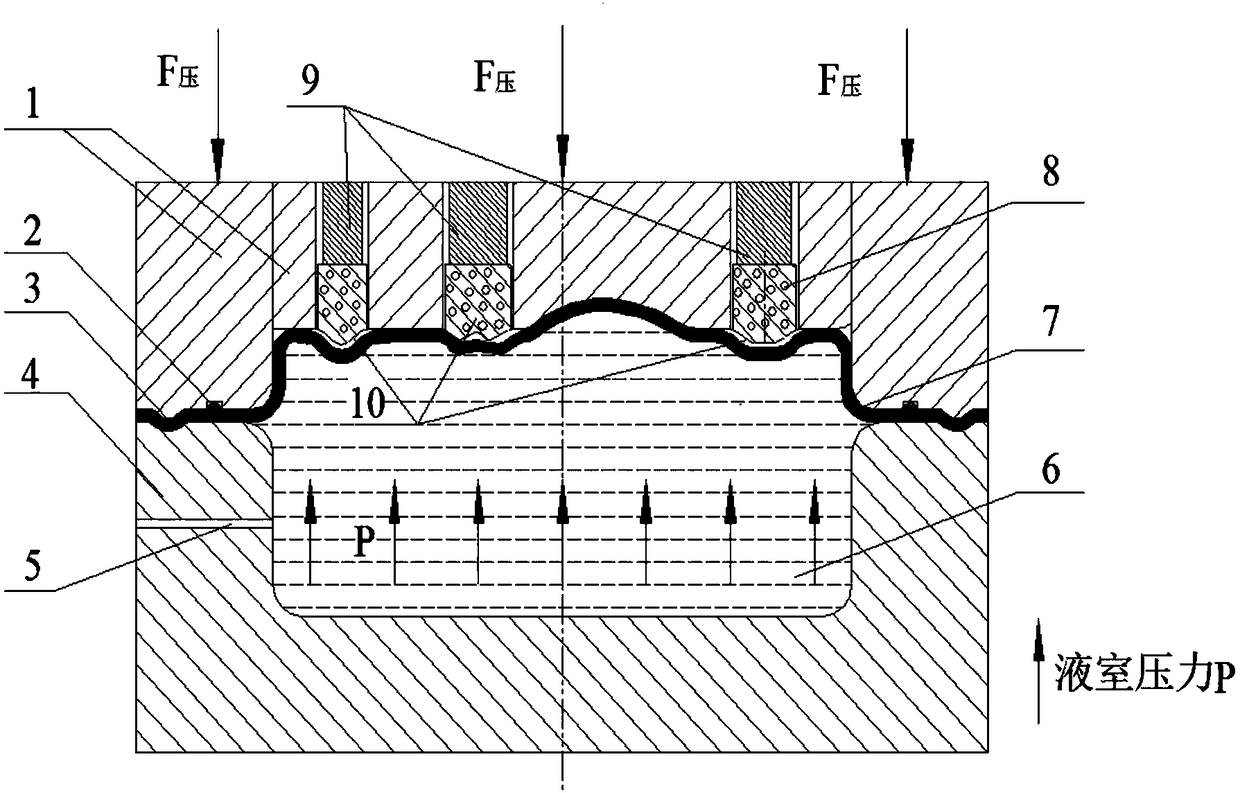

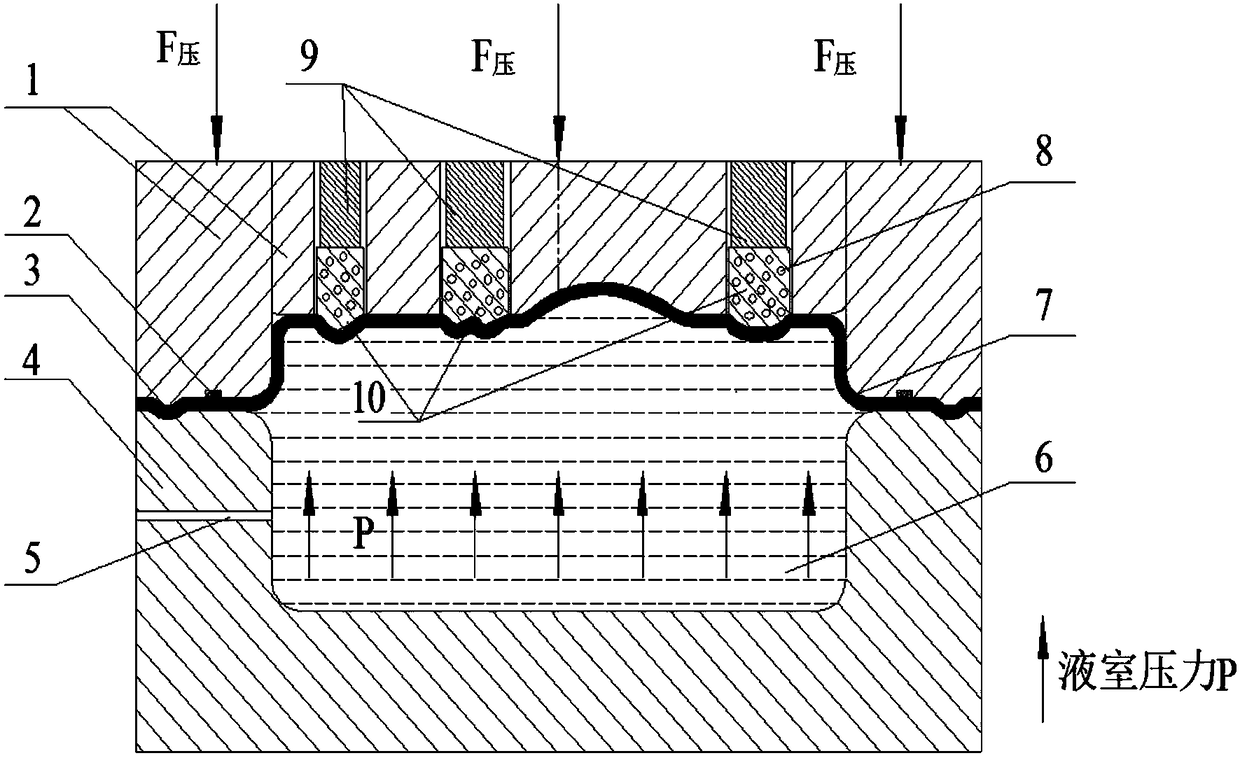

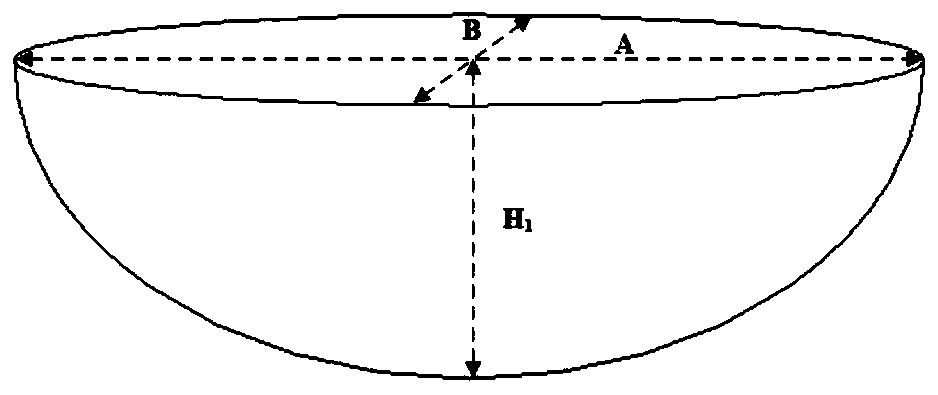

Bidirectional pressing liquid-charging forming method for large-size thin-wall complex characteristic panel

ActiveCN103846331AGive full play to plasticityUniform wall thickness distributionReduction rateEngineering

The invention relates to a bidirectional pressing liquid-charging forming method for a large-size thin-wall complex characteristic panel. The method comprises the following steps: coating lubricating oil on a single side of a thin-wall panel, thereby performing lubricating treatment; bulging the panel after being lubricated in advance in a pre-forming mould, thereby forming the rough shape of parts; reversely shaping the pre-formed panel in a shaping mould, thereby forming small circular bead features; cutting off addendum surfaces of the parts, thereby finally forming the parts. According to the bidirectional pressing liquid-charging forming method for the large-size thin-wall complex characteristic panel provided by the invention, the plasticity of the panel is fully utilized, the wall thickness reduction rate of the parts is effectively controlled and the panel parts with any complex shallow characteristics can be formed. Compared with the explosive forming of the traditional similar parts manufacturing method, the bidirectional pressing liquid-charging forming method has the advantages of high efficiency, low cost, convenience and safety in operation, high precision of formed parts, no manual repairing, and the like.

Owner:BEIHANG UNIV

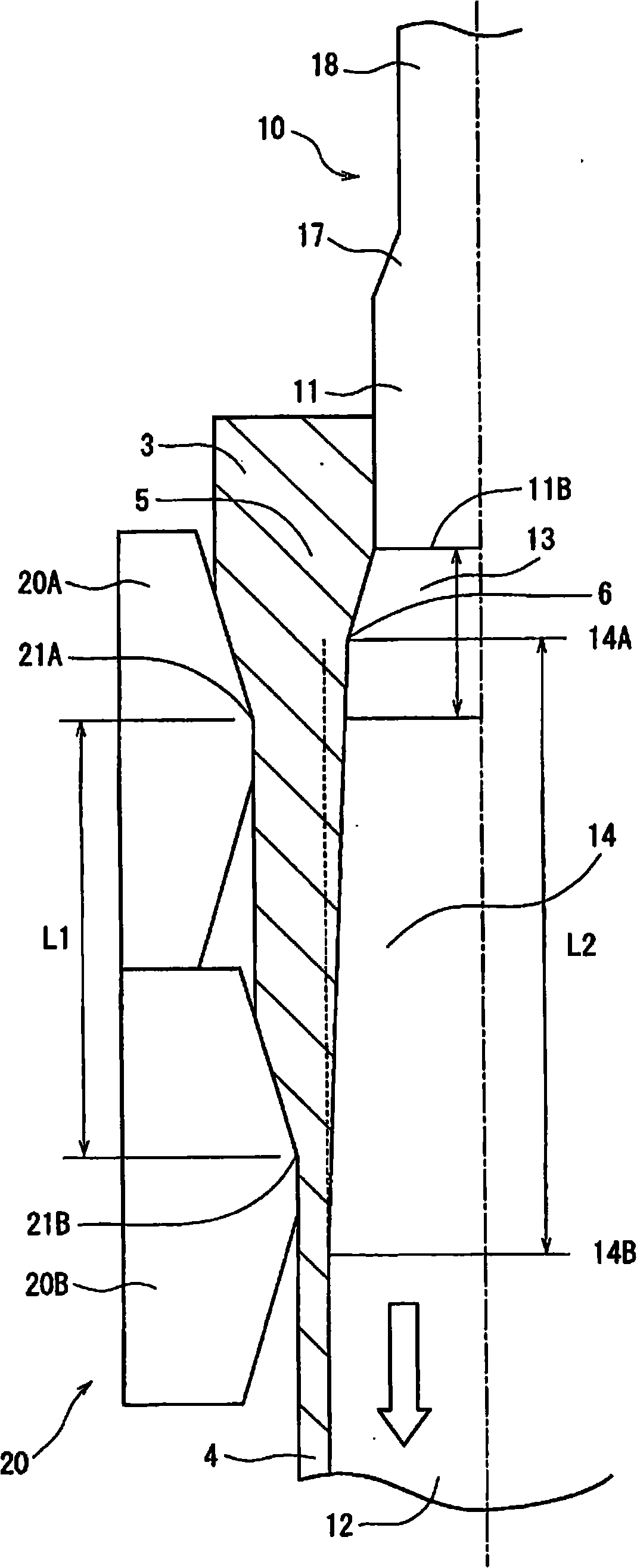

Overall superplastic forming method of variable cross-section cylindrical shell

ActiveCN106112388AUniform wall thicknessHigh dimensional accuracy of the outer surfaceEngineeringForming processes

Provides is an overall superplastic forming method of a variable cross-section cylindrical shell. Firstly, blank calculation is conducted, a designed part is equally divided into a plurality of sections through an axial sectioning method, the perimeter of each section is measured, and a cylindrical blank with the perimeter change trend close to the result is prepared according to the result. Then, the cylindrical blank is subjected to hot pressing performing, so that the change trend of the section appearance is close to that of a target part. Finally, overall blow molding is conducted through superplastic forming, and the forming process is completed. The overall superplastic forming scheme is adopted, the overall superplastic forming of cylindrical metal shell-class parts with the variable cross sections is achieved through the forming blank size calculation, forming mold design, hot pressing performing, superplastic finished forming and other processes, and the purposes of improving the integrality, the size accuracy and the wall thickness distribution accuracy of the parts are achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Deep-drawing attenuated processing method of resin clad metal plate as well as resin coating deep-drawing attenuated tank using said method

A method of the drawing / ironing of a resin-coated metal sheet which comprises drawing a resin-coated metal sheet comprising a metal sheet and an organic resin with which at least one side of the sheet is coated and then ironing it with a punch and adjacent dies to thereby mold a can comprising a bottom, a side-wall part, and a flange-forming part. By the method, barrel breakage accompanying a reduction in the thickness of the can side wall can be effectively prevented. Furthermore, a drawn and ironed can having a thickness reduced to a predetermined value can be efficiently molded.

