Method for online controlling uneven thickening of seamless steel pipe wall in reducing sizing production

A seamless steel pipe, reducing and sizing technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of lack of back tension, lack of front tension, constant motor speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

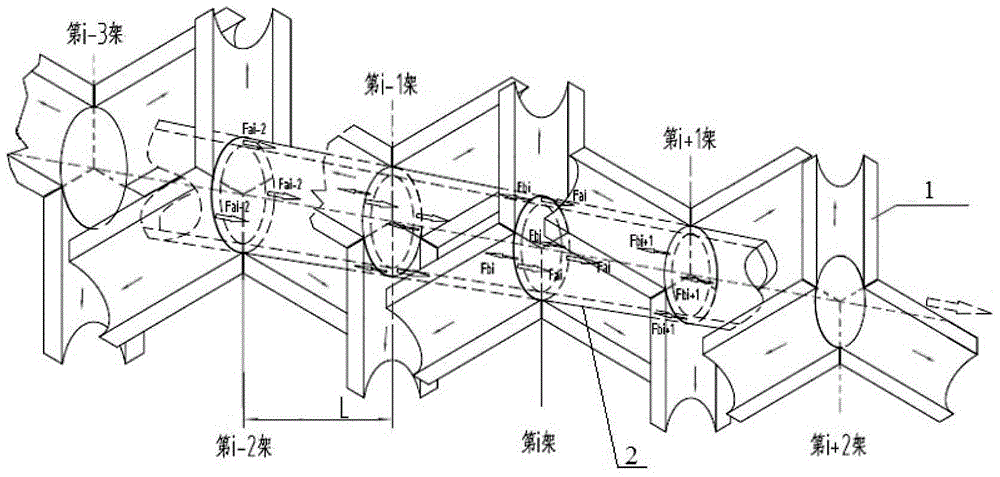

[0035] Hereinafter, the method for controlling the non-uniform thickening of the pipe wall of the seamless steel pipe on-line in the reducing and sizing production of the present invention will be described in detail.

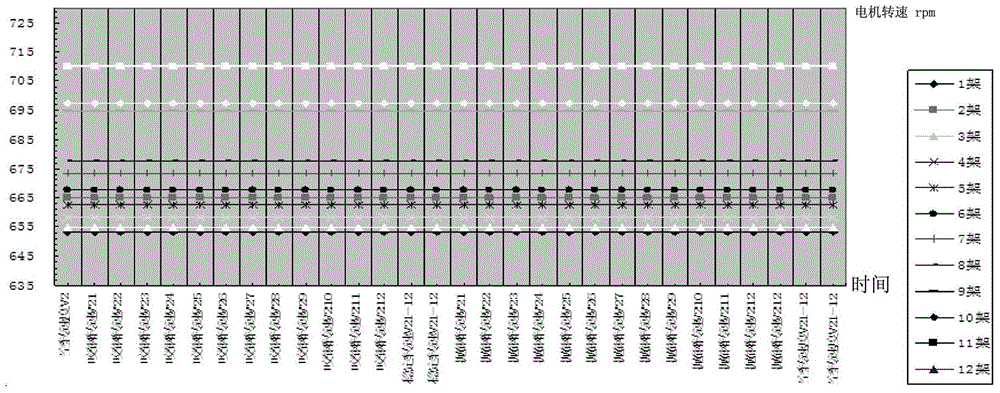

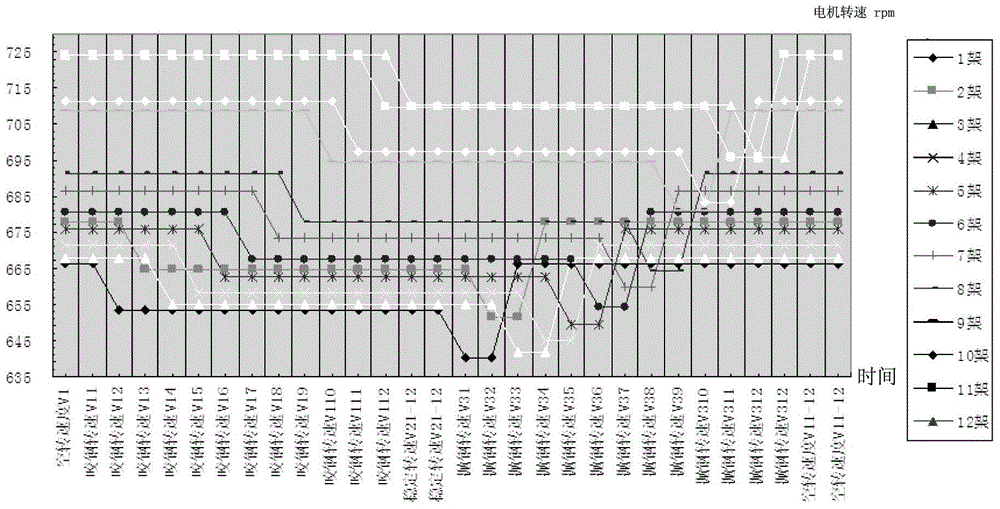

[0036] Due to the following two technical problems in the reduction and sizing production in the prior art: 1) the motor speed of each frame is constant, and the roller speed of each frame cannot be adjusted online according to the changes in the production process, resulting in piles of steel between the frames. The wall of the cross section in the pipe is unevenly thickened and exceeds the standard requirements of the steel pipe. In severe cases, the "inner hexagon" quality defect occurs and the steel pipe becomes a waste product; The lack of front tension at the top and the lack of back tension at the free tail make the thickness of the pipe wall at the head and tail more than that in the pipe, resulting in serious uneven axial wall thickness of the steel pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com