Forming method of resin lens in LED module

A technology of LED components and resin lenses, which is applied in semiconductor devices of light-emitting components, optical components, components of lighting devices, etc., can solve the problems of time-consuming curing process, lack of light transmission, and unfavorable mass production of LED components. Achieve the effects of shortening the curing process, saving equipment costs, and facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more definite and detailed, the preferred embodiments are listed hereby together with the following diagrams, and the structure and technical characteristics of the present invention are described in detail as follows:

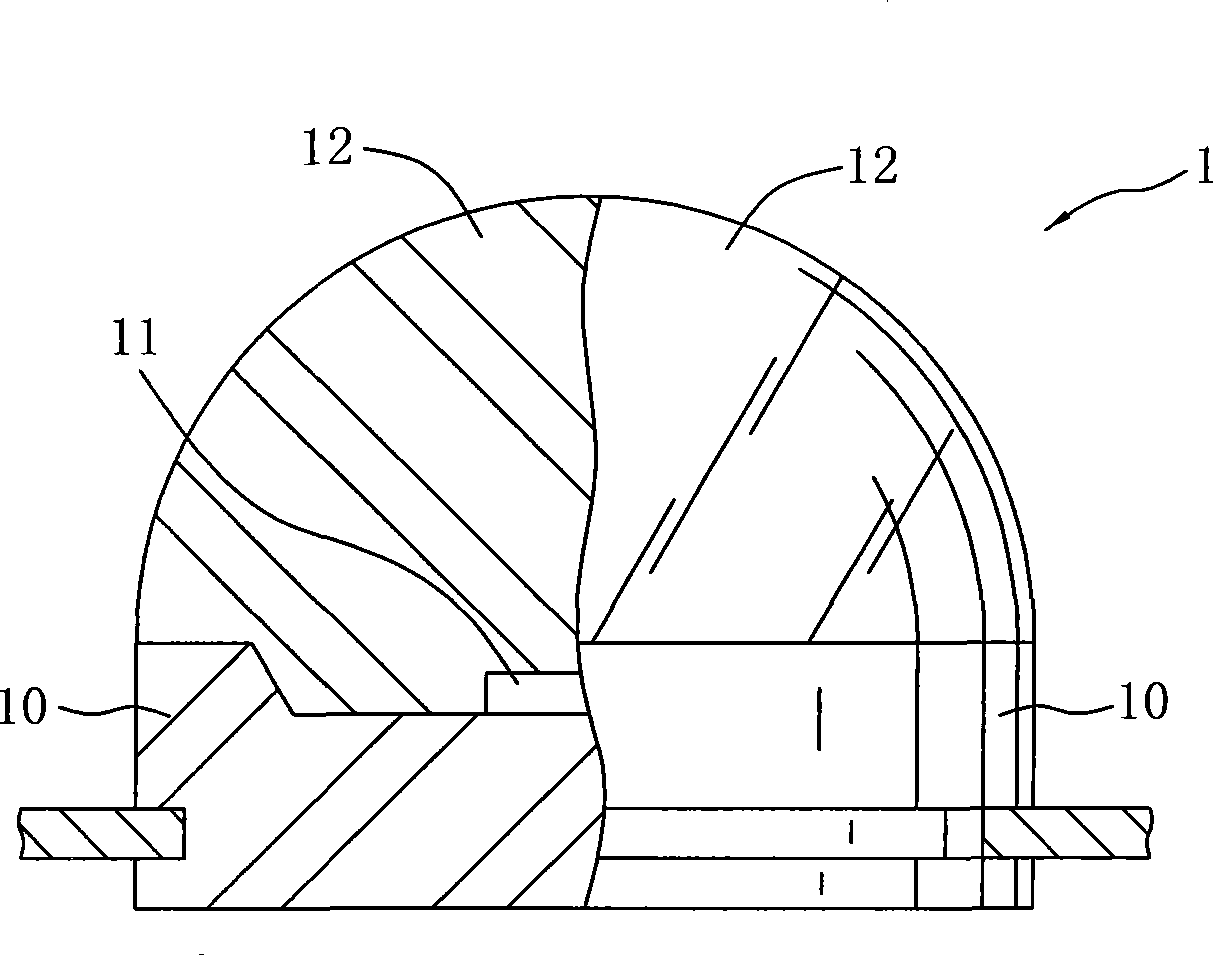

[0024] refer to figure 1 As shown, it is a schematic side view of an existing general LED assembly. The LED assembly 1 can be designed to have various packaging structures, and generally includes: a base 10 for carrying the LED die 11 and electrically connecting with the LED die 11, so that the LED die can be connected to an external power source to emit light ; one or several LED crystal grains 11, which can emit light after being connected to an external power supply; and one or more layers of cover lenses (cover lens) 12 formed by light-transmitting resin materials, used to cover the base 10 On the outside of the LED crystal grain 11, the base 10 and the LED crystal grain 11 are packaged into an LED component 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com