Preparation method of mulberry leaf metallothionein

A technology of metallothionein and mulberry leaves, which is applied in the fields of biotechnology and protein engineering, can solve problems such as impurity, and achieve the effects of high recovery rate, large processing capacity, high yield and stable expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

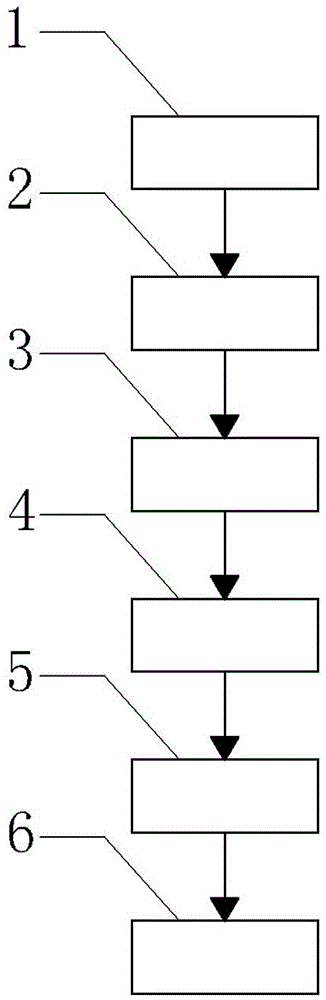

[0028] It can be seen from the content of the invention that a mulberry leaf metallothionein is extracted from mulberry leaf protein 1, constructed protein fusion vector expression 2, biofilm separation 3, directional metal ion slow release 4, enzymatic cleavage and elution 5, purified and freeze-dried 6 six steps to complete its preparation method;

[0029] Mulberry leaf protein extraction 1: The mulberry leaf slurry obtained by pretreatment of mulberry leaf raw materials is homogenized with Tirs-HCl buffer solution, the mulberry leaf slurry is evenly heated to 90°C and cooled to 65°C, and then a certain proportion of 2- The mixture of hydroxypropionic acid and ethanol is used to heat and precipitate mulberry leaf protein, and observe after standing for 45 minutes. The resulting precipitated part is mulberry leaf crude protein;

[0030] Construction of protein fusion vector expression 2: The mulberry leaf crude protein obtained through the above step 1 of mulberry leaf protei...

Embodiment 2

[0044] 100kg of fresh mulberry leaves were selected, and the mulberry leaf slurry was obtained through raw material pretreatment processes such as beating and juice pressing, and was homogenized with Tirs-HCl buffer solution and purified water at a ratio of 1:100. Heated at 90°C and cooled to 60°C. Then prepare and add a certain proportion of 2-hydroxypropionic acid and ethanol mixture for precipitation, the precipitated part is mulberry leaf crude protein; the content of mulberry leaf protein is determined by Bradford method; construct protein fusion vector expression, set the target product model device, and then Using the principle of molecular sieve hydrothermal conversion method, through adsorption, remove macromolecular organic matter, fractionally precipitate small molecular protein, and obtain MT small molecular protein solution mixture; through biofilm solid-liquid separation, concentration and other processes to obtain the target product MT protein concentrated liquid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com