Device and method for hot forming of titanium alloy corrugated pipe through current assistance

A corrugated pipe and titanium alloy technology, which is applied in the field of corrugated pipe thermoforming devices, can solve the problems of high cost, difficulty in manufacturing titanium alloy corrugated pipes, and low production efficiency, and achieve light oxidation, avoid energy loss, and short heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

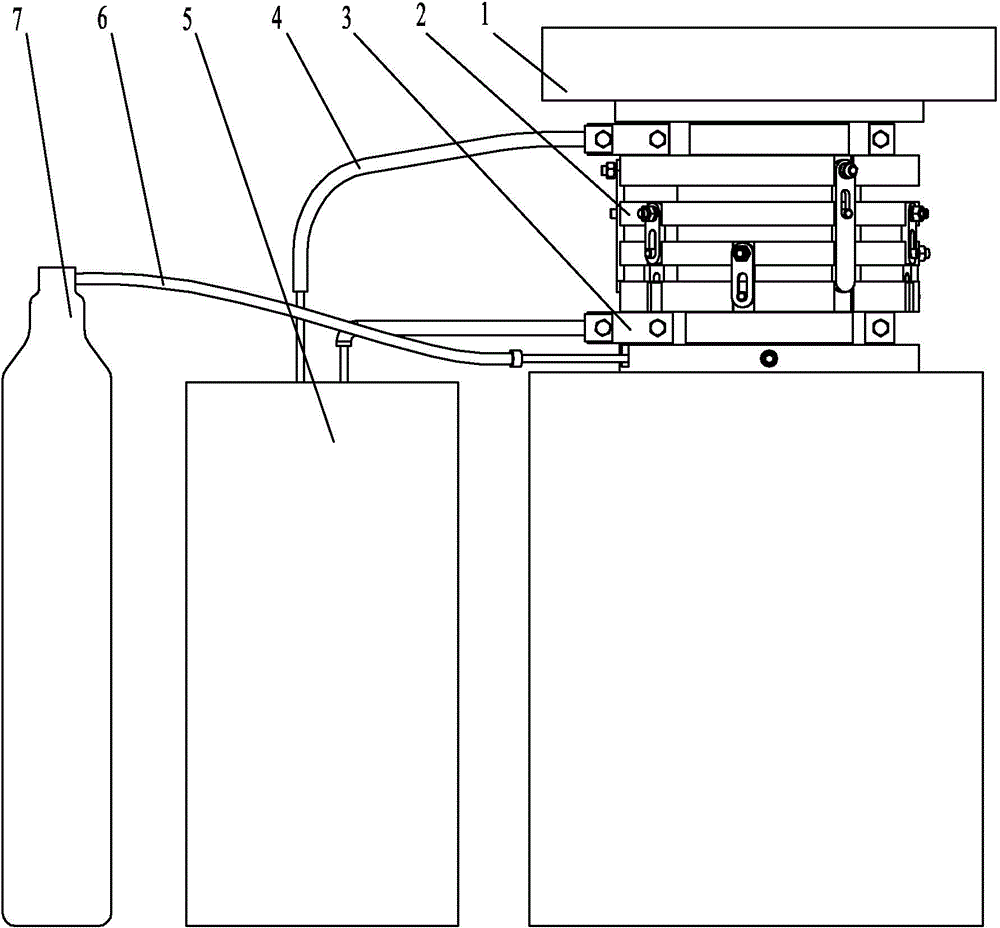

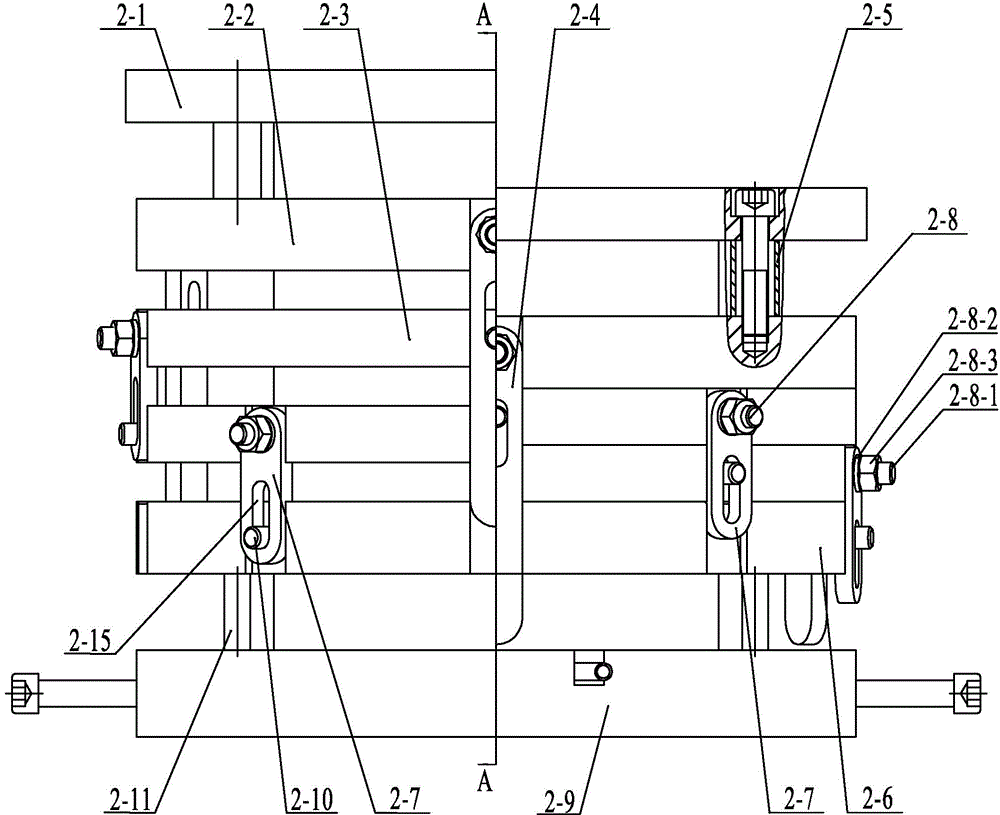

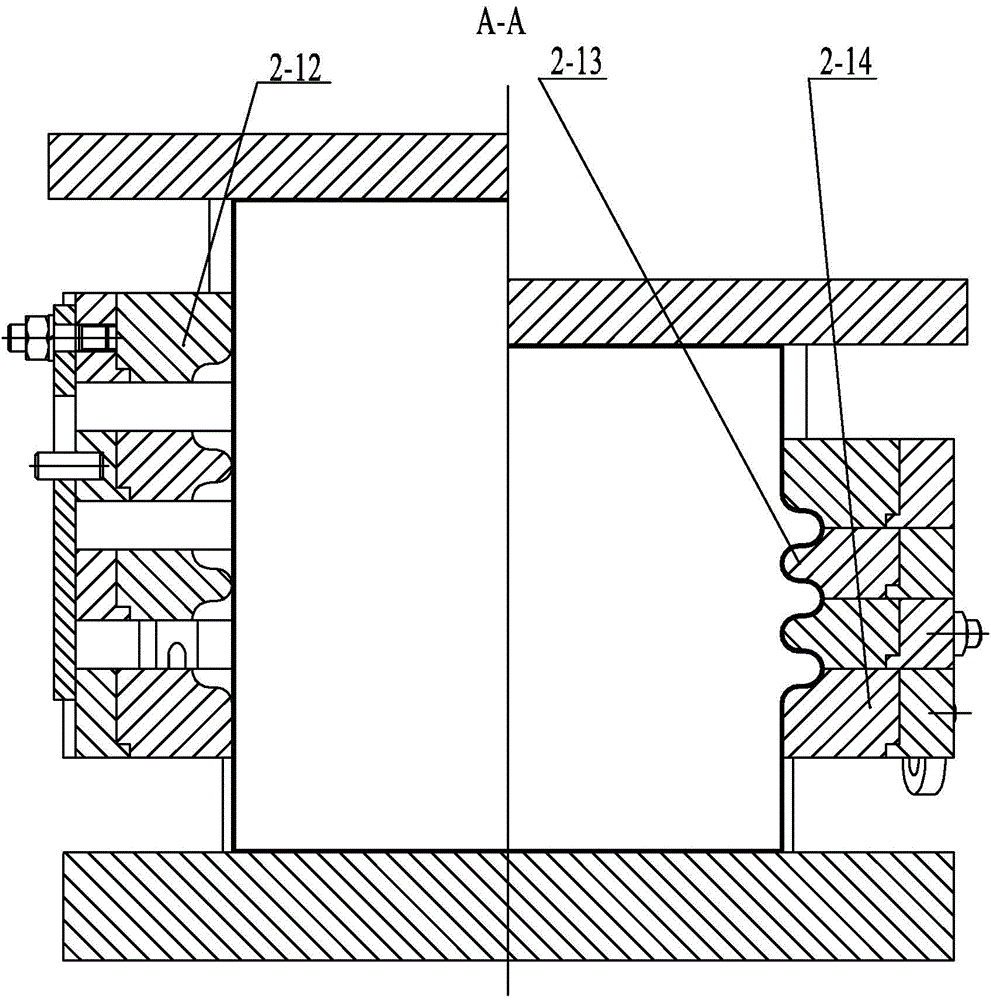

[0024] Specific implementation mode one: combine figure 1 , figure 2 and image 3 This embodiment is described. This embodiment includes a press 1, a current heating system and an internal pressurization system. The current heating system includes two electrodes 3, a wire 4 and a low-voltage high-current power supply 5. Connected to the positive and negative electrodes of the electrode 3, the titanium alloy bellows thermoforming device also includes a forming die 2, and the forming die 2 includes an upper end cover 2-1, a ring metal upper die 2-2, and a ring metal lower die 2- 6. Lower mold base 2-9, ceramic upper mold 2-12, ceramic lower mold 2-14, multiple ring metal intermediate molds 2-3, multiple first guide rods 2-4, multiple support sleeves 2 -5, multiple second guide rods 2-7, multiple guide rod connection assemblies 2-8, multiple guide pillars 2-10, multiple support cylinders 2-11 and multiple ceramic middle molds 2-13, upper end cover An electrode 3 is respective...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the guide rod connection assembly 2-8 of this embodiment includes a stud 2-8-1, a spring washer 2-8-2 and a nut 2-8-3, and the stud 2-8-1 is screwed on a circle Ring metal upper die 2-2, multiple ring metal middle dies 2-3, and nut 2-8-3 are screwed on the stud 2-8-1 through spring washer 2-8-2. With such arrangement, multiple first guide rods 2-4 and multiple second guide rods 2-7 can be firmly fixed on the ring metal upper mold 2-2 and multiple ring metal middle molds 2-3. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 2 To describe this embodiment, in this embodiment, the length of the first guide rod 2-4 is greater than the length of the second guide rod 2-7. With such arrangement, the first guide rod 2-4 can realize the guide of the whole mold, and the second guide post 2-7 plays the role of auxiliary guide while playing the role of positioning, so that the guide precision is high. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com