A kind of 3C electronic product shell and preparation method thereof

A technology for electronic products and housings, which is applied in the field of 3C electronic product housings and their preparation, can solve the problems that structural parts cannot maintain a complete and coherent appearance effect, cannot meet the high-end fashion appearance effect, and reduce the experience effect of metal texture of the housing. , to meet the appearance quality requirements, improve the problem of easy cracking, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

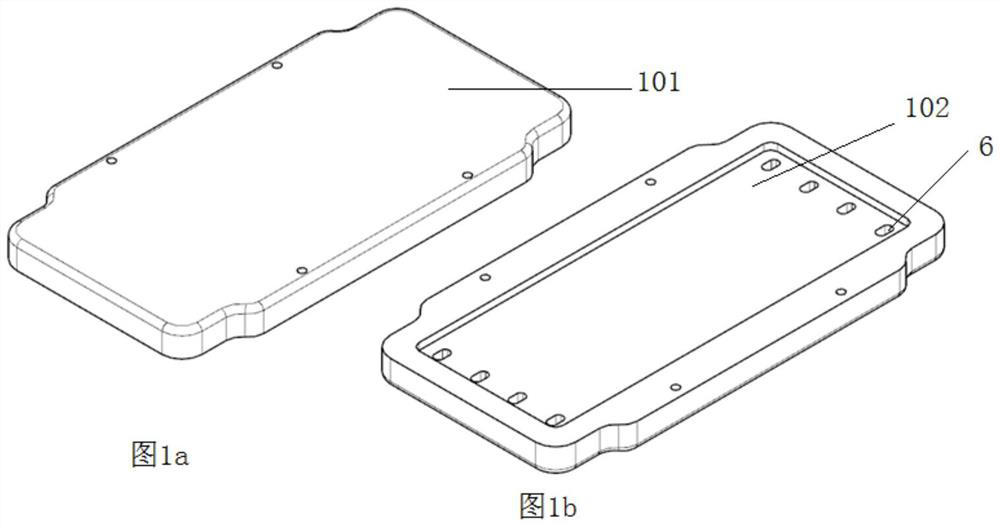

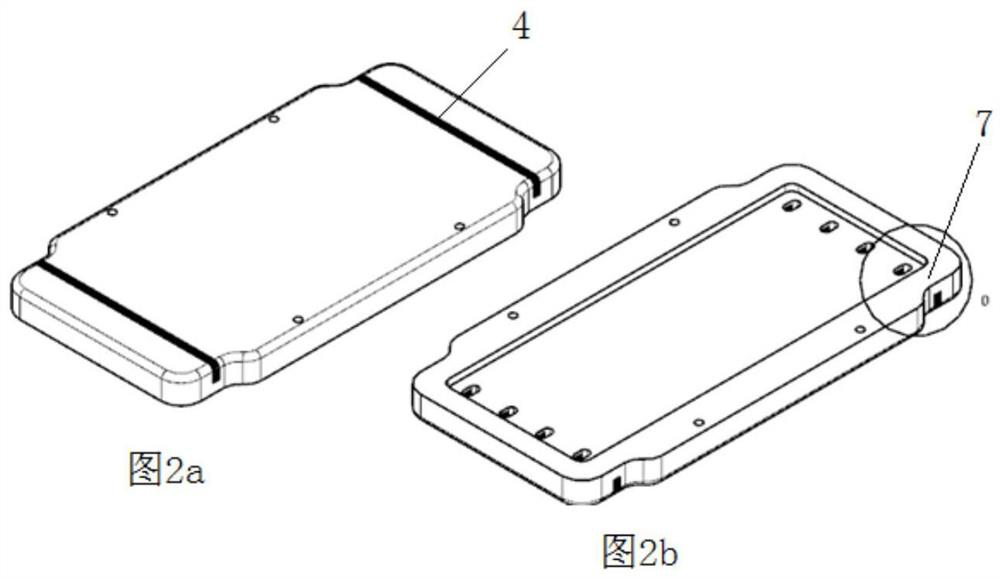

[0051] See Figure 1 to Figure 9c , a preparation method for preparing the casing of the 3C electronic product, comprising the following steps:

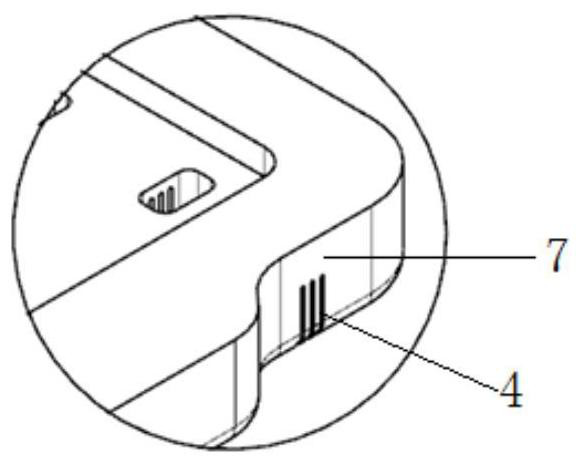

[0052] Between the back side 102 and the front side 101 of the metal blank, a penetrating antenna slit micro-slit 4 is processed, preferably by laser cutting or laser engraving or CNC technology;

[0053] Using a non-conductive pre-injection material to pre-inject the antenna slitting micro-slit 4 to fill the antenna slitting micro-slit;

[0054] Secondary injection molding is performed on the back of the metal blank to form a plastic structure, and the plastic structure 2 is integrally combined with the pre-injection molding material 3 with a set degree of strength and combined with the metal blank.

[0055] In a preferred embodiment, the metal blank has a reinforcement structure 7 to prevent deformation or separation of the cut metal area during micro-slit processing of the antenna slitting position; the reinforcement structure 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com