Method for producing polypropylene-based resin foamed blow-molded article

A technology of polypropylene-based resin and manufacturing method, which is applied in the field of manufacturing polypropylene-based resin foamed blow-molded objects, and can solve the problem of reduced foamability and blow-molding performance of foamed blanks, and difficulty in obtaining foamed blow-molded products with thickness accuracy. It is difficult to obtain the expansion ratio and other problems of plastic molding, and achieve the effect of excellent uniformity of wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

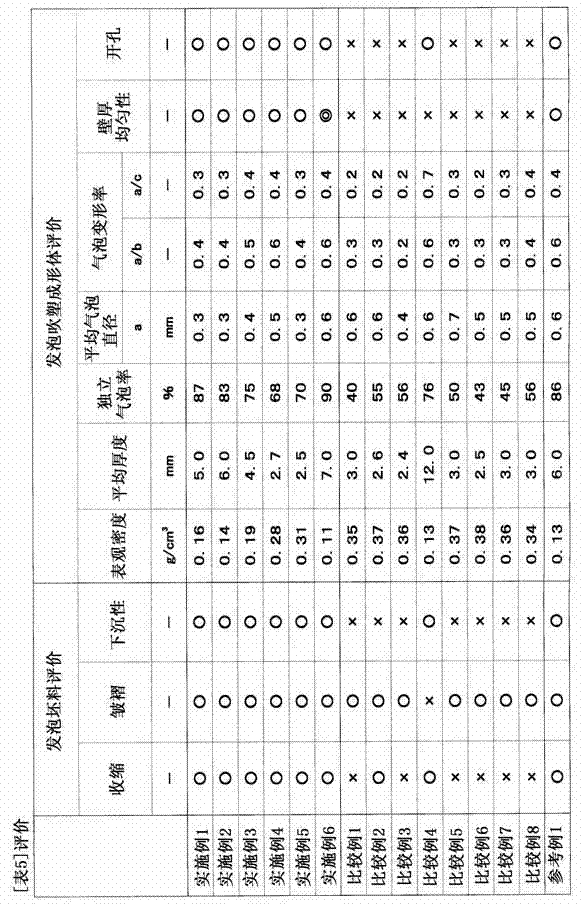

[0131] Hereinafter, the present invention will be described in more detail with reference to Examples and Comparative Examples.

[0132] Tables 1 to 3 show the types and physical properties of polypropylene-based resins used in Examples and Comparative Examples. In addition, the storage elastic modulus G' when the angular frequency of the polypropylene resin is 100 rad / sec, the slope of the storage elastic modulus G' when the angular frequency is between 1 and 100 rad / sec, and the loss when the angular frequency is 1 rad / sec Tangent tan δ, melt tension (MT) and melt flow rate (MFR) at 230° C. were measured according to the methods described above.

[0133]

[0134]

