Axial vibration damping system for stayed cable, stayed cable equipped with the system and manufacturing method thereof

A manufacturing method and system technology, applied in the direction of bridge construction, bridge parts, building components, etc., can solve the problems of difficulty in suppressing large-amplitude vibration of long cables, little effect of suppressing and weakening, and limited energy consumption, achieving compact structure, Convenient construction and good vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

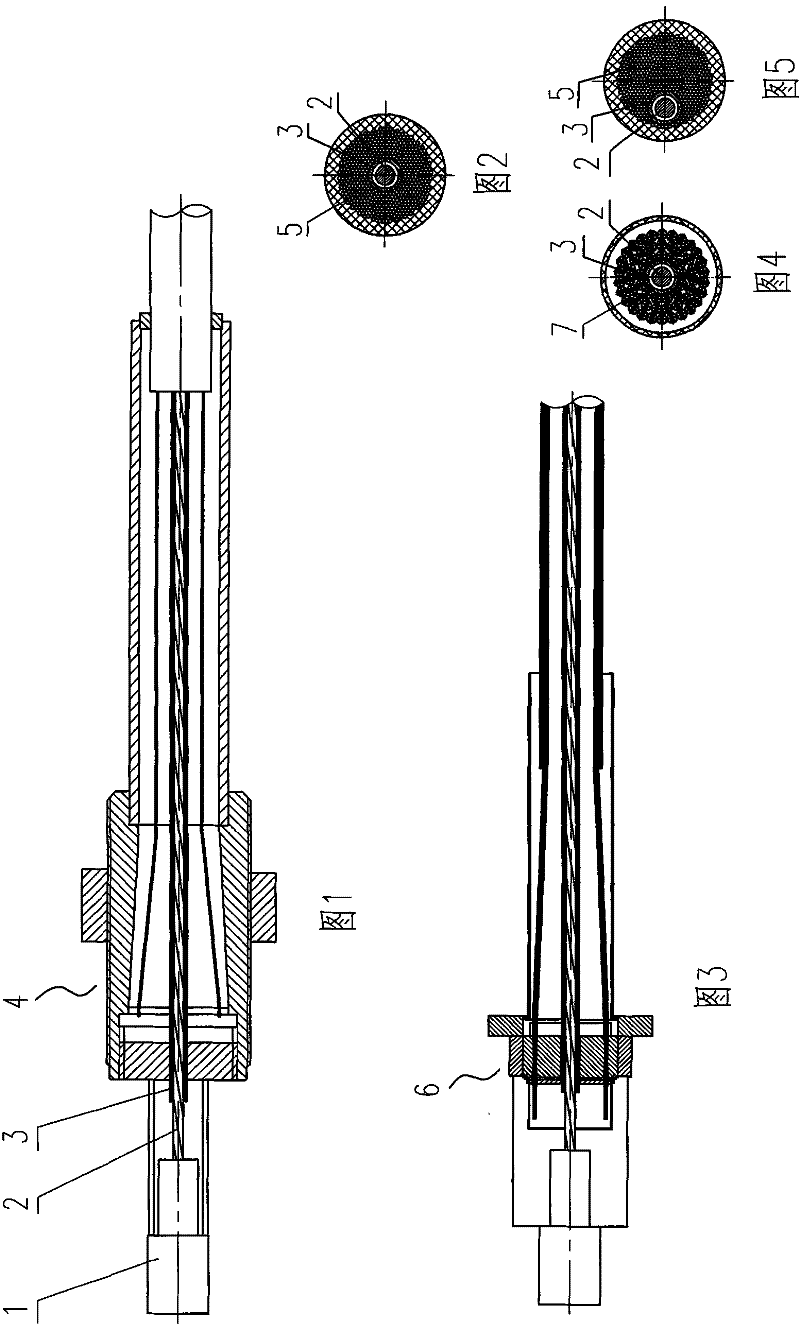

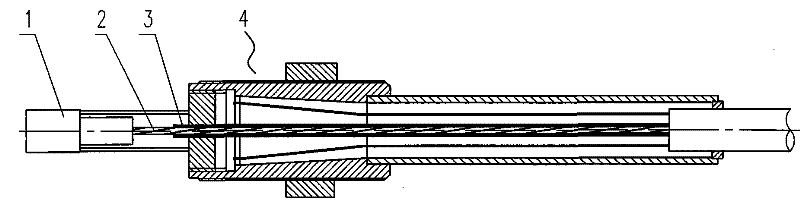

[0027] An axial damping system for a cable, comprising a shock absorber 1, a damping cable 2 and a damping cable sleeve 3, the vibration damping cable 2 is installed in the vibration damping sleeve 3, and can be installed in the vibration damping sleeve 3 Free to expand and contract, one end of the damping cable 2 is connected with a shock absorber 1, and the other end is not equipped with a shock absorber, but is anchored together with the cable body or on the fixed structure of the bridge, and the shock absorber 1 is fixed on the cable system 4 On the anchorage end or on the fixed structure of the bridge (see figure 1 ).

