Several-time drawing formation device for deep-cylinder-shaped piece

A technology for multiple deep-drawing and deep cylindrical parts, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of bottom cracking, inability to realize part forming, and high scrap rate of formed parts, so as to prevent bottom cracking , promote the flow trend, increase the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

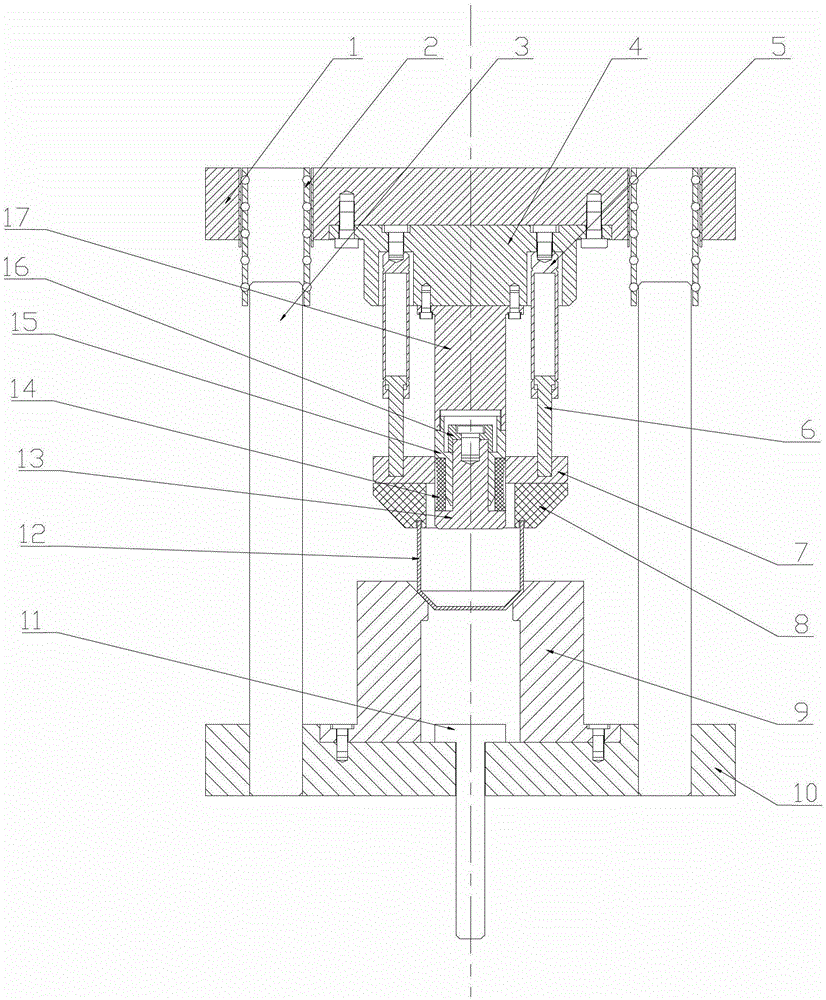

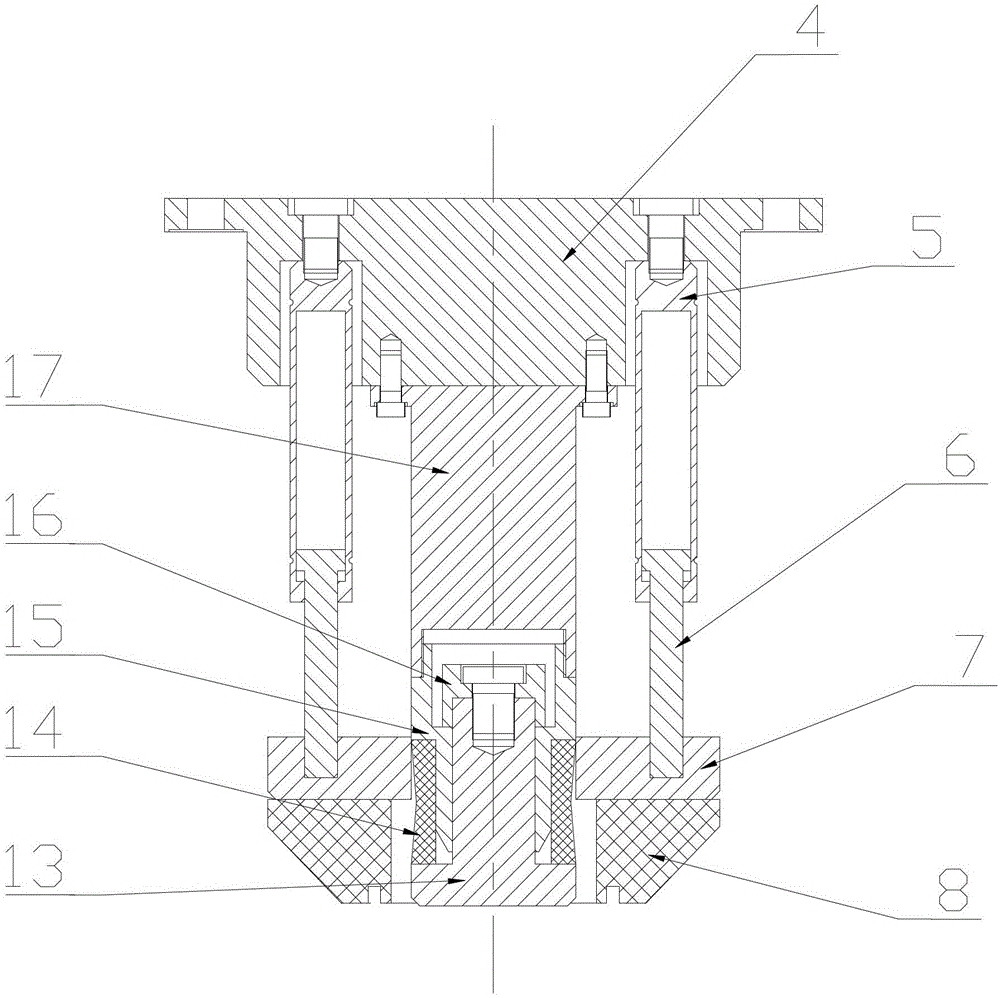

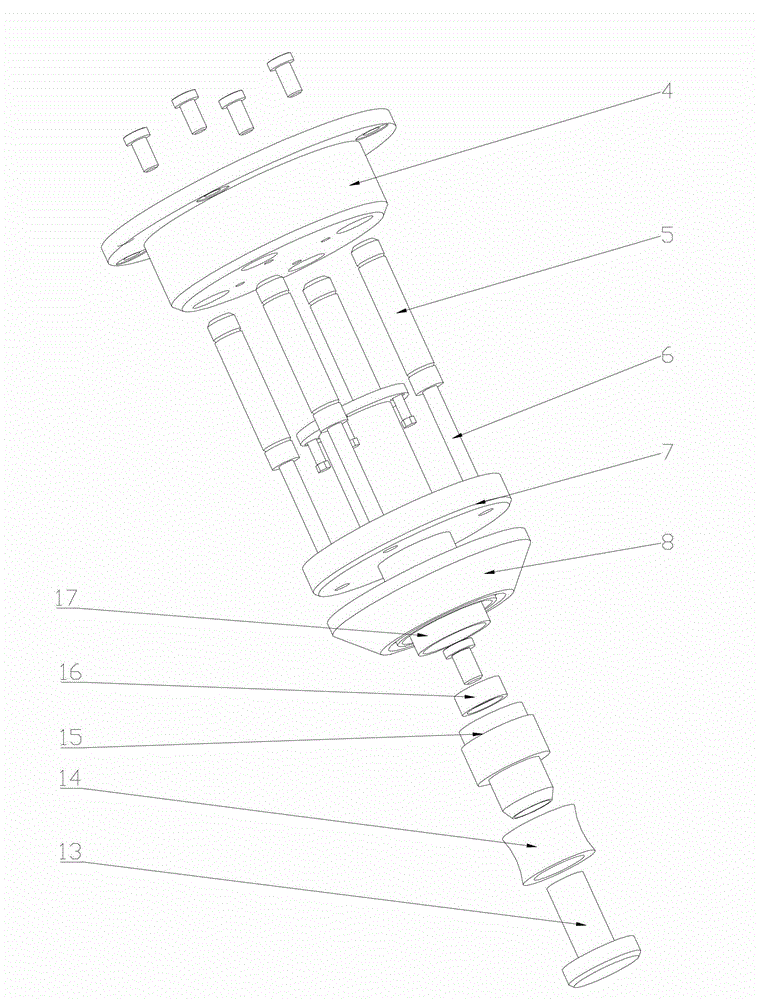

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , a device for multiple deep-drawing of deep cylindrical parts, including an upper mold base 1 and a lower mold base 10, the upper mold base 1 and the lower mold base 10 are connected to the guide column 3 through a ball guide bush 2, and the upper mold base 1 Install and fix the punch positioning part 4 with screws. There are 4 countersunk holes at the upper end of the punch positioning part 4. There are 4 evenly distributed deep holes at the lower end of the punch positioning part 4. Place 4 nitrogen cylinders in the deep holes. Fixed on the positioning part 4 of the punch by screws, the nitrogen cylinder is composed of a cylinder body 5 and a piston rod 6, replacing the traditional blank holder device, the piston rod 6 and the blank holder 7 are interference fit, and the rubber block 8 and the blank holder 7 Bonded together with an adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com