Owner:TOYO SEIKAN KAISHA LTD +1

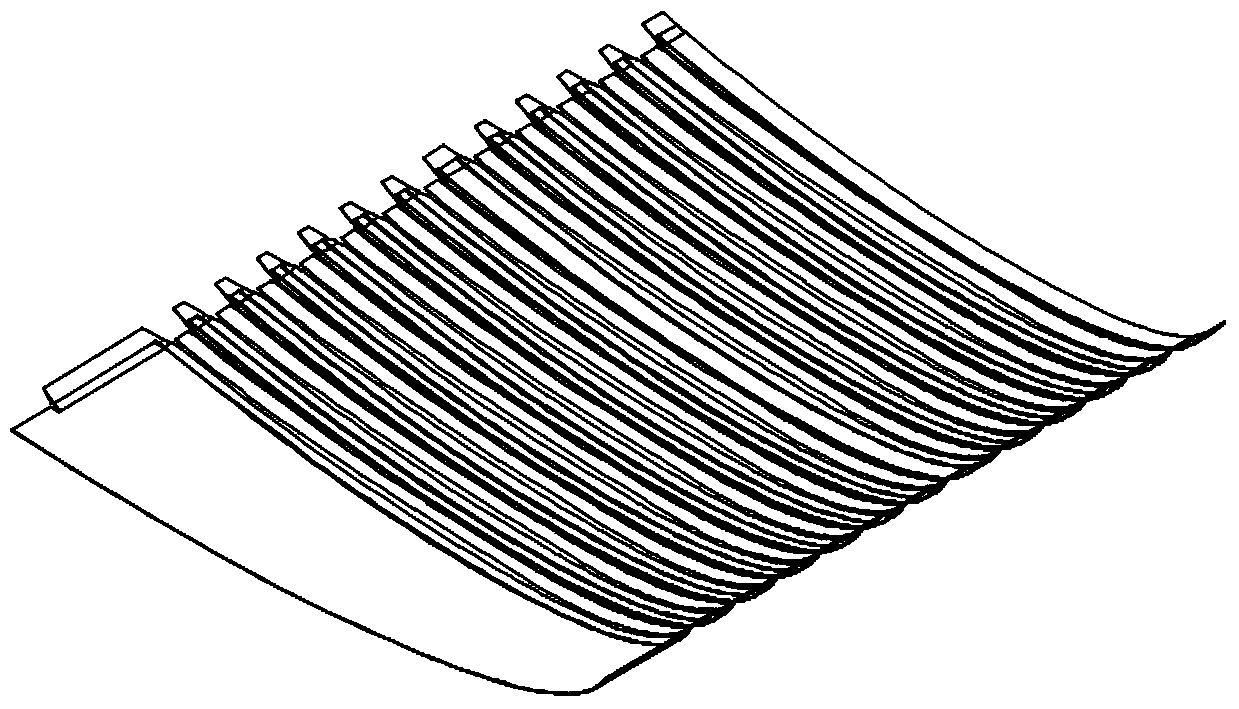

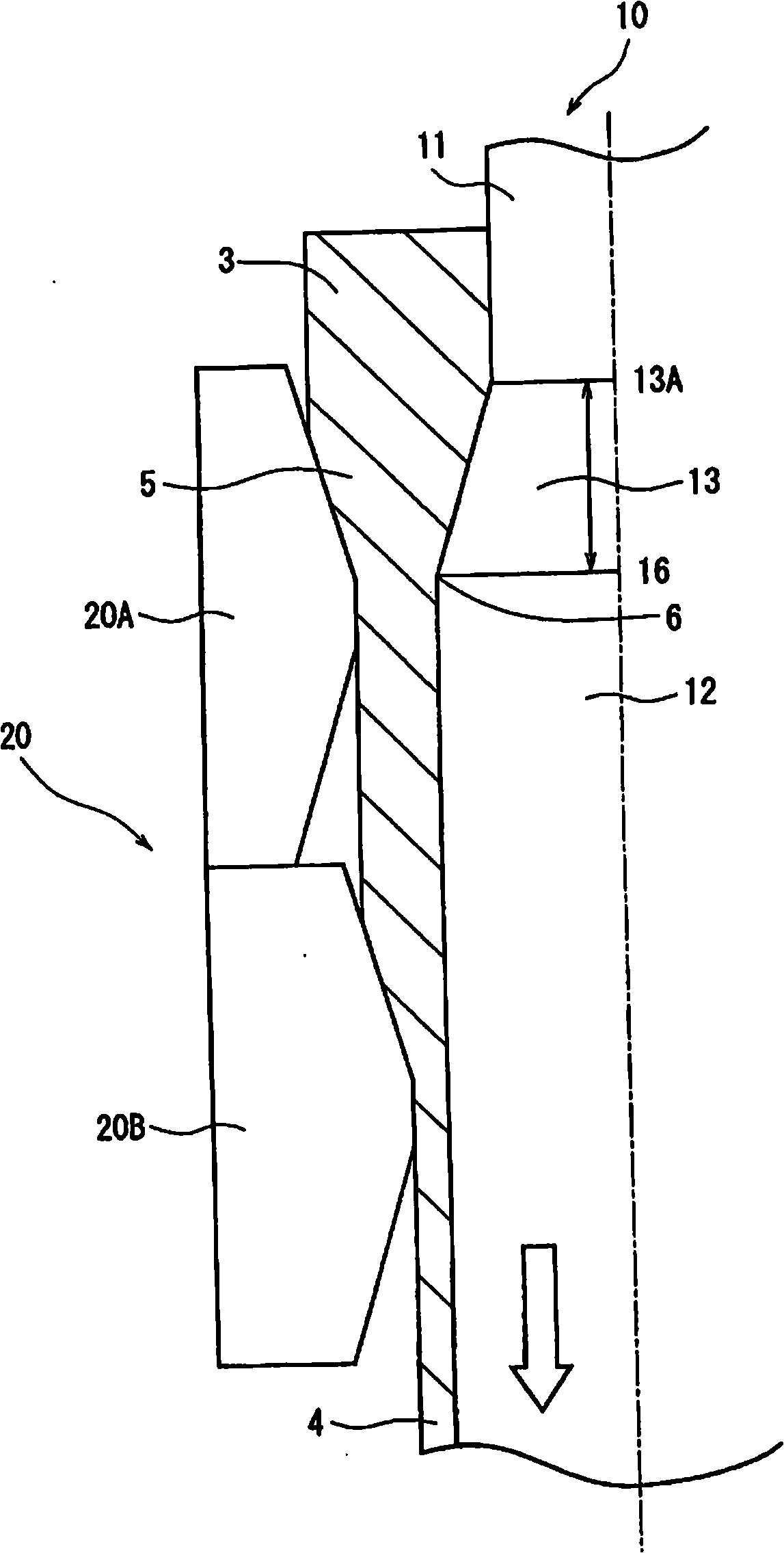

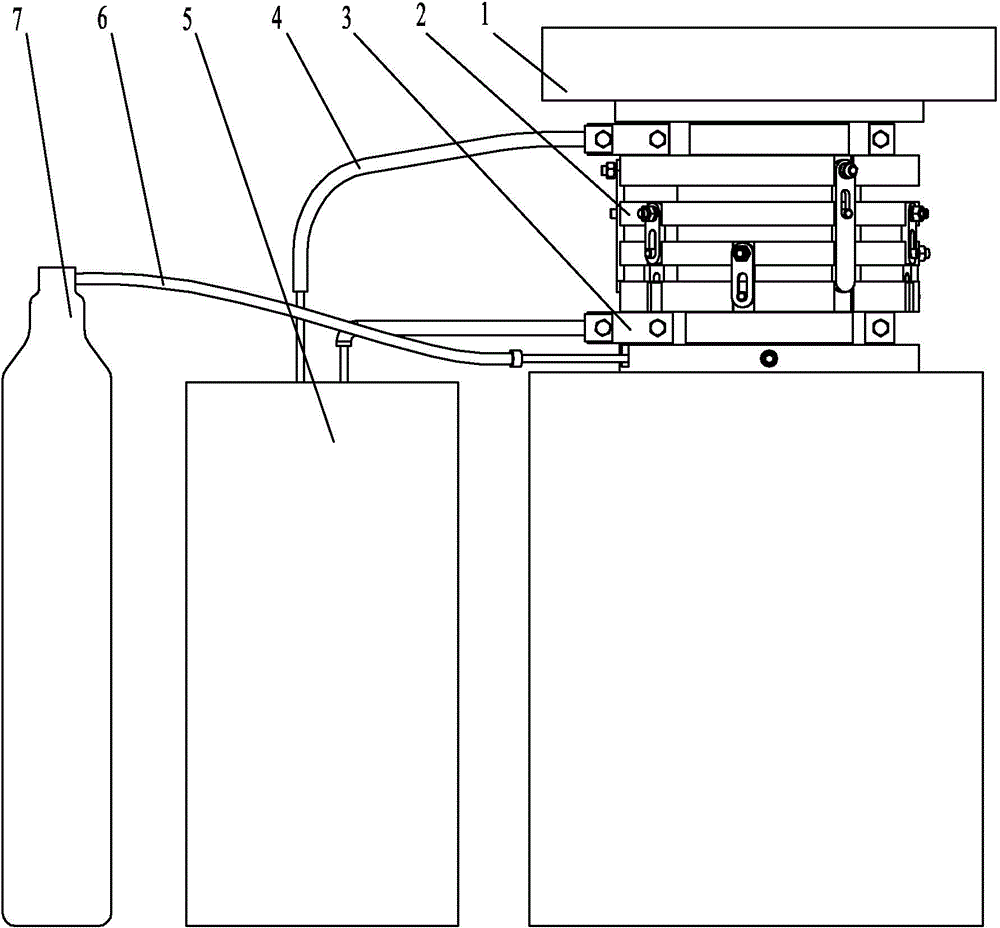

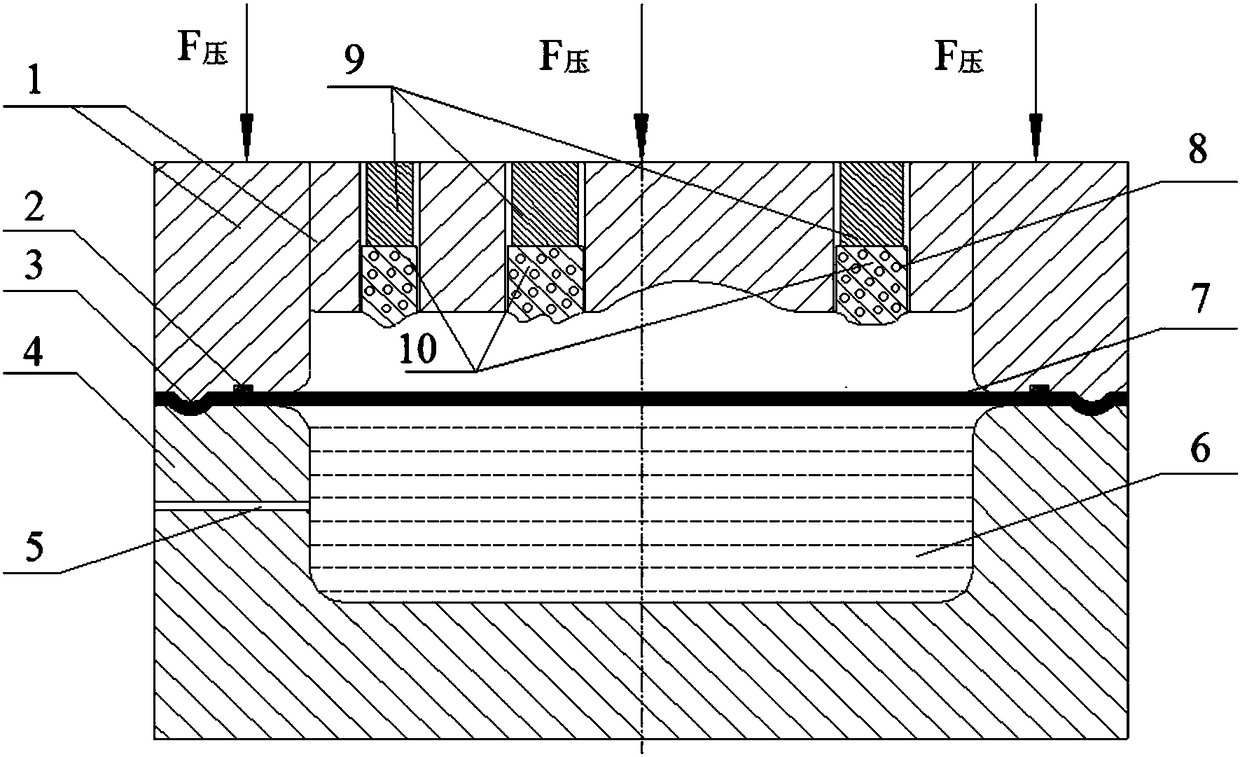

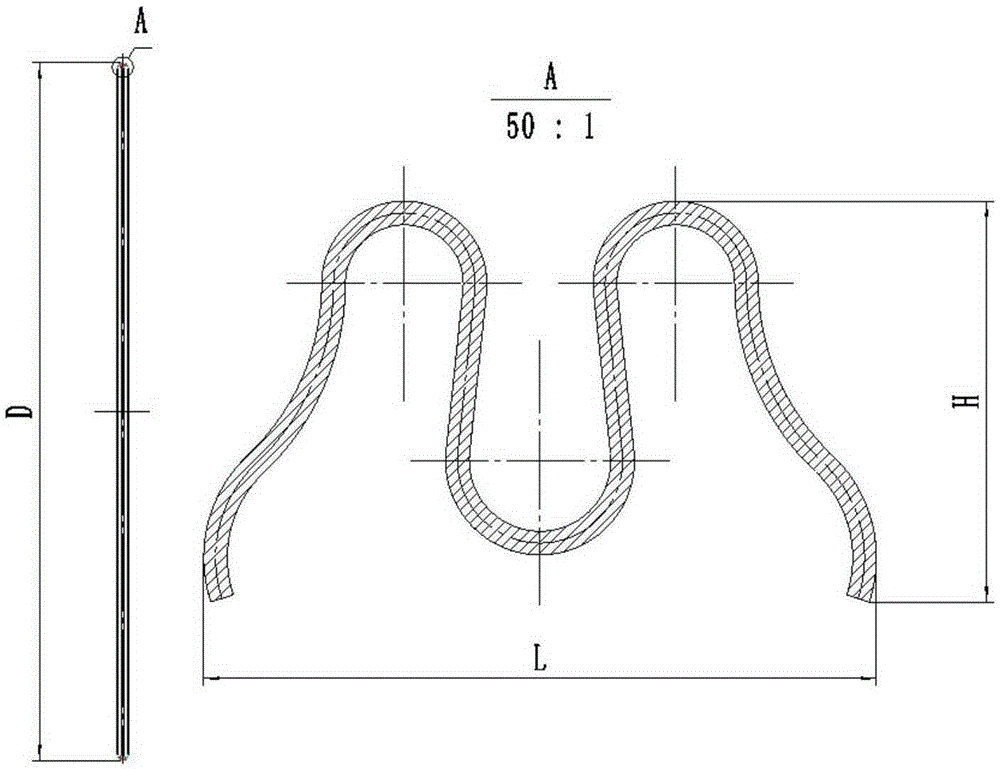

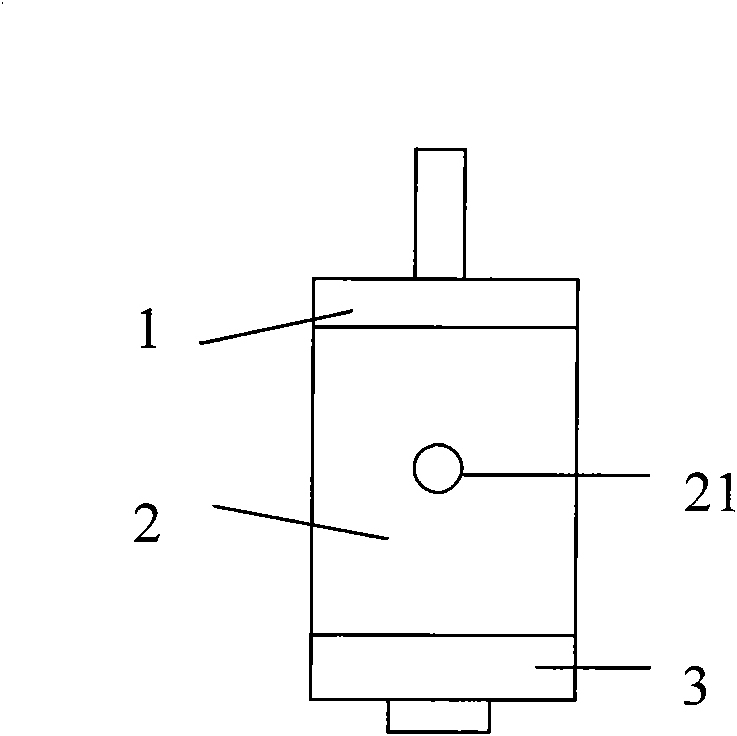

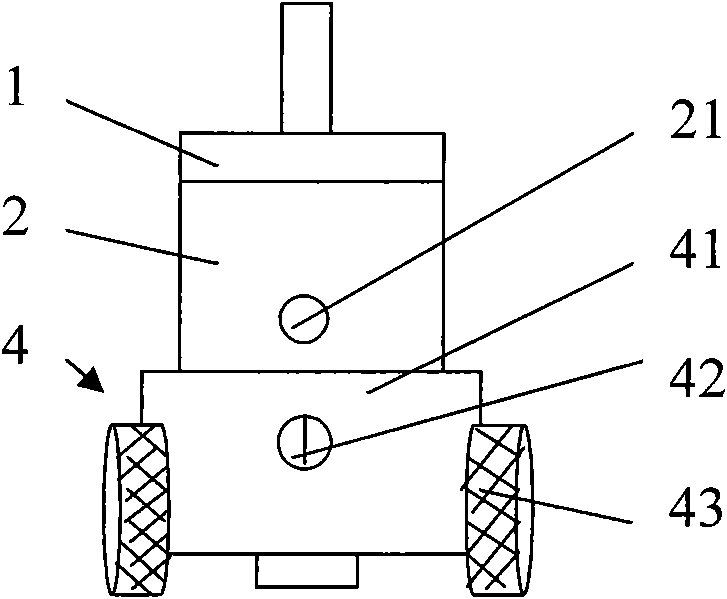

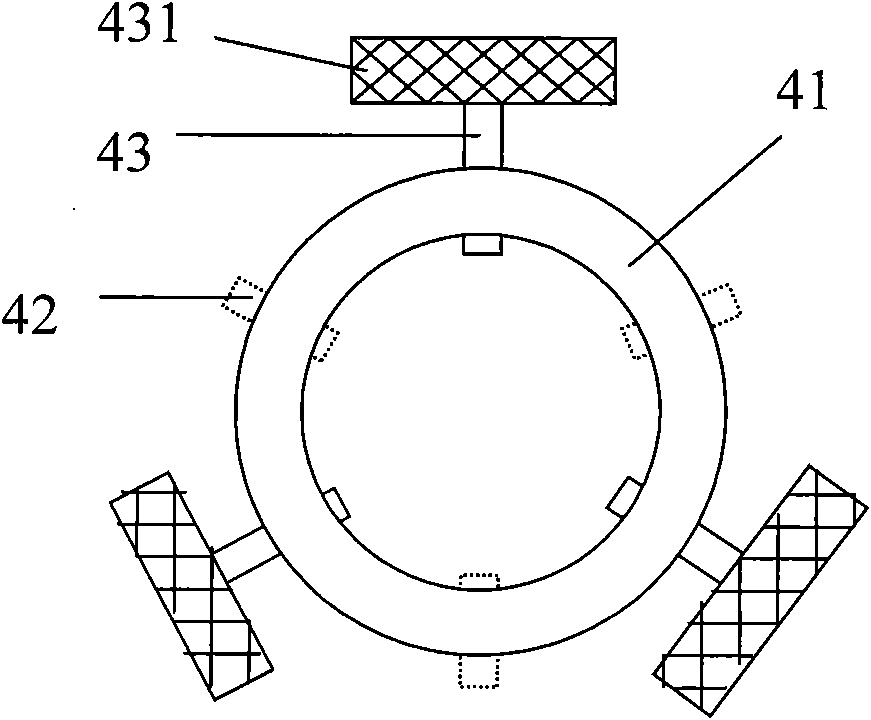

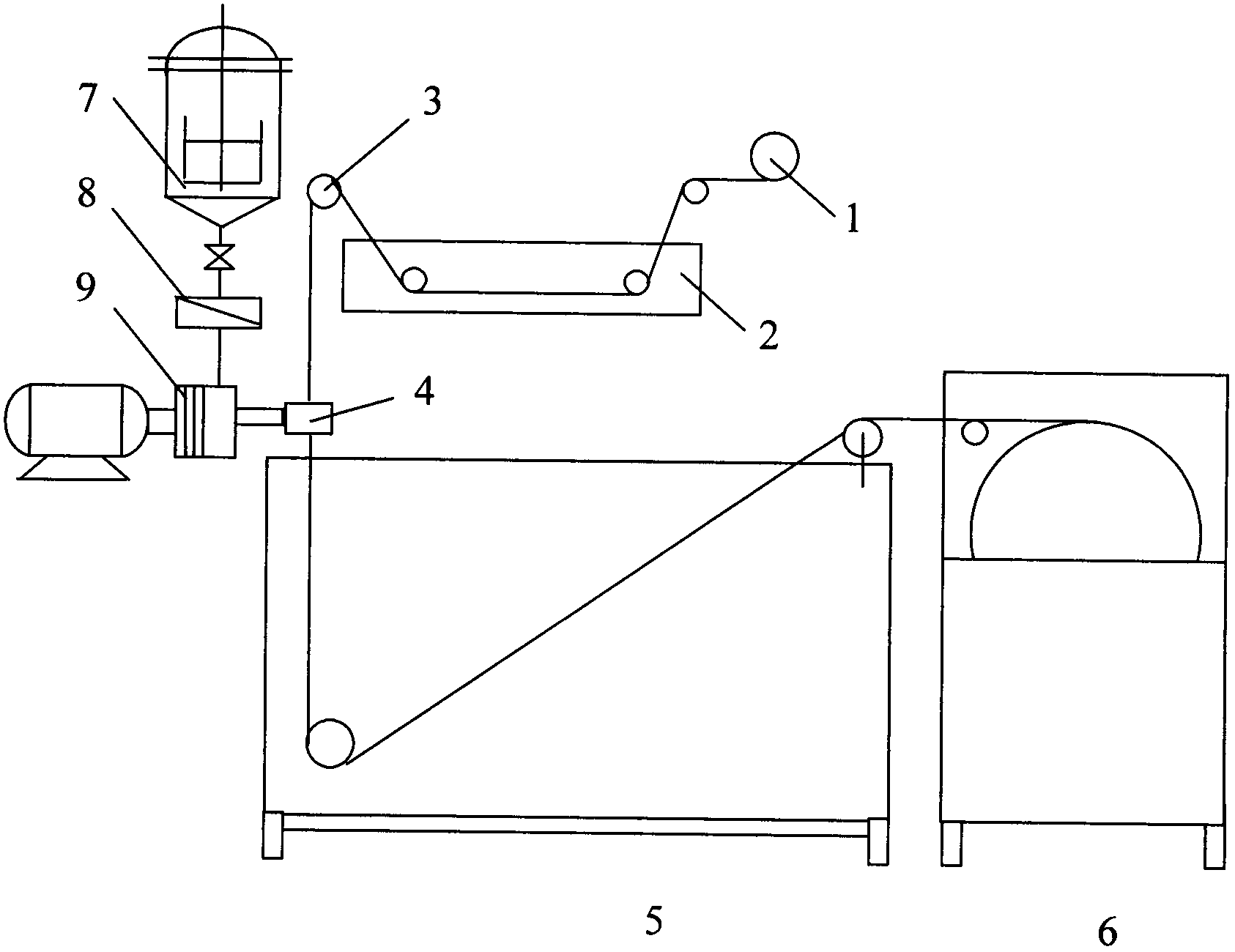

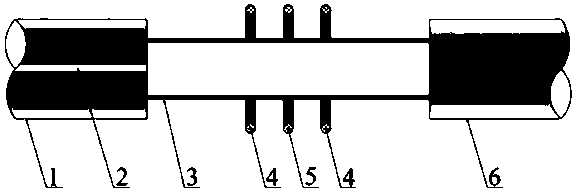

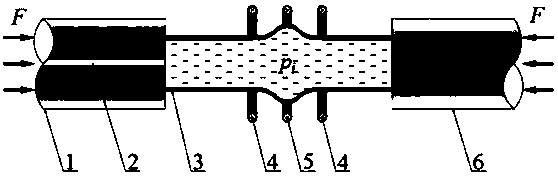

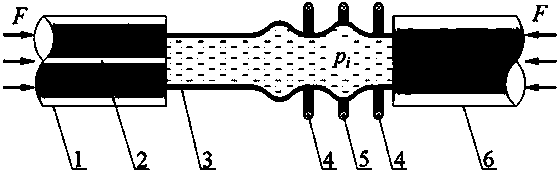

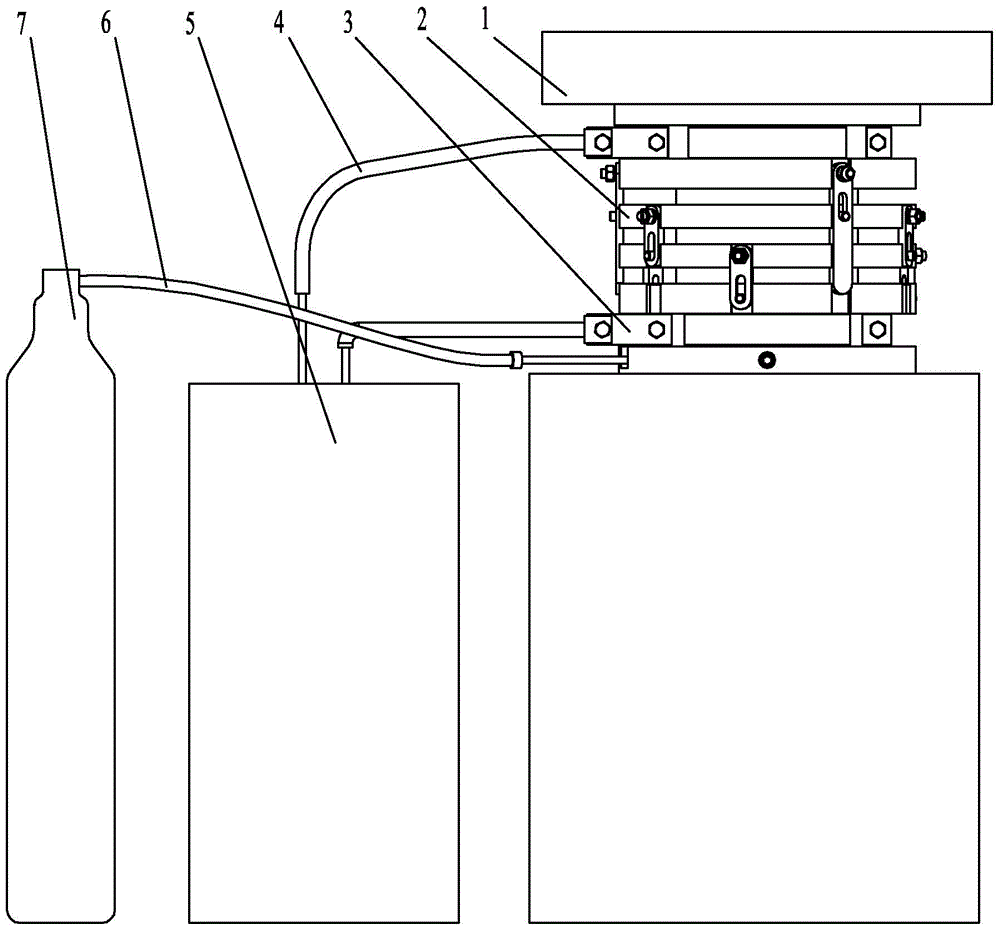

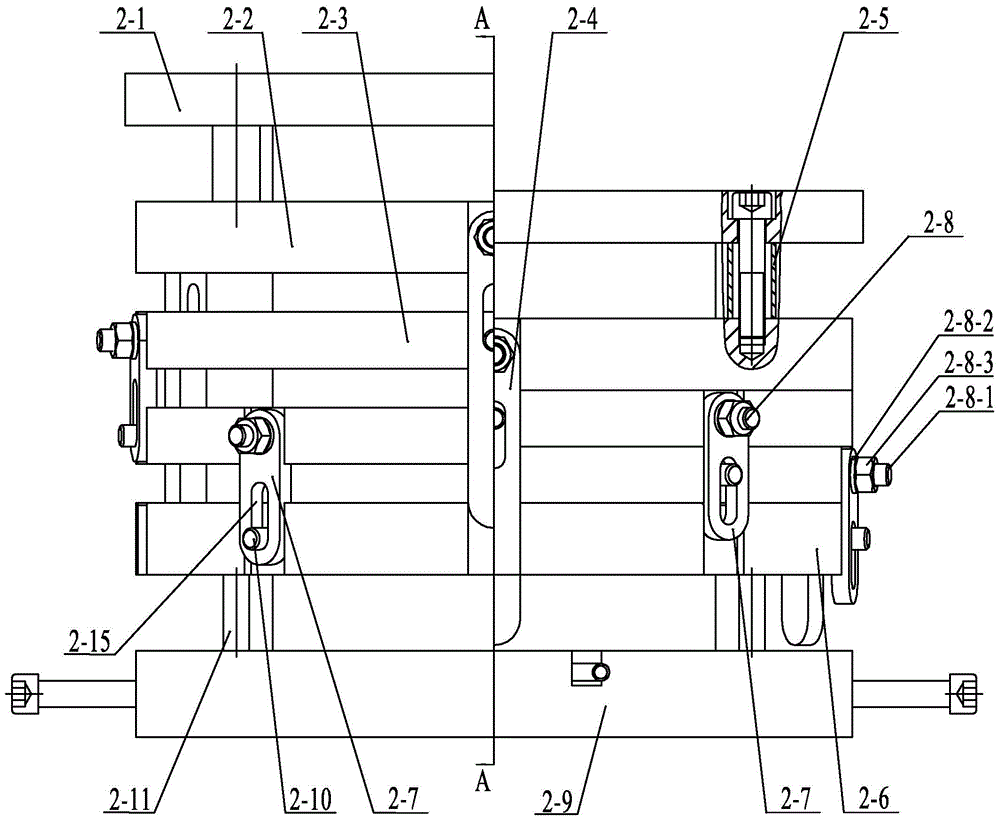

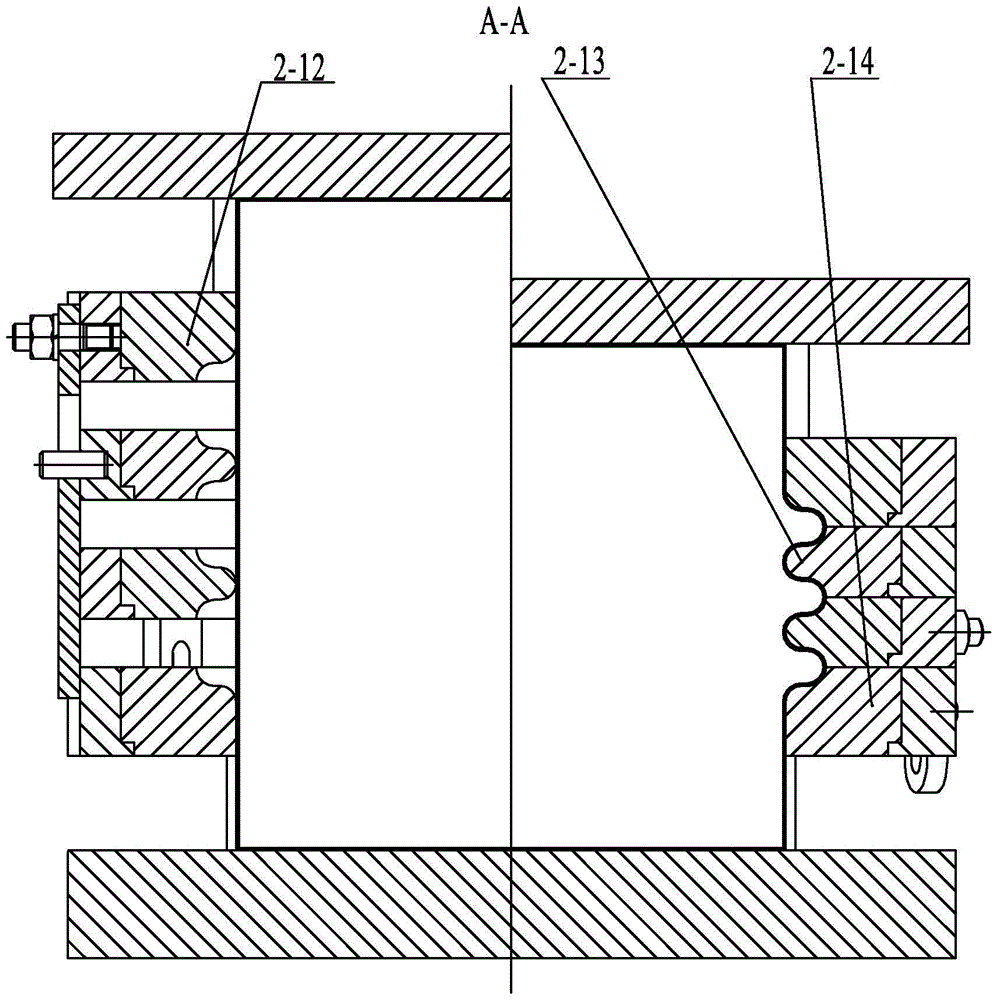

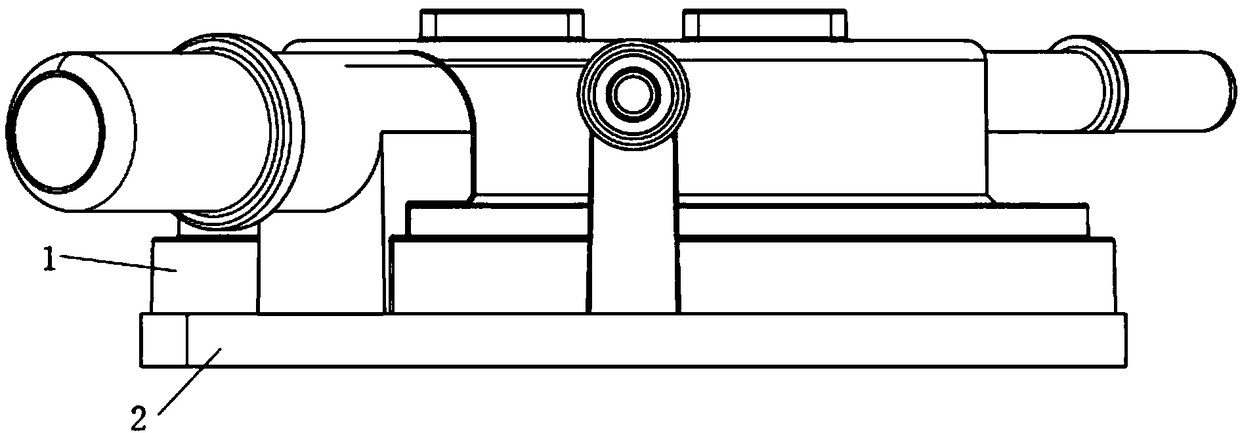

Device and method for hot forming of titanium alloy corrugated pipe through current assistance

ActiveCN104525660AImprove plastic deformation abilityUniform wall thickness distributionShaping toolsGas cylinderLow voltage

The invention discloses a device and method for hot forming of a titanium alloy corrugated pipe through current assistance, and relates to a device and method for hot forming of a corrugated pipe. The device and method for hot forming of the titanium alloy corrugated pipe through current assistance solve the problem that an existing titanium alloy corrugated pipe is difficult to manufacture, and high in cost and low in production efficiency. According to the device, the positive pole and the negative pole of an electrode (3) tightly sleeve the upper end and the lower end of a tube blank (10), a low-voltage high-current power source (5) is connected with the positive pole and the negative pole of the electrode (3) through a wire (4), a gas cylinder (7) is connected with a gas guide pipe (11) on the tube blank (10) through a gas pipe (6), and a forming die (2) is placed on a working platform of a press machine (1). The method comprises the steps that the first step, the tube blank (10) is manufactured; the second step, die setting is conducted; the third step, device installation is conducted; the fourth step, the corrugated pipe is formed; the fifth step, discharging is conducted; the sixth step, post-processing is conducted. The device and method are used for manufacturing the titanium alloy corrugated pipe.

