Method for producing whole ginkgo powder

A production method and ginkgo technology, applied in application, food preparation, food science, etc., can solve the problems of waste water discharge, unfriendly natural environment, large equipment investment, etc., and achieve ecological and environmental friendliness, efficient production method, and rehydration performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

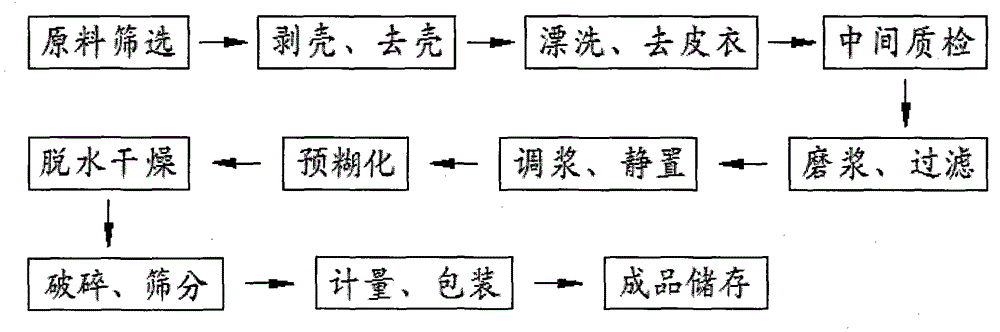

Image

Examples

Embodiment 1

[0035] Embodiment 1 A kind of production method of whole powder of ginkgo fruit of the present invention, it is carrying out the processing step of continuous large-scale production of whole powder of ginkgo fruit and the technological condition of this procedure:

[0036] Raw material screening process: Use a raw material sieve to sieve fresh ginkgo into three grades of ginkgo: ≥310 grains / kg, ≤310 grains / kg~≥400 grains / kg and ≤400 grains / kg, and divide the ginkgo according to the size of the fruit Separate shelling according to the specification can ensure the quality and high efficiency of shelling operation;

[0037] Shelling and shelling process: it is to continuously and evenly put fresh ginkgo fruits of the same size into the sheller to remove the outer hard shell and part of the leather;

[0038] Rinsing and peeling process: the peeled ginkgo nuts are continuously and evenly put into the leather cleaning tank, the leather is removed by sedimentation, and the ginkgo ker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com