Galvanized pipe-based glass fiber reinforced plastic tree-grain pipe and preparation method thereof

A technology of galvanized pipe and FRP, which is applied to chemical instruments and methods, glass/slag layered products, tubular articles, etc., can solve the problems affecting the surface quality of products, slow metal flow in the middle, and fast metal deformation at the edge, etc., to achieve Ensure dimensional uniformity and surface quality, reduce deformation resistance, and reduce rolling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

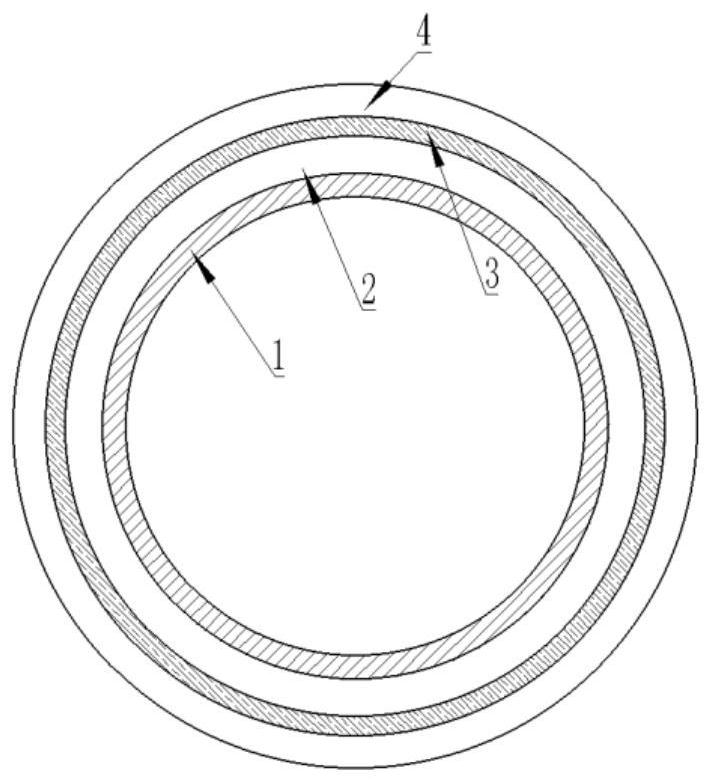

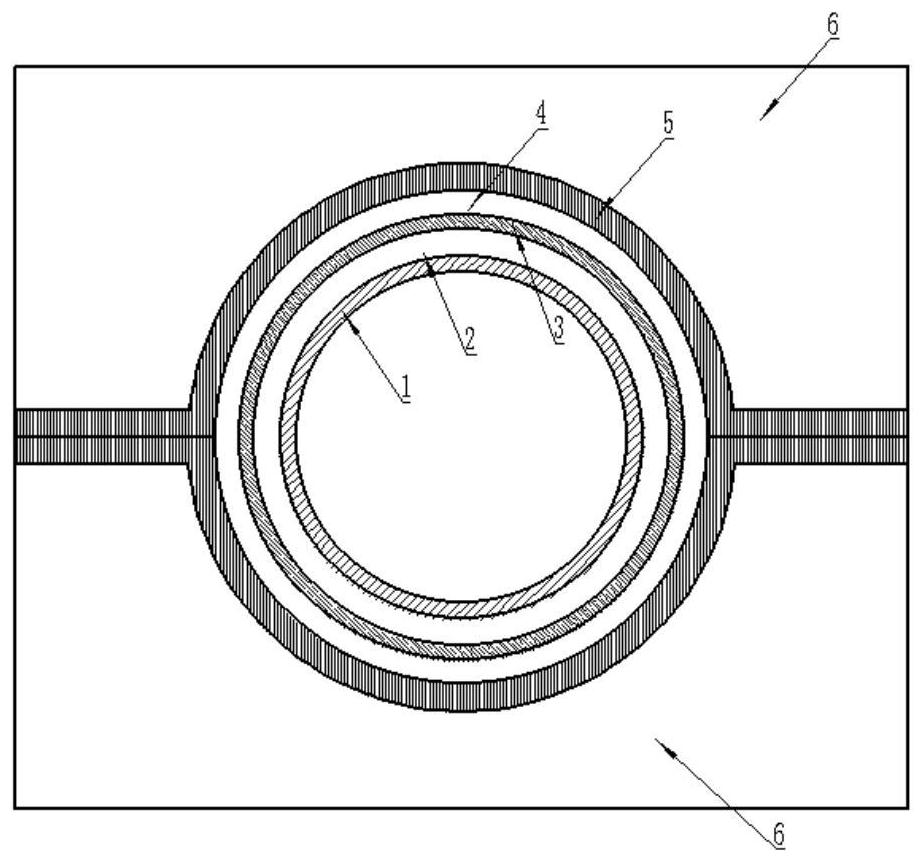

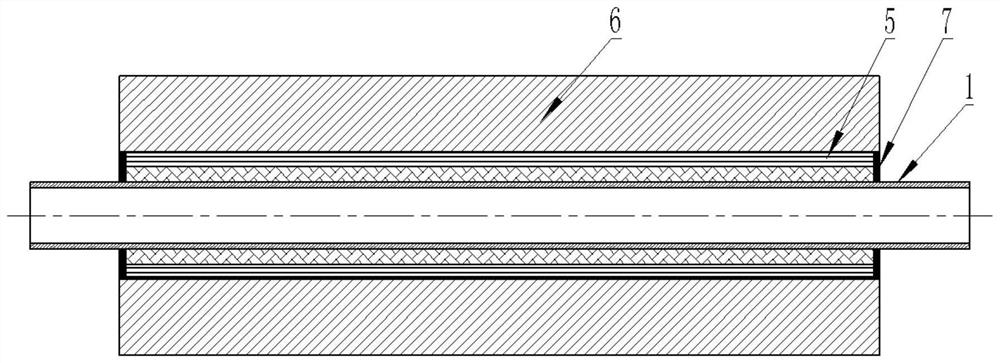

[0035] A fiberglass tree pattern pipe based on a galvanized pipe, comprising a galvanized pipe 1, an inner reinforcement layer 2, a tree pattern pipe reinforcement layer 3, and a tree pattern layer 4 which are sequentially coated from the inside to the outside; the galvanized pipe 1, the inner A pipe structure with a layered structure composed of the reinforcement layer 2 , the tree pattern tube reinforcement layer 3 , and the tree pattern layer 4 .

[0036] As a preferred embodiment, the internal reinforcement layer 2 is prepared by adding chopped glass fibers to unsaturated polyester resin; the length of the chopped glass fibers is 25±5mm.

[0037] As a preferred embodiment, the tree pattern reinforcement layer 3 is made of glass fiber cloth.

[0038] As a preferred embodiment, the tree layer 4 is made of unsaturated polyester resin.

[0039] The preparation method of the fiberglass tree-lined pipe based on galvanized pipe described in the present embodiment comprises the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com