Owner:HARBIN INST OF TECH

Quick determination method of load path of fittings hydraulic formation

The invention provides a method for quickly determining a loading path of hydraulic forming of pipe fittings, relates to the field of pipe fitting hydraulic forming, and solves the problems that the determination of the reasonable loading path of the pipe fitting hydraulic forming depends on the experience and test exploration so as to not only increase the test cost, but also waste a large amount of time. The method comprises the following steps: firstly, calculating out the initial internal pressure by the theory and determining the forming interval; secondly, adjusting axial feed supplementary amount to carry out numerical simulation, and determining reasonable feed supplementary amount according to the calculating result; and finally, adjusting the slope factor of the loading path to obtain the reasonable loading path. The method can accurately and quickly determine the reasonable loading path of the hydraulic forming of the pipe fittings, thereby saving the time and the test cost; and the optimized reasonable loading path is adopted to effectively realize the feed supplement of the forming interval, thereby obtaining smaller wall thickness reduction rate and oppositely-even wall thickness distribution, and improving the forming limit of the pipe fittings. The loading path determined by the invention is applied to pipe fitting hydraulic forming technology.

Owner:HARBIN INST OF TECH

Cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members

A cold-hot sequential coupling forming technology of large-scale aluminium alloy complex structural members is a novel forming technology which is derived from the intersection and fusion of liquid-filled forming technology and hot-stamping forming technology. The novel forming technology has the characteristics of liquid filling forming and hot stamping forming at the same time. The cold-hot sequential coupling forming technology comprises the steps that the upper and lower dies are closed, according to adjusting the blank holder force, a panel veneer is impacted between the dies; the panel veneer is attached to die profiles in function of high pressure liquid in a liquid chamber, the forming of most features is completed; and after forming the liquid-filled, according to the characteristic of the thermoplasticity of materials, the hot-stamping technology process is carried out by using heated movable insert blocks, the forming of local features is completed, sequential forming of different part features is completed, and final product parts are obtained. The dies are installed in one time, and two forming processes are realized, and thus the time-consuming of switching the dies is reduced, and the accuracy requirements of global forming and external dimensions of the product parts are guaranteed. At the same time, the movable insert blocks are convenient to install and easy to replace, so the time of repairing dies is reduced and the production efficiency is improved. The sequential forming technology has the unique advantages of in the forming of aerospace, automotive and other fields of complex structural alloy members, and has wide application prospect.

