Lithium iron phosphate system lithium ion battery and preparation method thereof

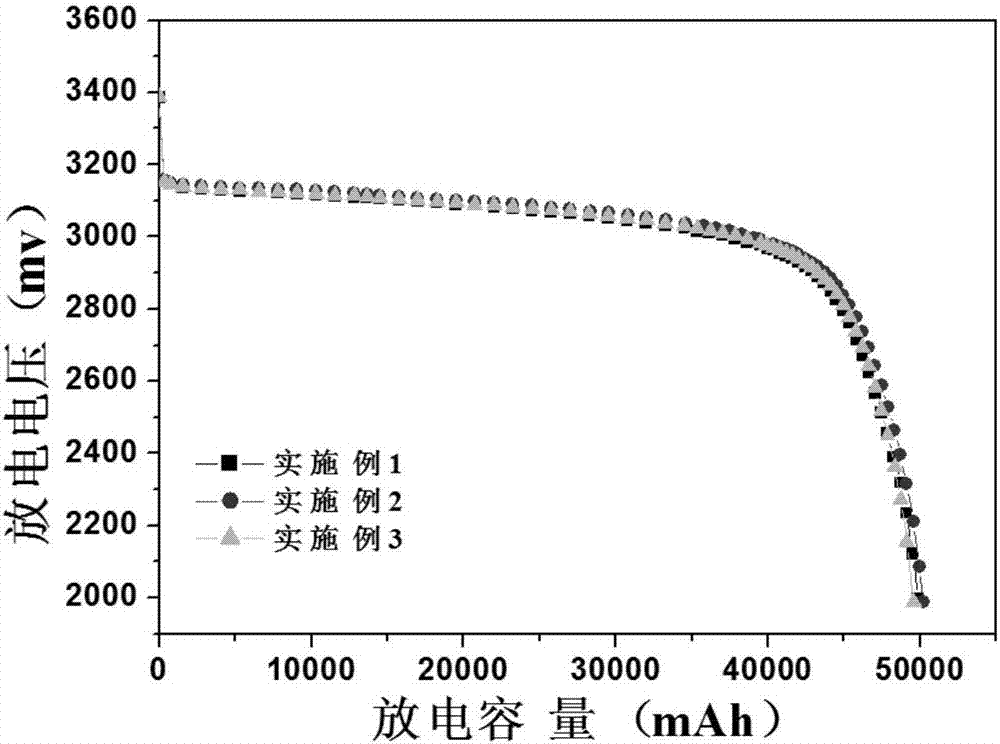

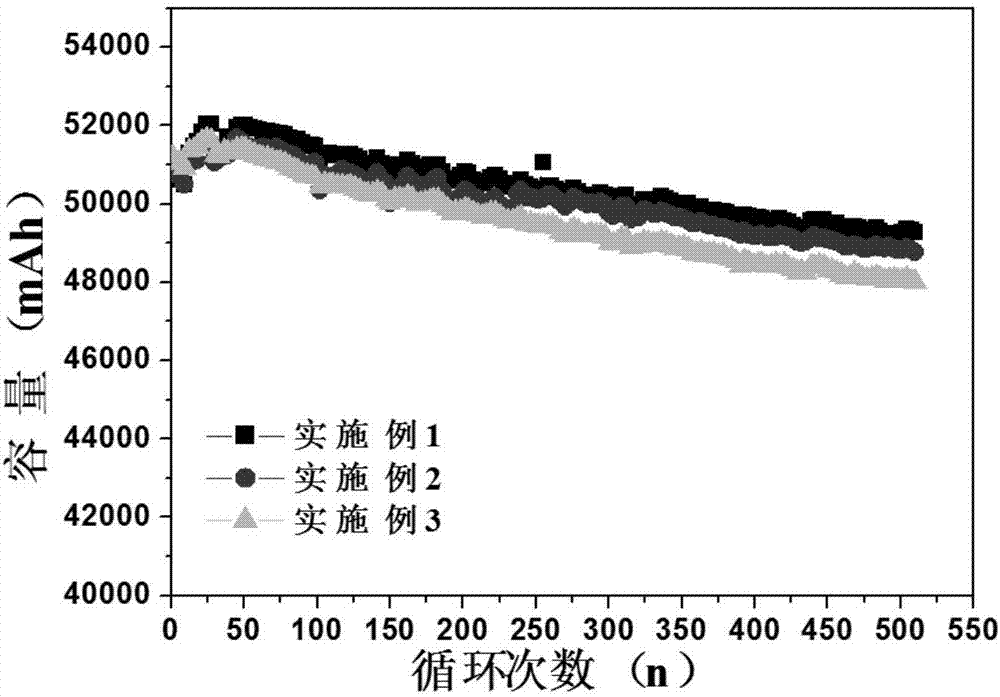

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, secondary battery, etc., can solve the problems of high cost, unsatisfactory cycle performance, difficult processability of negative electrode materials, etc., and achieve easy processing. , good electrochemical performance, excellent discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the lithium iron phosphate system lithium ion battery of the present invention comprises the following steps:

[0046] S1: positive electrode sheet production, the positive electrode material is uniformly mixed in N-methylpyrrolidone organic solvent according to the conventional process to make positive electrode slurry, and the positive electrode slurry is coated on the positive electrode current collector, Baking and cold pressing into a sheet structure, and then die-cutting the sheet structure to obtain a finished positive electrode sheet;

[0047] S2: Negative electrode sheet production, the negative electrode material is uniformly mixed in the carboxymethyl cellulose glue according to the conventional process, and the binder is added to make the negative electrode slurry, and the negative electrode slurry is coated on the negative electrode current collector, Baking and cold-pressing into a sheet-like structure, and then die-cutting the sh...

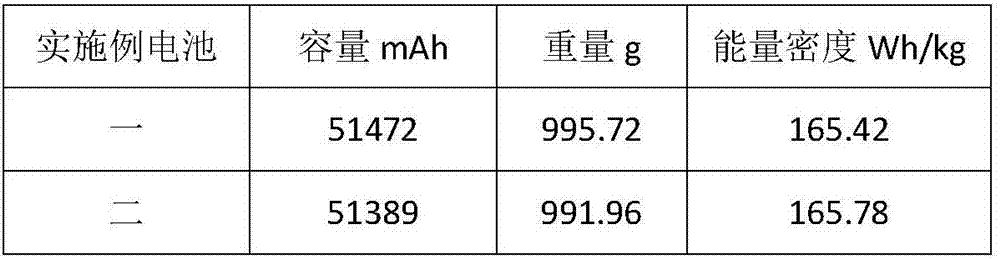

Embodiment 1

