Sodium doped graphite phase carbon nitride prepared by one-step synthesis and application thereof

A graphite phase carbon nitride and sodium doping technology, which is applied in nitrogen compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of complex process and high energy consumption, and achieve simple process, high efficiency and high-efficiency production method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

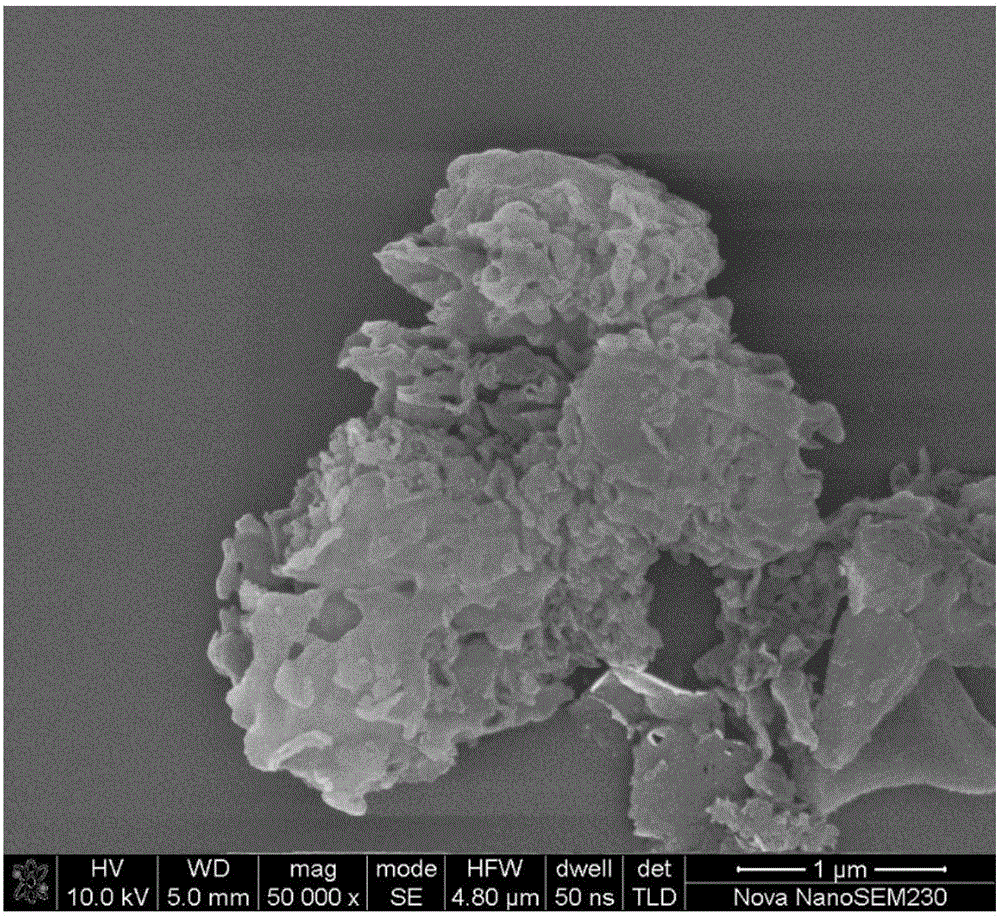

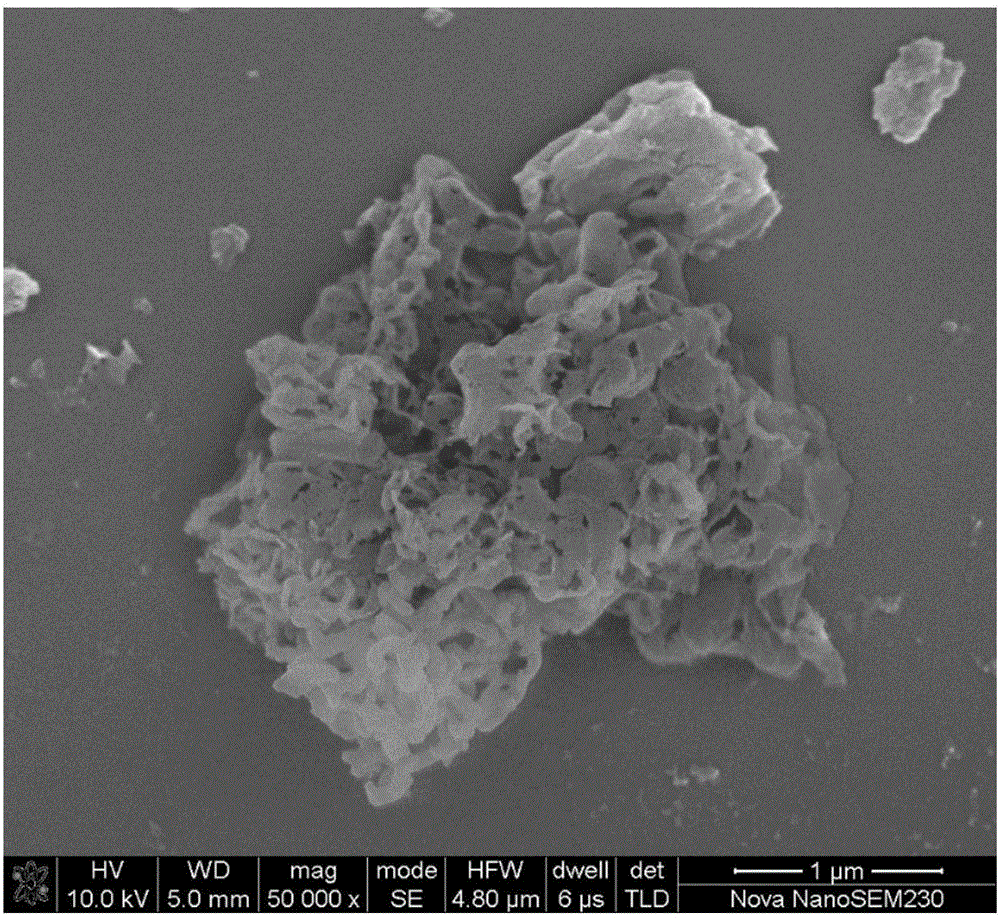

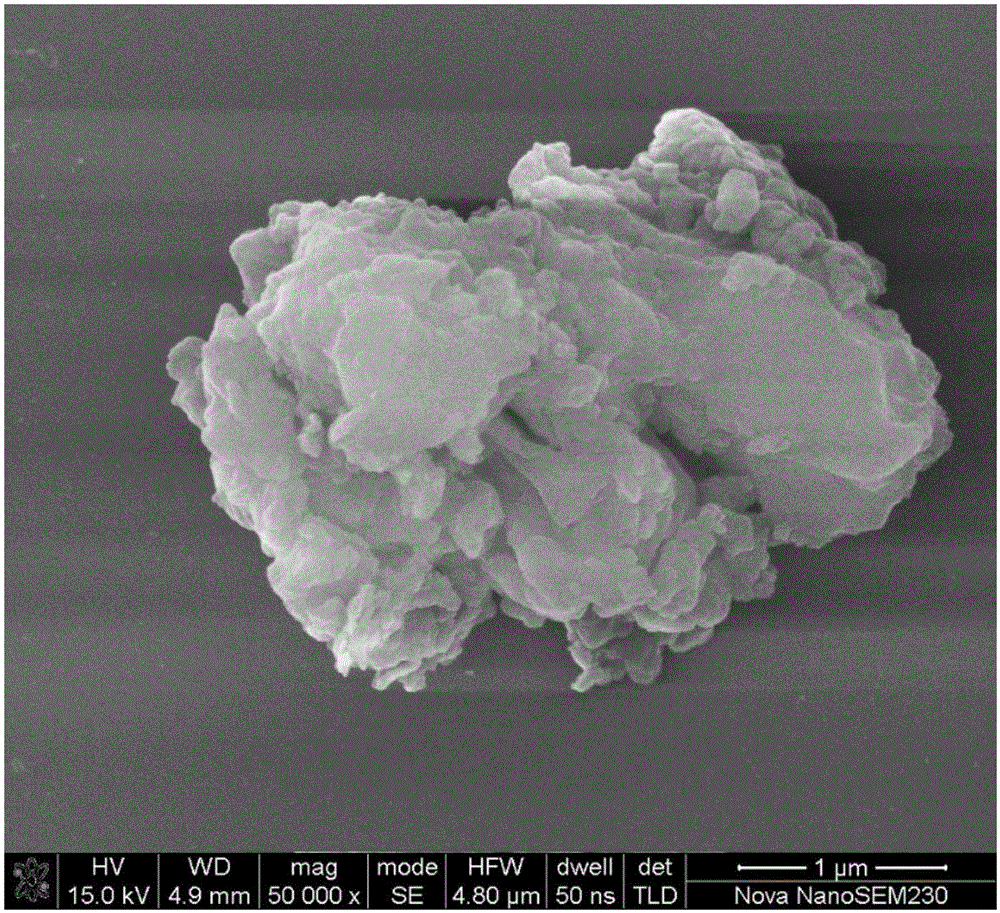

[0034] Weigh 8g of melamine with an electronic balance and put it into the ball mill jar, weigh 2g of sodium bicarbonate into the ball mill jar, add 10g of balls with a diameter of 4mm and 20g of balls with a diameter of 1cm, then tighten the ball mill jar and put it on the ball mill , set the rotating speed of 150r ball mill for 8h. After the ball milling is completed, put the ball abrasive into the alumina dry bed and cover it, raise the temperature in the muffle furnace to 550°C at 4°C / min, keep it for 4h, cool the furnace to room temperature, and take out the products with a volume fraction of 3%. Nitric acid deionized water and ethanol