Owner:BEIHANG UNIV

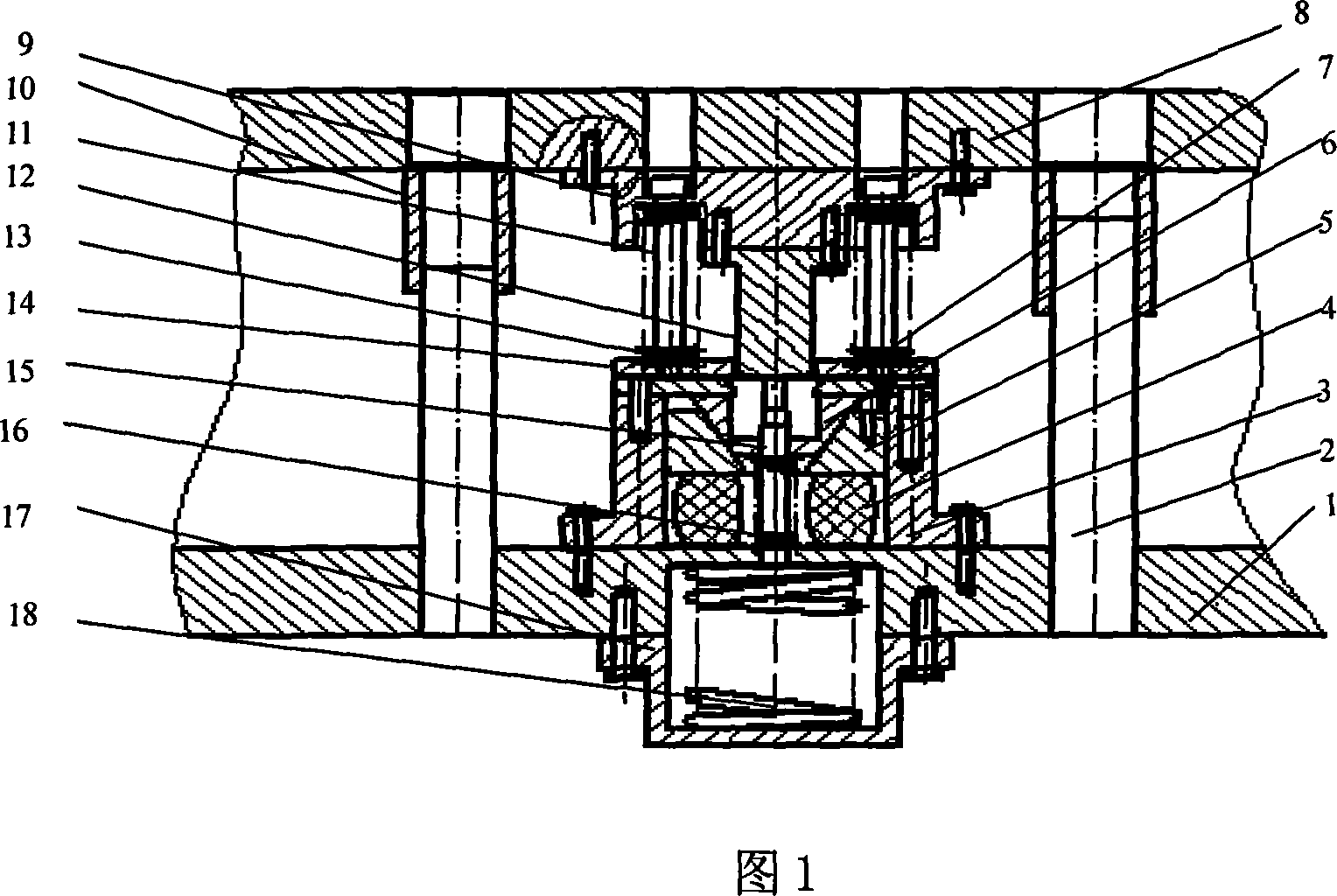

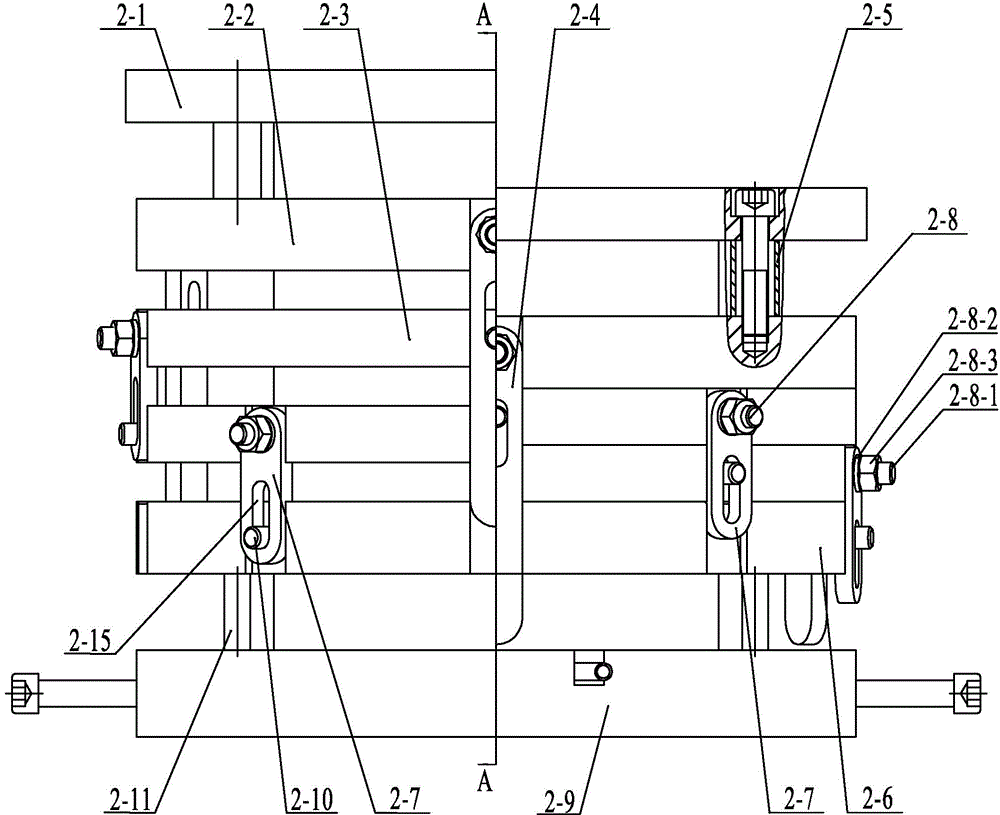

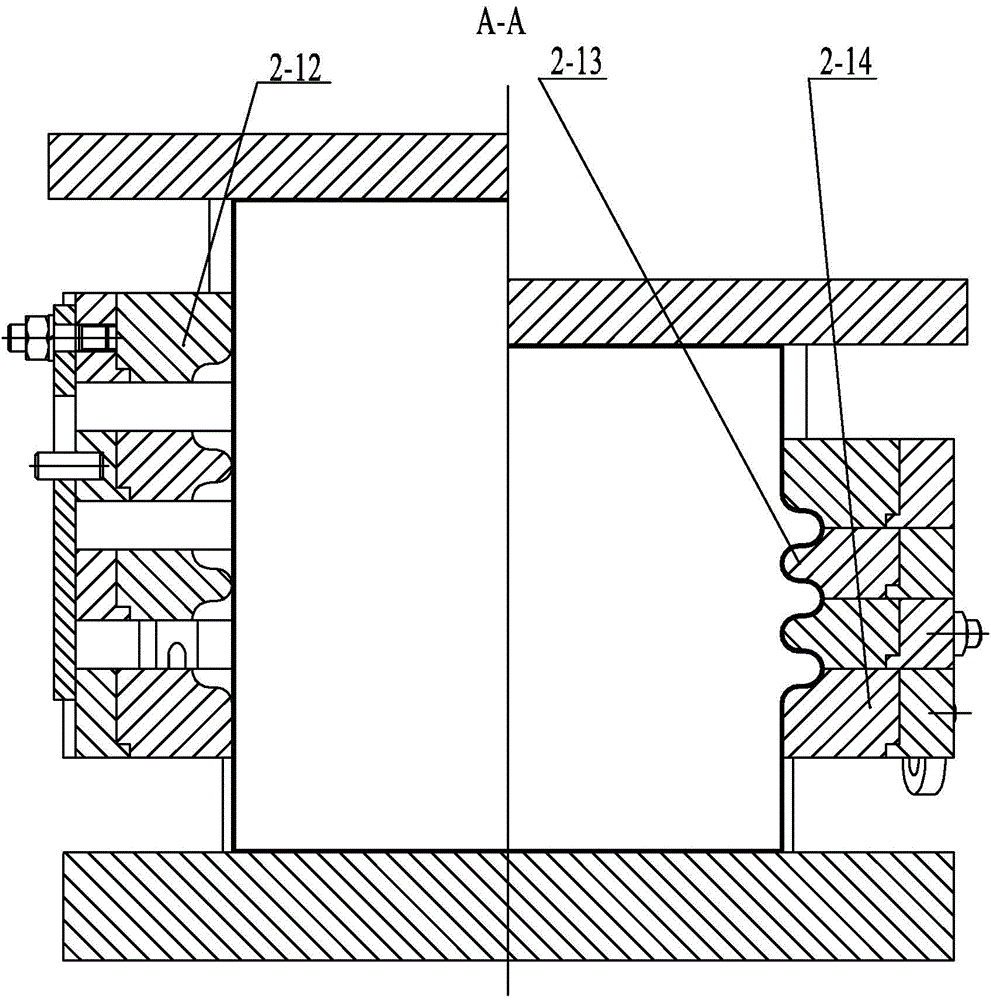

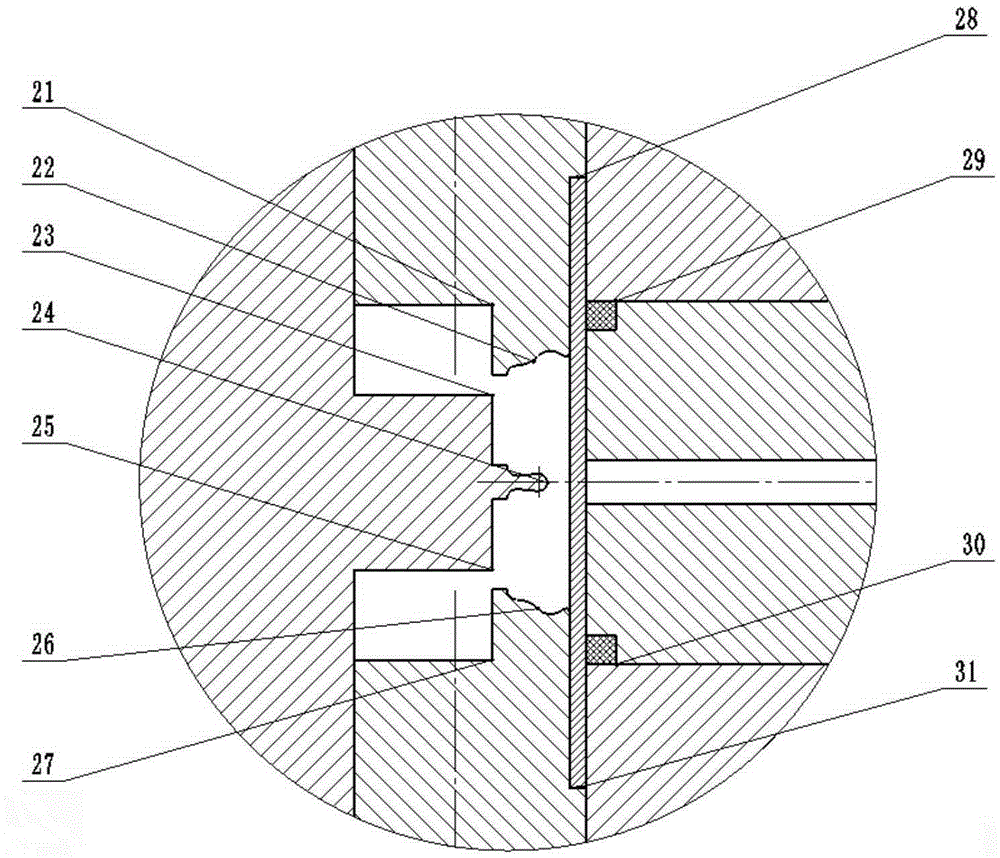

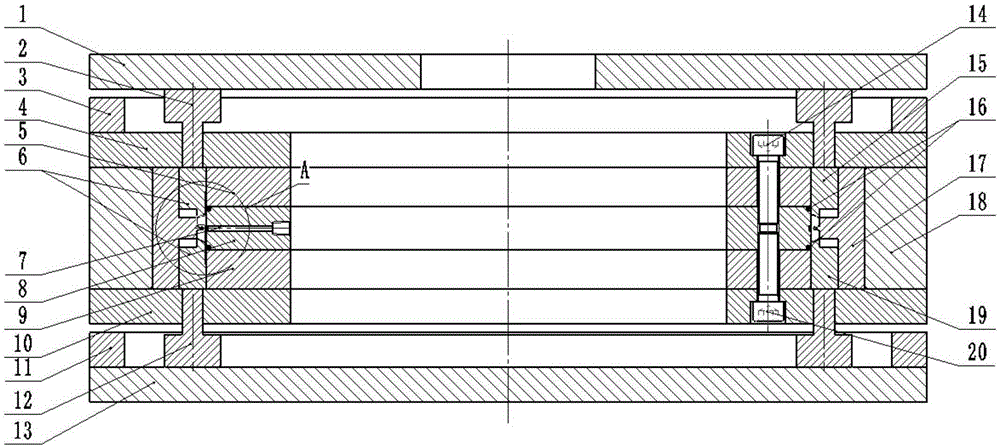

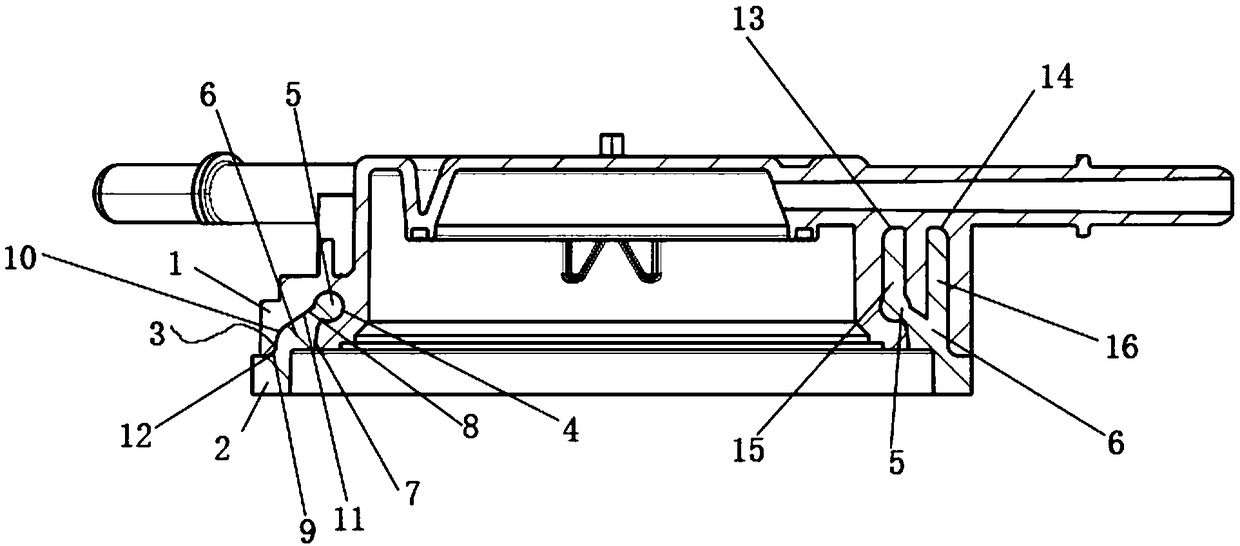

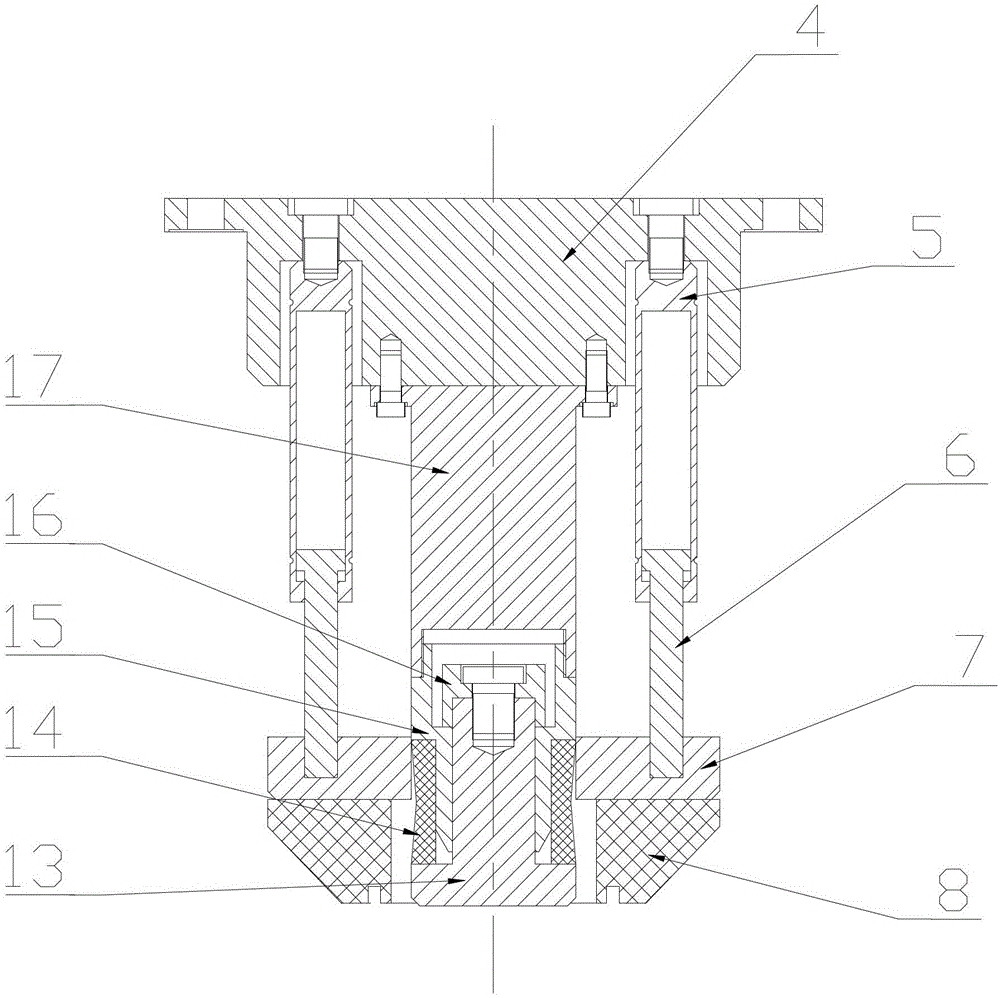

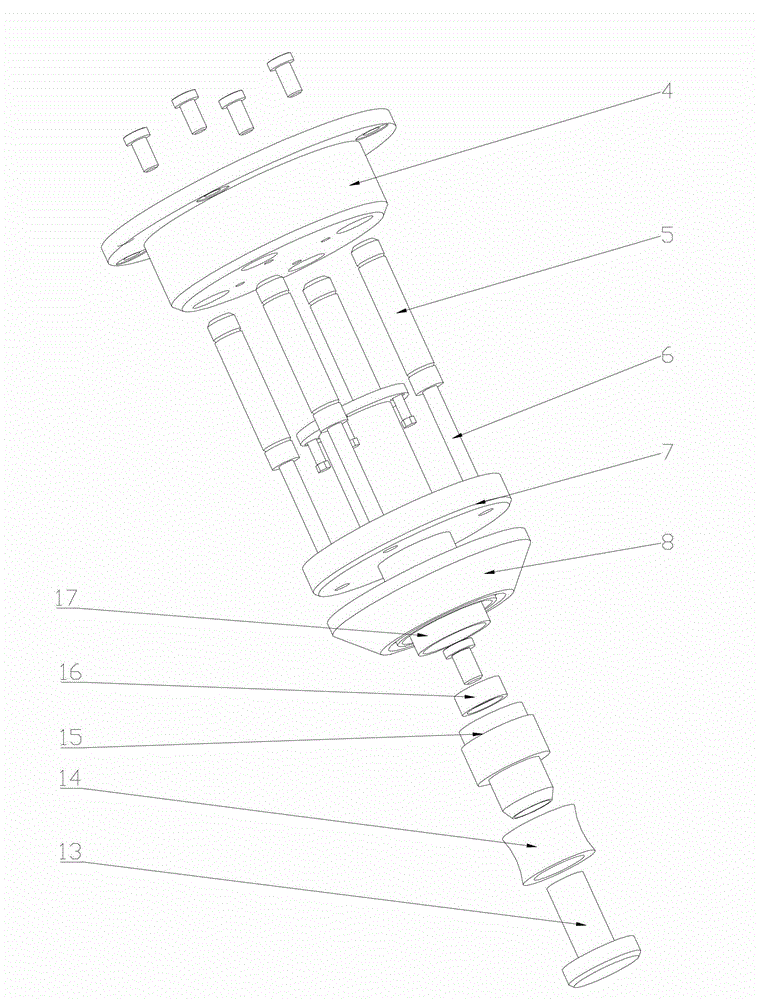

Single-pass integral molding device for M-shaped metal sealing ring

The invention provides a single-pass integral molding device for an M-shaped metal sealing ring. The single-pass integral molding device is characterized by comprising a bottom plate (13); a pressing plate (1), an upper feeding press block (2), an upper fixing plate (4), an upper sealing press block (5), a liquid chamber module (8), a lower sealing press block (9), a lower fixing plate (10) and a lower feeding press block (12) are sequentially arranged on the bottom plate (13) from top to bottom and are of an annular structure and consistent in axis; and the outer ring wall face of the upper sealing press block (5), the outer ring wall face of the liquid chamber module (8) and the outer ring wall face of the lower sealing press block (9) are flush with one another, and a movable mold (6), a middle mold (17) and an annular reinforced lantern ring (18) are sequentially arranged outwards from the outer ring wall faces, wherein the middle mold (17) is formed by two symmetrical half molds and of an annular structure, and the movable mold (6) is divided into a movable upper mold body (15) and a movable lower mold body (19).

Owner:中航空天发动机研究院有限公司

Inserting pipe-type spinning nozzle

InactiveCN101565862AUniform wall thickness distributionStable wall thickness distributionHollow filament manufactureScrew threadNozzle

The invention discloses an inserting pipe-type spinning nozzle, which comprises an inserting pipe, a spinning nozzle shell and a spinning plate and is characterized in that: the spinning nozzle is provided with a concentricity regulator consisting of a sleeve matched with the spinning nozzle shell, a terminal strand and a regulating bolt; the sleeve is evenly provided with 3 to 4 fixing screwed holes and 3-4 regulating screwed holes on two transversal sections which are parallel to each other; the terminal strand and the regulating bolts are assembled with the fixing screwed holes and the regulating screwed holes; and the sleeve is arranged on the spinning nozzle shell through the terminal strand and the regulating bolts are butted against the outer edge of the spinning plate. The inserting pipe-type spinning nozzle can regulate online in time according to the needs and guarantee the concentricity of the inserting pipe and the liquid outlet of casting film liquid.

Owner:TIANJIN POLYTECHNIC UNIV

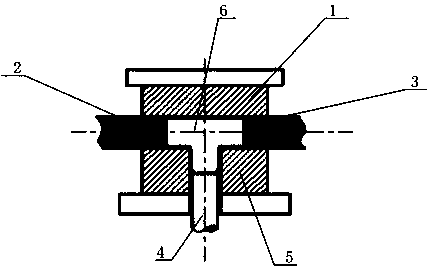

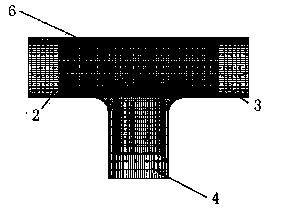

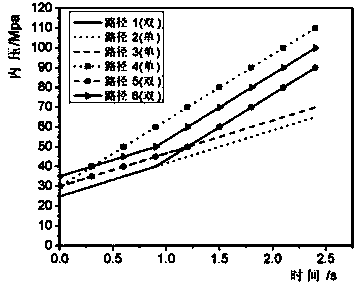

Researching method for hydraulic forming technical parameters of titanium T-shaped pipe

InactiveCN104239644ARaise the forming limitRealize feedingSpecial data processing applicationsInternal pressureTitanium

The invention relates to a researching method for hydraulic forming technical parameters of a titanium T-shaped pipe. The combination of a simulation model and a theory test is utilized to research the hydraulic forming of the T-shaped pipe; a 1 / 4 simulation model is adopted as the model; the researching time is shortened; the production efficiency is increased; a qualified T-shaped pipe is prepared in a hydraulic forming test by utilizing the technical parameters acquired from the research by researching the relation between inner-pressure loading and time (inner-pressure loading path) and the relation between punch feeding and time (punch loading path); the supplementary material of the forming area is effectively realized, so that the smaller wall-thickness thinning ratio and the relative uniform wall-thickness distribution are acquired; the forming limit of the T-shaped pipe is increased; the traditional research for the technical parameters by utilizing experiences and continuous tests is avoided; the cost is reduced.

