Novel interface structure

An interface structure, a new type of technology, applied in the layout combined with the fuel supply of the internal combustion engine, the sealing of the engine, the engine components, etc., can solve the problems of high evaporative emission limit, uneven material wall thickness, high leakage risk, and achieve the wall thickness Uniform distribution, reducing the probability of exudation, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

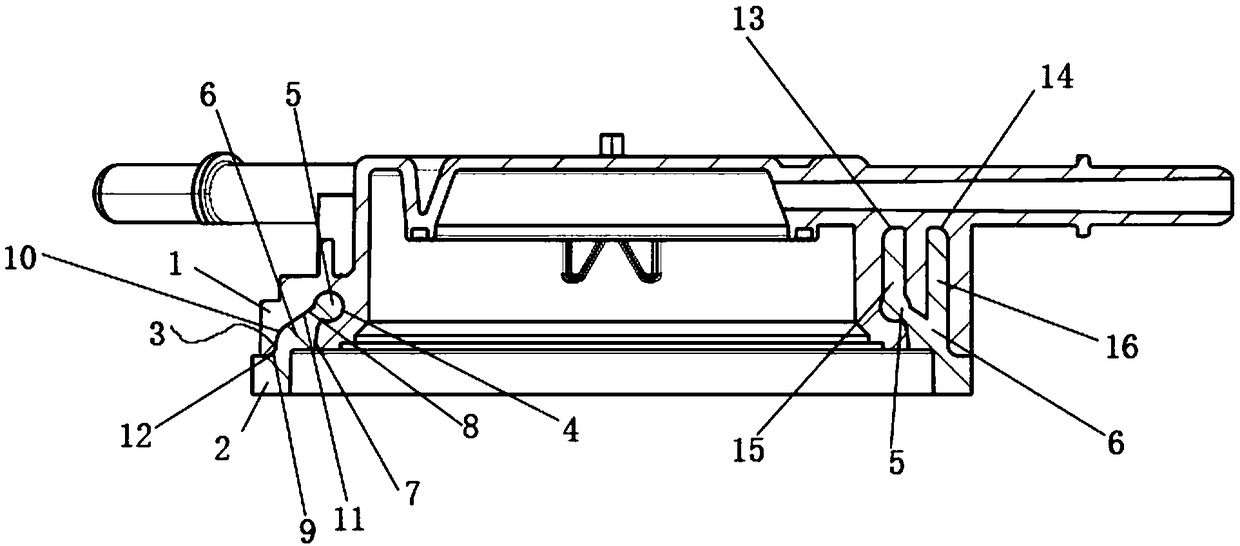

[0020] A new interface structure, see figure 1 , figure 2 : It includes a loam cake 1 and a welding ring 2. The lower annular surface of the loam cake 1 is provided with a concave annular groove 3. The longitudinal section of the annular groove 3 includes transition edges on both sides and an undercut cavity 4 on the top. The welding ring 2 corresponds to At the corresponding position of the annular groove 2, there is an upwardly convex undercut component. The longitudinal section of the undercut component includes the top undercut 5 and the lower transition connector 6. In the connected state, the undercut 5 enters into the Inside the top undercut cavity 4 , the two side edges of the transition connector 6 are arranged close to the transition edges of the corresponding sides, and the undercut 5 is arranged close to the inner wall of the top undercut cavity 4 .

[0021] The transition edges on both sides are the inner transition edge 7 and the outer transition edge 8 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com