were washed twice, and then dried in a constant temperature drying oven at 60°C. After drying, it was taken out and ground, and sample 1 was marked and stored for subsequent testing.

[0035] The performance test of the prepared sodium-doped graphite-phase carbon nitride catalyst for visible light is as follows: add 10 mg of the prepared ca...

Embodiment 2

[0037] Weigh 10g of melamine with an electronic balance and put it into the ball mill, weigh 2g of sodium bicarbonate and put it into the ball mill, add 10g of balls with a diameter of 4mm and 20g of balls with a diameter of 1cm, then tighten the ball mill and put it on the ball mill , set the rotating speed of 150r ball mill for 8h. After the ball milling is completed, put the ball abrasive into the alumina dry bed and cover it, raise the temperature in the muffle furnace to 550°C at 4°C / min, keep it for 4h, cool the furnace to room temperature, and take out the products with a volume fraction of 3%. Nitric acid deionized water and ethanol were washed twice, and then dried in a constant temperature drying oven at 60 degrees Celsius. After drying, it was taken out and ground, marked as sample 2, and stored for subsequent testing.

[0038] The performance test of the prepared sodium-doped graphite-phase carbon nitride catalyst for visible light is as follows: add 10 mg of the p...

Embodiment 3

[0040] Weigh 14g of melamine with an electronic balance and put it into the ball mill, weigh 2g of sodium bicarbonate and put it into the ball mill, add 14g of balls with a diameter of 4mm and 28g of balls with a diameter of 1cm, then tighten the ball mill and put it on the ball mill , set the rotating speed of 150r ball mill for 8h. After the ball milling is completed, put the ball abrasive into the alumina dry bed and cover it, raise the temperature in the muffle furnace to 550°C at 4°C / min, keep it for 4h, cool the furnace to room temperature, and take out the products with a volume fraction of 3%. Nitric acid deionized water and ethanol were washed twice, and then dried in a constant temperature drying oven at 60 degrees Celsius. After drying, it was taken out and ground, marked as sample 4, and stored for subsequent testing. The specific surface area of sample 4 is 7m 2 / g. The molar ratio of sodium to nitrogen in the finished product is 0.059:1.

[0041]The performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com