Environment-friendly anticorrosion abrasion-resistant luminescent marking coating production method

An anti-corrosion and wear-resistant, marking paint technology, applied in the field of marking paint, can solve the problem of unable to remind and warn drivers and other problems, achieve obvious reminder and warning, excellent wear resistance and anti-corrosion and water resistance, and efficient production method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides an environmentally friendly production method of anti-corrosion and wear-resistant luminescent marking paint, the method includes the following steps:

[0024] 1) Weigh 12.2 parts by weight of isopropanol and 140.8 parts by weight of dichloromethane into the reactor, start stirring and add 19 parts by weight of chlorinated rubber, mix 104 parts by weight of xylene, 6.1 parts by weight of acetone, Put 16.8 parts by weight of butyl acetate into the reaction kettle, stir until the chlorinated rubber is completely dissolved, add 190 parts by weight of acrylic resin and 28 parts by weight of modified piperylene petroleum resin, mix and melt the materials according to the requirements of each stage , make the reaction kettle rotating speed be 300-1440 rev / min, acrylic resin and modified piperylene petroleum resin are completely dissolved;

[0025] 2) Add 50 parts by weight of anti-yellowing polyurethane prepolymer to 30 parts by weight of chain extend...

experiment example 1

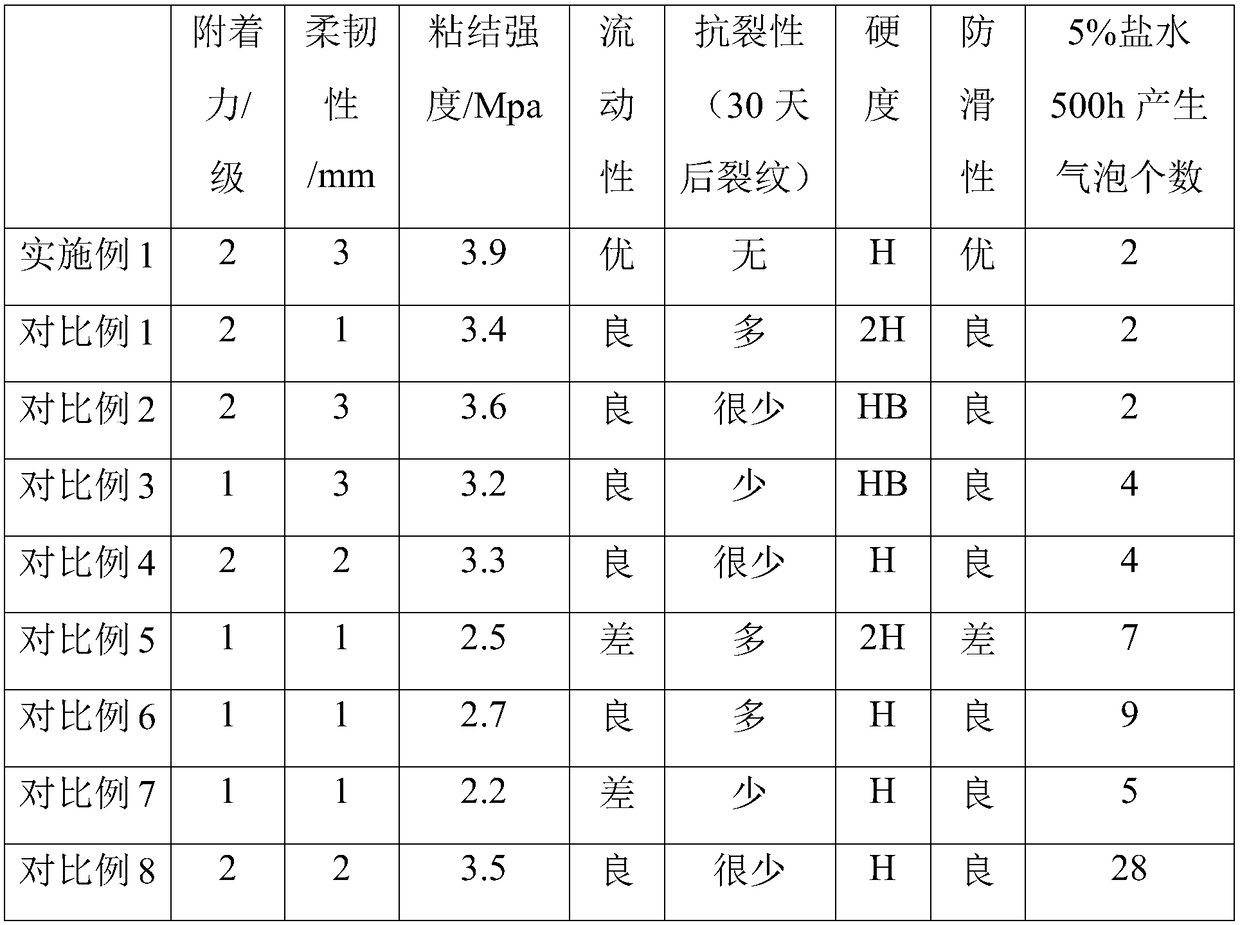

[0124] The environmental protection anticorrosion wear-resisting luminescent marking paint that embodiment 1 and comparative example 1-8 are produced carry out performance test, and the result is as follows table 1

