Production method of 5N selenium

A production method and product technology, which are applied in the production field of 5N selenium, can solve the problems of difficult product quality control, environmental pollution, and high production costs, and achieve the effects of simple and easy operation, reduced contamination, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

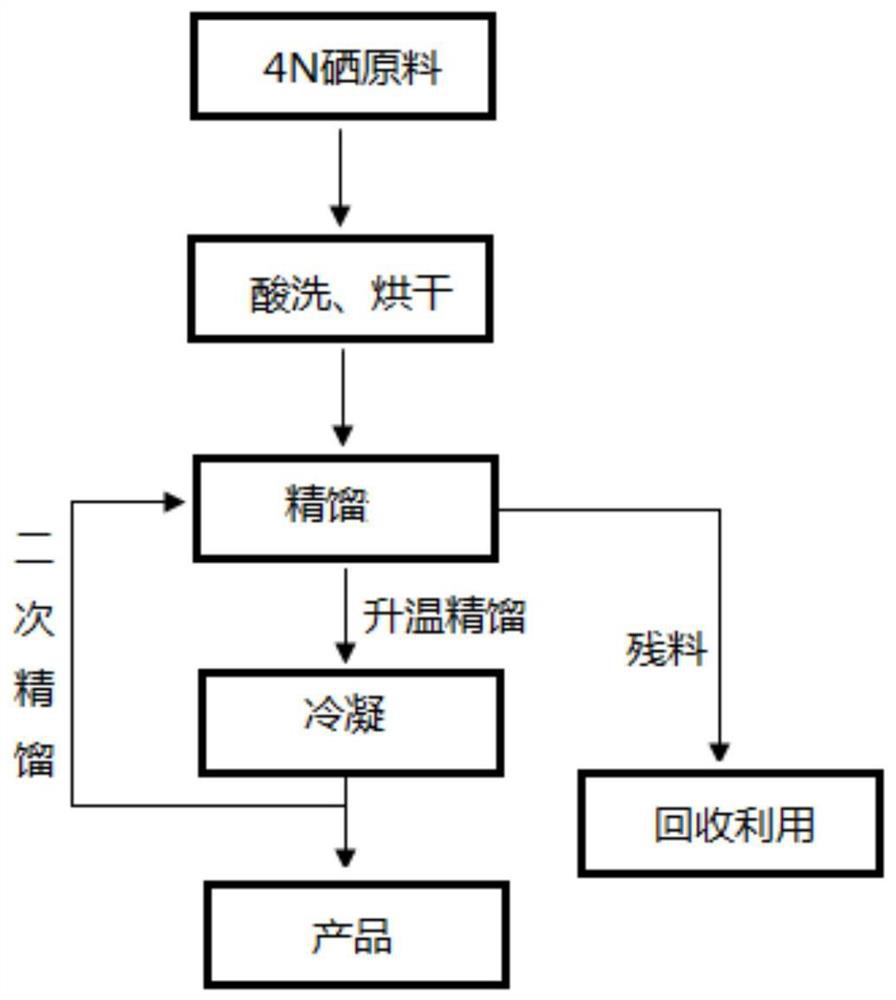

Method used

Image

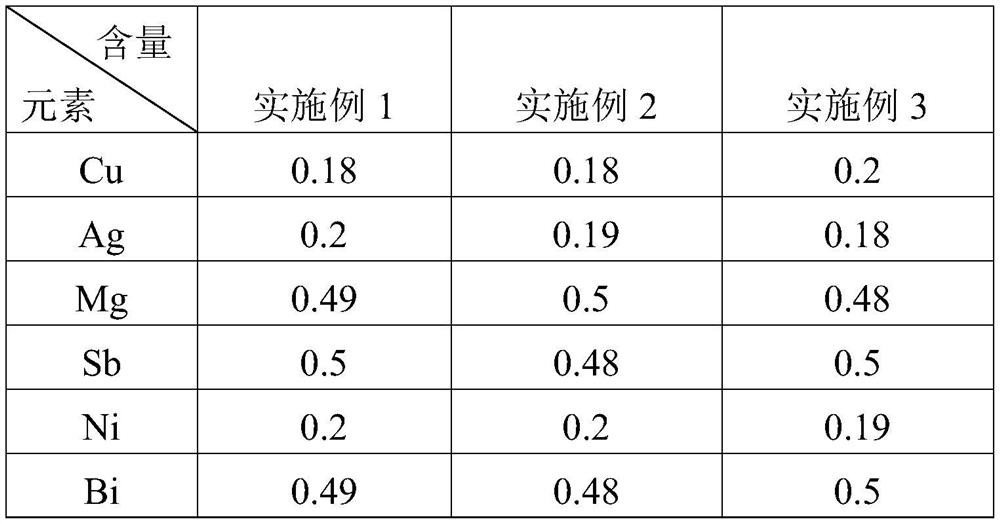

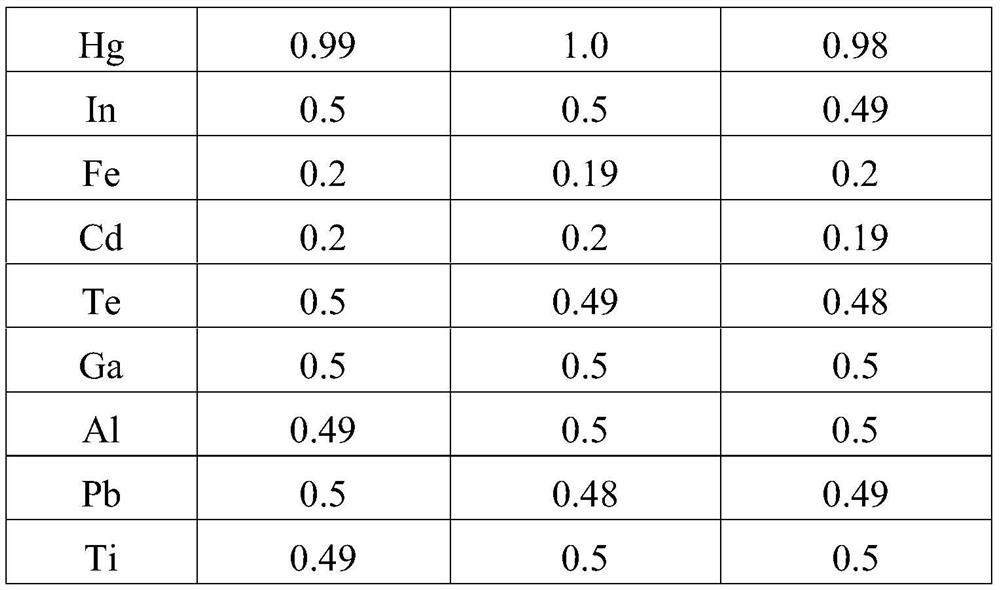

Examples

Embodiment 1

[0056] The production method of present embodiment 5N selenium comprises the following steps:

[0057] (1) The 4N selenium raw material is crushed into 4N selenium particles with a particle size not greater than 7.5mm, and the 4N selenium particles after the crushing are cleaned with dilute hydrochloric acid with a mass fraction of 1%. The cleaning time is 10min to remove the 4N selenium particles on the surface The oxidation slag is rinsed with water after cleaning, until it is neutrally dried. The drying temperature is 220°C, and the drying time is 2 hours, so as to remove some low-boiling impurities in the 4N selenium particles.

[0058] (2) Soak the rectification raw material kettle and utensils with mixed acid (the mass ratio of concentrated hydrochloric acid and concentrated nitric acid is 1.5:1) for 10 minutes, wash with deionized water after soaking, and dry after washing. Add the 4N selenium particles treated in step (1) into the rectification raw material kettle, cov...

Embodiment 2

[0062] The production method of present embodiment 5N selenium comprises the following steps:

