Braided tube-reinforced hollow fiber membrane and preparation apparatus and manufacturing process thereof

A braided tube and reinforced technology, which is applied in the field of braided tube-reinforced hollow fiber membrane and its preparation device and production process, can solve the problems of complex process, low degree of continuity, general bonding strength, etc., and achieve uniform wall thickness distribution , to avoid material leakage and slow down the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Preparation device for braided tube reinforced hollow fiber membrane

[0070]This example illustrates the structure and construction of the braided tube-reinforced hollow fiber membrane preparation device described in this application.

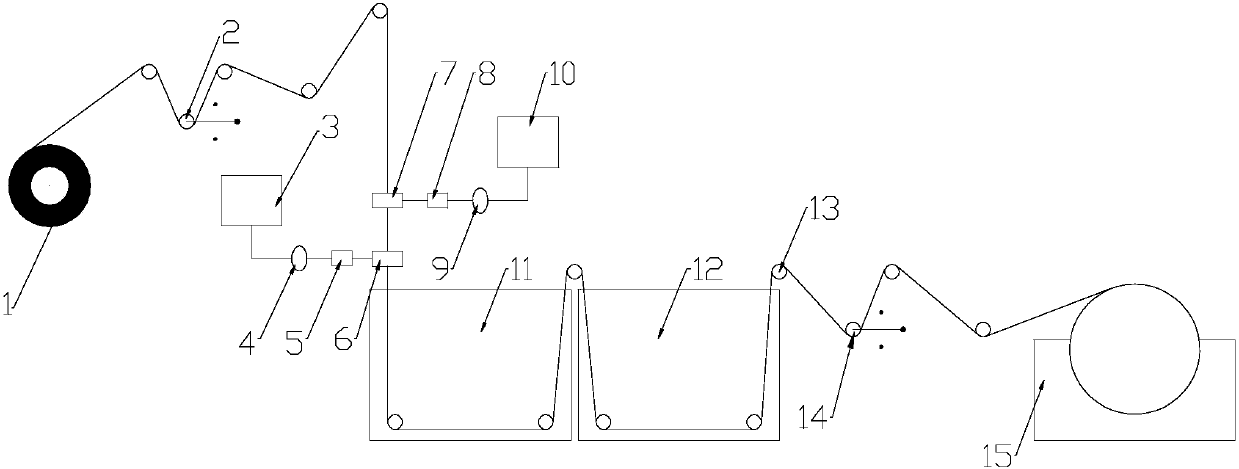

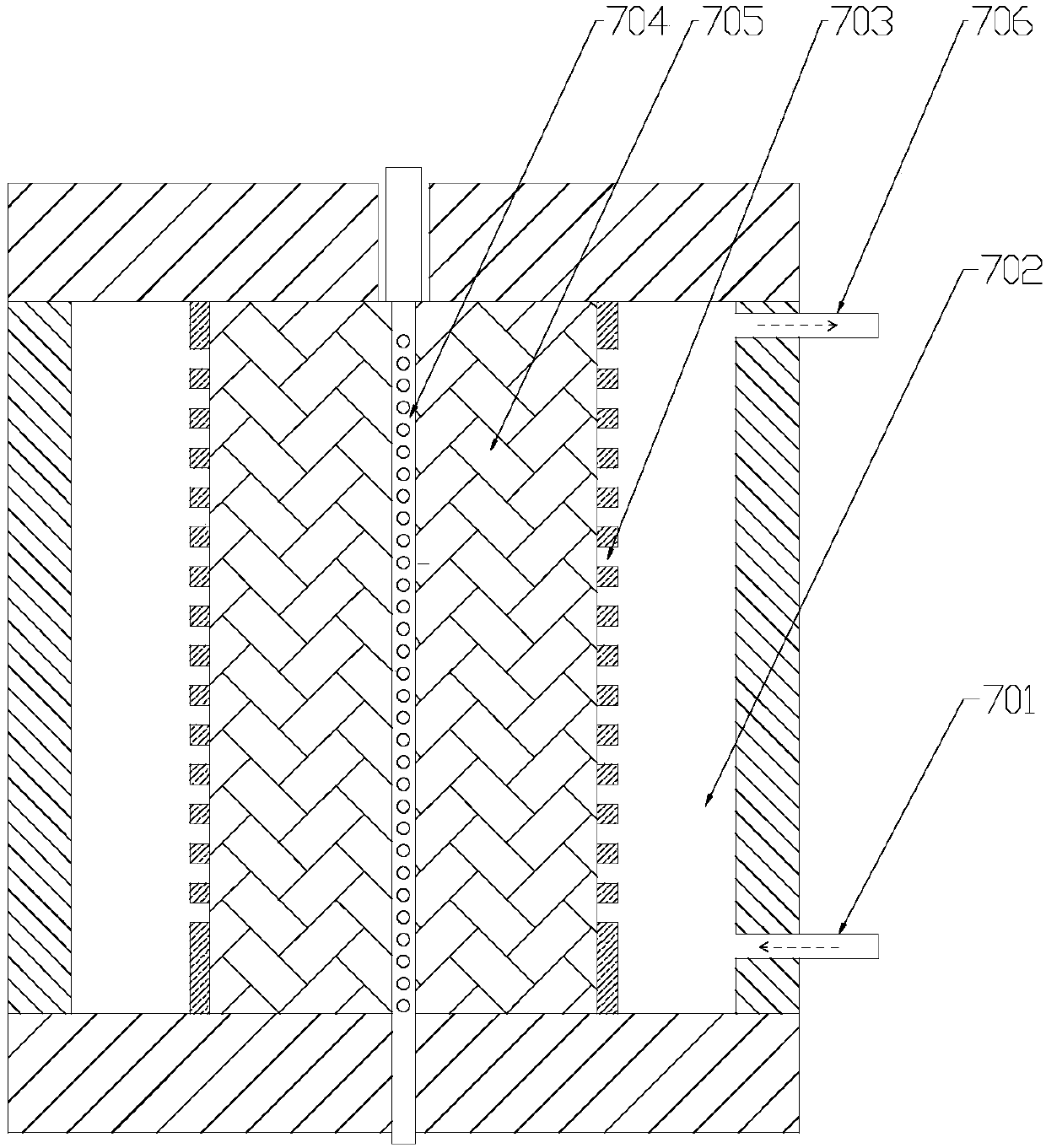

[0071] The braided tube reinforced hollow fiber membrane preparation device in this embodiment combines figure 1 , mainly composed of line supply mechanism 1, line supply floating roller 2, casting solution spinning tank 3, casting solution filter 4, casting solution metering pump 5, coating head 6, pre-coating head 7, pre-coating head Coating liquid metering pump 8, pre-coating liquid filter 9, pre-coating liquid tank 10, coagulation tank 11, rinsing tank 12, wire take-up mechanism 13, wire take-up floating roller 14, wire winding wheel 15 are composed. Wherein, the wire supply mechanism 1 is connected with the wire supply floating roller 3, and is used to control the constant tension of the fiber braided pipe before and af...

Embodiment 2

[0076] Example 2: Processing Technology of Braided Tube Reinforced Hollow Fiber Membrane

[0077] This example illustrates the method for preparing a braided tube-reinforced hollow fiber membrane using the device for preparing a braided tube-reinforced hollow fiber membrane in Example 1.

[0078] Step 1, prepare the fiber braided tube:

[0079] The fiber braided tube is braided by chemical fiber multifilament, which has excellent chemical stability and mechanical strength. The material is one or a mixture of polyester fiber, polypropylene fiber, polyamide fiber and polyurethane fiber. Factors such as braiding density and number of braiding spindles affect the size and performance of fiber braided tubes. In this embodiment, the weaving density is 20-50 meshes, and the fiber braided tube with high weaving density has little deformation, but the output is low, and it is difficult for the pre-coating liquid to penetrate into the inside and the inner surface of the fiber braided ...

