Inset tube type multi-holed jet

A technology of inserting tube type and spinneret, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc., can solve the problems of backward technology, low production efficiency, unreasonable structure, etc., and achieve uniform wall thickness distribution and product quality and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. The specific embodiments are only for further clearly illustrating the porous spinneret of the present invention, and do not constitute limitations on the claims of the present invention.

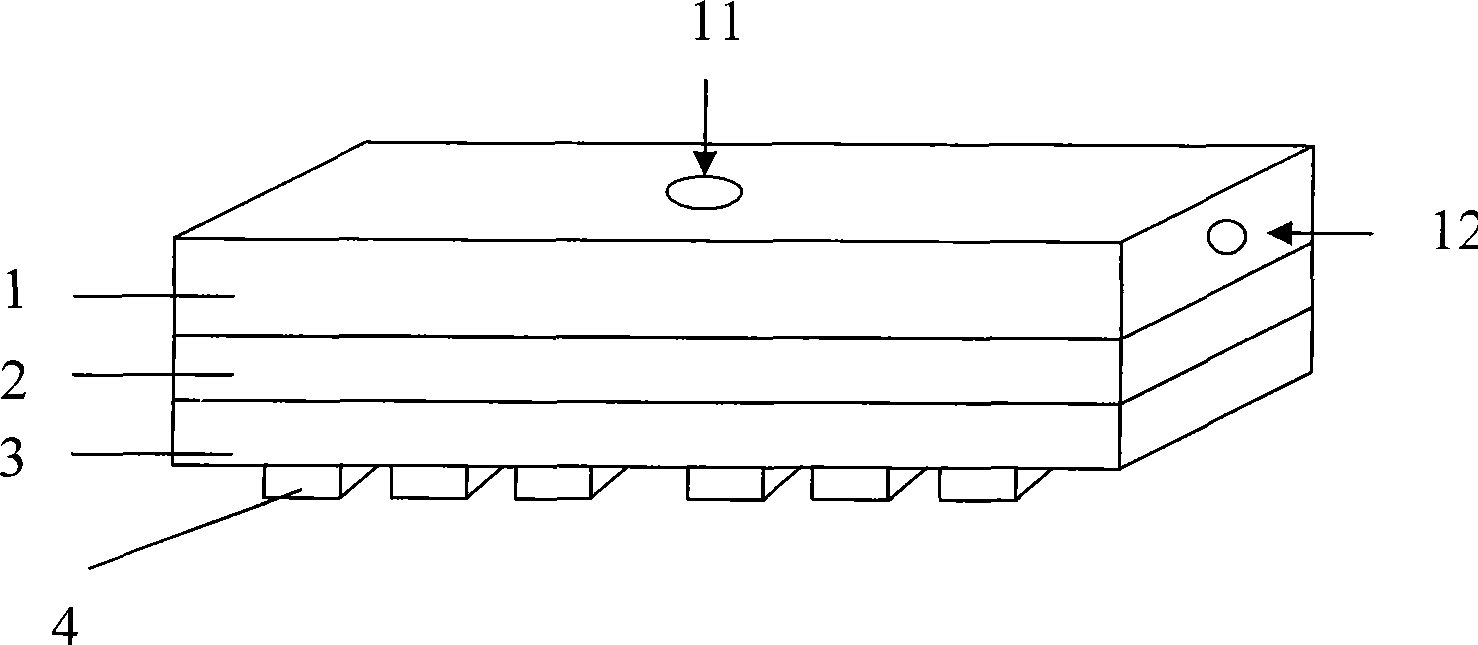

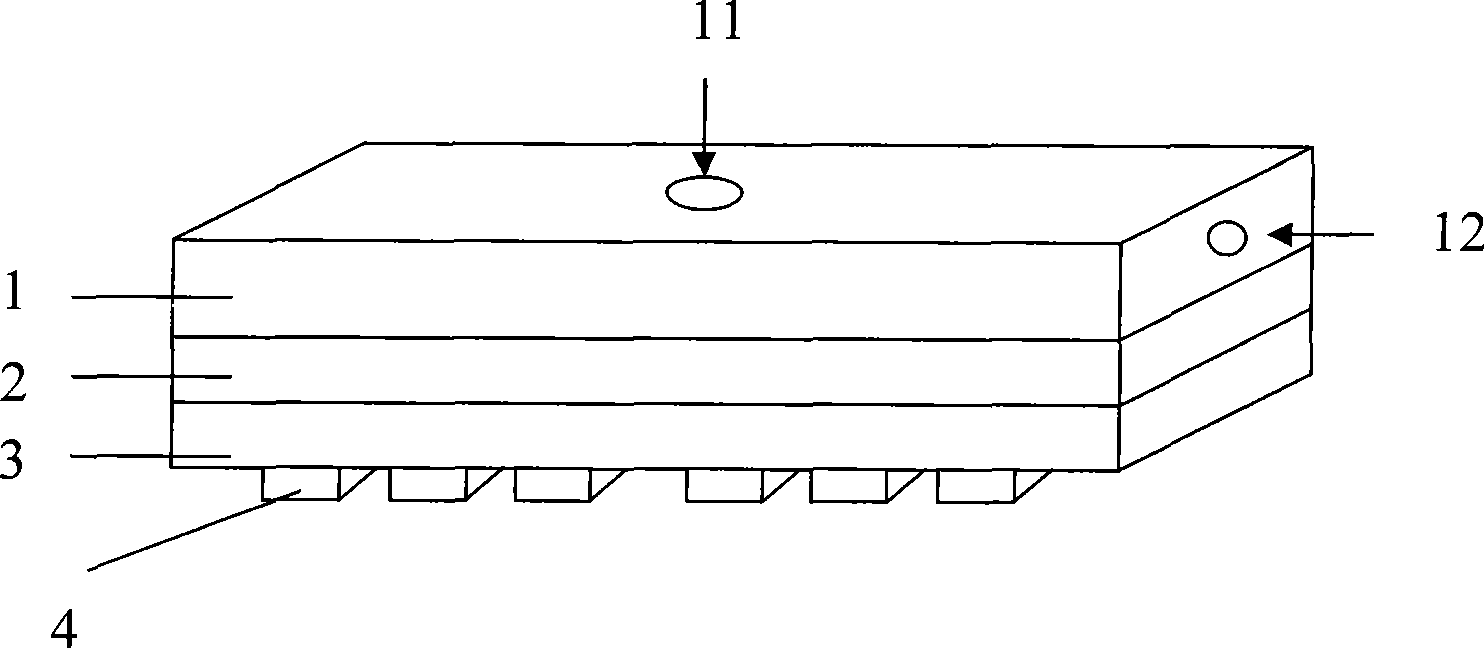

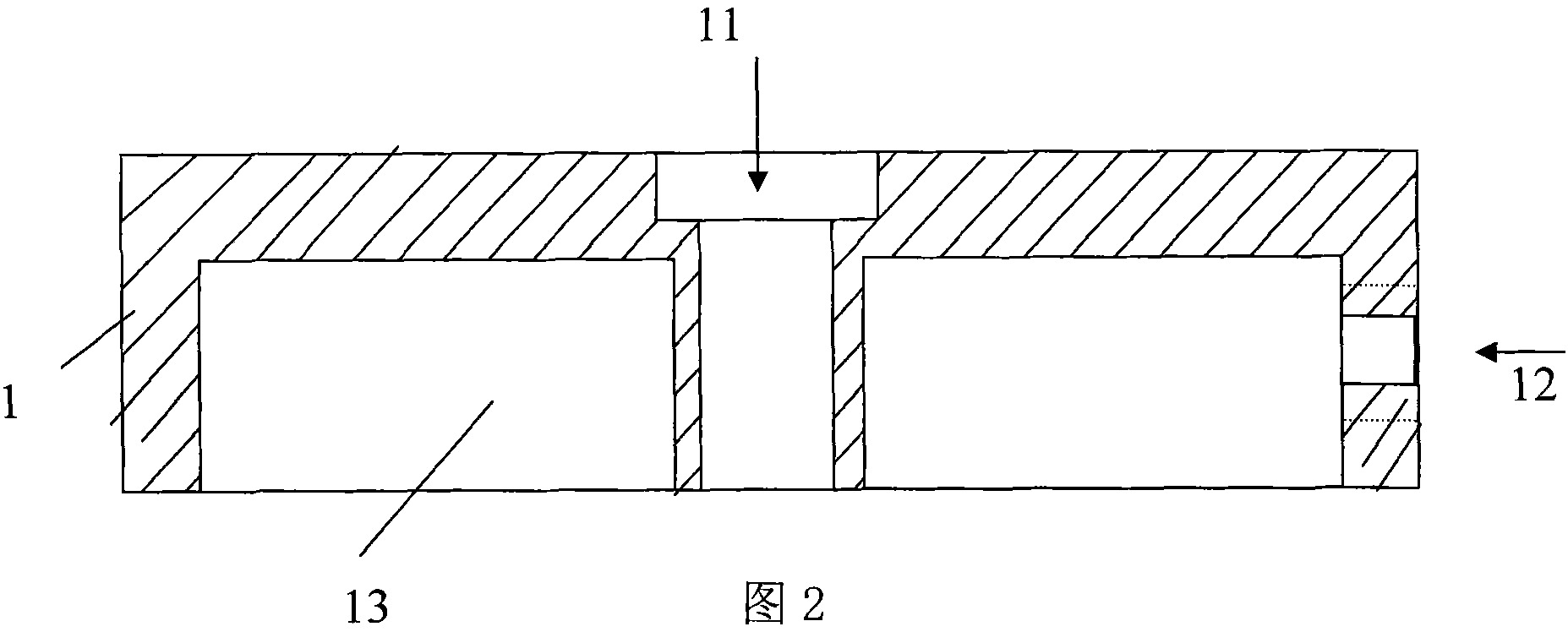

[0017] The insert tube type porous spinneret (hereinafter referred to as the porous spinneret for short, referring to Fig. 1-7) of the preparation hollow fiber membrane of the present invention design, comprises insert tube 5 and spinneret 4, is characterized in that this spinneret is made of The upper plate 1, the middle plate 2, the lower plate 3 and the spinneret plate 4 are cuboids composed of screws; the center of the upper plate 1 is provided with the first casting solution connected to the metering pump seat (not shown in Fig. 1) Inlet 11, a core liquid or nitrogen inlet 12 is opened on the side of the upper plate 1, and the first casting liquid inlet 11 and the core l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com