[0057] A lithium iron phosphate lithium-ion battery, comprising a battery casing, a core body in the casing, and an electrolyte filled in the casing, the core body is composed of a positive electrode sheet, a negative electrode sheet, and is attached between the positive electrode sheet and the negative electrode sheet diaphragm composition. The positive electrode sheet and the negative electrode sheet are respectively composed of positive and negative electrode collectors and positive and negative electrode materials coated on the positive and negative electrode collectors.

[0058] The positive electrode active material used in the positive electrode material is lithium iron phosphate material, the conductive agent is conductive carbon black, and the positive electrode binder is polyvinylidene fluoride. Wherein, the mass percentage of lithium iron phosphate material in the positive electrode material is 96.5%, the mass percentage of conductive carbon black is 1.5%, and the m...

Embodiment 2

[0067] In the lithium iron phosphate lithium ion battery in this embodiment, the fabrication of the positive electrode sheet, the fabrication of stacked cores, and the formation after liquid injection are completely consistent with those in Embodiment 1 of the present invention. The difference is that in Example 2, the production of the negative electrode sheet: the negative electrode material is uniformly mixed in carboxymethyl cellulose glue according to the conventional process to make the negative electrode slurry, and the negative electrode slurry is evenly coated on the copper foil to make On the negative electrode current collector with a thickness of 6um, it is cold pressed after baking, and the compacted density is 1.60g / cm 3 , the thickness of the prepared negative electrode sheet was 104 μm. Then, the negative electrode sheet was die-cut to obtain a finished negative electrode sheet with a size of 195 mm×237.5 mm.

[0068] In addition, the electrolyte solution of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com