Device for preparing fiber-reinforced hollow fiber membrane

A technology of fiber reinforcement and preparation device, which is applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as difficulty in controlling the uniformity of the wall thickness of hollow fiber membranes, and achieve the improvement of product quality, reliability and wall thickness. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

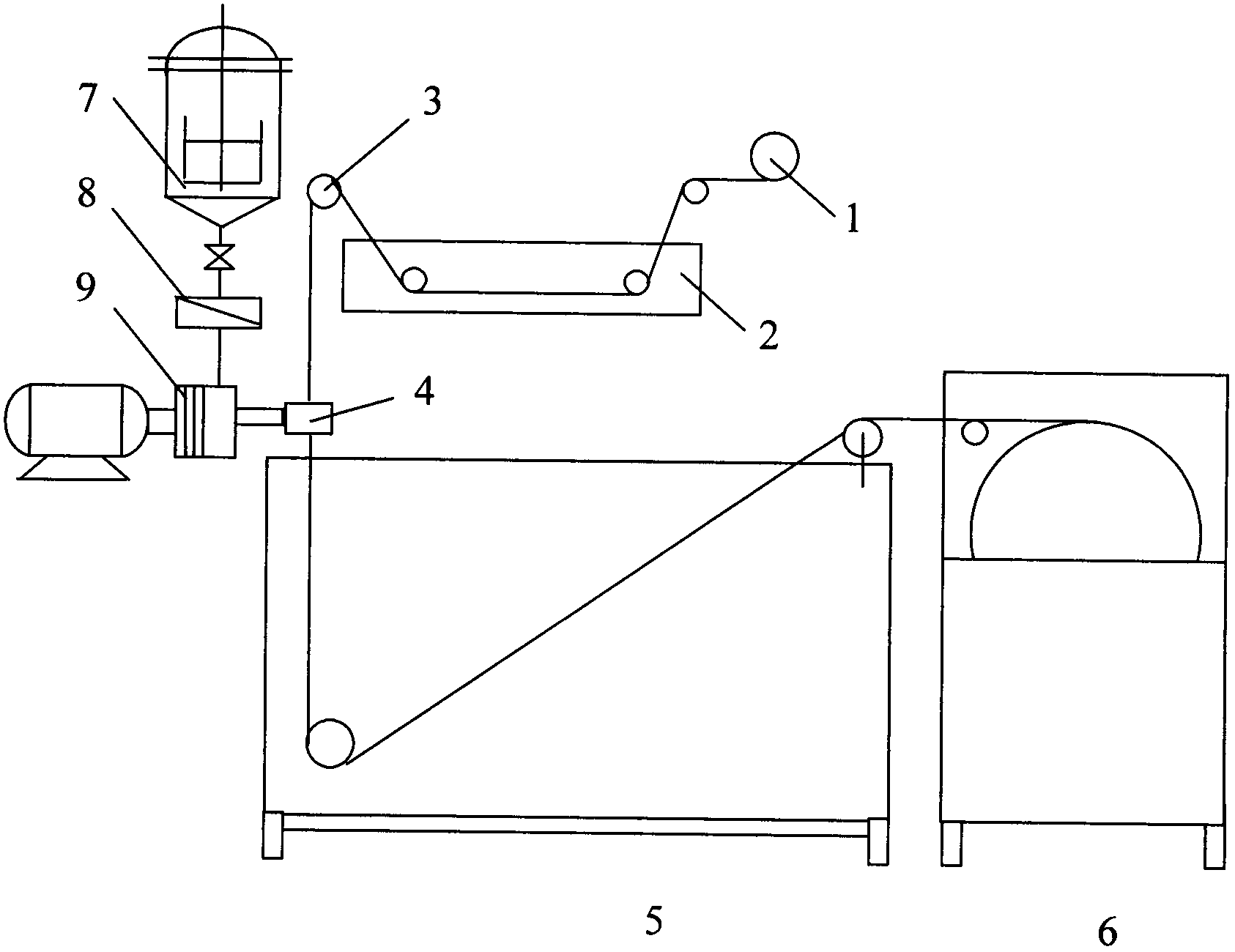

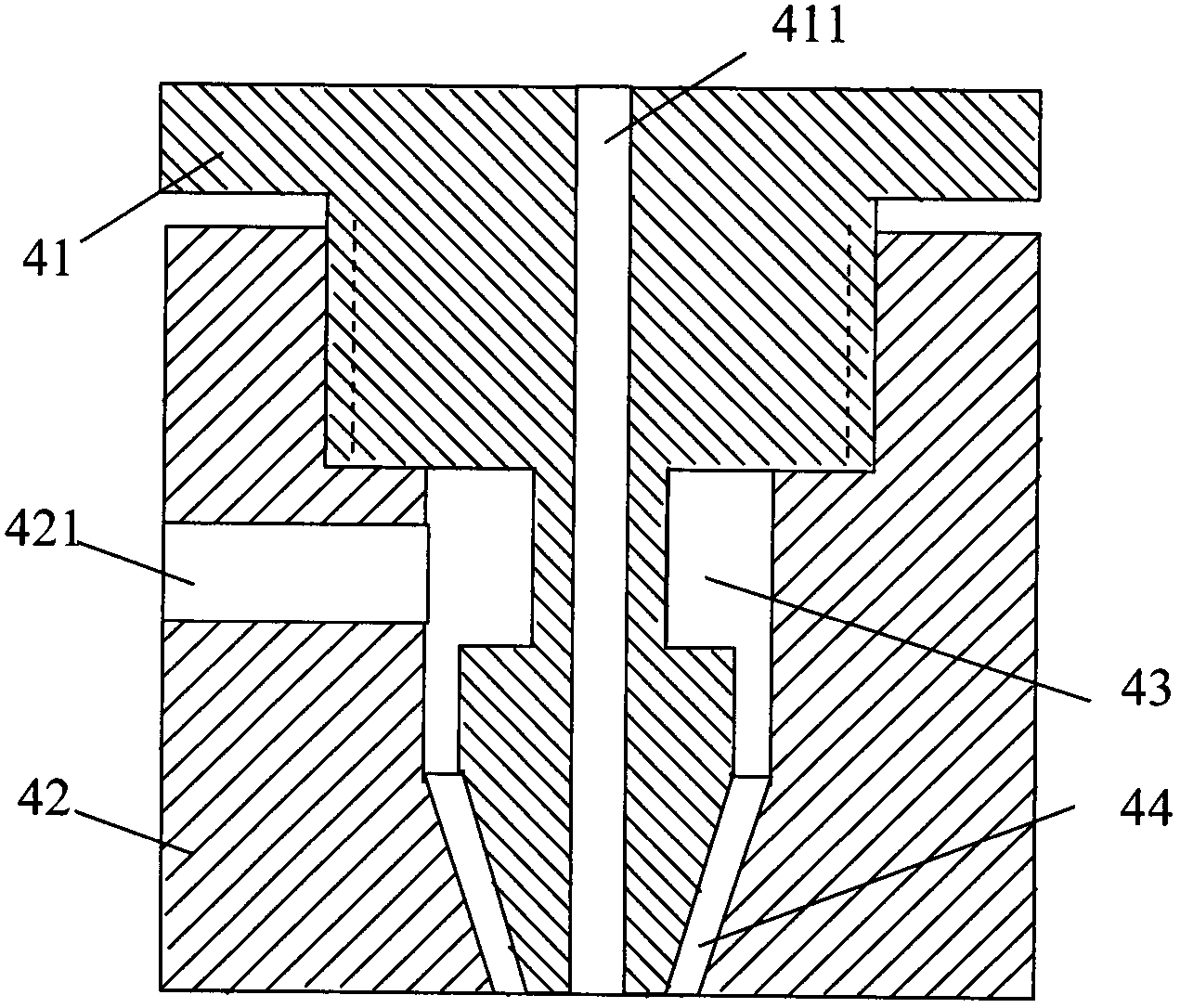

[0013] The technological process of the fiber-reinforced hollow fiber membrane preparation device designed by the present invention is as follows figure 1 As shown, the device includes a reinforced fiber feeding roller 1, a core solution dipping tank 2, a guide roller 3, a casting solution coating die 4, a coagulation bath 5, a winding machine 6, a dissolution kettle 7, a filter 8, and a metering pump 9. figure 2 It is a schematic cross-sectional structure diagram of the casting solution coating die head 4, the coating die head 4 is composed of parts 41 and 42, 411 is the fiber braided tube channel, 421 is the casting solution inlet, and the cylindrical shape made of parts 41 and 42 The cavity 43 is a dynamic storage area for the casting solution. The first section of the annular slit 44 is equal in diameter, and then the annular slit gradually converges; the cross-sectional area of the cavity 43 is 3 times the maximum cross-sectional area of the annular slit 44. times. ...

Embodiment 2

[0017] With the same device and process as in Example 1, the reinforcing fiber of the present invention is a polyester low-elastic yarn, which is made into a cylindrical mesh tubule with a diameter of 2mm through a braiding machine with a setting device; the casting solution is made of polyester It is composed of vinylidene fluoride, polyvinylpyrrolidone and dimethylacetamide; the core liquid is composed of dimethylacetamide aqueous solution; the coagulation bath is water.

[0018] What is not mentioned in the present invention is applicable to the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com