Film forming mold

A technology for forming molds and films, applied in the preparation of test samples, etc., can solve the problems affecting the accuracy of performance test samples, the thickness of sample edges, the accuracy and consistency of test results, etc., to improve compatibility and flexible application. performance, reduce the scrap rate, and avoid the effect of uneven width of the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

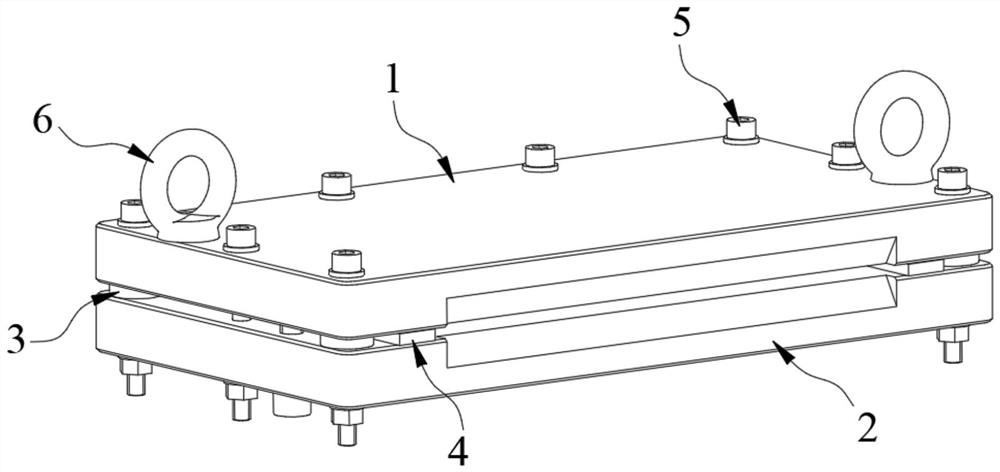

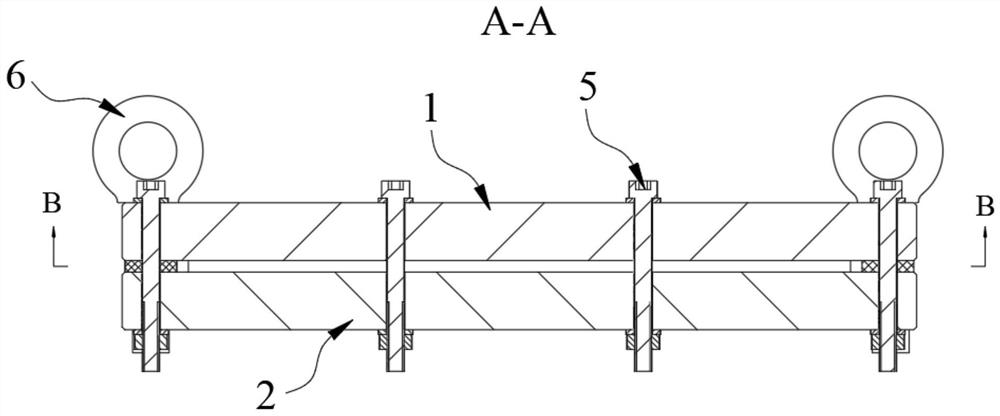

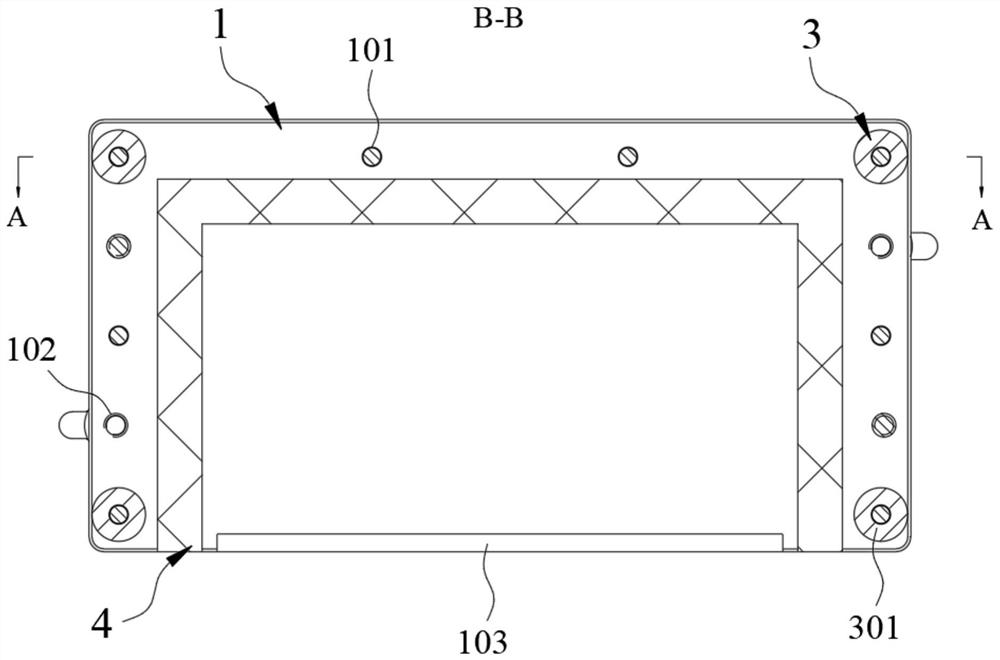

[0045] see Figure 1-12, the film forming mold in the preferred embodiment of the present invention includes two templates arranged in pairs, that is, the first template 1 and the second template 2, separated by a gasket 3 between the two templates, and a certain shape is formed between the two templates. The wide gap is used for accommodating the mold sheet 4 of corresponding thickness, thereby realizing the forming of the film.

[0046] Specifically, the first formwork 1 and the second formwork 2 in the preferred embodiment respectively have a plate structure, and the two formworks are arranged opposite to each other, and the opposite end surfaces are smooth surfaces parallel to each other, so that the formwork 4 is clamped on both sides. between smooth surfaces. At the same time, in order to realize the accuracy of the distance between the two templates, a plurality of gaskets 3 are arranged between the two templates to ensure that the two templates can be accurately separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com