Owner:WUXI XINFENG TUBE IND

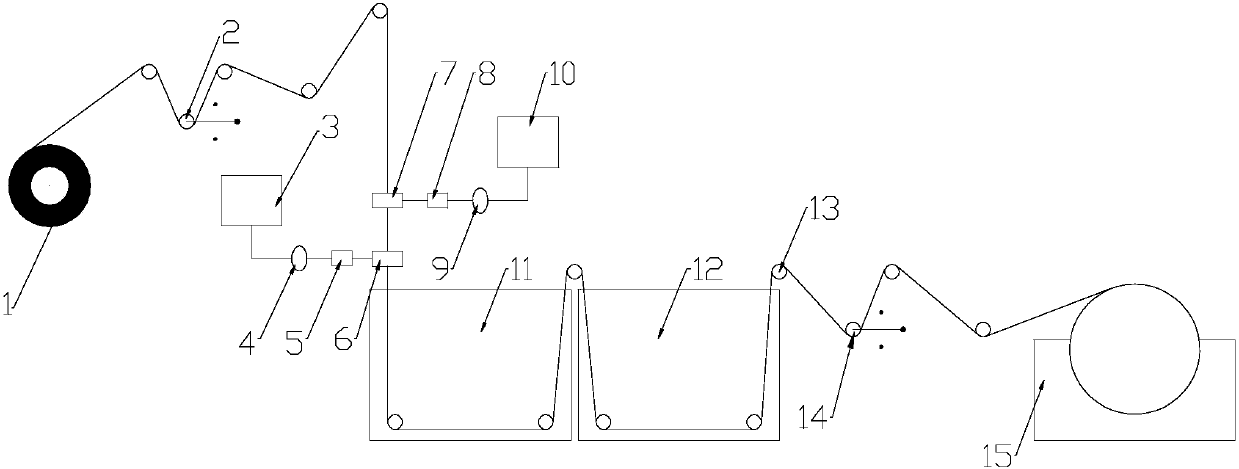

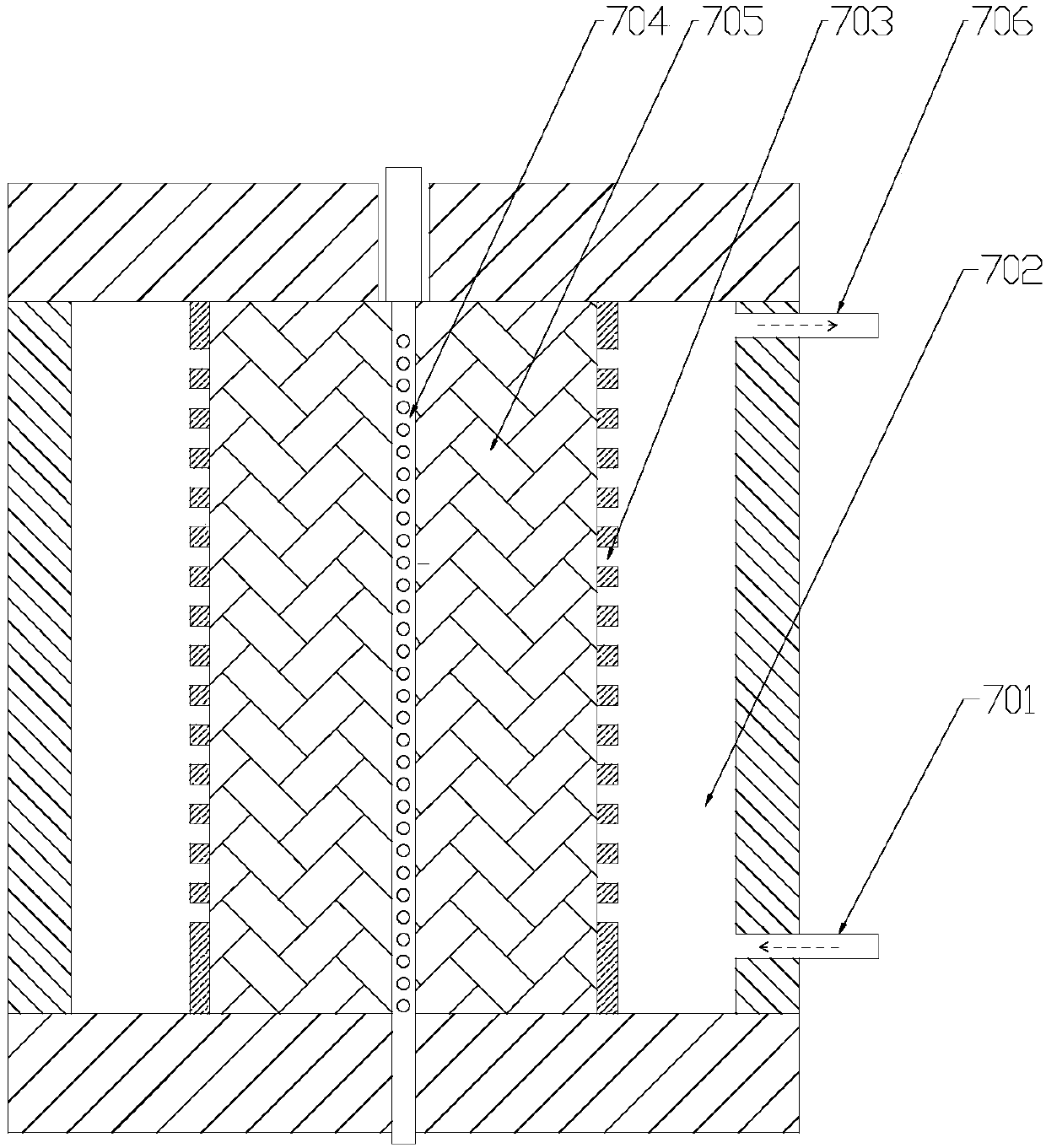

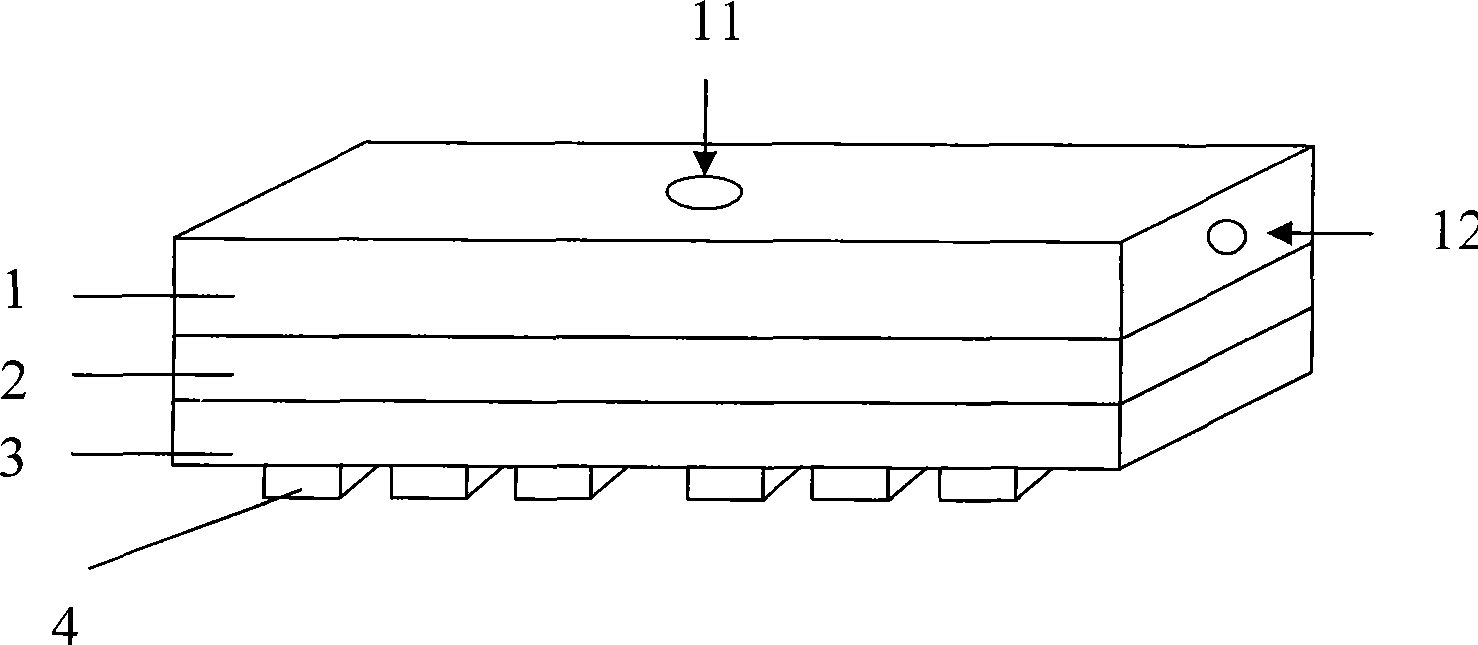

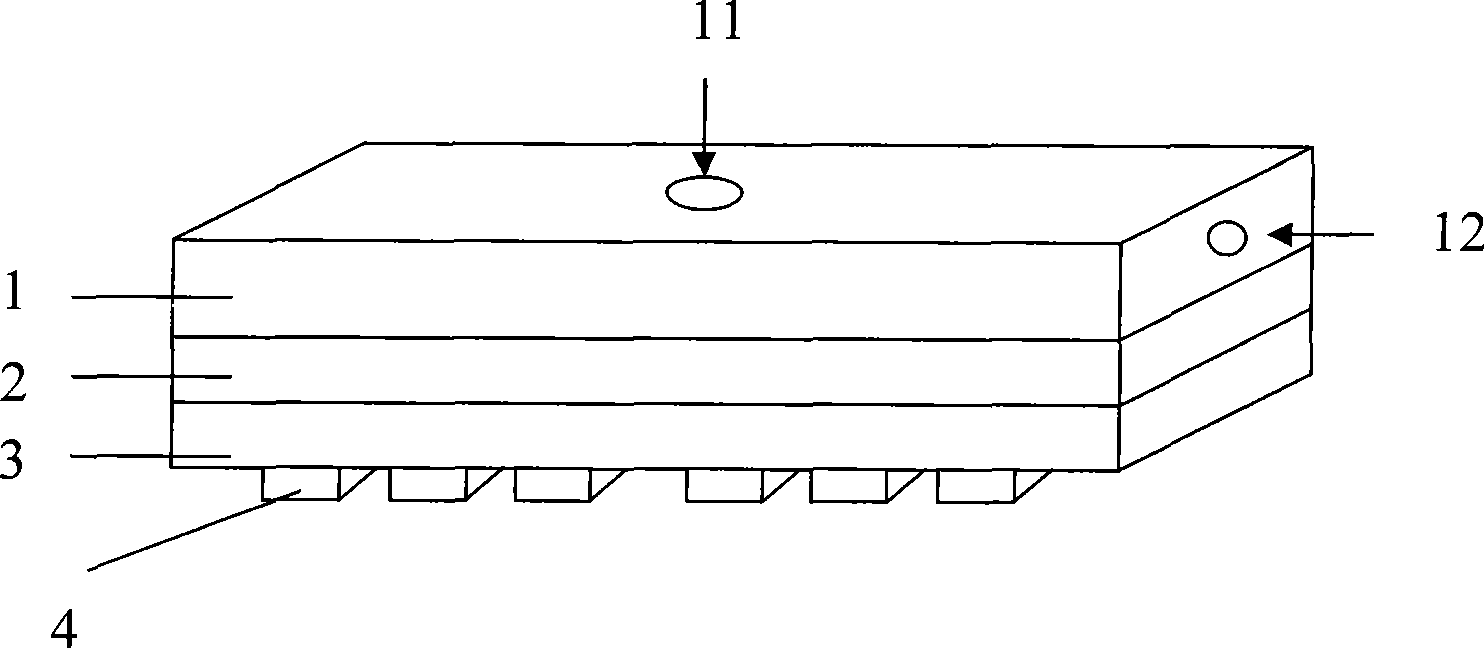

Device for preparing fiber-reinforced hollow fiber membrane

InactiveCN103263857AUniform wall thickness distributionImprove product qualitySemi-permeable membranesHollow fibre membraneHigh intensity

The invention discloses a device for preparing a fiber-reinforced hollow fiber membrane. The device for preparing the fiber-reinforced hollow fiber membrane comprises a feeding roller of a fiber-reinforced weaving pipe, a core liquid dipping tank, a guide roller, a cast membrane liquid preparation system, a coating die head, a coagulating bath tank and a winding roller. The device for preparing the fiber-reinforced hollow fiber membrane is characterized in that the surface of the fiber weaving pipe passing through a dipping core liquid is covered with a cast membrane liquid fully and uniformly by virtue of the coating die head, then the fiber weaving pipe is formed after entering the coagulating bath, and finally is wound, thereby obtaining a fiber-reinforced hollow fiber separating membrane with uniform degree of hollowness and wall thickness.

Owner:TIANJIN POLYTECHNIC UNIV

Useful wrinkle prefabrication method for improving internal high-pressure forming limit in pipe

Owner:TAIYUAN UNIV OF TECH

A current-assisted titanium alloy bellows hot forming device and method

ActiveCN104525660BImprove plastic deformation abilityUniform wall thickness distributionShaping toolsLow voltageGas cylinder

Owner:HARBIN INST OF TECH

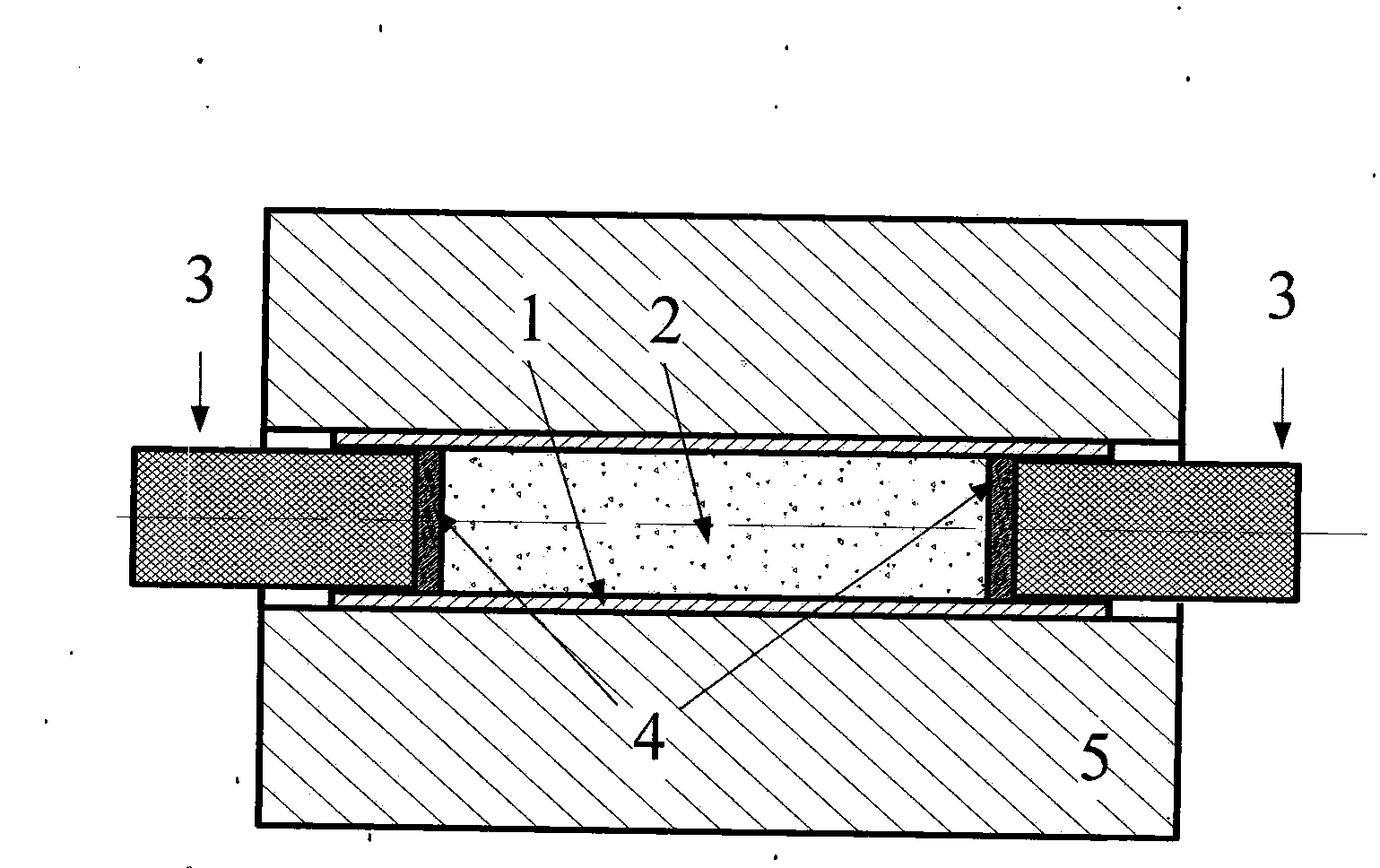

Preparation method of stainless steel/carbon steel chip core composite board

InactiveCN102553959AAchieve metallurgical bondingUniform wall thickness distributionHigh volume manufacturingHeating furnace

The invention relates to a preparation method of a stainless steel / carbon steel chip core composite board, which comprises the following steps that: (1). stainless steel pipes and chips produced by carbon steel machining are used as raw materials; (2) the carbon steel chips are pressed into the stainless steel pipes to be made into bimetal composite billets; (3) the press-mounted stainless steel / carbon steel chip core composite billets are placed into a heating furnace to be heated at a heating temperature of 1100 to 1200 DEG C for insulation of 30 to 60 minutes; (4) the heated composite billets are rolled on a rolling mill; and (5) after being rolled to the required size, the composite billets are cut with a constant length. The method provided by the invention is simple, is low in cost, and is suitable for industrial mass production, the metallurgical bonding is formed between carbon steel chips and between stainless steel and carbon steel chips in the prepared stainless steel / carbon steel chip core composite board, the structure of the carbon steel chip core is continuous and dense, the surface quality of the composite board is good, and the wall thickness of the stainless steel is uniformly distributed. Compared with the stainless steel composite board produced by other methods, the stainless steel / carbon steel chip core composite board has more excellent performance-price ratio.

Owner:YANSHAN UNIV

Method for automatically adjusting extruded rubber blank and controlling extrusion blow molding based on three-dimensional (3D) scanning

InactiveCN107775942AUniform wall thickness distributionSolve the difference in wall thicknessAutomatic controlElectromagnetic induction

The invention belongs to the field of blow molding production, and in particular relates to a method for automatically adjusting extruded rubber blank and controlling extrusion blow molding based on three-dimensional (3D) scanning. The method comprises the steps of scanning a 3D model or 3D drawing for inputting; automatically selecting an appropriate flow rubber head and determining a flow rubbercurve; automatically mixing raw materials, checking feedback and automatically adjusting the proportion of masterbatch; carrying out electromagnetic induction heating, adjusting the flexible neck-direction and axial wall thicknesses of a mold blank, monitoring the wall thicknesses of the mold blank and feeding back, and automatically adjusting the wall thicknesses of the mold blank; carrying outa blow molding process according to preset process parameters, automatically adjusting blow molding pressure and gas volume, controlling mold temperature, mold opening and closing speed and cycle, andautomatically correcting the size, wall thicknesses and the like of blow molding equipment so as to realize the closed-loop automatic control. The method provided by the invention has the beneficialeffects that operation is adjusted based on a continuous and automatic process without needing any manual intervention, the raw materials in a container are accurately allocated, online wall thicknessmeasurement feedback is monitored in real time, and the wall thicknesses of the mold blank is automatically adjusted, so that the product wall thickness distribution is enabled to be more uniform, and the quality of the hollow container is improved.

