3D hydraulic forming method for special-shaped sealing ring of aero-engine

An aero-engine and hydroforming technology, which is applied in the field of sealing ring manufacturing, can solve problems such as inability to ensure accurate synchronous loading, poor dimensional accuracy of formed parts, and poor wall thickness uniformity, so as to shorten the search trial and error interval, poor dimensional accuracy, Precise effect of material flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

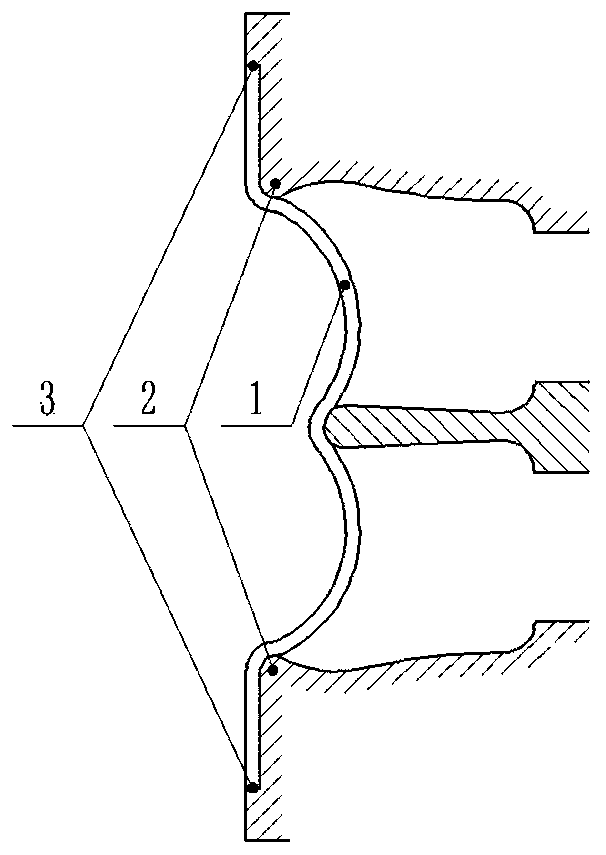

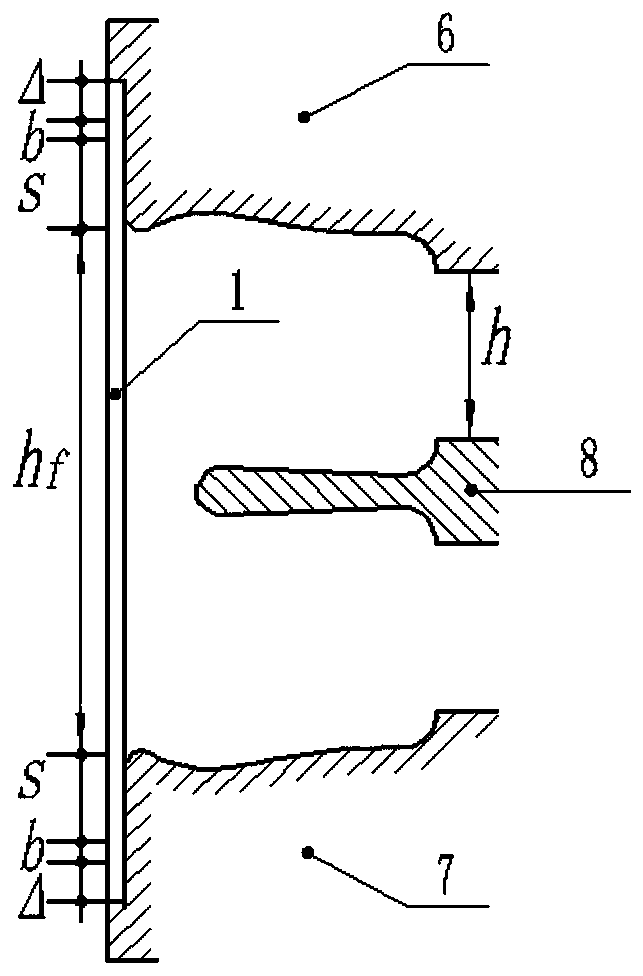

[0049] S1: Determine the blank feeding method, such as figure 1shown. The two ends of the blank 1 are stuck in the limit step groove 3 of the front mold 6 and the rear mold 7, the blank 1 and the limit step groove 3 are kept in close contact and relatively static, and the blank is pre-expanded and close to the front mold 6 And the lip area 2 of the rear mold 7, under the action of hydraulic pressure and axial feed, rely on the blank 1, the limit step groove 3 and the lip area 2 to generate static friction, transmit the axial load, push the blank to bulge and deform, and finally form It is an M-shaped sealing ring. During the forming process, the blank 1 does not participate in the deformation in the area of the limiting step groove 3, which restricts the flow of materials and controls the amount of deformed materials.

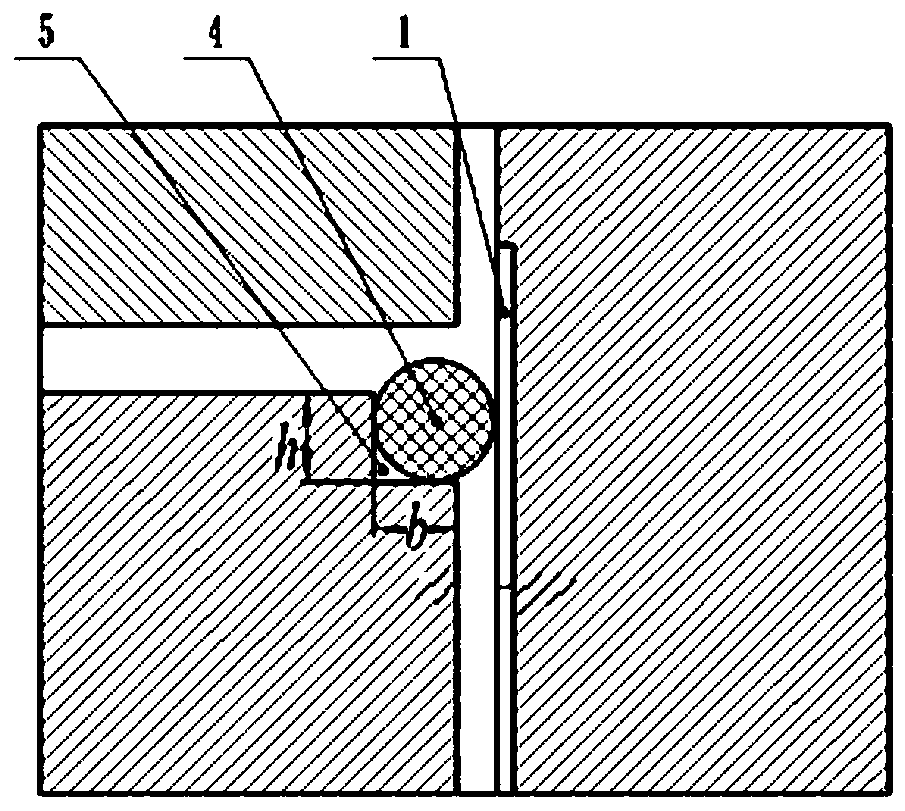

[0050] S2: Design the sealing structure of the forming device, such as figure 2 shown. The sealing structure of the forming device affects the precise c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com