Cream puff and production method thereof

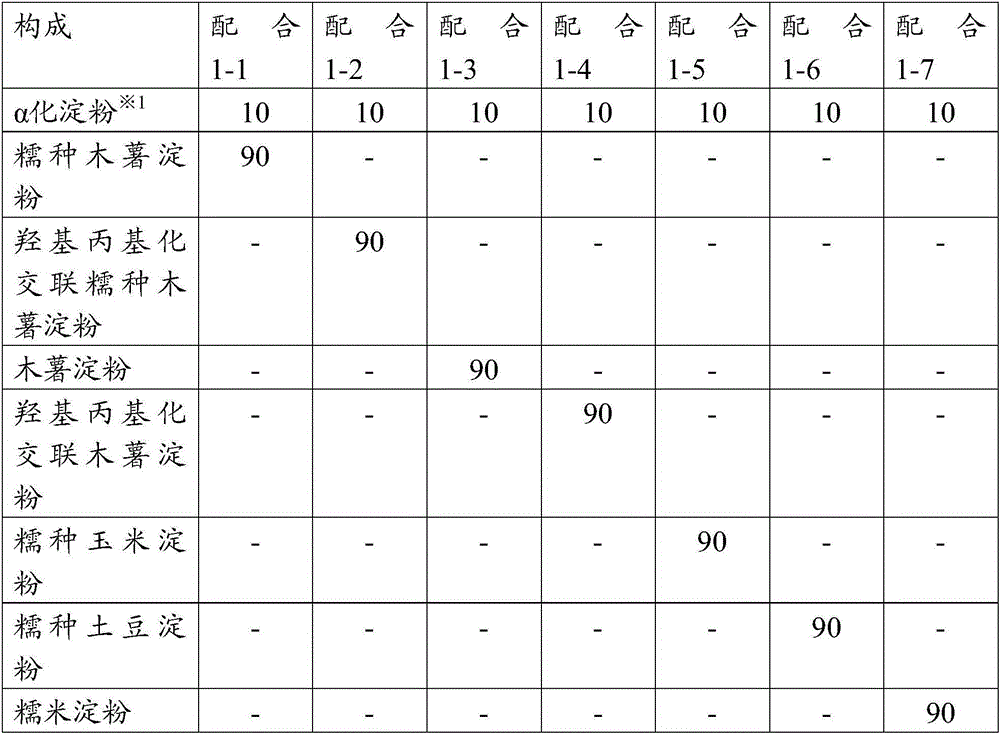

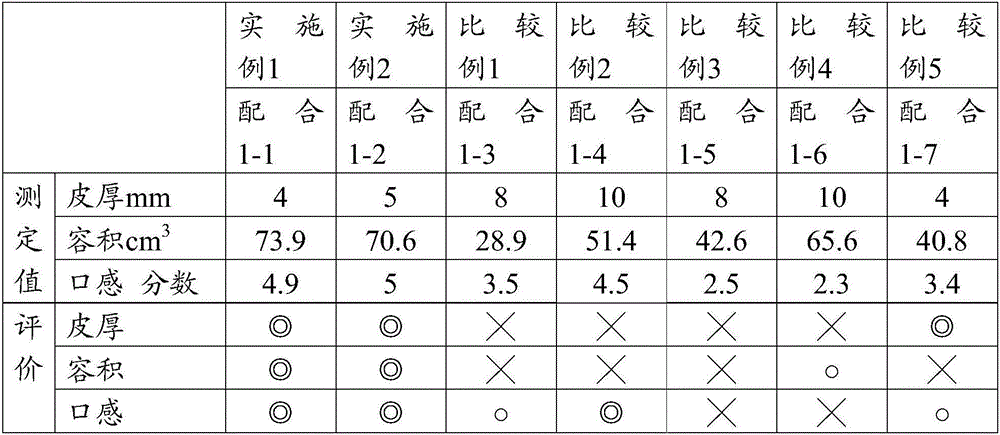

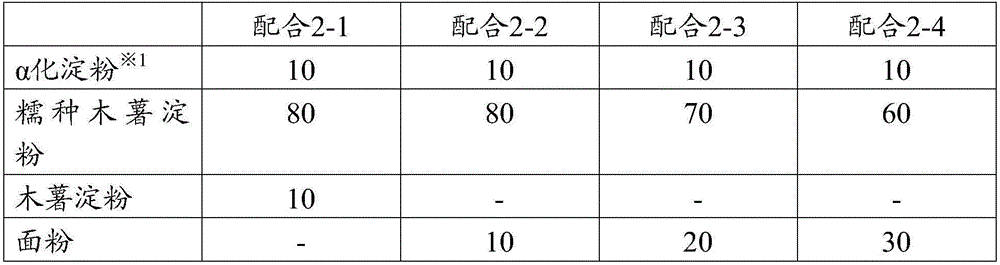

A technology of puff and puff production, which is applied in baked food, baking, food science, etc. It can solve the problems of difficult to chew puff puff pastry, puff puff pastry is easy to become thick, and puff puff pastry is thin, etc. Achieve the effect of excellent sticky and waxy taste, simple sticky and waxy taste, and thin puff puff pastry

Active Publication Date: 2017-04-19

MATSUTANI CHEM INDS CO LTD +1

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it is described that the donut has a sticky texture, there is a problem that when the hydroxypropylated tapioca starch described as a preferable starch is applied to the puff dough, the volume of the puff does not increase sufficiently, The puff puff pastry tends to become thicker. If you use this puff to make cream puffs, it is difficult to break the puff puff pastry. When you bite the puff puff pastry, the cream contained in it will easily escape and it is difficult to eat

However, although it is a method for obtaining puffed foods with good puffing properties, none of the puffed foods described in this patent document exhibits a glutinous texture, and the disclosed method is not suitable as a method for manufacturing puffs with a glutinous texture.

[0008] As described above, in recent years, various methods have been disclosed as methods for producing puffs. However, according to the recent trend of consumers who like chewy texture (sticky texture), puffs are also required to have a sticky texture. Among them, there has not been provided a method for easily producing puffs with excellent glutinous texture, large volume, thin puff skin and easy to eat.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0061] [Evaluation method]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