Owner:岱纳包装(天津)有限公司

Molding technology for controlling wall thickness distribution of hollow-blow-molded product through temperature of machine head

InactiveCN105269795AUniform wall thickness distributionImprove smoothnessTemperature controlBlow molding

The invention relates to a molding technology for controlling wall thickness distribution of a hollow-blow-molded product through the temperature of a machine head, and belongs to the technical field of hollow blow molding. The technological conditions are characterized in that the temperature of an opening mold ranges from 170 DEG C to 200 DEG C; the temperature of a first section of a barrel is 165 DEG C, the temperature of a second section of the barrel is 170 DEG C, the temperature of a third section of the barrel is 170 DEG C, the temperature of a fourth section of the barrel is 175 DEG C, and the temperature of a fifth section of the barrel is 180 DEG C; the temperature of a mold ranges from 40 DEG C to 80 DEG C; the blowing-up pressure ranges from 0.6 MPa to 0.8 MPa; the blowing time is 20 s; the cooling time is 40s; the piece taking time is 10 s; the molding cycle is 80 s; and an extruding machine is in a single-screw type, an extruding machine head is in a piston type, and the extrusion rate ranges from 100 cm<3> / s to 180 cm<3> / s. By means of the molding technology, the wall thickness distribution of the manufactured piece can be even, quality can be good, the surface can be smooth, and glossiness can be good.

Owner:天津市科润特包装有限公司

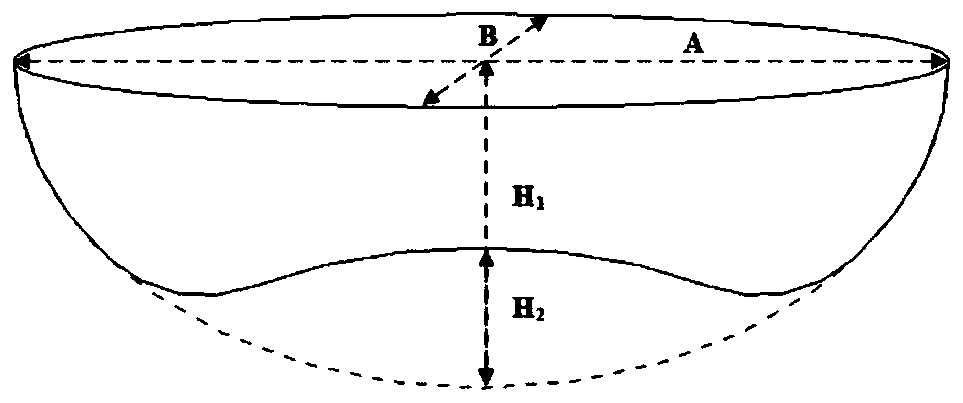

Sheet metal part die-free machining method

The invention relates to a sheet metal part die-free machining method. The sheet metal part die-free machining method comprises the following steps that firstly, four boundaries of a rectangular metalplate material are fixed to a forming machine tool through clamps; secondly, a half-ellipsoid-shaped die is formed as a first intermediate structure, the surface area of the first intermediate structure accounts for 60-80% of the surface area of the finally formed part, and the first intermediate structure is formed in the first pass; thirdly, a reversely raised swell is established upwards fromthe center of the lower side of the first intermediate structure and used as a second intermediate structure, the area of the raised swell accounts for 30-40% of the surface area of the first intermediate structure, and a lower forming tool is adopted to form the second intermediate structure along a preset second formation path in the second pass; and fourthly, the second intermediate structure is machined to be in the shape of the finally formed part in the third pass. The sheet metal part die-free machining method does not need a dedicated mold, the machining period is short, and a large-wall angle or straight-angle piece, complicated-structure pieces and other parts difficult to machine can be formed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Molding technology for controlling wall thickness distribution of hollow blow-molded product through inflation pressure

The invention relates to the technical field of hollow blowing molding, in particular to a molding technology for controlling wall thickness distribution of a hollow blow-molded product through inflation pressure. According to the technological condition, the temperature of a bush die ranges from 170 DEG C to 200 DEG C, and the temperature of a material barrel is divided into five segments, wherein the temperature of the first segment is 165 DEG C, the temperature of the second segment is 170 DEG C, the temperature of the third segment is 170 DEG C, the temperature of the fourth segment is 175 DEG C, and the temperature of the fifth segment is 180 DEG C; the temperature of a die ranges from 40 DEG C to 80 DEG C; the inflation pressure ranges from 0.6 MPa to 0.8 MPa; the blowing time is 20 s; the cooling time is 40 s; the part taking time is 10 s; the molding period is 80 s; and the extrusion speed ranges from 100 cm<3> / s to 180 cm<3> / s. The technological process comprises the following steps that firstly, a started blow molding die is moved to the position below the extrusion machine head, a molded blank is extruded in the blow molding die, then die assembling is carried out, and the die is moved out of the position below the extrusion machine head; the mold blank is in contact with the die, a gas channel is formed in the center of the die, and compressed air is introduced in to the molded blank for blowing up the mold blank, so that the mold blank is in contact with the inner surface of the blow molding die, and after cooling shaping, the die is opened for part taking.

