Compounded insecticidal suspension emulsion with chlorpyrifos and spirotetramat and preparation method of compounded insecticidal suspension emulsion

A technology of spirotetramat and suspoemulsion, applied in the directions of insecticides, botanical equipment and methods, biocides, etc., can solve the problems of compounding chlorpyrifos and spirotetramat, and achieve the solution of drug resistance and duration of effect , The effect of lower cost and qualified physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

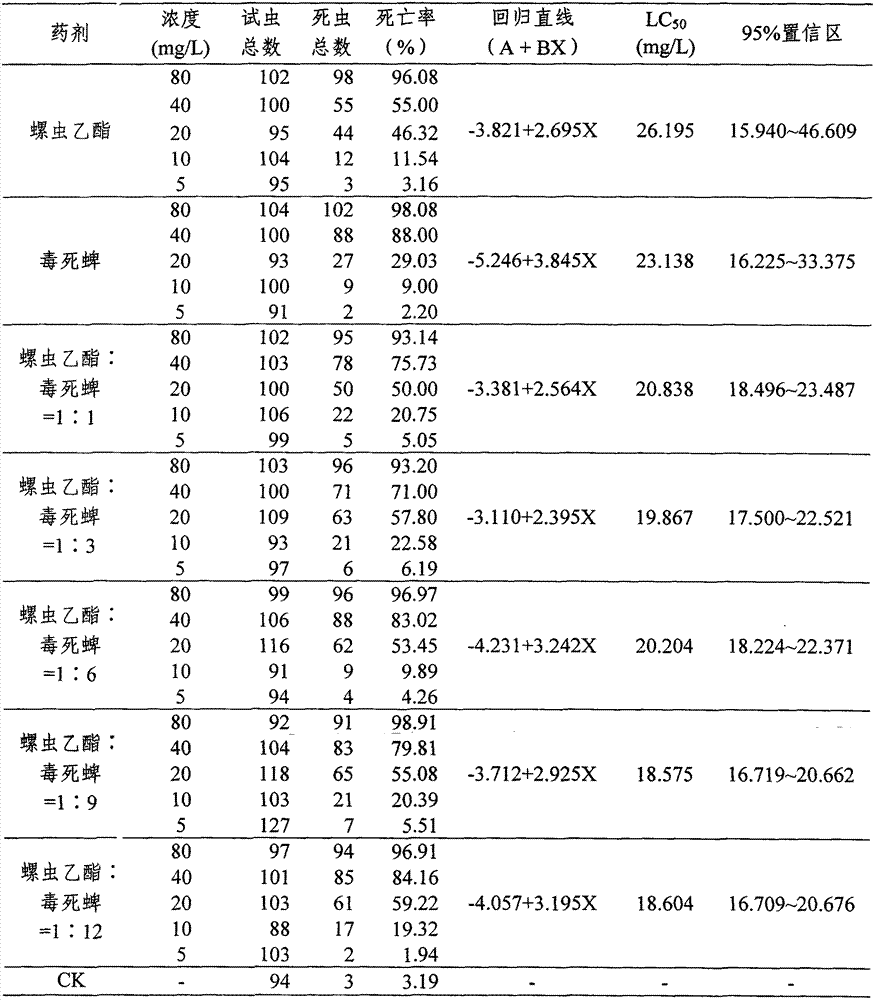

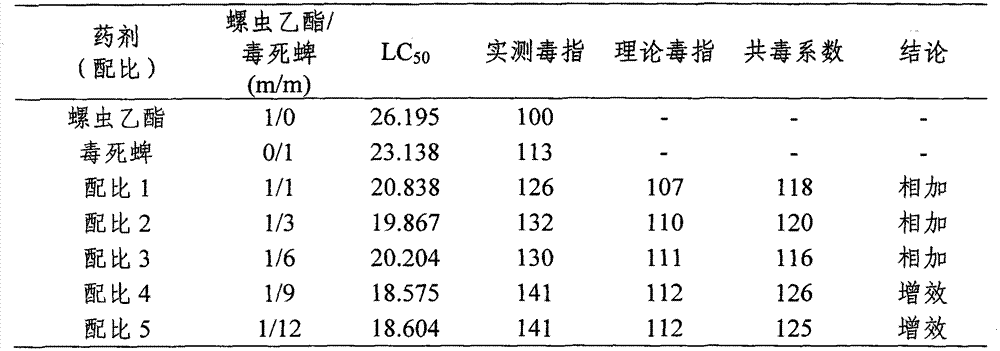

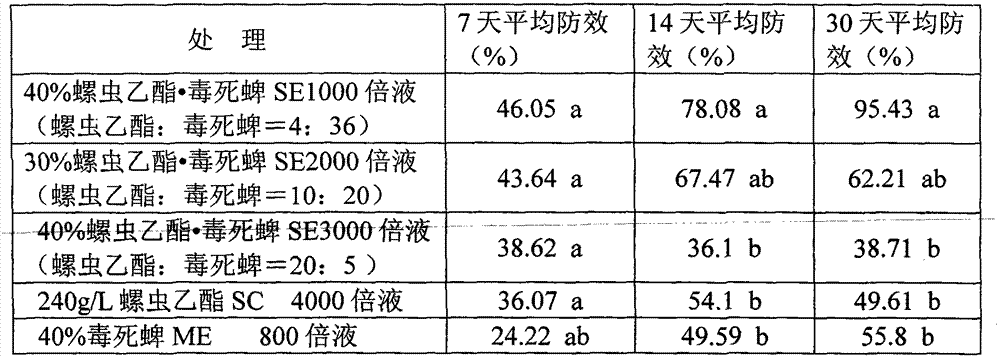

Method used

Image

Examples

Embodiment 1

[0082] 42% active compound (2% spirotetramat and 40.0% chlorpyrifos composition): 20.0% spirotetramat, EO / PO block polyether 1%, phenolsulfonic acid condensate sodium salt 2%, acrylic acid homopolymer 1.0% sodium salt, 2.0% ethylene glycol, 0.3% xanthan gum, 0.1% polyether defoamer, and deionized water are fully mixed, and then put into high-shear homogeneous emulsifier for high-speed shearing coarse grinding and Homogenized, then pumped to a sand mill for sanding, sanded to a certain particle size, and then filtered to obtain a suspending agent. Containing 20.0% spirotetramat in suspending agent, D 90 The particle size is 3-5 microns. Then add 10% of 20.0% spirotetramat suspending agent, chlorpyrifos 40.0%, xylene 20.0%, n-butanol 3%, alkylphenol formaldehyde resin polyoxyethylene ether 4%, fatty alcohol ethoxylate 8.0%, 3.0% ethylene glycol, 0.1% xanthan gum, 0.1% polyether defoamer, and deionized water are supplemented and mixed thoroughly, sheared at high speed, homogene...

Embodiment 2

