Diaphragm cloth for water electrolyser and method for producing diaphragm cloth

A technology of water electrolysis cell and production method, applied in the direction of diaphragm, electrolysis process, electrolysis components, etc., can solve the problems of long cleaning time, poor safety, environmental pollution, etc., and achieve fast production method, high air tightness and hydrophilicity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

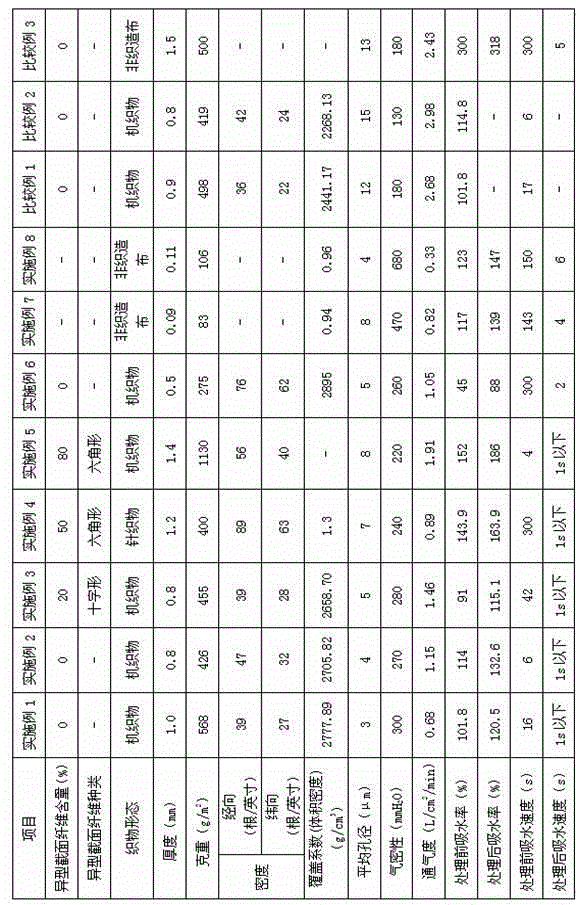

Embodiment 1

[0054] Both the warp and weft yarns are woven with 20s / 6 polyphenylene sulfide yarns to obtain a plain weave fabric with a warp yarn density of 39 yarns / inch and a weft yarn density of 27 yarns / inch. The surface of the sulfide plain weave fabric is treated with vacuum plasma, and the treatment conditions are: under the simultaneous action of oxygen and argon, the treatment intensity is 150KW·s / m 2 Finally, the coverage factor is 2777.89, the average pore diameter is 3 μm, and the pores with a pore diameter in the range of 0.2-10 μm account for 90% of all pores, and the strength in the warp and latitude directions is 4008 N / 5cm and 3218 N / 5cm respectively. Diaphragm cloth, the prepared diaphragm cloth is tested by X-ray photoelectron spectrum analyzer, and the surface of polyphenylene sulfide fiber in the diaphragm cloth contains hydrophilic groups, and the content of oxygen element contained in the surface of polyphenylene sulfide fiber is measured The hydrophilic group includ...

Embodiment 2

[0056] Both the warp and weft yarns are woven with 20s / 4 polyphenylene sulfide yarns to obtain a plain weave fabric with a warp yarn density of 47 yarns / inch and a weft yarn density of 32 yarns / inch. The surface of the sulfide plain weave fabric is subjected to vacuum plasma treatment, the treatment conditions: under the action of air, the treatment intensity is 150KW·s / m 2 Finally, the coverage factor is 2705.82, the average pore diameter is 4 μm, and the pores with a pore diameter in the range of 0.2-10 μm account for 85% of all pores, and the latitude and longitude strength are 2247 N / 5cm and 2110 N / 5cm respectively Diaphragm cloth, the prepared diaphragm cloth is tested by X-ray photoelectron spectrum analyzer, and the surface of polyphenylene sulfide fiber in the diaphragm cloth contains hydrophilic groups, and the content of oxygen element contained in the surface of polyphenylene sulfide fiber is measured 30% by weight, the hydrophilic groups include carbonyl (C=O) and ...

Embodiment 3

[0058] Mix cross-section polyphenylene sulfide fibers with circular cross-section polyphenylene sulfide fibers at a weight ratio of 20:80, and obtain 15s / 4 polyphenylene sulfide yarns through a spinning process, and then the above-mentioned The obtained polyphenylene sulfide yarn is woven as a warp and a weft, and is woven into a plain weave fabric with a warp density of 39 threads / inch and a weft density of 28 threads / inch, refining and drying after weaving, and then polyphenylene sulfide plain weave The surface of the fabric is treated with atmospheric pressure plasma, and the treatment conditions are: under the action of air, the treatment intensity is 50KW·s / m 2 Finally, the diaphragm cloth for water electrolyzer with a coverage factor of 2658.70, an average pore diameter of 5 μm, and pores with a pore diameter in the range of 0.2 to 10 μm accounted for 80% of the total pores, and a latitude and longitude strength of 2600 N / 5cm and 2216 N / 5cm respectively were obtained. , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com