Thin plastic shell with plastic binder and manufacturing method thereof

A technology of metal thin and bonded parts, which is applied in the direction of metal shells, metal layered products, chemical instruments and methods, etc., can solve problems such as process and application limitations, complicated process, shape or tactile limitation, etc., to achieve high production efficiency and easy The effect of mass production, process and mold simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

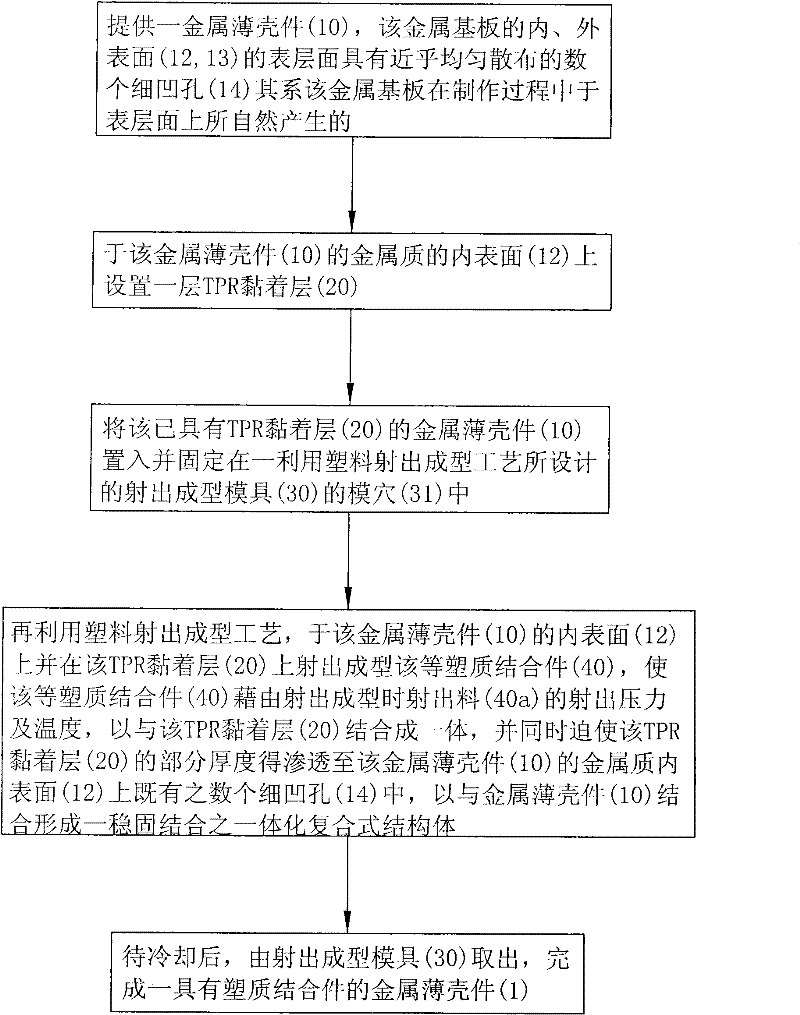

Method used

Image

Examples

Embodiment 1

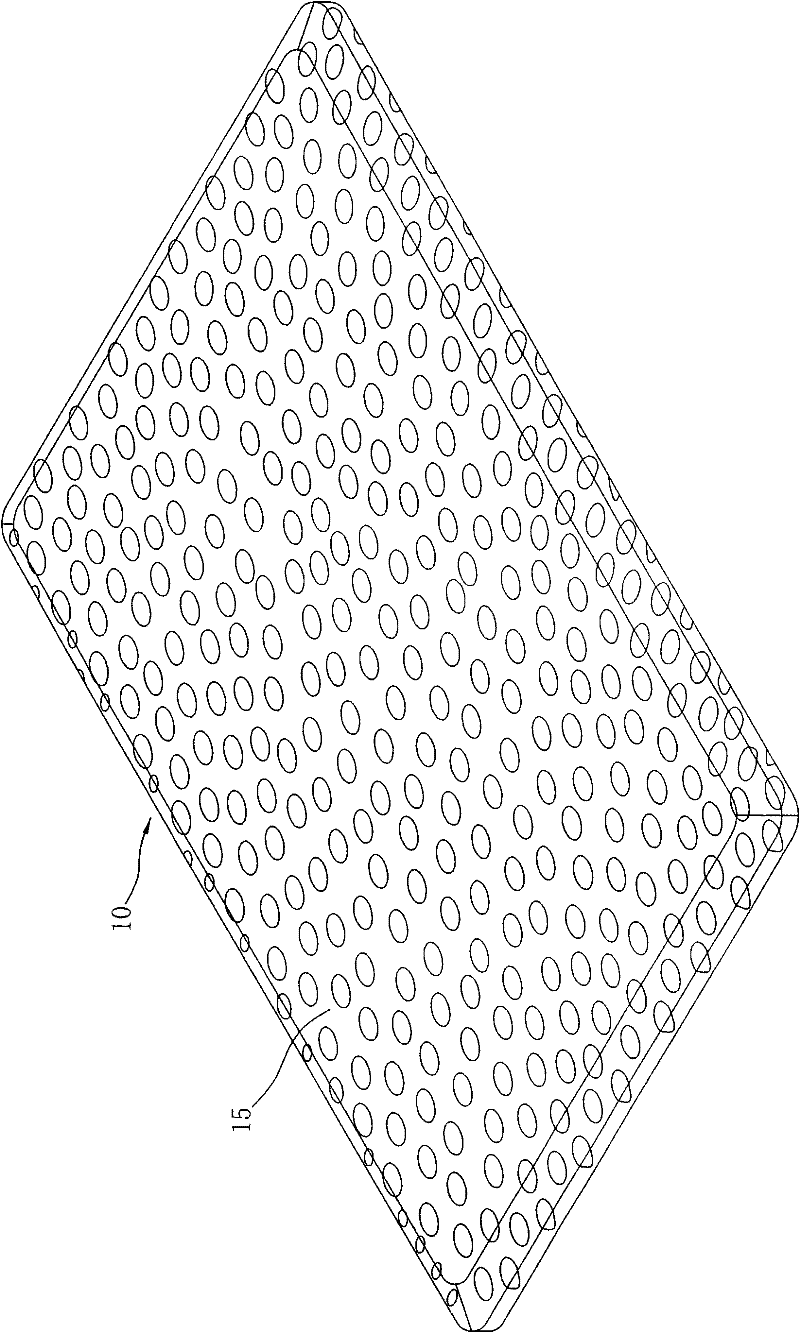

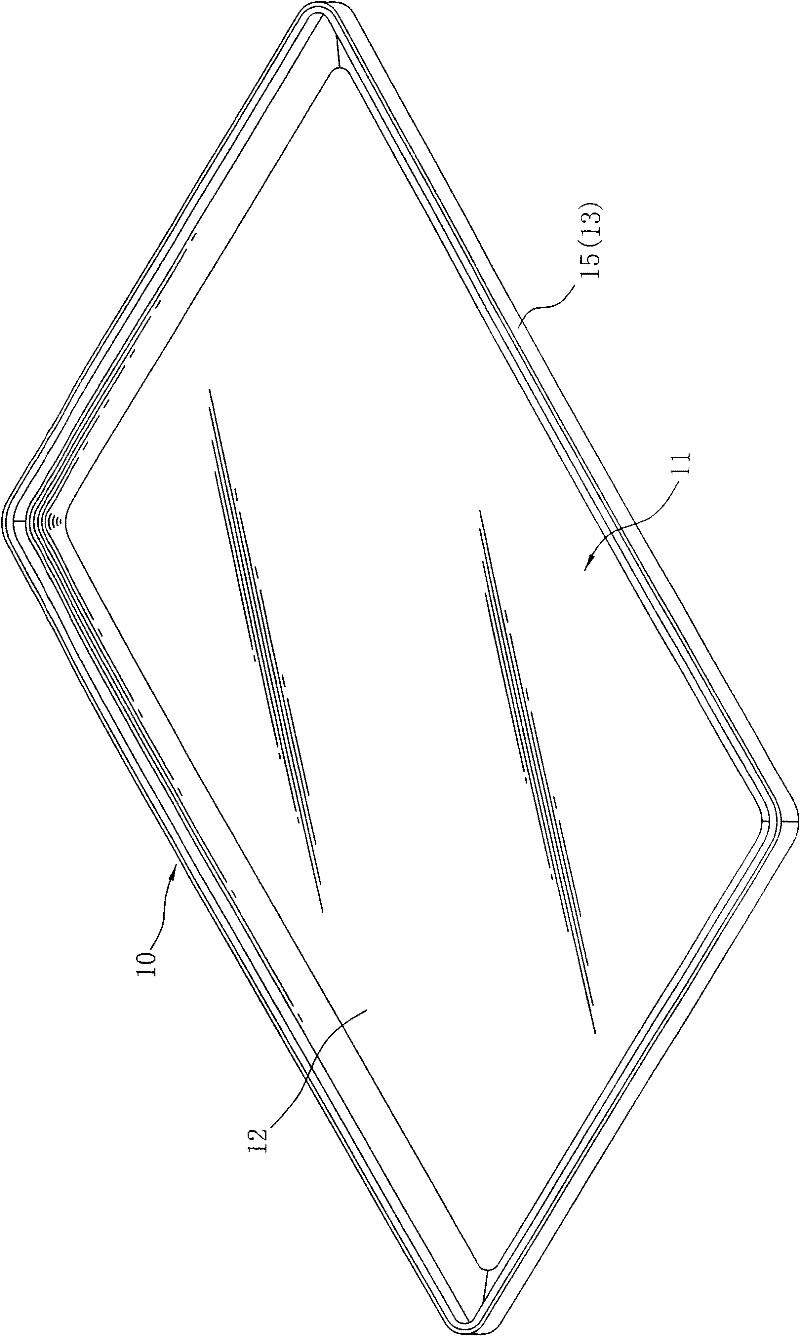

[0053] The metal shell 1 with resin-bonded parts in this embodiment includes: a metal shell 10 is composed of an aluminum alloy substrate 11 with a thickness of 0.8 mm, and a decorative outer coating 15 on its outer surface is a cloth layer. The cloth layer is composed of man-made fibers such as nylon, polyester fiber, acrylic fiber, etc. and has a thickness of 0.3 mm; the TPR adhesive layer 20 is composed