[0084] 40% active compound (5.0% spirotetramat and 35.0% chlorpyrifos composition): 25.0% spirotetramat, alkyl naphthalene sulfonate 1.0%, sodium lignosulfonate 2.0%, polymer polycarboxylate 1.0%, polyethylene glycol 400 2.0%, aluminum magnesium silicate 0.4%, polyether defoamer 0.1%, deionized water 68.6%, fully mixed, and then put into high-shear homogeneous emulsifier and high-speed shear coarse grinding and homogeneous, and then pumped to a sand mill for sand grinding to a certain particle size, and then filtered to obtain a suspending agent. Containing 25.0% spirotetramat in suspending agent, D 90 The particle size is 3-5 microns. Then 20.0% of 25.0% spirotetramat suspension concentrate, chlorpyrifos 35.0%, No. 1800 solvent 10.0%, isobutanol 5%, castor oil polyoxyethylene ether 3.0%, fatty alcohol alkoxylate 3.0%, polyethylene glycol Diol 3.0%, aluminum magnesium silicate 0.3%, polyether defoamer 0.1%, deionized water to 100%, fully mixed, high-speed shearing, homogeneo...

Embodiment 3

[0086] 30% active compound (10.0% spirotetramat and 20.0% chlorpyrifos composition): 40.0% spirotetramat, 2.0% fatty alcohol polyoxyethylene ether, 3.0% sodium methylnaphthalenesulfonate formaldehyde condensate, methylene 1.0% sodium dinaphthalene sulfonate, 2.0% propylene glycol, 0.6% sodium carboxymethylcellulose, 0.1% polyether defoamer, 51.5% deionized water, fully mixed, and then put into high-shear homogeneous emulsifier at high speed Shear coarse grinding and homogenization, then pump to the sand mill for sanding, sanding to a certain particle size, and then filter to obtain the suspending agent. 40% spirotetramat in suspension, D 90 The particle size is 3-5 microns. Then 25.0% of 40.0% spirotetramat suspension concentrate, chlorpyrifos 20.0%, No. 1500 solvent 10.0%, tallow ethoxylated ammonium salt 3.0%, alkylphenol polyoxyethylene ether 4.0%, propylene glycol 2.0%, carboxymethyl 0.3% sodium cellulose, 0.1% polyether defoamer, and 35.6% deionized water are fully mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com