Embodiment 1~6、 comparative example 1~8

[0135] Examples 1-6, Comparative Examples 1-8, Reference Example 1

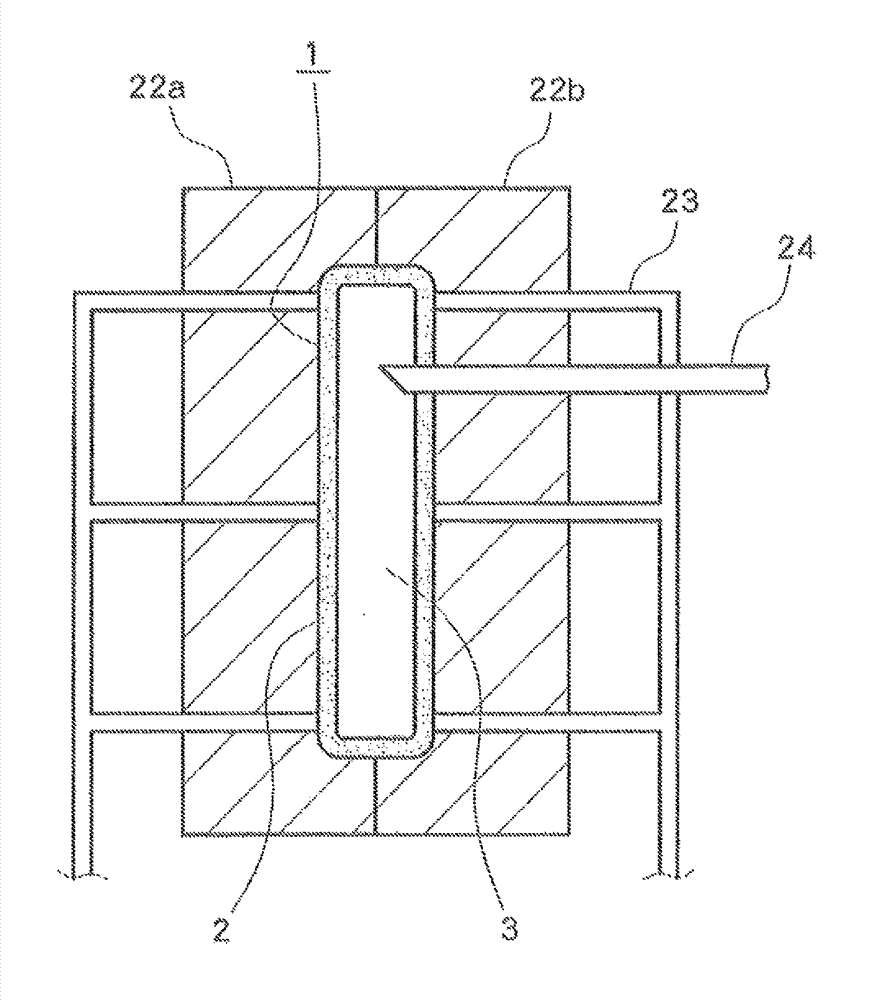

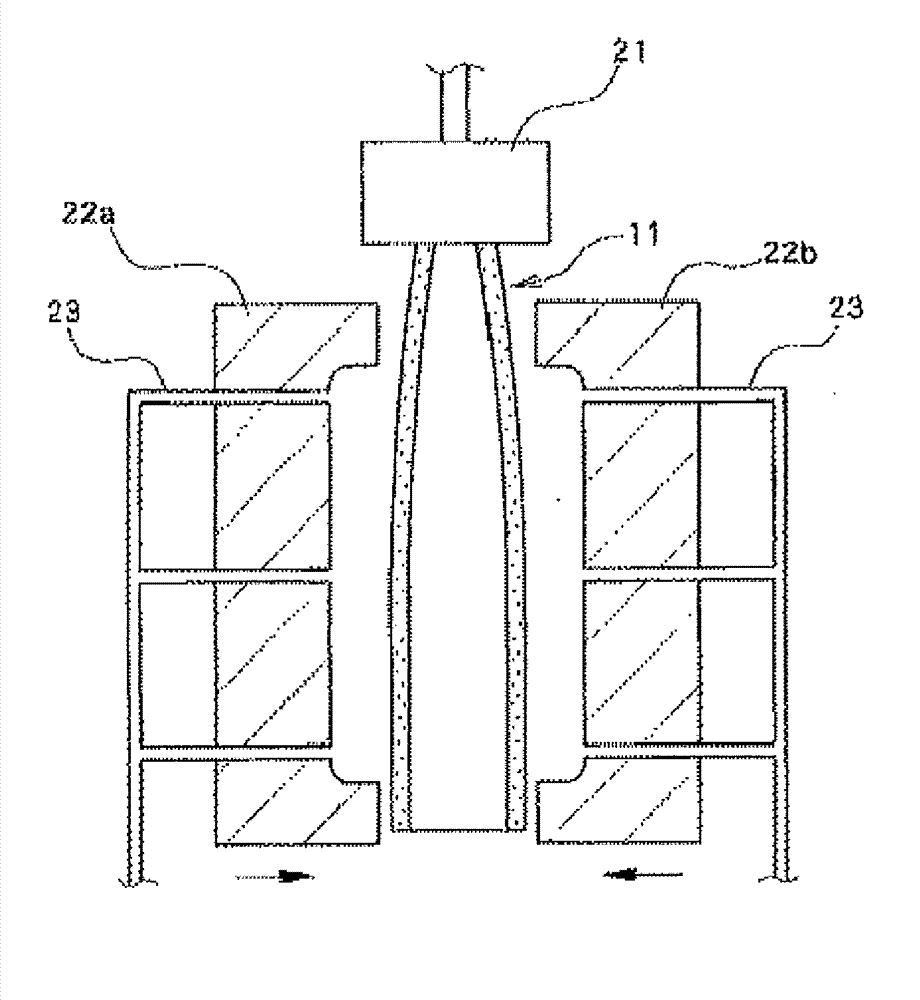

[0136] The types and compounding amounts of polypropylene-based resins shown in Table 4 and talc as a cell regulator were supplied to an extruder with a diameter of 65 mm, and melted and kneaded in the extruder. Next, carbon dioxide (CO 2 ) by pressing and mixing so that the injection amount (mol / kg) shown in Table 4 per 1 kg of polypropylene-based resin was obtained to prepare a foamable molten resin. Next, an expandable molten resin is filled into an accumulator connected to the extruder. Then, the foamable molten resin was extruded and foamed in the normal-pressure region through the annular die arranged at the front end of the pressure accumulator to form a foamed billet. Next, while blowing pre-blowing gas into the foamed billet, the foamed billet is sandwiched between the two combined metal molds arranged directly below the die, and blown into the foamed billet from the blowing rod. The plastic gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com