Embodiment 3

[0105] Example 3: Processing Technology of Braided Tube Reinforced Hollow Fiber Membrane

[0106] The setting and working principle of this embodiment are the same as that of Embodiment 2, the difference is:

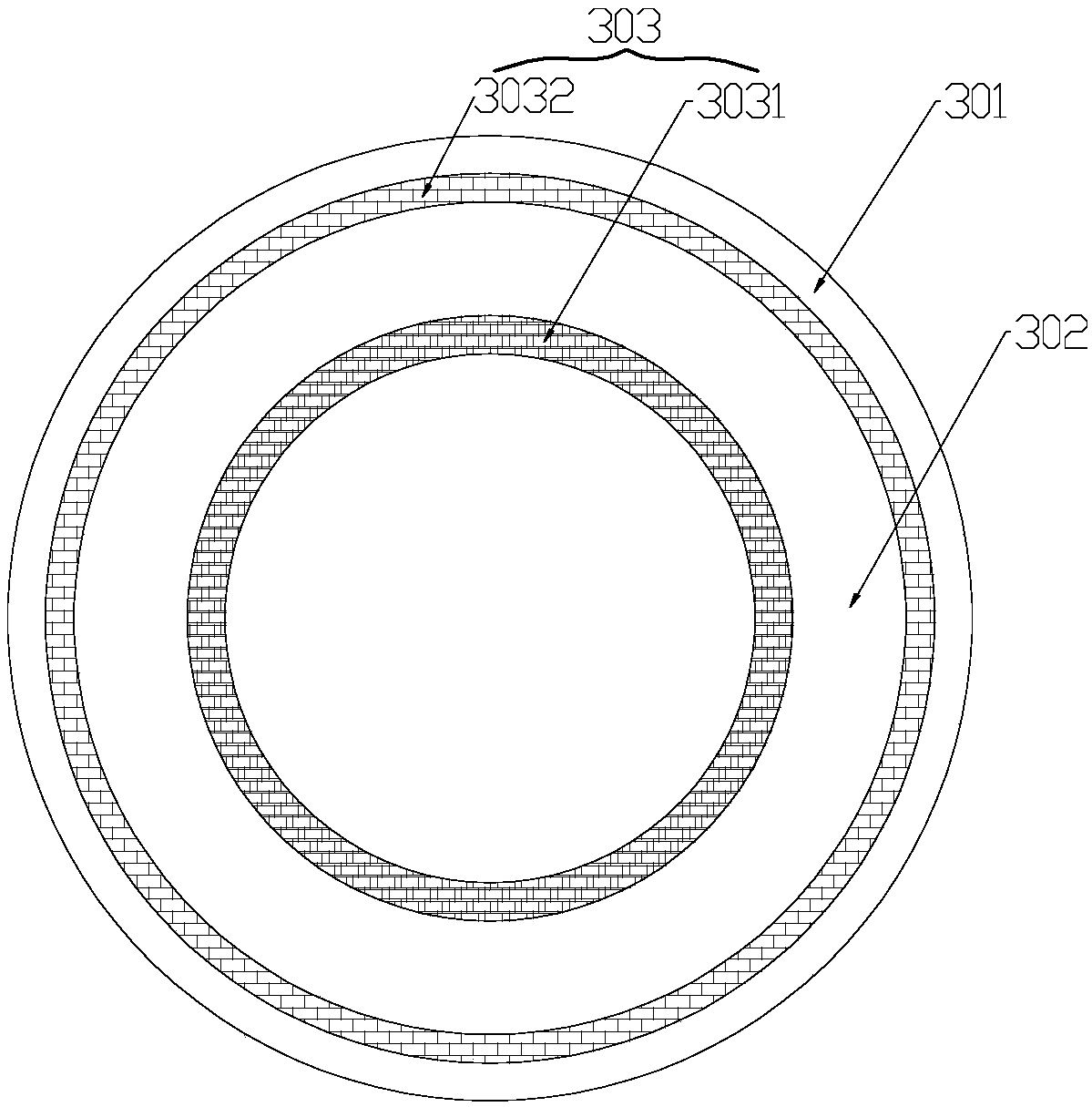

[0107] combine image 3 , the braided tube 302 is prepared from chemical fiber filament polyester fiber, the density of the braided tube 302 is 35 mesh, the number of braided spindles is 20, and the obtained fiber braided tube has an outer diameter of 1.8 mm and an inner diameter of 1.0 mm.

[0108]The PVDF resin of the pre-coating solution is Kynar 761 with a content of 10%; the hydrophilic agent is glycerol with a content of 10%; the content of diatomaceous earth is 3%; the solvent is dimethylacetamide with a content of 77%. The above raw materials are put into the dissolution tank in the order of first liquid and then solid, first small molecular weight and then large molecular weight, and stir at 70-75°C to make a uniform pre-coating liquid, and then transfer to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com