[0063] (1) The 4N selenium raw material is crushed into 4N selenium particles with a particle size not greater than 7.5mm, and the 4N selenium particles after the crushing are cleaned with 1.5% dilute hydrochloric acid for a cleaning time of 8 minutes to remove the 4N selenium particles on the surface The oxidation slag is rinsed with water after cleaning, until it is neutrally dried, the drying temperature is 250°C, and the drying time is 1.5h, so as to remove some low-boiling impurities in the 4N selenium particles.

[0064] (2) Soak the rectification raw material kettle and utensils with mixed acid (the mass ratio of concentrated hydrochloric acid and concentrated nitric acid is 1.7:1) for 10 minutes, wash with deionized water after soaking, and dry after washing. Add the 4N selenium particles treated in step (1) into the rectification raw material kettle, cover the charging plug...

Embodiment 3

[0068] The production method of present embodiment 5N selenium comprises the following steps:

[0069] (1) The 4N selenium raw material is crushed into 4N selenium particles with a particle size not greater than 7.5mm, and the 4N selenium particles after the crushing are cleaned with 2.5% dilute hydrochloric acid for a cleaning time of 12 minutes to remove the 4N selenium particles on the surface of the 4N selenium particles. The oxidation slag is rinsed with water after cleaning, until it is neutrally dried, the drying temperature is 300°C, and the drying time is 1h, so as to remove some low-boiling impurities in the 4N selenium particles.

[0070] (2) Soak the rectification raw material kettle and utensils with mixed acid (the mass ratio of concentrated hydrochloric acid and concentrated nitric acid is 1.3:1) for 10 minutes, wash with deionized water after soaking, and dry after washing. Add the 4N selenium particles treated in step (1) into the rectification raw material ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com