According to the present invention, a starchy raw material to be contained in cream puffs contains, with respect to 100 parts by mass of the starchy raw material: (A) 70-92 parts by mass of a starch having an amylopectin content of 80 mass% or higher, and (B) 8-20 parts by mass of a pregelatinized starch so as to satisfy A+B<=100 parts by mass; or (A) 70-92 parts by mass of the starch having an amylopectin content of 80 mass% or higher, and (B) 8-20 parts by mass of the pregelatinized starch so as to satisfy A+B<100 parts by mass, wherein, as the remaining portion of the starchy raw material, (C) 22 parts by mass or less of a grain flour is blended, and at least 8 parts by mass of the starch having an amylopectin content of 80 mass% or higher is a glutinous tapioca starch. Cream puff dough is prepared by using this starchy raw material as the starchy raw material for cream puff production, and cream puffs having an excellent rice-cake texture, a large volume, and a thin puff shell are produced by using the dough and are provided.

Description

technical field [0001] The present invention relates to puffs (シューパフ) with excellent chewy texture (glutinous texture: glutinous texture like a rice-cake just making), large volume, and thin skin, and their Production method and puff dough (シュー生地) and mixed powder for the puff. Here, "choux pastry" is a "puff pastry" made by expanding and cooking choux pastry dough, also called "choux pastry". Background technique [0002] Cream puffs (シュークリーム), which are filled with cream in puffs (puff shells), are one of the favorite foods around the world because they can be eaten easily. So far, puffs (puff meringue), which make up the skin of cream puffs, are basically boiled by adding water and fat, gelatinized by adding flour, slowly adding eggs to adjust the hardness, and extruding to It is manufactured by putting it on a flat plate and putting it into an oven and roasting. In order to make the shape, size and taste of the baked product consistent, it only depends on the experienc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A21D13/30A21D2/18A21D2/36

CPCA21D2/186A21D2/36

Inventor 浦上淳一菅野祥三L·维拉沃特K·阿卡莫尔

Owner MATSUTANI CHEM INDS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com