Preparation method of stainless steel/carbon steel chip core composite board

A technology for stainless steel and composite panels, which is applied in the field of preparation of stainless steel composite panels, can solve problems such as inability to produce composite panels, noise and smoke pollution, and poor surface quality, and achieve excellent mechanical strength and plastic deformation ability, low cost, and high surface quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

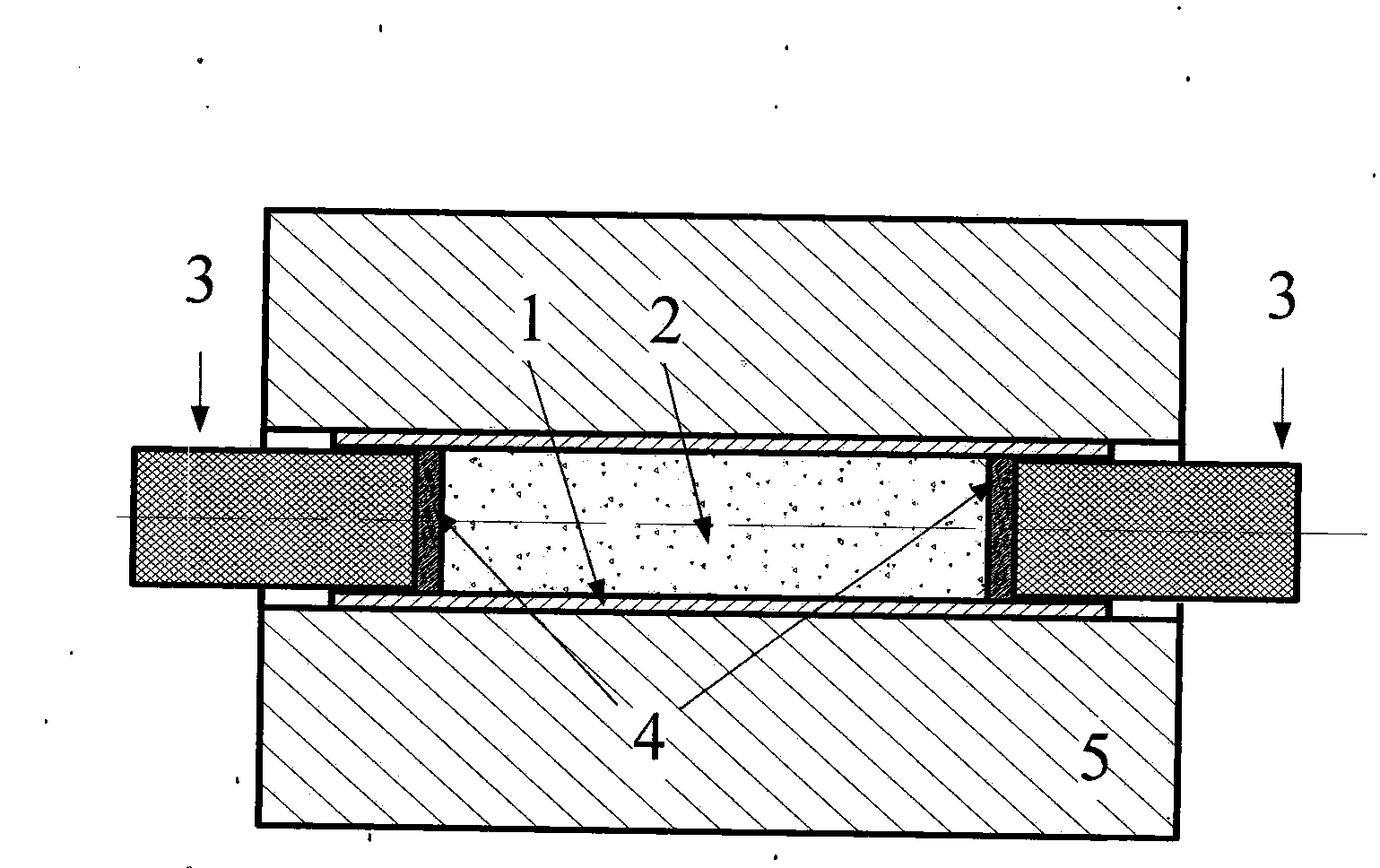

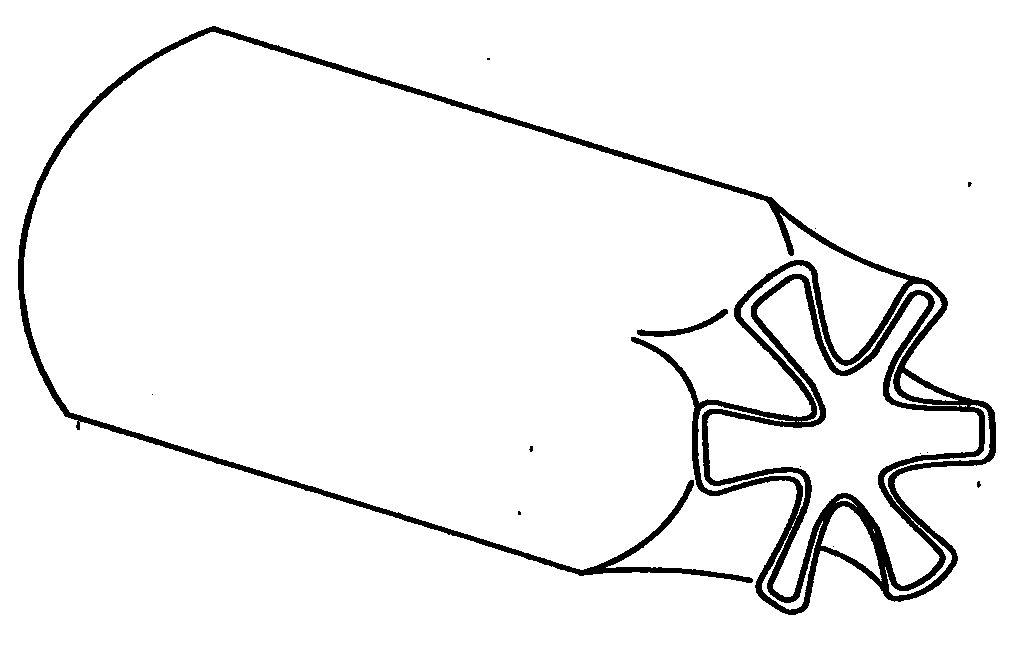

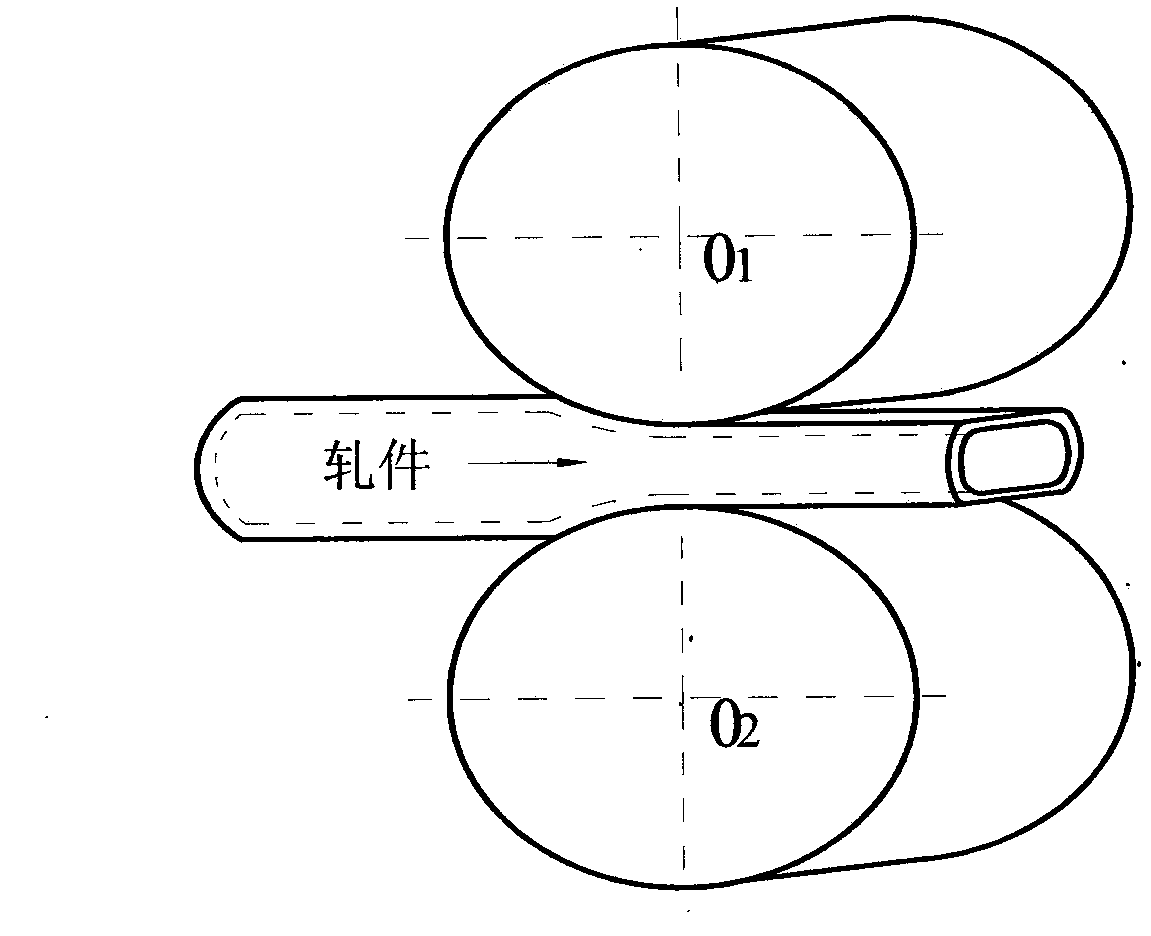

[0028] 304 stainless steel seamless pipe 1 and Q195 carbon steel chips 2 are used as raw materials, wherein the diameter of the stainless steel pipe is 200mm, and the wall thickness of the pipe is 20mm. The inner wall of the above-mentioned stainless steel pipe is