[0125]

experiment example 2

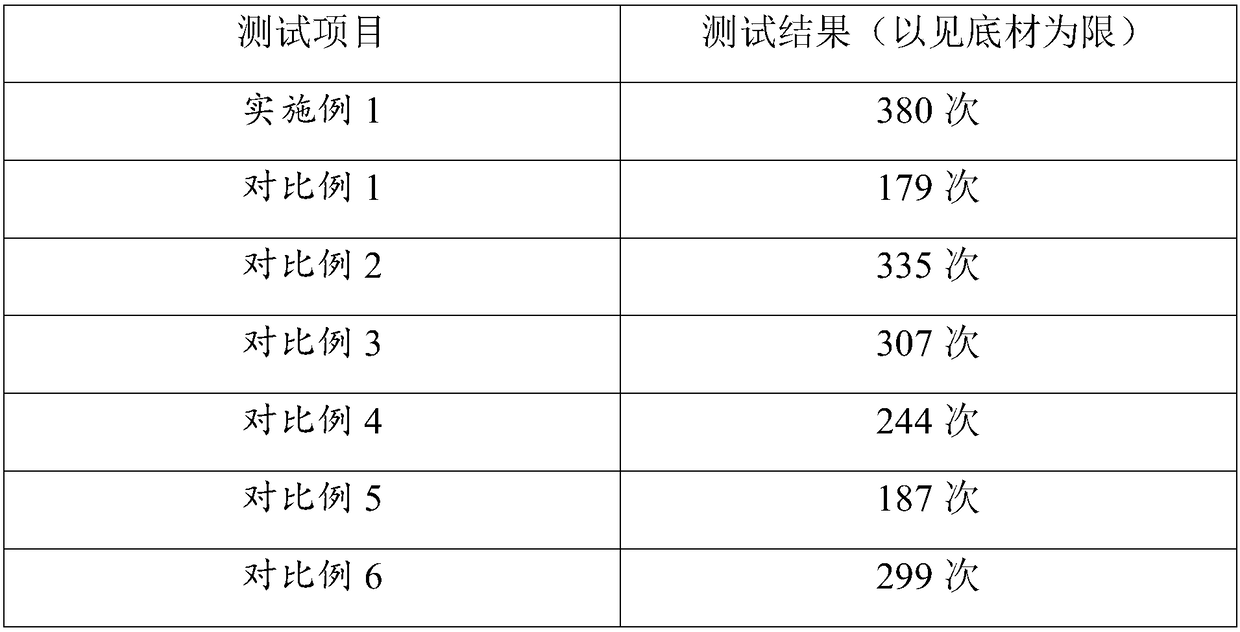

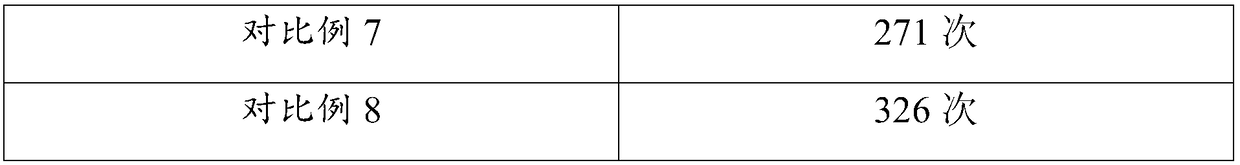

[0127] The marking paint corresponding to Example 1 and Comparative Examples 1-8 was rubbed on the paper tape, and the wear resistance test of the product was carried out by the RCA wear tester under the load parameter of 175g force, and the results are shown in Table 2

[0128]

[0129]

[0130] It has been verified by experiments that the environmentally friendly anti-corrosion and wear-resistant luminescent marking paint in Example 1 has better performance than Comparative Examples 1-8, with good adhesion, high toughness, high strength, and good impact resistance, and presents Excellent advection and anti-slip properties; among them, the wear resistance and anti-corrosion and water-resistance properties are more prominent, and the service life is longer; the production method of the environmentally friendly anti-corrosion and wear-resistant luminescent marking paint of the present invention has strict components and proportions. What is required cannot be changed at wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com