General rubber preparation granulation process

A general-purpose rubber and rubber granule technology, which is applied in the rubber industry, can solve problems affecting the normal cutting work, rubber material and blade adhesion, rubber material moldy, etc., to ensure size uniformity, speed up separation speed, and avoid adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

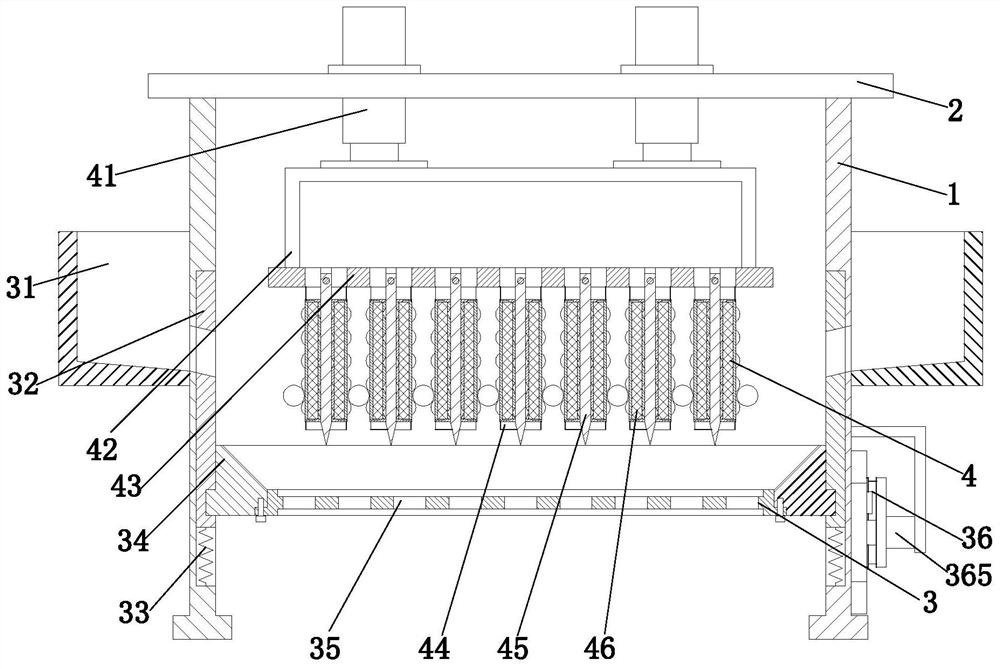

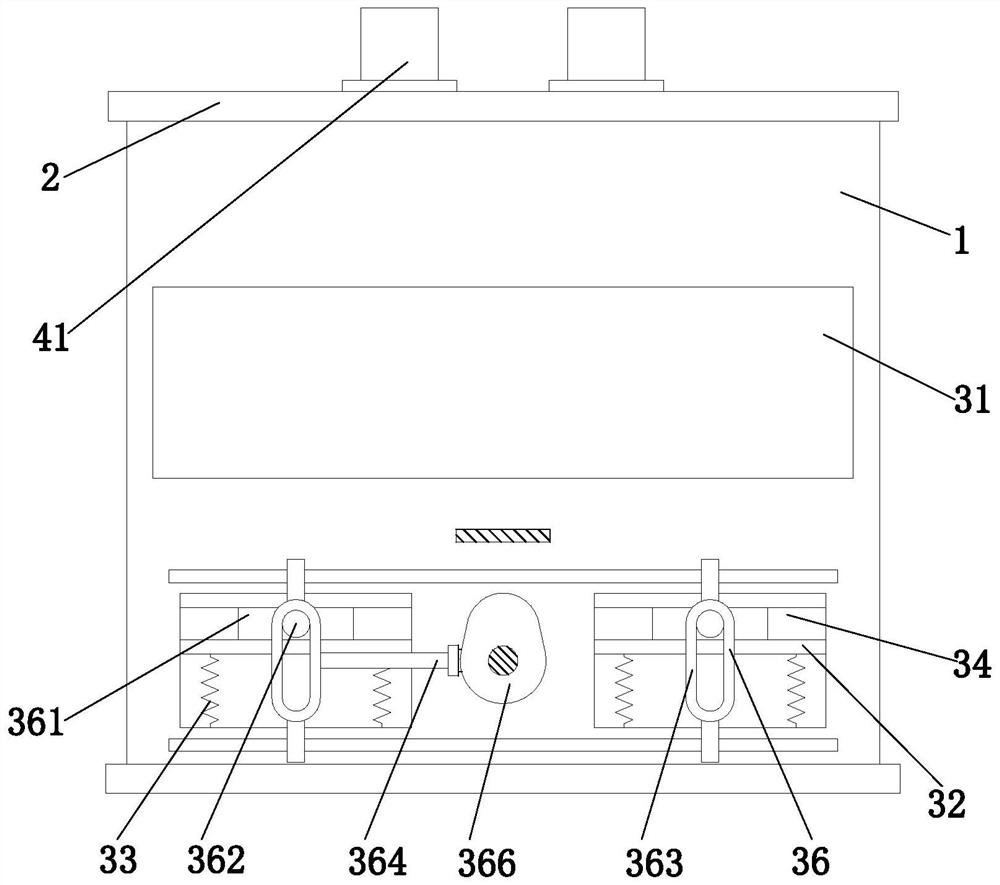

[0038] Such as Figure 1 to Figure 8 As shown, a general-purpose rubber preparation and granulation process uses a cutting device, which includes a base frame 1, a top frame 2, a material receiving device 3 and a cutting device 4, and is prepared by the above cutting device The specific method for rubber particles is as follows:

[0039] S1. Waste recycling: recycle waste rubber materials and classify them according to the specific materials;

[0040] S2. Slitting of waste materials: using slitting equipment to slitting and processing the recycled waste rubber materials to obtain rubber fragments;

[0041] S3. Frozen crushing: After the rubber fragments are subjected to cryogenic treatment, they are crushed with a hammer crusher or a roller crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com