3C electronic product shell and manufacturing method thereof

A technology for electronic products and casings, which is applied in the field of 3C electronic product casings and its preparation, and can solve the problems that structural parts cannot maintain a complete and coherent appearance effect, cannot meet high-end fashion appearance effects, and reduce the metal texture experience effect of casings, etc. , to meet the requirements of appearance quality, improve the problem of easy cracking, and facilitate mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

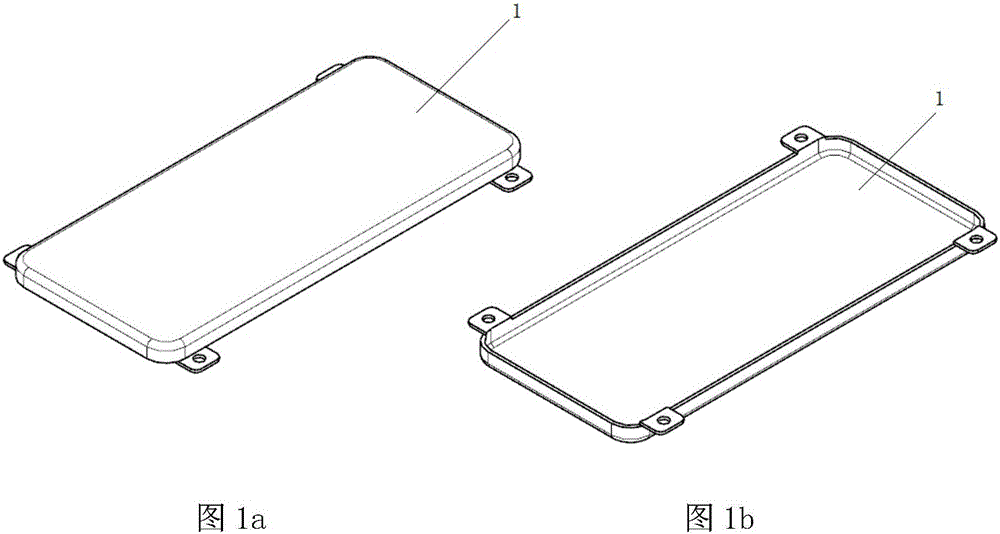

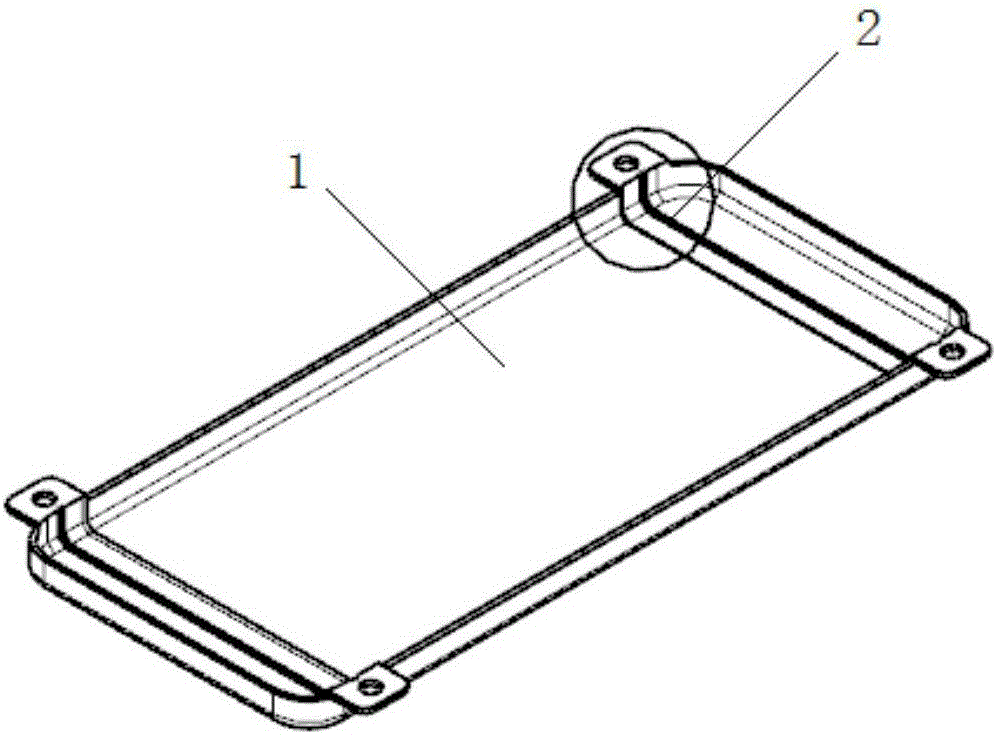

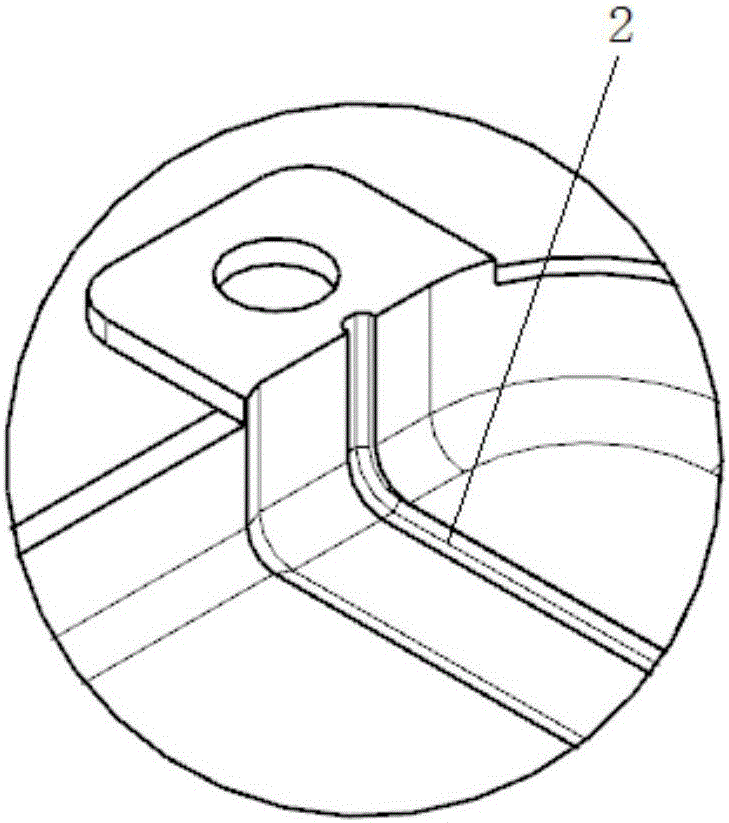

[0041] refer to Figure 1a to Figure 8c , in one embodiment, a 3C electronic product housing, including a metal structure 1 as the shell body, an antenna slot is opened between the back and the front of the metal structure 1, and the antenna slot includes a slot The cavity 2 and the antenna slitting micro-slit 3 penetrating from the cavity 2 to the front of the metal structure 1, the antenna slitting micro-slit 3 is filled with a non-conductive substance, and the metal structure 1 There is an integrally injection-molded plastic structure layer 4 on the back side, and the plastic structure layer 4 at least partially fills the slot cavity 2 of the antenna slot.

[0042] The specific width and quantity of the micro-slits for cutting the antenna can be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com