Method for directly synthesizing sodium borohydride by solid phase ball milling at room temperature

A room temperature solid-phase, sodium borohydride technology, applied in the direction of borane/diborane hydride, etc., can solve the problems of difficult large-scale application, high requirements for preparation conditions, high energy consumption, etc., and achieves a controllable reaction process. The effect of adjustment, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

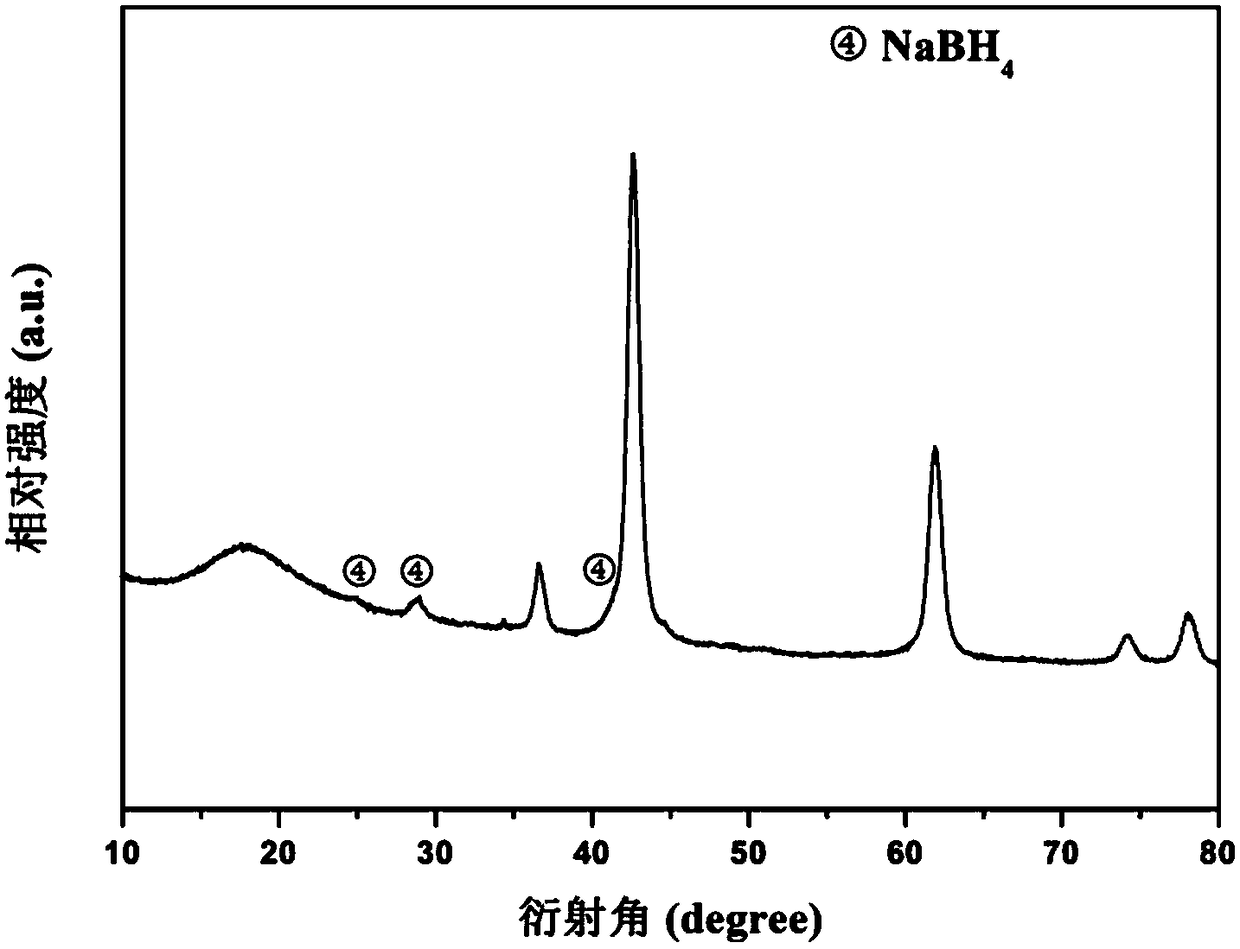

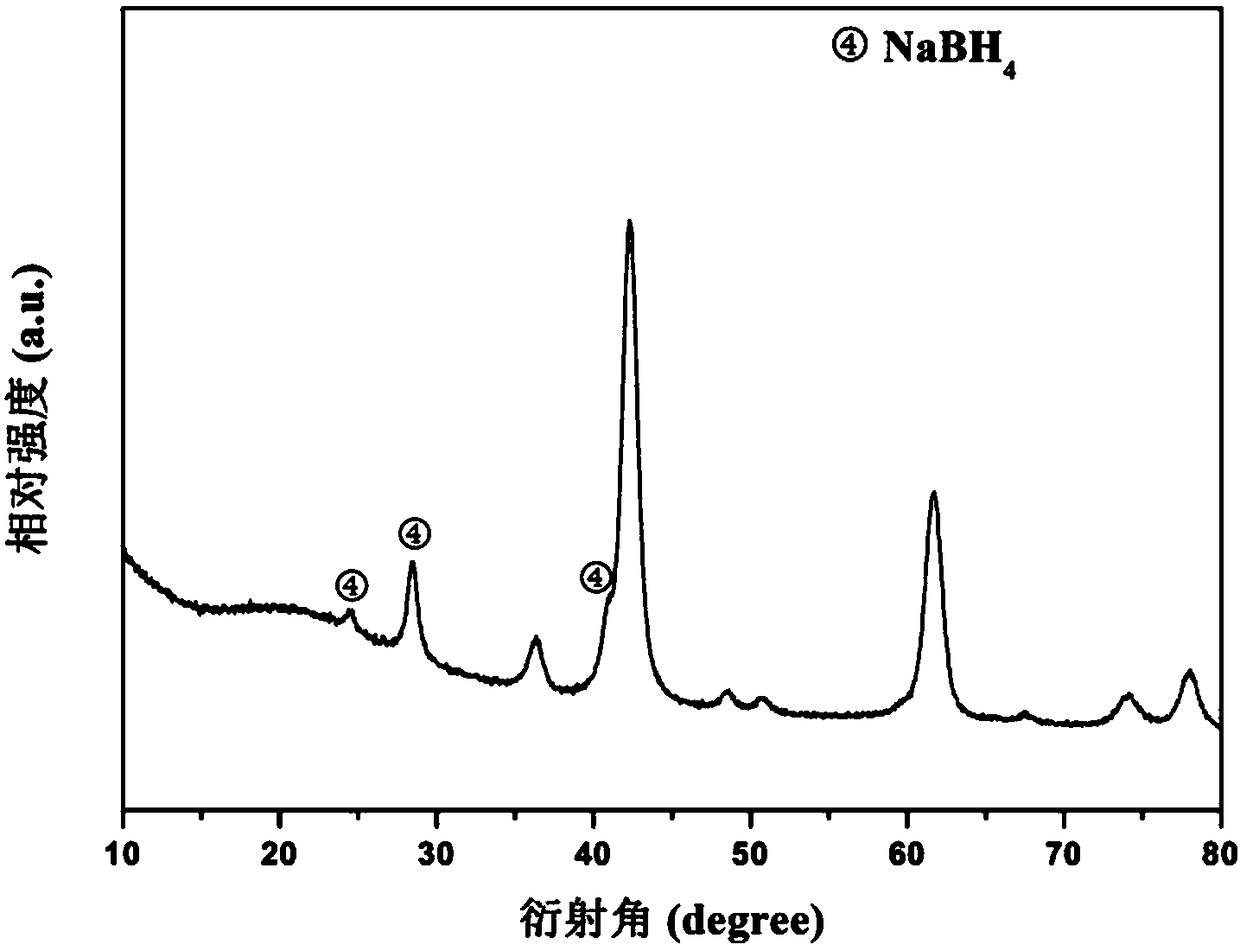

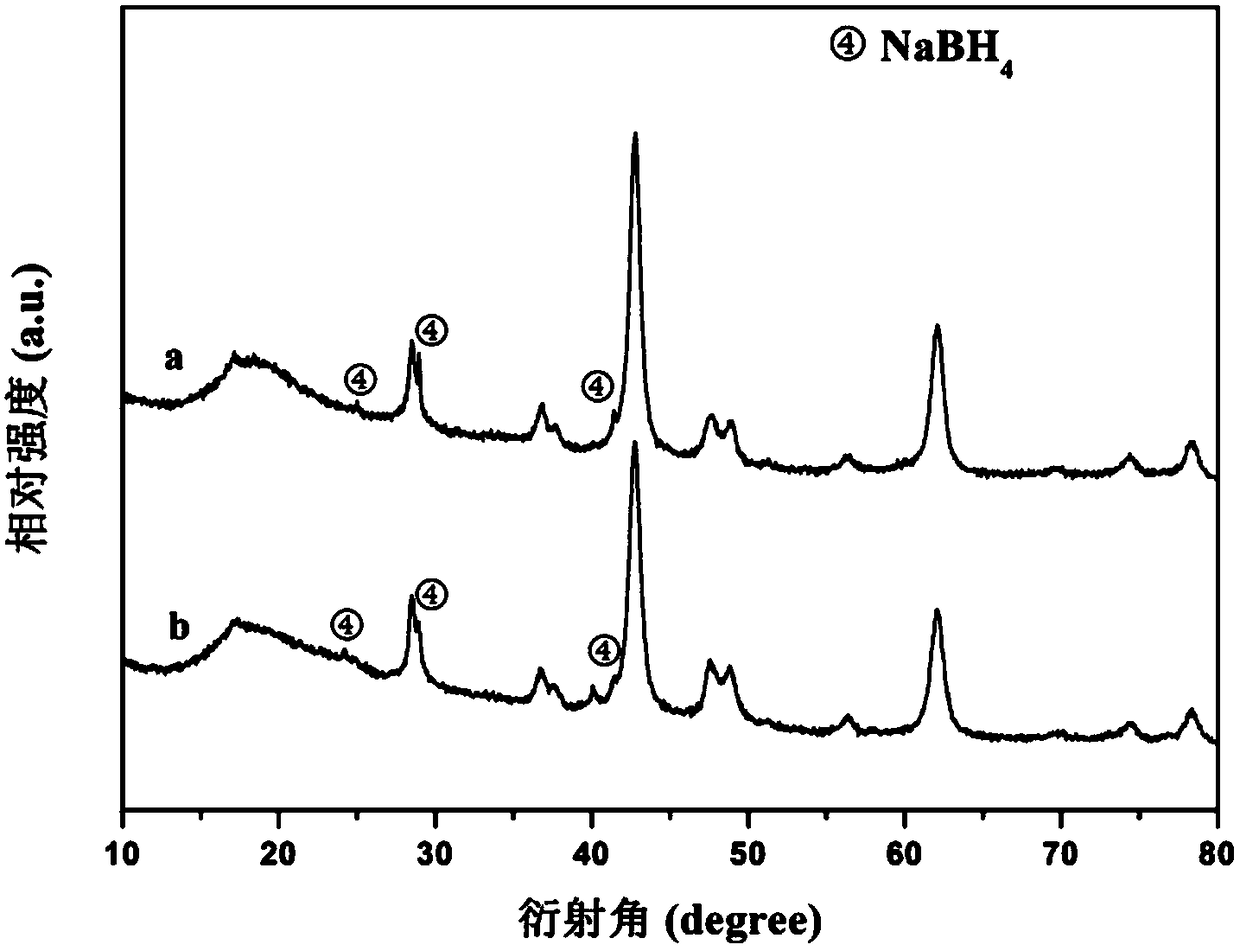

[0054] In a 0.1MPa argon atmosphere glove box, weigh magnesium, sodium carbonate and sodium tetraborate decahydrate with a molar ratio of 28:1:1, mix them into a ball mill jar and place the ball mill jar in a high-energy pendulum ball mill ( In QM-3C), the ball-to-material ratio is 50:1, the ball milling speed is 1000 rpm, and ball milling is performed directly in the argon atmosphere for 20 hours. figure 1 It is the XRD spectrum of the ball milling product. The diffraction