of a thermoplastic rubber film composed of styrene-butadiene block copolymer and hydrocarbon petroleum resin. , the thickness is about 400-500 μm; the plastic joint 40 includes but is not limited to a hollow cylindrical receiving seat such as Figure 5-7 As shown, the interior of the hollow cylindrical socket can be hot-melted into a metal (such as copper) package to form a metal socket for strong locking by the fastener; and the dimensions of the plastic joints 40 are: The length is 262mm, the width is 178mm, the thickness is 1mm, and the height is 9.5mm; it is found that t...

Embodiment 2

[0055] The metal shell 1 with resin-bonded parts in this embodiment includes: a metal shell 10 is composed of an aluminum alloy substrate 11 with a thickness of 0.8 mm, and the decorative coating 15 on the outer surface of the metal shell 10 is PVC (vinyl chloride resin) ) synthetic rayon or PU (polyurethane, Polyurethane) synthetic rayon, the TPR adhesive layer 20 is composed of a thermoplastic rubber film synthesized by styrene-butadiene block copolymer and hydrocarbon petroleum resin, with a thickness of about 400-500 μm; the plastic The combination piece 40 includes but is not limited to a hollow cylindrical socket for hot-melting a metal sleeve to form a metal socket, and the dimensions of the plastic combination pieces 40 are: length 262mm, width 178mm, thickness 1mm, The height is 9.5mm; it is found that the peel strength and adhesion of the plastic joint 40 of this embodiment is 5 kg per square centimeter, and the environmental test adhesion is from -40°C to 85°C and 85...

Embodiment 3

[0057] The structure of the thin metal shell 1 with resin bonding parts in this embodiment is basically the same as that of the second embodiment, the difference is that the thin metal shell 10 is formed by stamping an aluminum alloy substrate 11 with a thickness of 0.8 mm from an aluminum plate, and The outer coating layer 15 is the outer coating layer after the aluminum alloy substrate 11 with a thickness of 0.8 mm is punched and formed, and then treated by sandblasting and anode surface coloring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com