Railway locomotive right shaft box body assembly

An axle box body and railway track technology, which is applied to the field of the right axle box body of a railway rail car, can solve the problems of weak mechanical properties of the axle box body, high processing difficulty, poor manufacturability, etc., so as to meet the requirements of appearance quality and improve the overall mechanical performance. , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

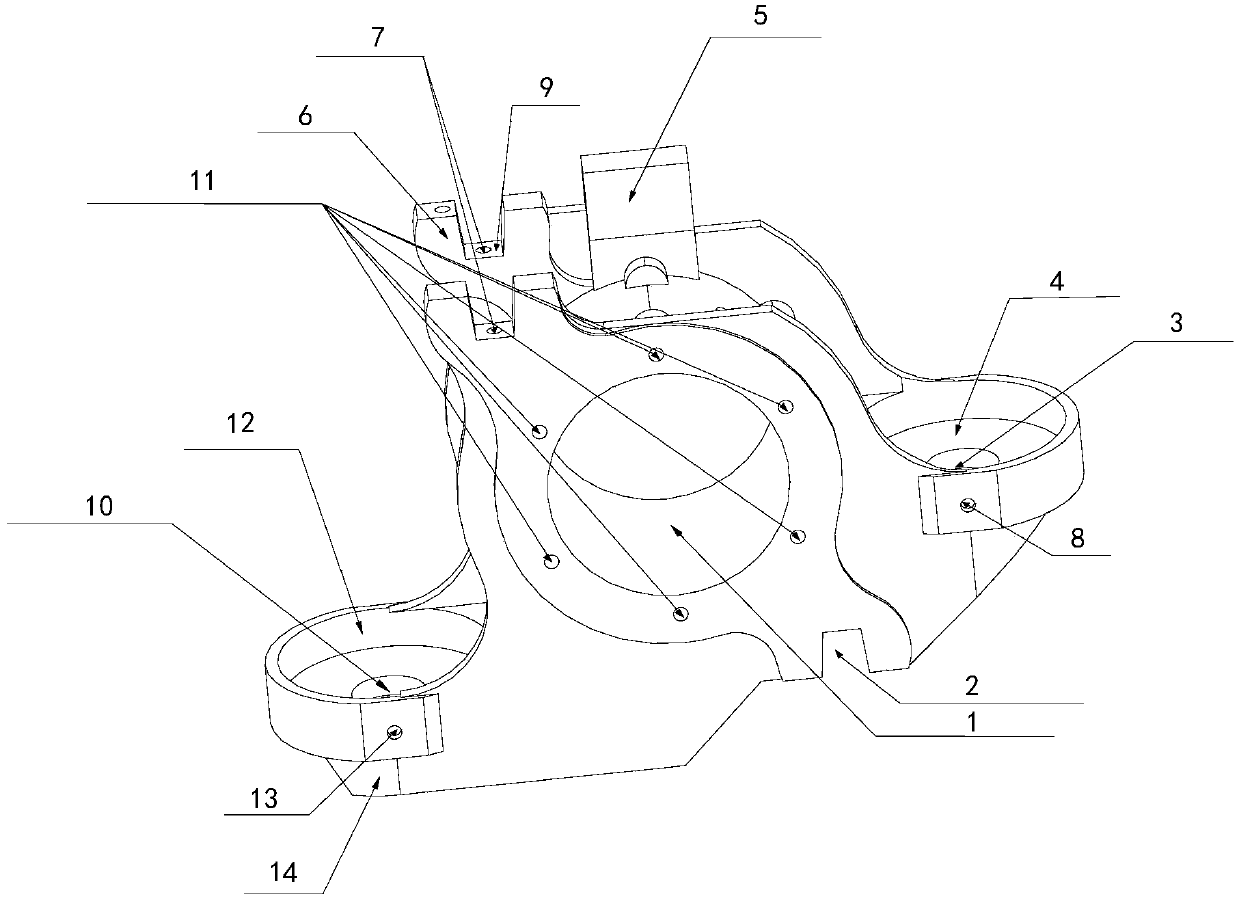

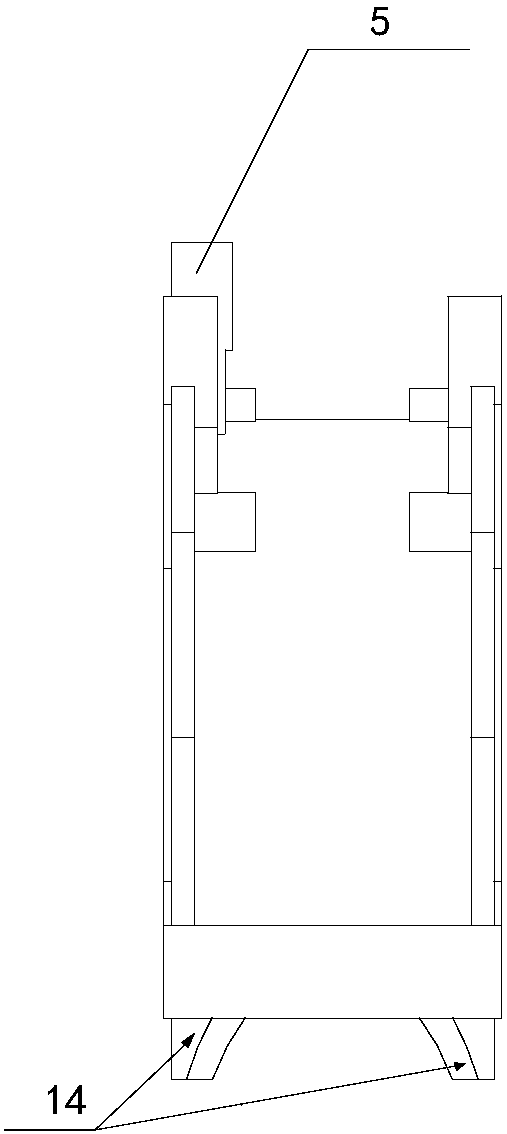

[0014] Such as Figure 1-2 As shown, a right axle box of a railway rail car according to the present invention includes a bearing hole 1, a first trapezoidal groove 2, a first pin hole 3, a first spring hole 4, an upper vertical plate 5, and an inner opening gear Surface 6, tie rod locking hole 7, first drain hole 8, second trapezoidal groove 9, second pin hole 10, threaded hole 11, second spring hole 12, second drain hole 13, axle box support plate 14.

[0015] Bearing hole 1 is the main center part of the product, connecting the upper and lower mounting parts and the right and right mounting parts. Bearing hole 1 is processed by boring, and six rings are evenly distributed on the outside of bearing hole 1 and processed by drilling chips. The purpose of the threaded hole 11 is to improve the installation accuracy and installation st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com