Chromium-plated plastic product

A plastic and chrome-plating technology, which is applied in the field of plastic chrome-plated products, can solve problems such as high cost, heavy pollution, and complicated process, and achieve the effects of light weight, simplified production process, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

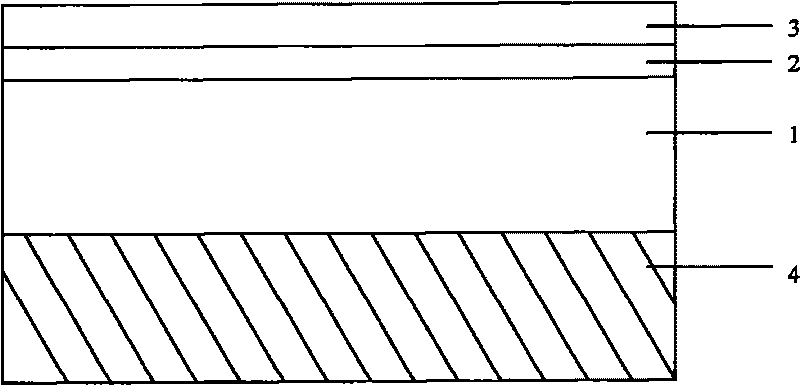

[0028] A plastic chrome-plated product, from the inside to the outside: ABS plastic workpiece 4, alicyclic epoxy modified acrylic resin coating 1, vacuum ion chrome plating layer 2, titanium oxide film coating 3; alicyclic epoxy The thickness of the modified acrylic resin coating 1 is 15 μm; the thickness of the vacuum ion chromium plating layer 2 is 3 μm; the thickness of the titanium oxide thin film coating is 4 μm. Cycloaliphatic epoxy-modified acrylate light-curing coating is formed by mixing and cross-linking cycloaliphatic epoxy resin and hydroxyacrylate. It is a photosensitive prepolymer with the performance characteristics of both cycloaliphatic epoxy and acrylate. At the same time it also contains photoinitiator, reactive diluent and other various additives.

[0029] The production method of above-mentioned product comprises the following steps successively:

[0030] 1. Pretreatment First, scrub with alcohol organic solvent to remove the oil stain and residual mold r...

Embodiment 2

[0041] A plastic chrome-plated product, from the inside to the outside: ABS plastic workpiece 4, alicyclic epoxy modified acrylic resin coating 1, vacuum ion chrome plating layer 2, titanium oxide film coating 3; alicyclic epoxy The thickness of the modified acrylic resin coating is 12 μm; the thickness of the vacuum ion chromium plating layer 2 is 2 μm; the thickness of the titanium oxide film layer 3 is 2 μm.

[0042] The manufacturing method of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com