Fixing slotting device for vehicle transmission gear

A technology for automotive gearboxes and gears, which is applied in the field of gear processing, and can solve problems such as short service life, unsatisfactory surface roughness, and low machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

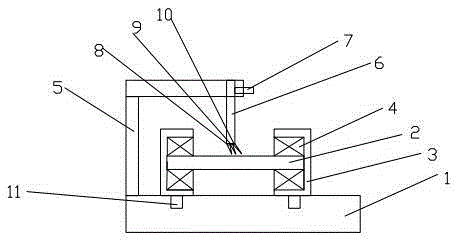

[0020] Such as figure 1 As shown, a kind of automotive gearbox gear fixing slotting device according to the present invention includes a base 1, a gear 2, a U-shaped frame 3 and a bracket 5, and two U-shaped frames 3 are arranged on the upper end of the base 1, and the The U-shaped frame 3 is directly provided with a gear 2, the side of the base 1 is provided with a bracket 5, the top of the bracket 5 is provided with a drooping rod 6, and the lower end of the drooping rod 6 is provided with a third-stage groove cutter 8 and a second-stage groove cutter 9 And first-level groove cutter 10.

[0021] A spring block 4 is arranged between the U-shaped frame 3 and the gear 2, and the spring block 4 is arranged on the upper and lower ends of the gear 2. The setting of the spring block can further fix the gear, and at the same time, it can ensure that the U-shaped frame 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com