brushed, high-pressure cleaned, and dried. The carbon steel is crushed and impurities are screened out, and then heated at 600°C in a reduction furnace for annealing treatment, and the surface oil is cleaned and then cooled. Put the above-mentioned stainless steel tube into the mold 5, and use a press to fill the above-mentioned processed carbon steel chips into the above-mentioned tube, so that the stainless steel tube and the carbon steel chip core are tightly fitted, and the two ends of the tube are inserted into the pressure rod 3, After compacting under a pressure of 600MPa, continue to fill and compact repeatedly until the carbon steel chips in the tube are 70mm away from the nozzle, then fill the two ends of t...

Embodiment 2

[0031] 304 stainless steel straight seam welded pipe and Q195 carbon steel chips are used as raw materials, the diameter of the stainless steel pipe is 200mm, and the wall thickness of the pipe is 20mm. The inner wall of the above-mentioned stainless steel pipe is brushed, high-pressure cleaned, and dried. The carbon steel is crushed and impurities are screened out, and then heated in a reduction furnace at 700°C for annealing treatment, and the surface oil is cleaned and then cooled. Put the above-mentioned stainless steel tube into the mold, and use a press to fill the above-mentioned processed carbon steel chips into the above-mentioned tube, so that the stainless steel tube and the carbon steel chip core are tightly fitted, and the two ends of the tube are inserted into the pressure rod, and the pressure is passed through 600MPa. Then continue to fill and compact repeatedly until the carbon steel chips in the tube are 80mm away from the nozzle, then fill the two ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com