Automatic circulating equipment and method for perforating machine core rods

A technology of automatic circulation and piercing machine, which is used in metal processing equipment, unloading mandrels, metal rolling, etc., can solve the problems of slow rhythm, waste of time, low production efficiency, etc., and achieve the effect of reducing round-trip time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with accompanying drawing and embodiment:

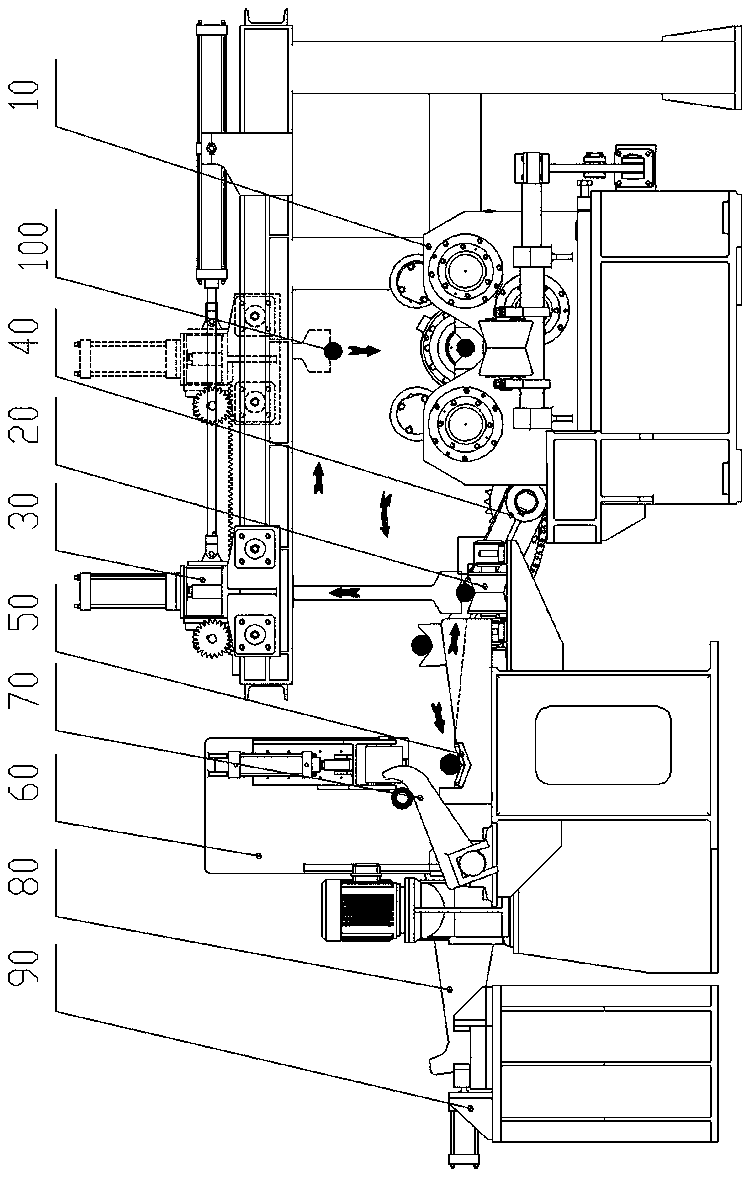

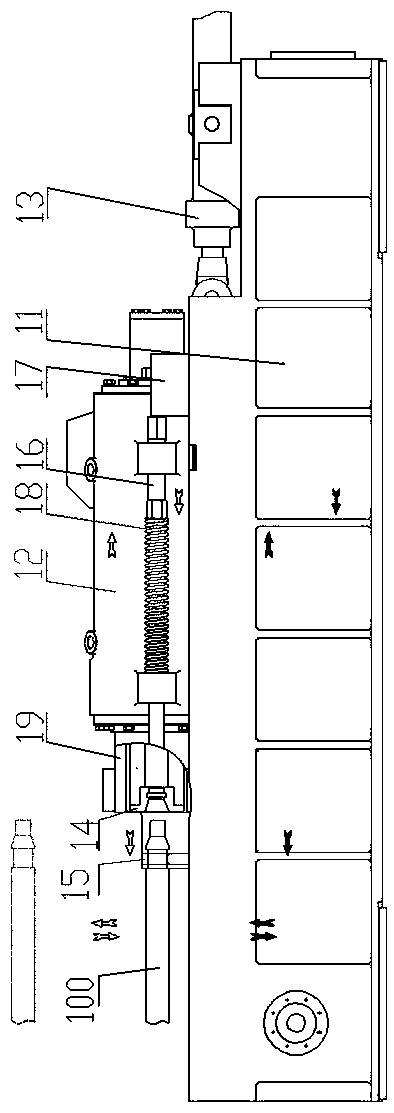

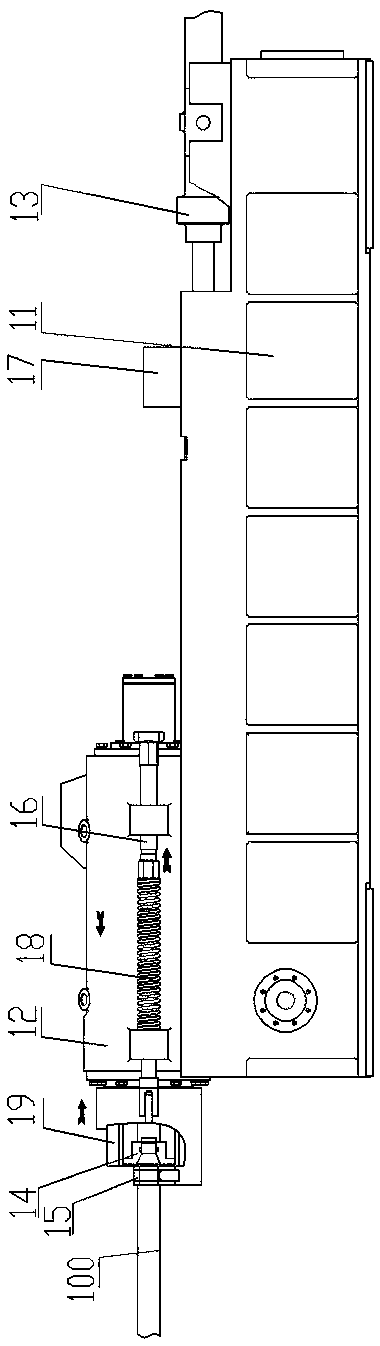

[0028] see Figure 1 to Figure 3 , as shown in the legend therein, an automatic circulation device for piercing mandrel rods, including a piercing machine 10 for piercing the mandrel rods into the pipe material, and also includes:

[0029] - return roller table 20, used to carry the core rod to be used;

[0030] - The first feeding mechanism 30 is used to send the core rod on the return roller table 20 to the piercer 10;

[0031] - The second feeding mechanism 40 is used to send the pipe material with the core rod on the piercer 10 to the stripping roller table 50;

[0032] - The stripping roller table 50 is used to carry the pipe material that penetrates the core rod;

[0033] - The stripping device 60 is used to break away from the tube material on the stripping roller table 50 and the core rod worn therein;

[0034] - The third feeding mechanism 70 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com