A flat bar manufacturing method based on multilayer composite pipe

A multi-layer composite and manufacturing method technology, applied in metal rolling and other directions, can solve the problems of affecting the surface quality of products, reducing the yield of flat bars, and rapidly deforming the metal at the edge, to ensure dimensional uniformity, simple structure, The effect of reducing deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for manufacturing a flat bar based on a multilayer composite pipe, which is specifically implemented according to the following steps:

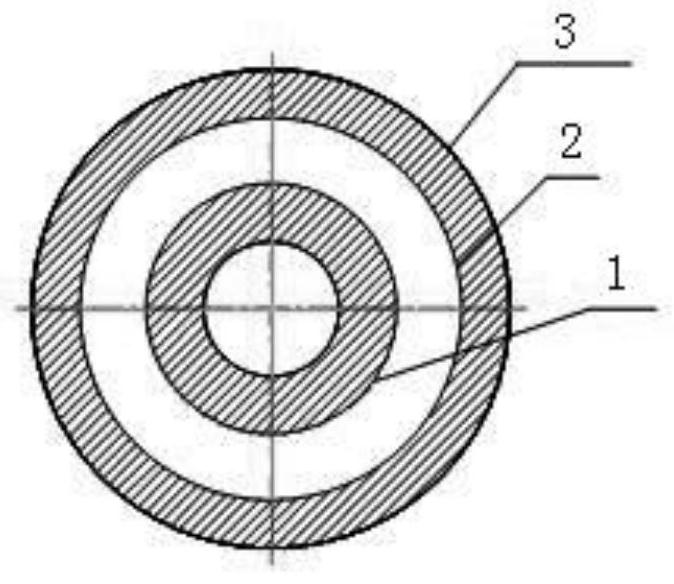

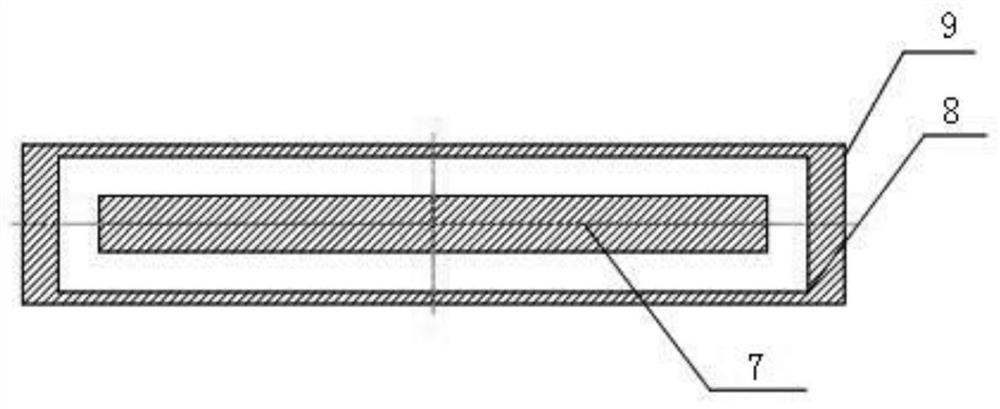

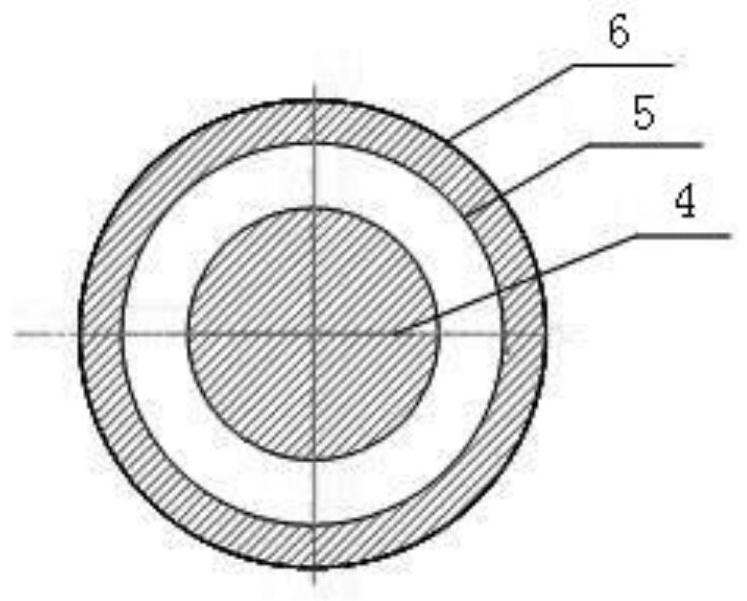

[0039] Step 1. Select the outer pipe, middle pipe and inner pipe with different inner diameters, and clean and dry the inner and outer surfaces of the outer pipe, middle pipe and inner pipe respectively to obtain clean inner metal pipe 1, middle metal pipe 2 and The outer metal tube 3, the inner metal tube 1, the middle metal tube 2 and the outer metal tube 3 have no oil stains, oxidized color or metal particles and other non-metallic objects except the tube body, and the outer diameter of the inner metal tube 1 is relatively small. The inner diameter of the outer metal tube 3 is 0.2mm smaller, and the outer diameter of the inner metal tube 1 is 0.1mm smaller than the outer diameter of the middle metal tube 2;

[0040] Step 2: Assemble the middle metal tube 2 outside the inner metal tube 1, and then as...

Embodiment 2

[0048] This embodiment provides a method for manufacturing a flat bar based on a multilayer composite pipe, which is specifically implemented according to the following steps:

[0049] Step 1. Select the outer pipe, middle pipe and inner pipe with different inner diameters, and clean and dry the inner and outer surfaces of the outer pipe, middle pipe and inner pipe respectively to obtain clean inner metal pipe 1, middle metal pipe 2 and The outer metal tube 3, the inner metal tube 1, the middle metal tube 2 and the outer metal tube 3 have no oil stains, oxidized color or metal particles and other non-metallic objects except the tube body, and the outer diameter of the inner metal tube 1 is relatively small. The outer diameter of the outer metal tube 3 is 0.4 mm smaller than the outer diameter of the inner metal tube 1 by 0.4 mm;

[0050] Step 2: Assemble the middle metal tube 2 outside the inner metal tube 1, and then assemble the outer metal tube 3 outside the middle metal tube...

Embodiment 3

[0058] This embodiment provides a method for manufacturing a flat bar based on a multilayer composite pipe, which is specifically implemented according to the following steps:

[0059] Step 1. Select the outer pipe, middle pipe and inner pipe with different inner diameters, and clean and dry the inner and outer surfaces of the outer pipe, middle pipe and inner pipe respectively to obtain clean inner metal pipe 1, middle metal pipe 2 and The outer metal tube 3, the inner metal tube 1, the middle metal tube 2 and the outer metal tube 3 are free of oil stains, oxidized color or metal particles and other non-metallic objects except the tube body, and the outer diameter of the inner metal tube 1 The inner diameter of the outer metal tube 3 is 0.2 mm smaller than that of the outer metal tube 3, and the outer diameter of the inner metal tube 1 is 0.4 mm smaller than the outer diameter of the middle metal tube 2;

[0060] Step 2: Assemble the middle metal tube 2 outside the inner meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com