Deep-drawing attenuated processing method of resin clad metal plate as well as resin coating deep-drawing attenuated tank using said method

一种加工方法、拉深减薄的技术,应用在应用、家里用具、其他家里用具等方向,能够解决难以形成壁厚分布、成本降低、罐侧壁破断等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~2

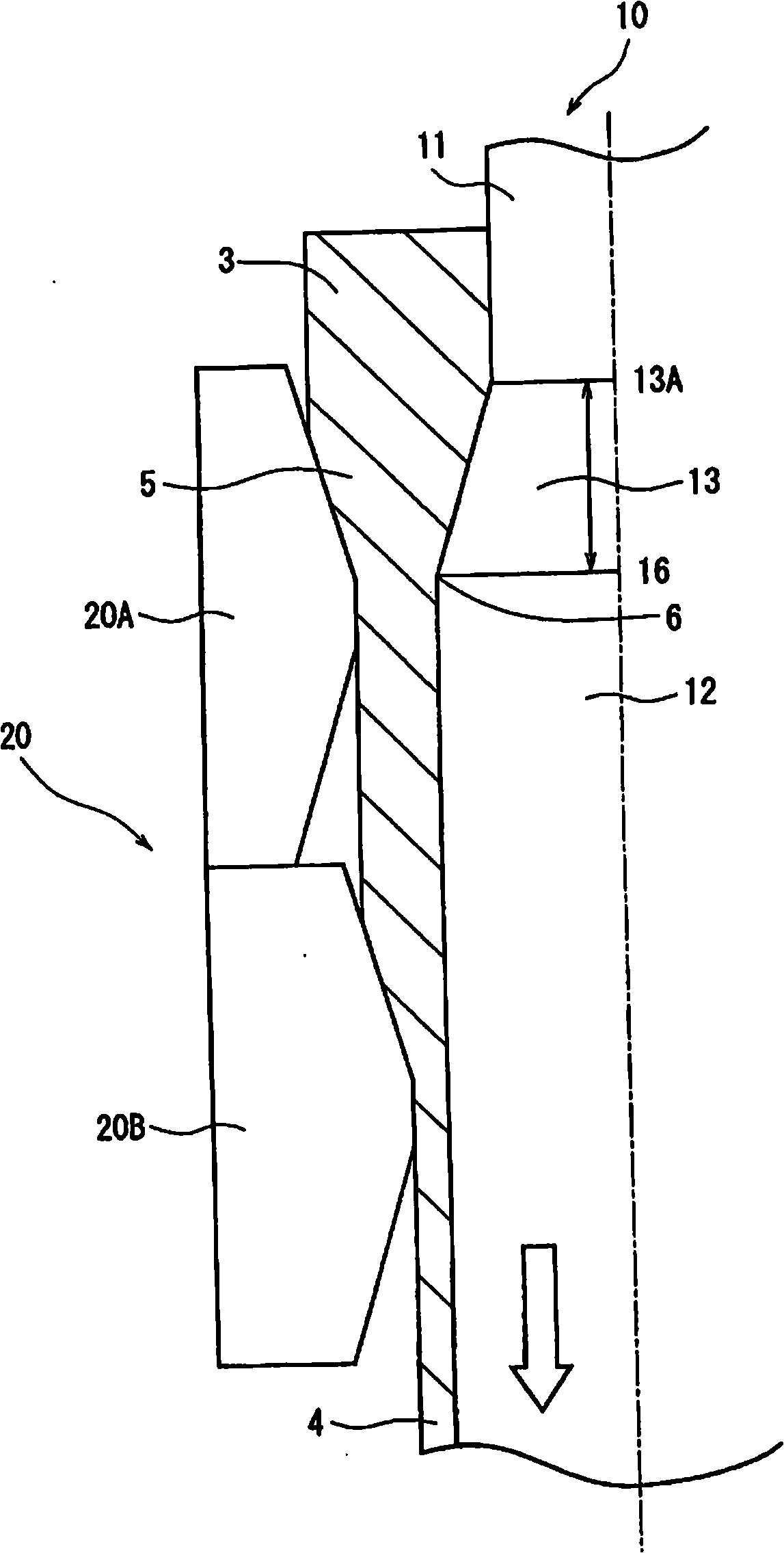

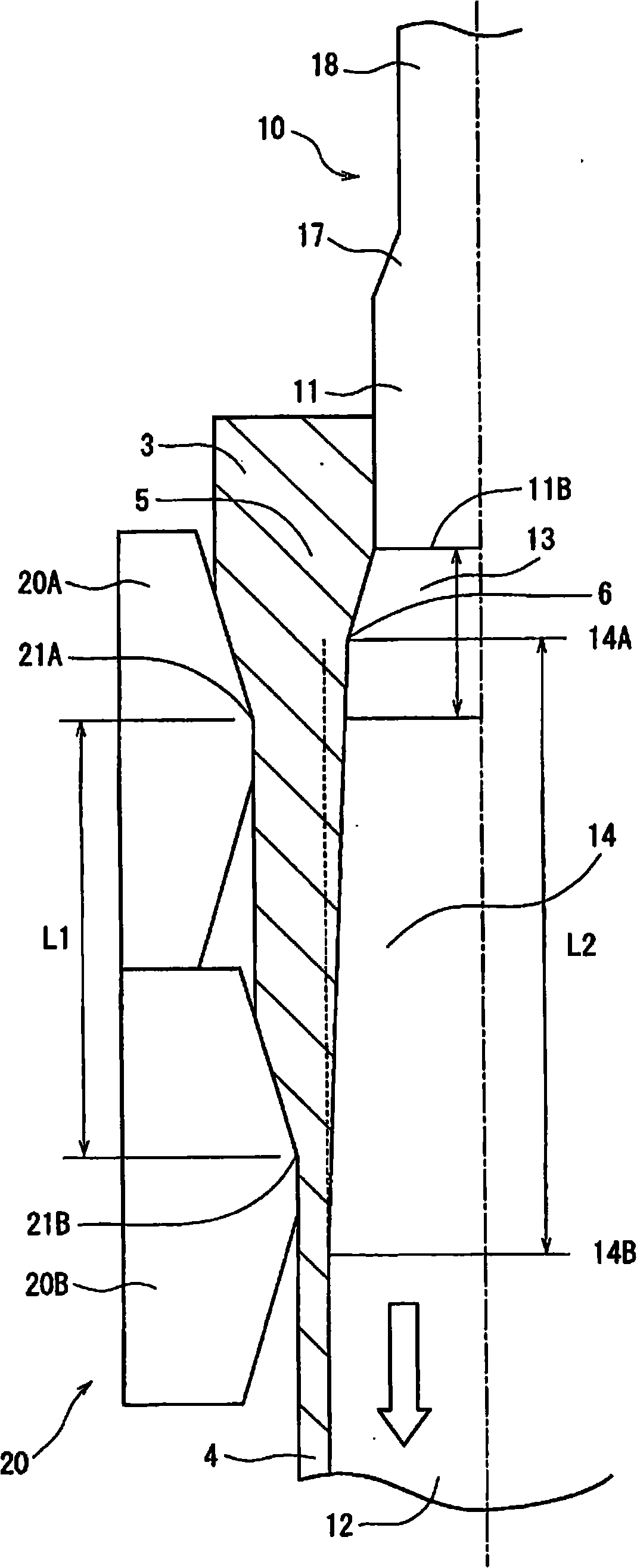

[0069] As the test plate, the following organic resin-coated steel plate was used: a transparent polyester film with a thickness of 28 μm was coated on the surface of the electrolytic chromate-treated steel plate with a thickness of 0.190 mm to become the inner surface of the can, and the surface that became the outer surface of the can was covered with The side surfaces were covered with white polyester resin to which a titanium oxide-based pigment was added in a thickness of 16 μm. After punching out a circular blank with a diameter of 151 mm from this organic resin-coated steel sheet, a drawn cup body with a diameter of 91 mm was formed by the first-stage drawing process, and then a drawn cup body with a diameter of 66 mm was formed by the second-stage drawing process. deep drawn cup body.

[0070] The cup body was subjected to thinning processing under the conditions shown below using a thinning processing apparatus composed of two stages of thinning processing sections to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com