Owner:天津市科润特包装有限公司

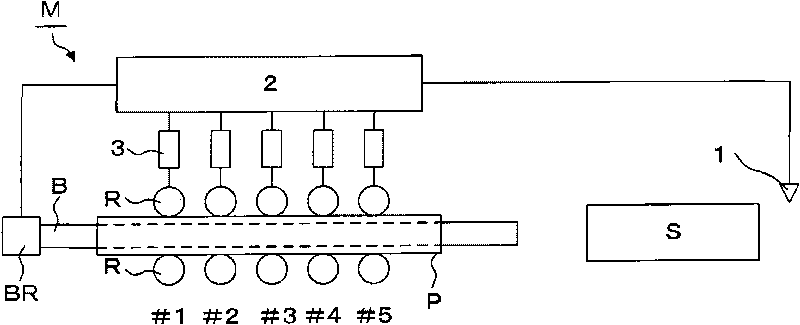

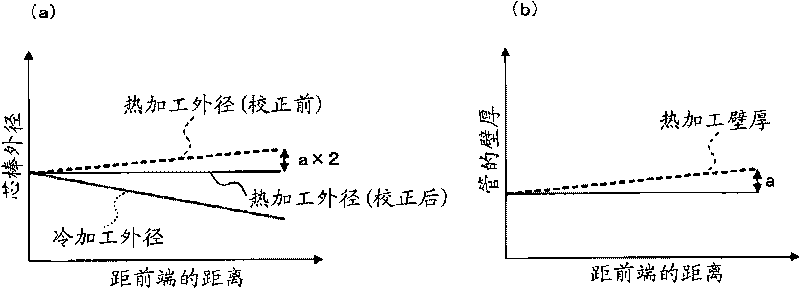

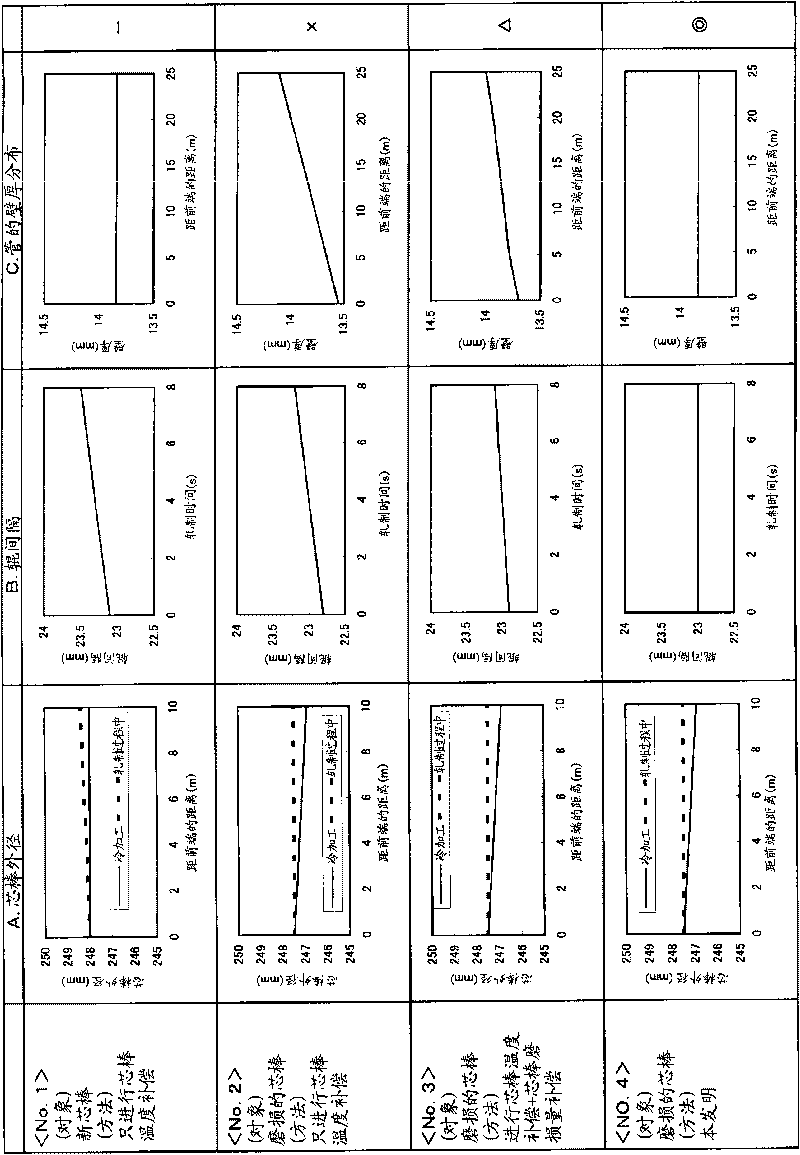

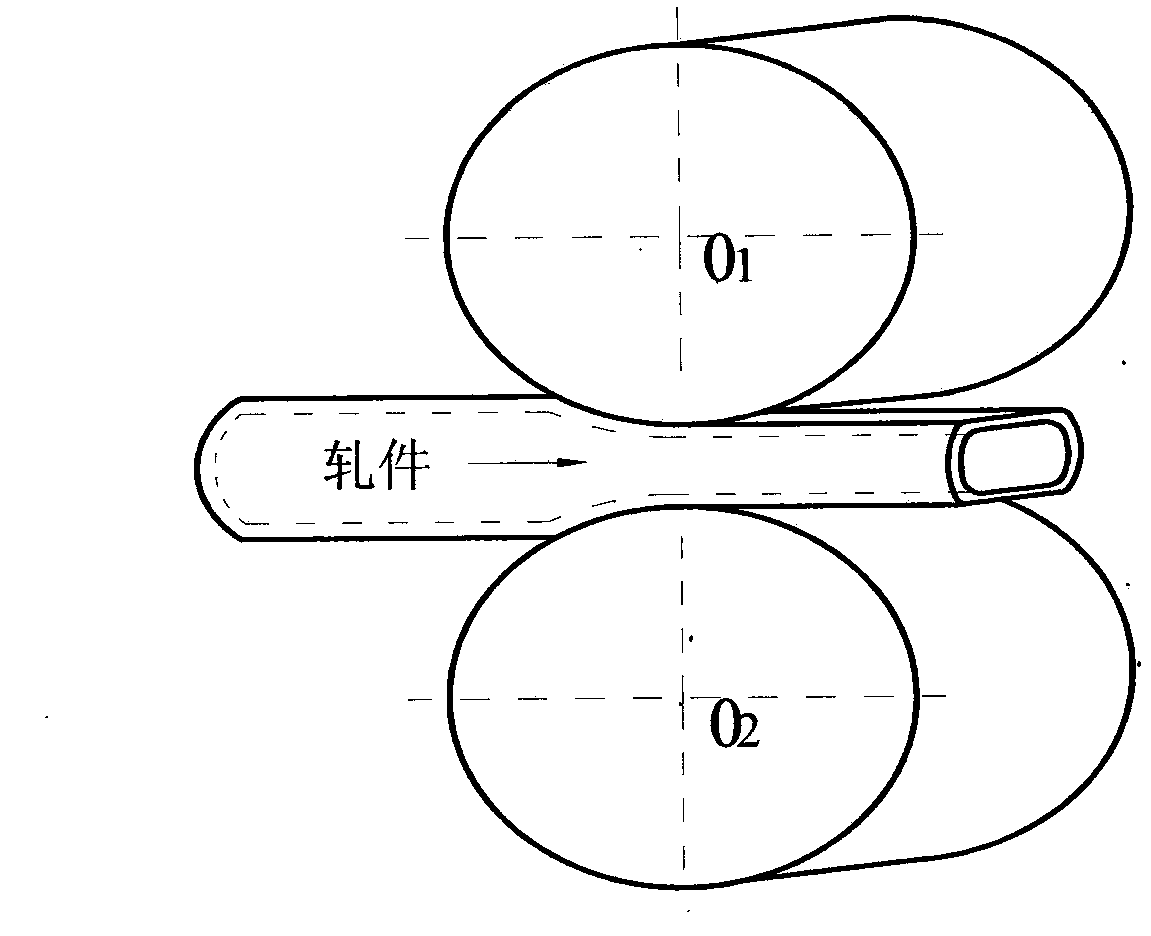

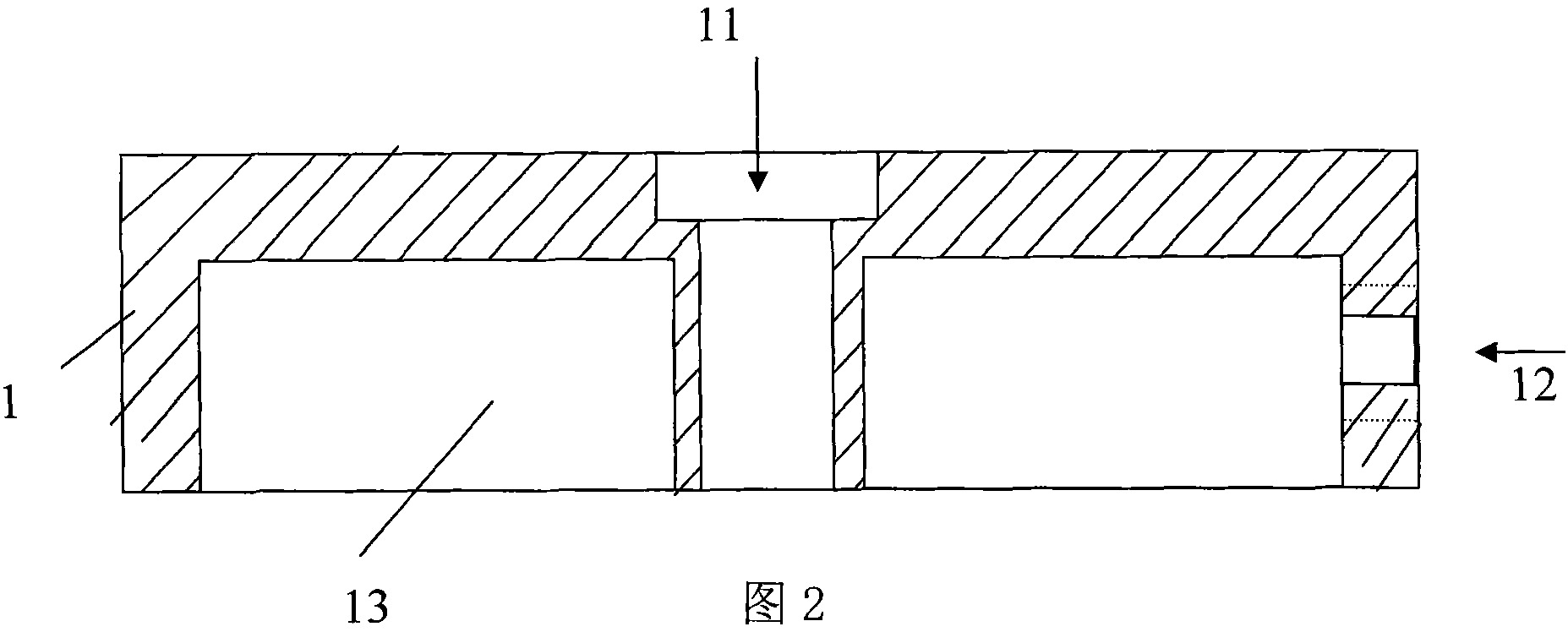

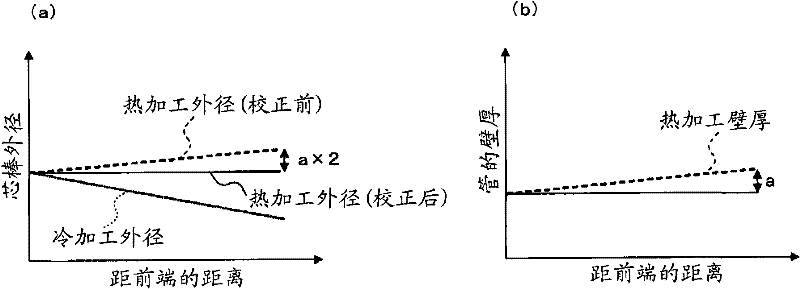

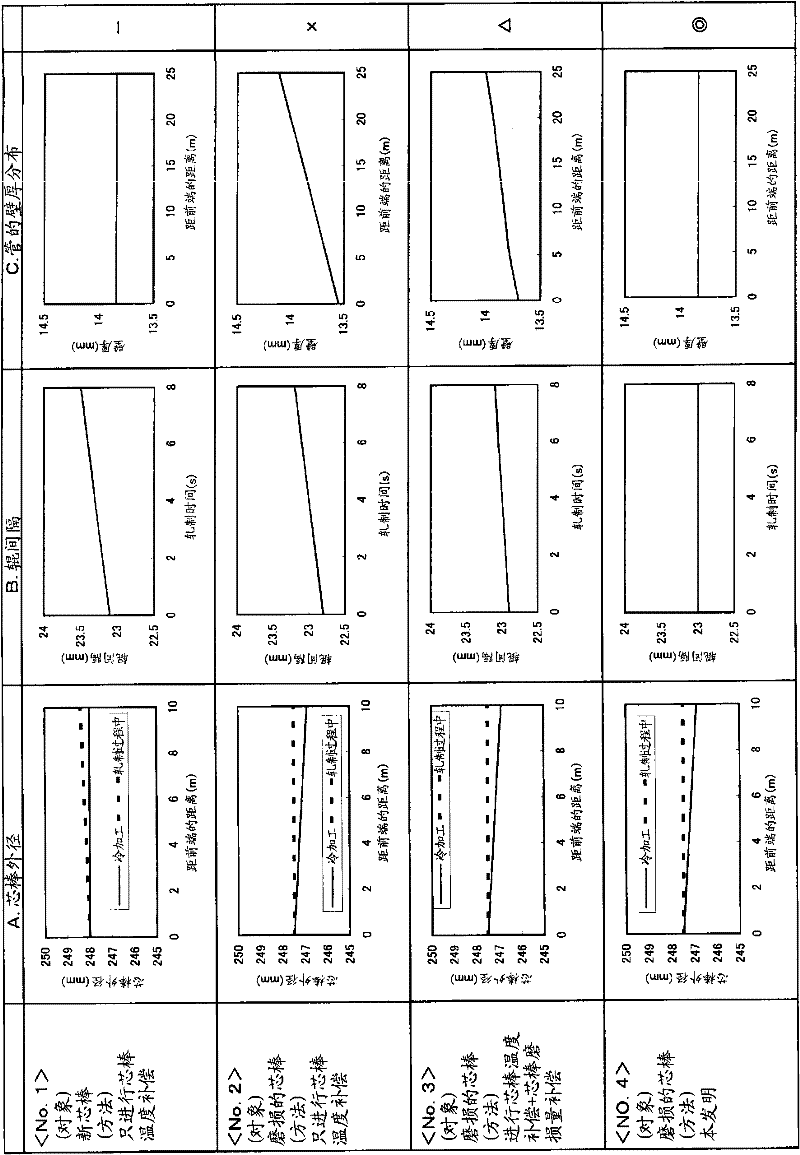

Seamless pipe manufacturing method

ActiveCN101711190AUniform wall thickness distributionRoll mill control devicesMetal rolling arrangementsEngineeringMechanical engineering

There is provided a method for manufacturing a seamless pipe or tube that is capable of making more uniform the wall thickness distribution of a pipe or tube along the longitudinal direction of the pipe or tube than the prior art. The method for manufacturing a seamless pipe or tube according to the present invention comprises a first step of measuring the outside diameter distribution of thg mandrel bar B along the longitudinal direction of the mandrel bar at normal temperature; a second step of measuring the temperature distribution of the mandrel bar along the longitudinal direction of the mandrel bar in the mandrel bar after it being used for a drawing and rolling step in a mandrel mill M; and a third step of measuring the wall thickness distribution of the pipe or tube in the hot state after it being subjected to drawing and rolling with the mandrel bar being inserted thereinto, along the longitudinal direction of the pipe or tube. And the method comprises a fourth step of calculating the outside diameter distribution of the mandrel bar along the longitudinal direction of the mandrel bar at the time of being used for drawing and rolling on the basis of the respective parameters which have been obtained at the first to third steps, and a fifth step of adjusting the setting position of the grooved roll R in the rolling direction on the basis of the outside diameter distribution of the mandrel bar along the longitudinal direction of the mandrel bar when the mandrel bar is inserted into the inside of a pipr or tube at the next timing for being used for drawing and rolling.

Owner:NIPPON STEEL CORP

Manufacturing method of titanium alloy hollow component

ActiveCN101786223BIncrease productivityImprove efficiencyNon-electric welding apparatusTitanium alloyStressed skin

The invention relates to a manufacturing method of a titanium alloy thin-wall ribbed hollow component. The method comprises the following steps that: a. the titanium alloy hollow component is decomposed into a stressed-skin and ribbed structure form or a stressed-skin ribbed structure form according to the structure features of a hollow component, and an inner sheath and an outer sheath structureforms are determined according to a hollow part of the hollow component; b. the stressed-skin and ribbed or the stressed-skin ribbed structural part is processed or formed according to the decomposedstructure forms; c. the inner and the outer sheaths are processed or formed; d. the stressed-skin and ribbed or the stressed-skin ribbed structural part being well processed is assembled with the inner and the outer sheaths, the inner and the outer sheaths are sealed in a welding way and are vacuum encapsulated, and the vacuum degree is 1.0 *10-3Pa; e. the dispersion connection of each structuralpart is realized through a hot isostatic pressing method; f. surface treatment on each prefabricated structural part is undertaken so as to prepare the hollow structural component. The manufacturing method has high production efficiency; a plurality of components can be prepared through one technical circulation; and the welding rate is more than 95 percent.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Novel interface structure

PendingCN108237896AImprove sealingReduce the chance of exudationEngine sealsFuel supplyEngineeringHydrogen molecule

The invention provides a novel interface structure which allows a lower annular surface of an upper cover and a welding ring to be connected in an inverted manner, so that a bonding path is shortenedand the sealing performance at an interface joint is good, so as to reduce the probability of carbon-hydrogen molecules leaking from the interface joint. The novel interface structure comprises the upper cover and the welding ring, wherein the lower annular surface of the upper cover is provided with an inwardly-concave annular groove; the longitudinal section of the annular groove comprises transition edges on the two sides and a top inverted cavity; the welding ring is provided with an upwardly-convex inverted assembly at the position corresponding to the annular groove; the longitudinal section of the inverted assembly comprises an inverted part at the top part and a transition connector at the lower part; the inverted part enters into the top inverted cavity along the transition edgeson the two sides under the connection state; the two edges of the transition connector cling to the transition edges on the corresponding sides; and the inverted part clings to the inner wall of the top inverted cavity.

Owner:STANT AUTOMOTIVE SYST SUZHOU

Production preparing method of composite foam aluminum

ActiveCN111434788AUniform wall thickness distributionImprove pressure resistance and sound absorptionLiquid surface applicatorsCoatingsGraphite oxideMechanical properties of carbon nanotubes

The invention discloses a production preparing method of composite foam aluminum. The method specifically comprises the following steps of S1, making a preliminary foaming sphere, and after drying, carrying out standby application; S2, making a final foaming sphere, and after drying, carrying out standby application; S3, forming oxidized grapheme slurry, and carrying out standby application; S4, forming an aluminum alloy melt; S5, stirring to form a pre-treated aluminum alloy melt; S6, carrying out penetrating casting, and forming a foam aluminum plate blank; S7, removing a mold, carrying outultrasonic immersing for a period of time, and after washing, performing drying under the inert gas protection; S8, attaching the other foam aluminum plate blank to a foam aluminum plate blank sprayedwith graphene oxide slurry, and forming a composite type foam aluminum plate blank; and S9, putting the composite foam aluminum plate blank into a heating furnace, carrying out heating, and rolling to become a final composite foam aluminum plate. The composite foam aluminum prepared through the method has the good mechanical property, the structural strength can be improved, density is small, andheat insulation performance is good.

Owner:杨怡虹

Preparation method of stainless steel/carbon steel chip core composite board

InactiveCN102553959BAchieve metallurgical bondingUniform wall thickness distributionHigh volume manufacturingHeating furnace

The invention relates to a preparation method of a stainless steel / carbon steel chip core composite board, which comprises the following steps that: (1). stainless steel pipes and chips produced by carbon steel machining are used as raw materials; (2) the carbon steel chips are pressed into the stainless steel pipes to be made into bimetal composite billets; (3) the press-mounted stainless steel / carbon steel chip core composite billets are placed into a heating furnace to be heated at a heating temperature of 1100 to 1200 DEG C for insulation of 30 to 60 minutes; (4) the heated composite billets are rolled on a rolling mill; and (5) after being rolled to the required size, the composite billets are cut with a constant length. The method provided by the invention is simple, is low in cost, and is suitable for industrial mass production, the metallurgical bonding is formed between carbon steel chips and between stainless steel and carbon steel chips in the prepared stainless steel / carbon steel chip core composite board, the structure of the carbon steel chip core is continuous and dense, the surface quality of the composite board is good, and the wall thickness of the stainless steel is uniformly distributed. Compared with the stainless steel composite board produced by other methods, the stainless steel / carbon steel chip core composite board has more excellent performance-price ratio.

Owner:YANSHAN UNIV

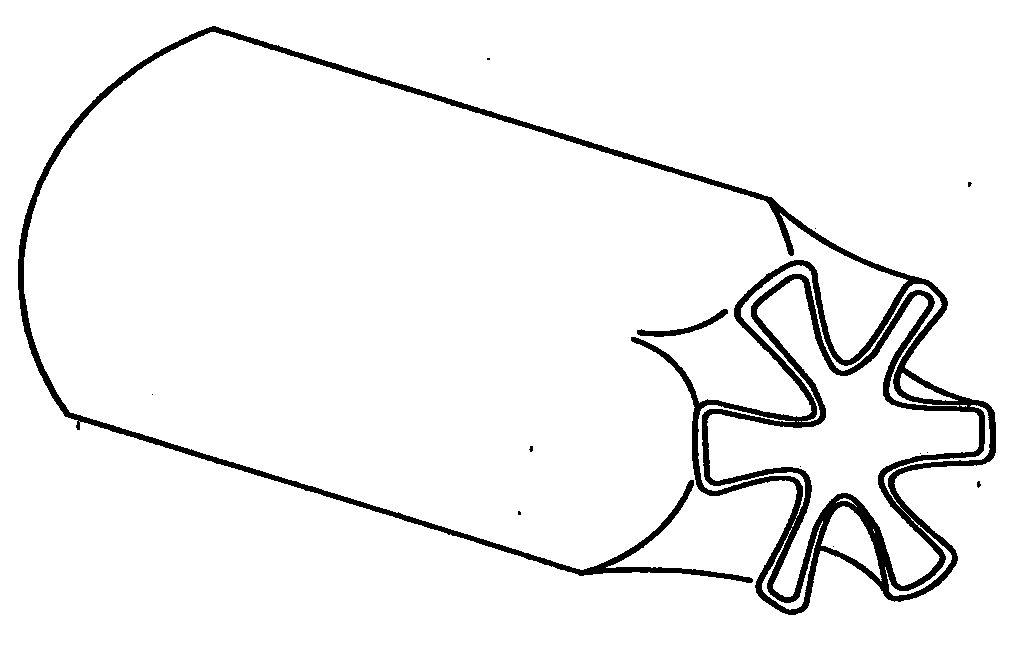

Inset tube type multi-holed jet

InactiveCN101372765BUniform wall thickness distributionStable wall thickness distributionSpinnerette packsEngineeringTubes types

The invention relates to an insert tube multi-holed jet which comprises an insert tube and a spinneret plate. The invention is characterized in that the multi-holed jet is a cuboid assembled by an upper plate, a middle plate and a lower plate; the center of the upper plate is provided with a first casting liquid inlet and the side surface is provided with a core liquid or nitrogen inlet; the two inlets are not communicated; the center of the middle plate is provided with a second casting liquid inlet which is vertically penetrated with a casting liquid distribution tube; the two sides of the casting liquid distribution tube are symmetrically provided with 3 to 6 casting liquid distribution pipelines from the inside to the outside; besides, the diameters thereof are increased gradually from the middle to the two sides; the two sides of the casting liquid distribution tube are symmetrically provided with tube holes for mounting the insert tube; each tube hole is provided with a lower perforating plate and the insert tube of the spinneret plate; the lower plate is provided with a casting liquid slot; a lower casting liquid pipeline is arranged on the casting liquid slot; the diameterof the lower casting liquid pipeline is 1 to 3mm more than the diameter of the insert tube arranged in the lower casting liquid pipeline; the mounting hole of the spinneret plate is arranged on the bottom surface of the lower plate; a fixing hole the diameter of which is 0.5 to 1.5mm more than the diameter of the mounting hole is correspondingly arranged on the spinneret plate.

Owner:TIANJIN POLYTECHNIC UNIV

Seamless pipe manufacturing method

ActiveCN101711190BUniform wall thickness distributionRoll mill control devicesMetal rolling arrangementsEngineeringMechanical engineering

There is provided a method for manufacturing a seamless pipe or tube that is capable of making more uniform the wall thickness distribution of a pipe or tube along the longitudinal direction of the pipe or tube than the prior art. The method for manufacturing a seamless pipe or tube according to the present invention comprises a first step of measuring the outside diameter distribution of thg mandrel bar B along the longitudinal direction of the mandrel bar at normal temperature; a second step of measuring the temperature distribution of the mandrel bar along the longitudinal direction of themandrel bar in the mandrel bar after it being used for a drawing and rolling step in a mandrel mill M; and a third step of measuring the wall thickness distribution of the pipe or tube in the hot state after it being subjected to drawing and rolling with the mandrel bar being inserted thereinto, along the longitudinal direction of the pipe or tube. And the method comprises a fourth step of calculating the outside diameter distribution of the mandrel bar along the longitudinal direction of the mandrel bar at the time of being used for drawing and rolling on the basis of the respective parameters which have been obtained at the first to third steps, and a fifth step of adjusting the setting position of the grooved roll R in the rolling direction on the basis of the outside diameter distribution of the mandrel bar along the longitudinal direction of the mandrel bar when the mandrel bar is inserted into the inside of a pipr or tube at the next timing for being used for drawing and rolling.

Owner:NIPPON STEEL CORP

Several-time drawing formation device for deep-cylinder-shaped piece

InactiveCN103084483BFacilitate Mobility TrendsPrevent thinningShaping toolsPolyurethane elastomerBall bearing

Disclosed is a several-time drawing formation device for a deep-cylinder-shaped piece. The several-time drawing formation device for the deep-cylinder-shaped piece comprises an upper die base and a lower die base. The upper die base and the lower die base are connected with guide pillars through ball bearing guide bushings, a protrusion locating piece is fixedly installed on the upper die base, nitrogen cylinders are arranged on the lower end of the protrusion locating piece, piston rods of the nitrogen cylinders and blank holders tightly press blank materials through a groove at the lower end of a rubber block, a protrusion main body is installed on the protrusion locating piece and is composed of a protrusion die, a polyurethane elastomer, a locating ring, a pressing plate and a protrusion die connecting piece, a cone-shaped concave mould is fixed on the lower die base, and an ejector rod ejects out a workpiece after several-time drawing are finished. Due to the fact that a nitrogen cylinder flange pressing device and the polyurethane elastomer are both used on the several-time drawing formation device for the deep-cylinder-shaped piece, efficiency and quality of drawing formation can be ensured.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com