peaks at 25.1, 28.9, and 41.4° in the curve belong to sodium borohydride crystals, which proves that sodium borohydride crystals are generated; the mixture is dissolved in ethylenediamine and filtered to obtain a clear filtrate, and the filtrate is subjected to A white powder was obtained after vacuum drying, Image 6 It is the XRD pattern of white powder, the diffraction peaks appearing at 25.1, 28.9, 41.4, 49.0, 51.3, 60.0, 66.0, 68.0° belong to sodium borohydride crystal, which proves that the white powd...

Embodiment 2

[0056] In a 0.1MPa argon atmosphere glove box, weigh magnesium, sodium carbonate and sodium tetraborate decahydrate with a molar ratio of 22:1:1, mix them into a ball mill jar and place the ball mill jar in a high-energy pendulum ball mill ( In QM-3C), the ball-to-material ratio is 30:1, the ball milling speed is 1000 rpm, and the ball milling is directly carried out in the argon atmosphere for 10 hours. The XRD pattern and figure 1 Similarly, the diffraction peaks at 25.1, 28.9, and 41.4° in the curve belong to sodium borohydride crystals, which proves that sodium borohydride crystals are formed; the mixture is dissolved in ethylenediamine and filtered to obtain a clear filtrate, which is vacuum-dried to obtain a white powder , the quantitative yield was 42% by iodine titration.

Embodiment 3

[0058] In a 0.1MPa argon atmosphere glove box, weigh magnesium, sodium carbonate and sodium tetraborate decahydrate with a molar ratio of 18:1:1, mix them into a ball mill jar and place the ball mill jar in a high-energy pendulum ball mill ( In QM-3C), the ball-to-material ratio is 5:1, the ball milling speed is 1000 rpm, and ball milling is performed directly in the argon atmosphere for 5 hours. The XRD pattern and figure 1 Similarly, the diffraction peaks at 25.1, 28.9, and 41.4° in the curve belong to sodium borohydride crystals, which proves that sodium borohydride crystals are formed; the mixture is dissolved in ethylenediamine and filtered to obtain a clear filtrate, which is vacuum-dried to obtain a white powder , the quantitative yield by iodometric titration was 21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com