A heat treatment method for improving damage resistance of aluminum-lithium alloy sheet

A heat treatment method and technology of aluminum-lithium alloy, applied in the field of heat treatment of aluminum alloy sheets, can solve problems such as unfavorable damage resistance performance, affecting the dimensional uniformity of wide-width plates, etc., so as to improve preparation efficiency and yield, improve damage resistance, and improve The effect of damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

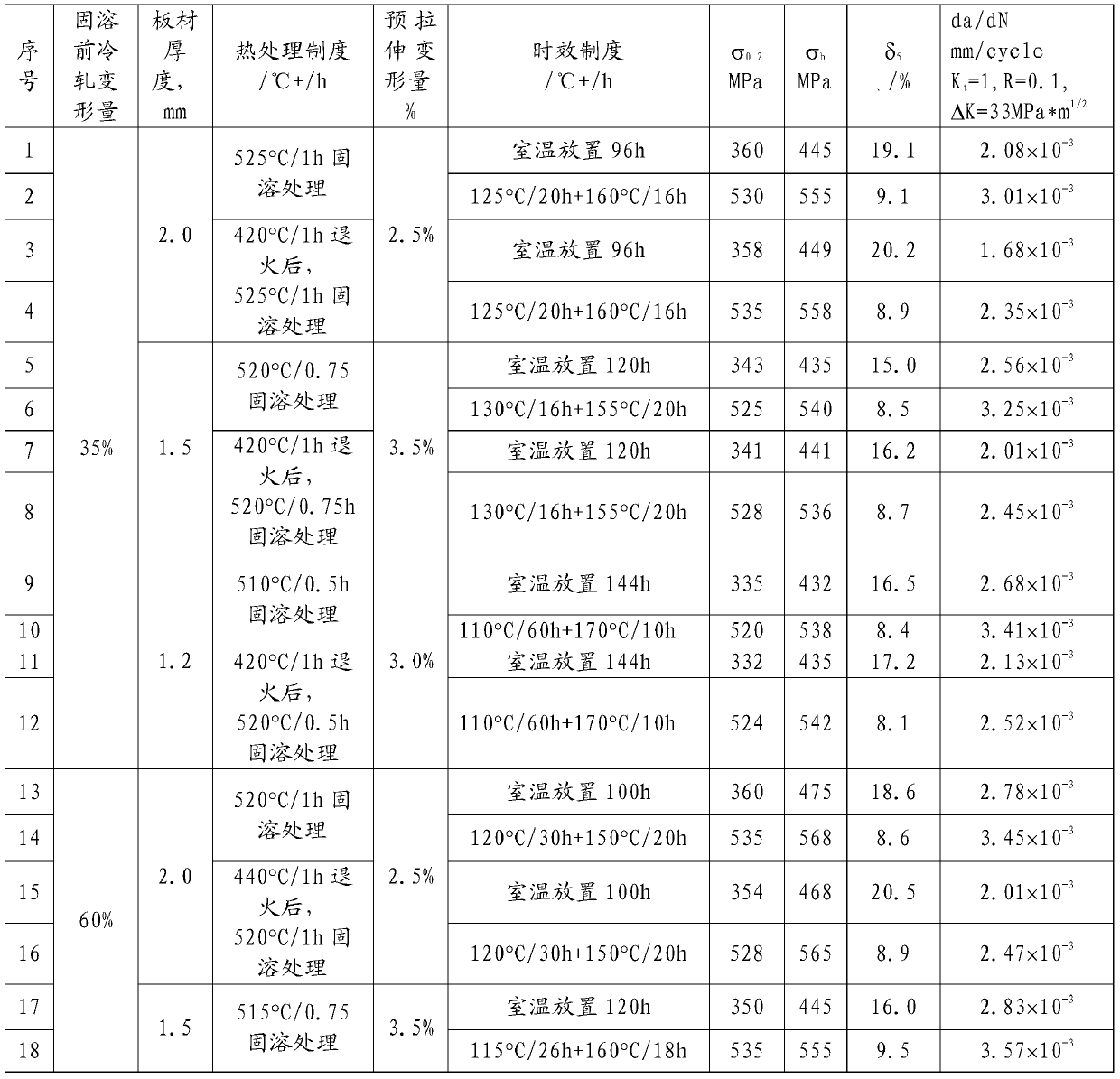

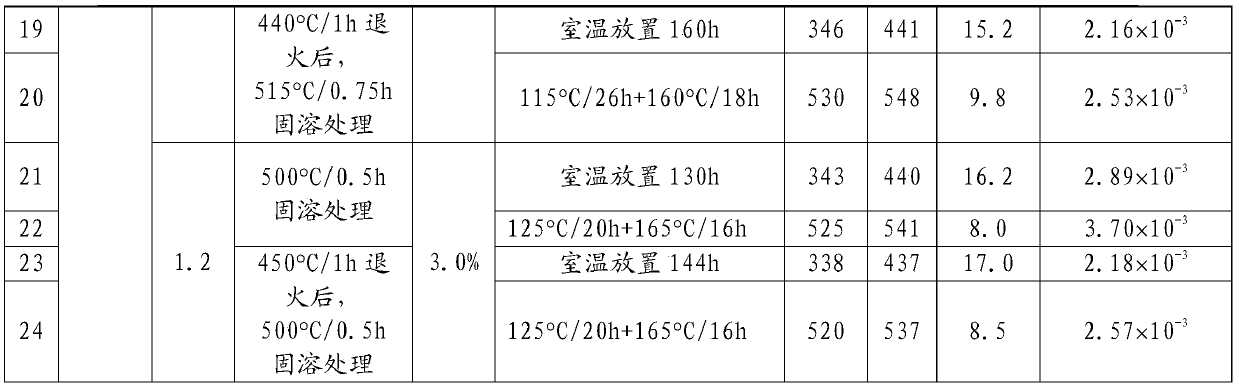

[0017] Using the Al-Cu-Li-X aluminum-lithium alloy heat treatment method involved in the present invention, the cold-rolled sheets of three specifications of 2.0, 1.5mm and 1.2mm were respectively annealed + solid solution + aging treatment, and the plates were treated to T3 State, the cold rolling deformation of the plate before solid solution is 35% and 60%, respectively, the tensile properties and da / dN properties of the plate are measured, and compared with the T3 state properties of the traditional solution process, the specific properties are shown in Table 1 shown.

[0018] Table 1 The corresponding properties of 24 embodiments of the present invention and plates with different thicknesses

[0019]

[0020]

[0021] Based on the data in Table 1, it fully demonstrates that the heat treatment method for aluminum-lithium alloy sheet proposed by the present invention can improve the damage resistance of the alloy under the premise that other properties remain unchange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com