Bidirectional pressing liquid-charging forming method for large-size thin-wall complex characteristic panel

A two-way pressurized and liquid-filled forming technology, which is applied in the field of metal pressure processing, can solve problems such as high pressure and high forming pressure, and achieve the effects of high efficiency, high precision and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

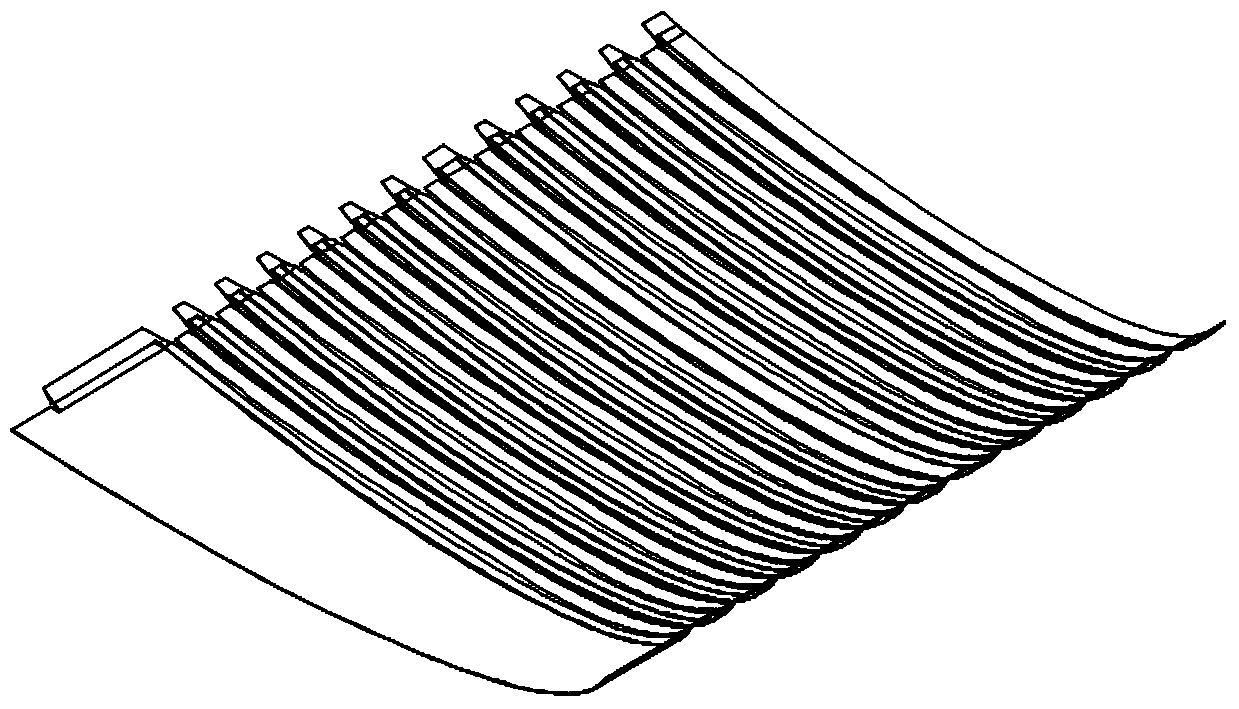

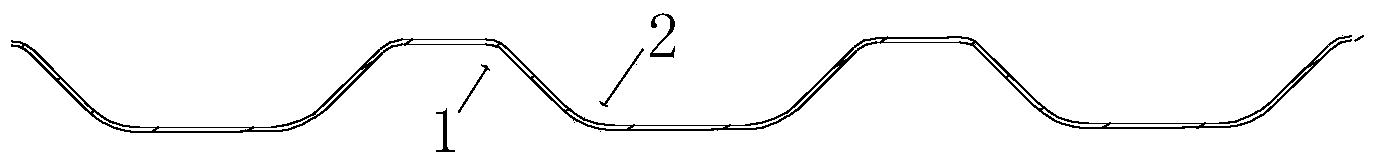

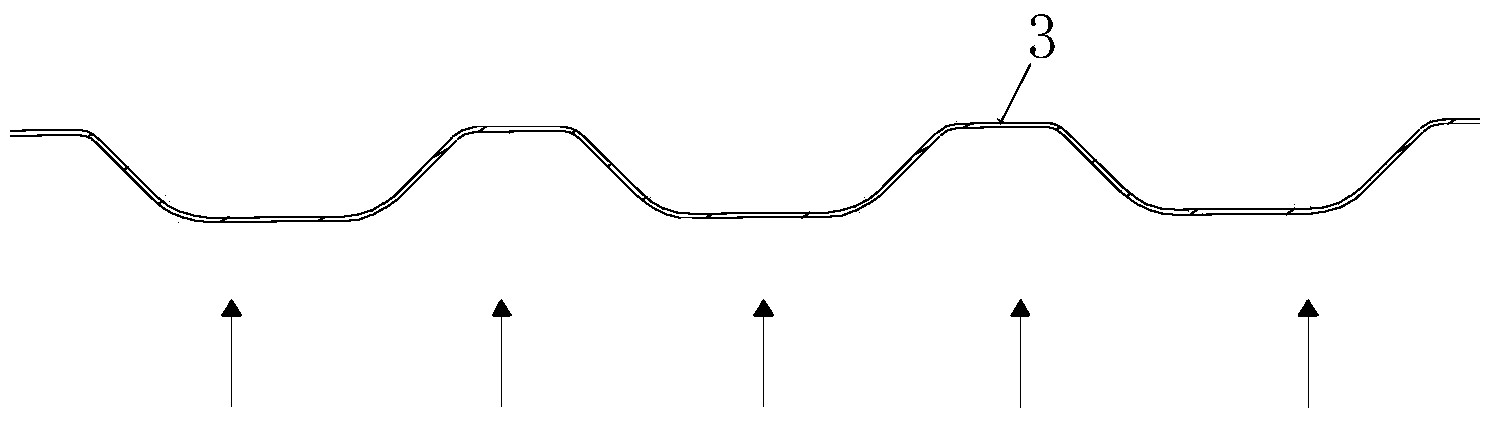

[0023] like figure 1 -- Image 6 As shown, the two-way pressurized and liquid-filled forming method for large thin-walled and complex-featured sheet materials provided by the present invention includes the following steps in order

[0024] 1) Select an aluminum alloy 2024 plate 5 with a wall thickness of 0.5mm as the blank, apply lubricating oil to one side of the blank 5 to reduce friction, and leave the other side untreated.

[0025] 2) Put the lubricated sheet into the die 5 of the preforming die, wherein the side coated with lubricating oil faces the preforming punch 4 , and the side not coated with oil faces the preforming die 5 .

[0026] 3) After the sheet is placed, the preforming punch 4 goes down, relying on the limit pad 6 on the preforming die to ensure a gap of about 1.1 times the thickness of the sheet between the preforming punch 4 and the preforming die 7 . Apply a pressure of 8Mpa to the liquid chamber of the preforming die through the liquid inlet on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com