Researching method for hydraulic forming technical parameters of titanium T-shaped pipe

A technology of hydroforming and process parameters, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high cost, waste of time, lack of maturity, perfect process plan, etc., to achieve uniform wall thickness distribution, shortening Study time, the effect of increasing the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

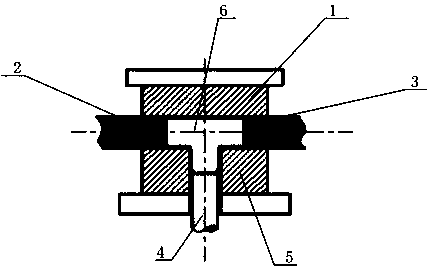

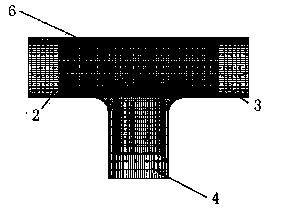

[0033] Step 1: Carry out three-dimensional modeling of the mold, punch and tube blank 6 involved in the hydroforming of titanium T-shaped tubes (UG modeling is used for three-dimensional modeling), in which the mold surface is formed by the intersecting main pipe and branch pipe of Φ219mm , the mold fillet radius is 55mm; the punch is a plane punch in the form of a round shaft, divided into left punch, right punch and middle punch, the size is Φ219mm×200mm, the length of the tube blank 6 is 580mm, and the wall thickness is 5mm. The outer diameter is 219mm. Through three-dimensional modeling, IGES format files about the mold, punch (including left punch, right punch and middle punch) and tube blank are obtained. There are 5 IGES format files in total.

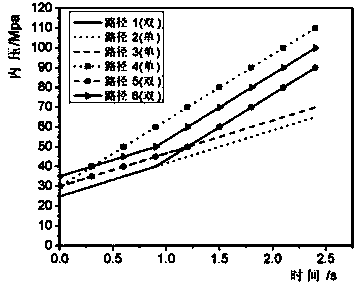

[0034] Step 2: Import the above five IGES format files about mold, punch (including left punch, right punch and middle punch) and tube blank into dynafrom, a special simulation software for sheet metal forming, and use sheet meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com