[0028] The damping cable 2 is a cable body with a certain tensile capacity, a certain rigidity, and a certain flexibility. It is either a large-diameter steel strand, or a cable made of steel wire or steel strand. body, or a multi-segment connected steel rod.

[0029] The damping cable sleeve 3 is a hollow pipe with a certain rigidity and flexibility. Th...

Embodiment 2

[0034] A steel wire cable provided with an axial vibration damping system for a cable, comprising a steel wire cable system with a steel wire as a cable body and an axial vibration damping system for a cable, the axial vibration damping system for a cable is The axial vibration damping system for the cable including the shock absorber 1, the vibration damping cable 2 and the vibration damping cable sleeve 3 described in the first embodiment, the axial vibration damping system for the cable is axially arranged in the cable system, the The damping cable sleeve 3 of the axial vibration damping system for the cable is arranged in the center of the cable body of the parallel steel wire cable system 4 instead of the position of several steel wires in the center and is integrated with the cable body, and the vibration damping cable 2 is installed on the cable body. 3, and can freely expand and contract in the damping cable sleeve 3, both ends of the damping cable 2 are connected with ...

Embodiment 3

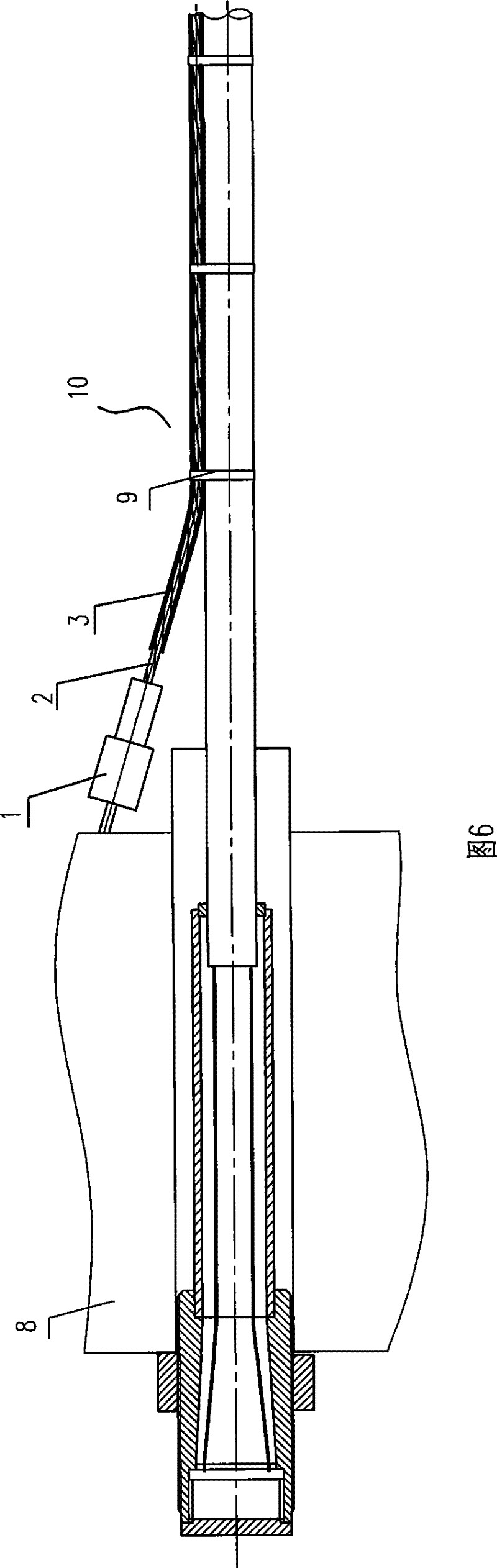

[0036] A steel strand cable provided with an axial vibration damping system for the cable, including a steel strand cable system with a steel strand as the cable body and an axial vibration damping system for the cable. The axial vibration damping system is the axial vibration damping system for the cable that includes the shock absorber 1, the vibration damping cable 2 and the vibration damping cable sleeve 3 described in the first embodiment, and the vibration damping of the axial vibration damping system for the cable Cable sleeve 3 is arranged on the cable body center of steel strand cable system 6, replaces the position of several steel strands in the center and is made into one body with the cable body (see image 3 , Figure 4), the vibration damping cable 2 is installed in the vibration damping cable sleeve 3, and can freely expand and contract in the vibration damping cable sleeve 3. The shock absorber 1 is installed, and the other end is not equipped with a shock ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com