Patents

Literature

163 results about "Indometacin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indomethacin is used to relieve pain, swelling, and joint stiffness caused by arthritis, bursitis, and tendonitis.

Composition and method for inducing mesenchymal stem cells to be differentiated to cartilage cells

The invention provides a composition and a method for inducing mesenchymal stem cells to be differentiated to cartilage cells. The composition comprises 20-80 uM of L-ascorbic acid-2-phosphate, 2-10 ng / ml of TGF beta 3, 50-150 nM of dexamethasone, 10-50 ug / ml of vitamin C, 10-50 ug / ml of proline, 0.5-5 ug / ml of indometacin, 1xITS+1premix and 0.5-10 ug / ml of chlormadinone ester. The combination when being used as an inducer of a culture medium can improve differentiation activity and differentiation directionality.

Owner:安沂华

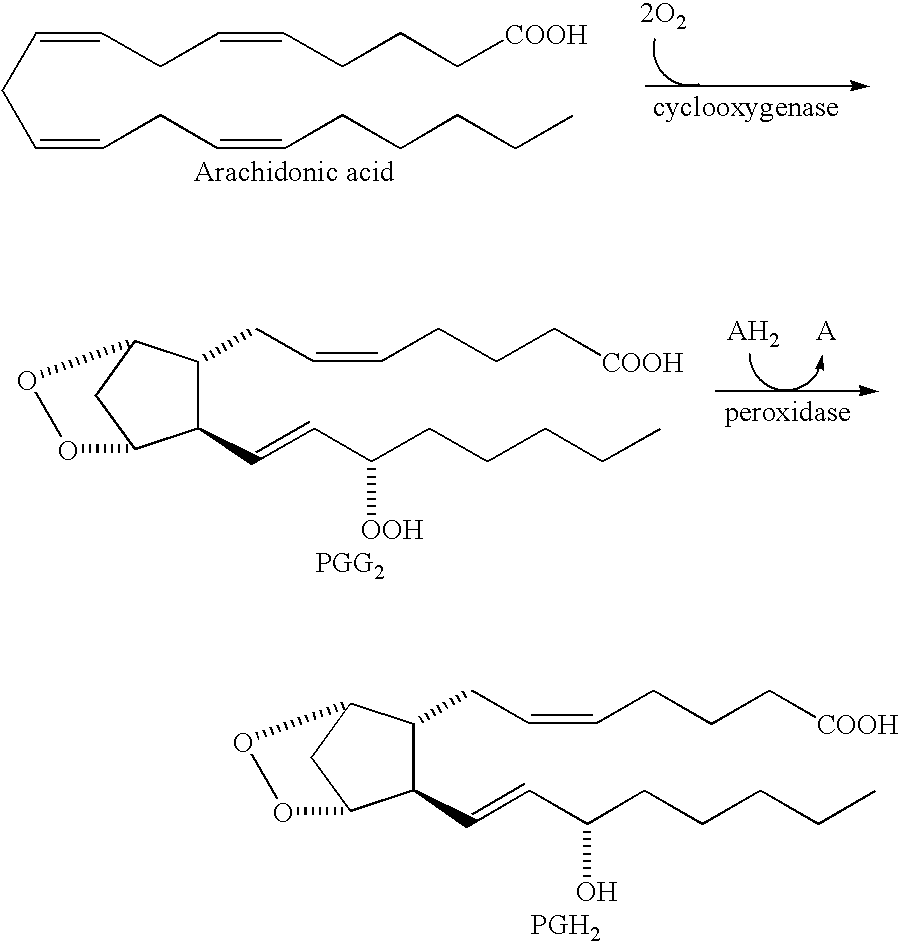

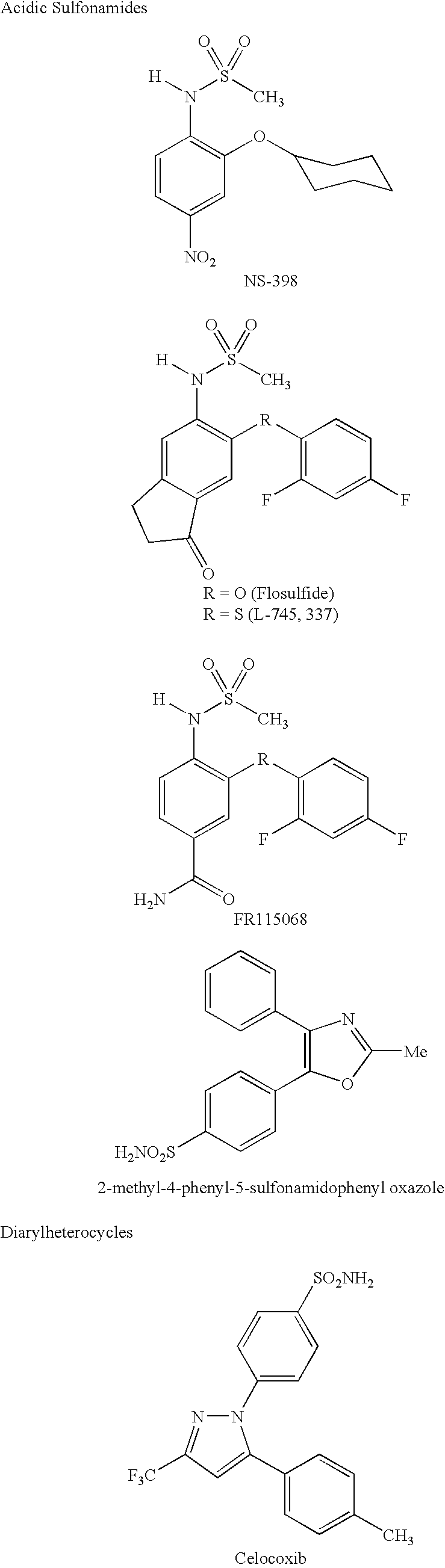

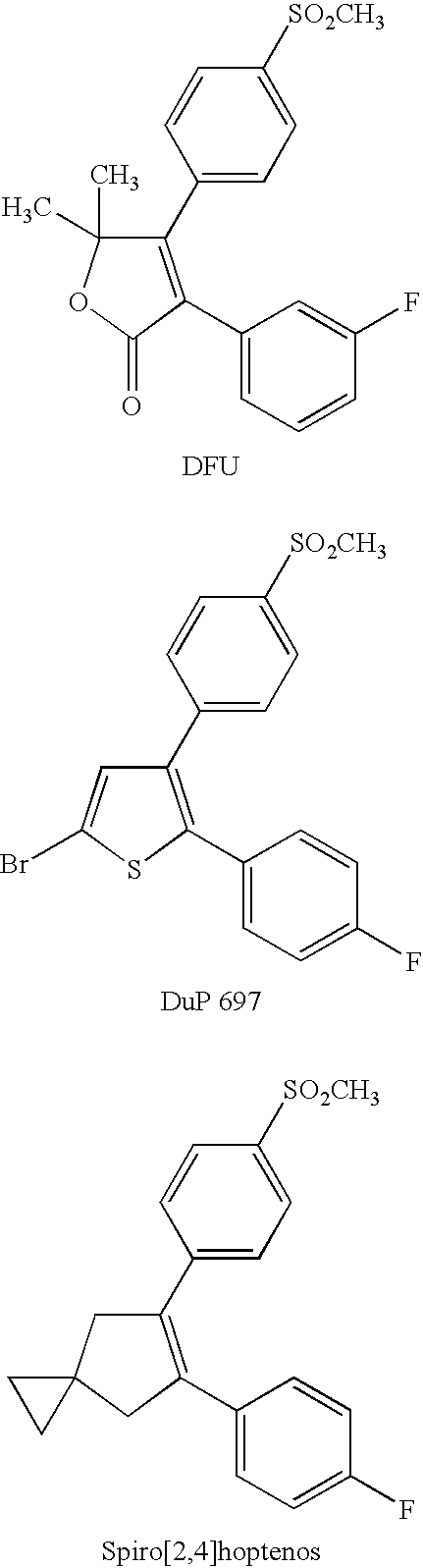

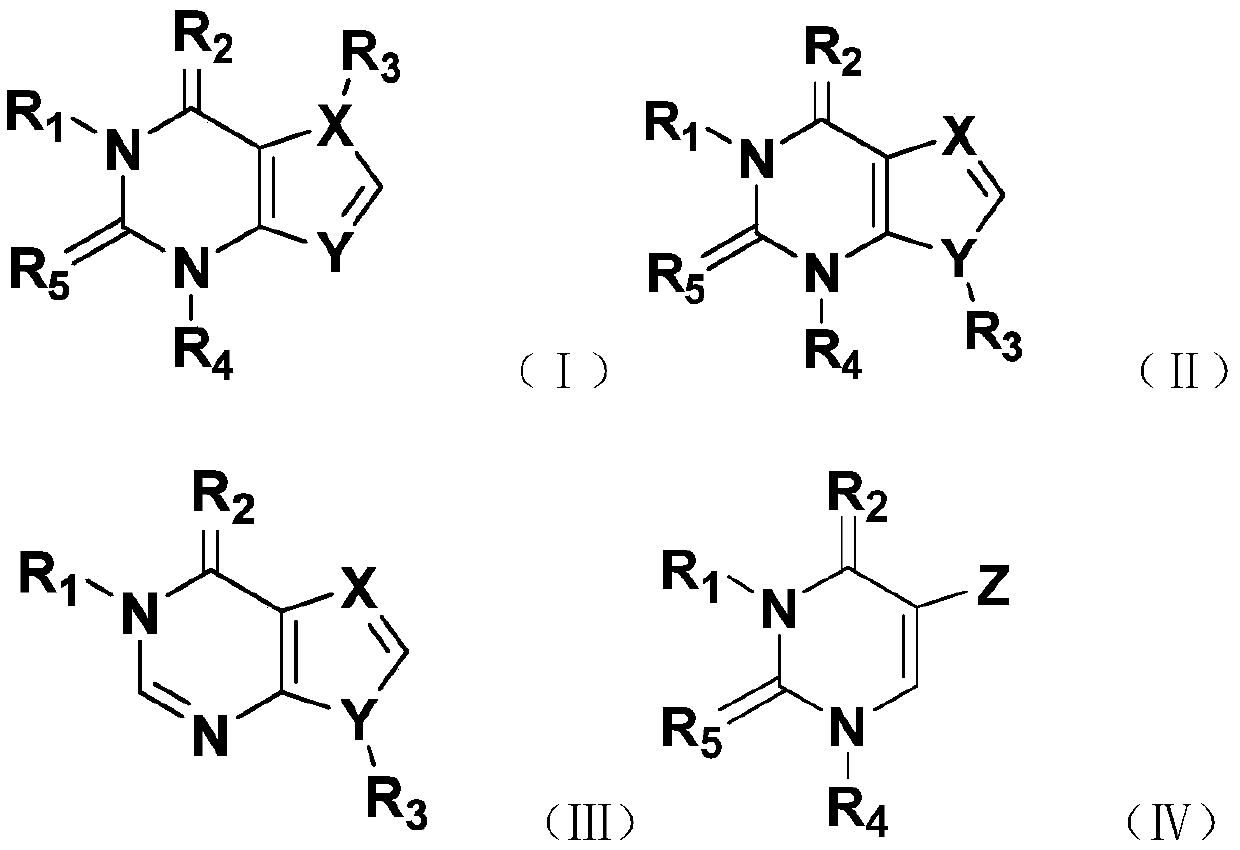

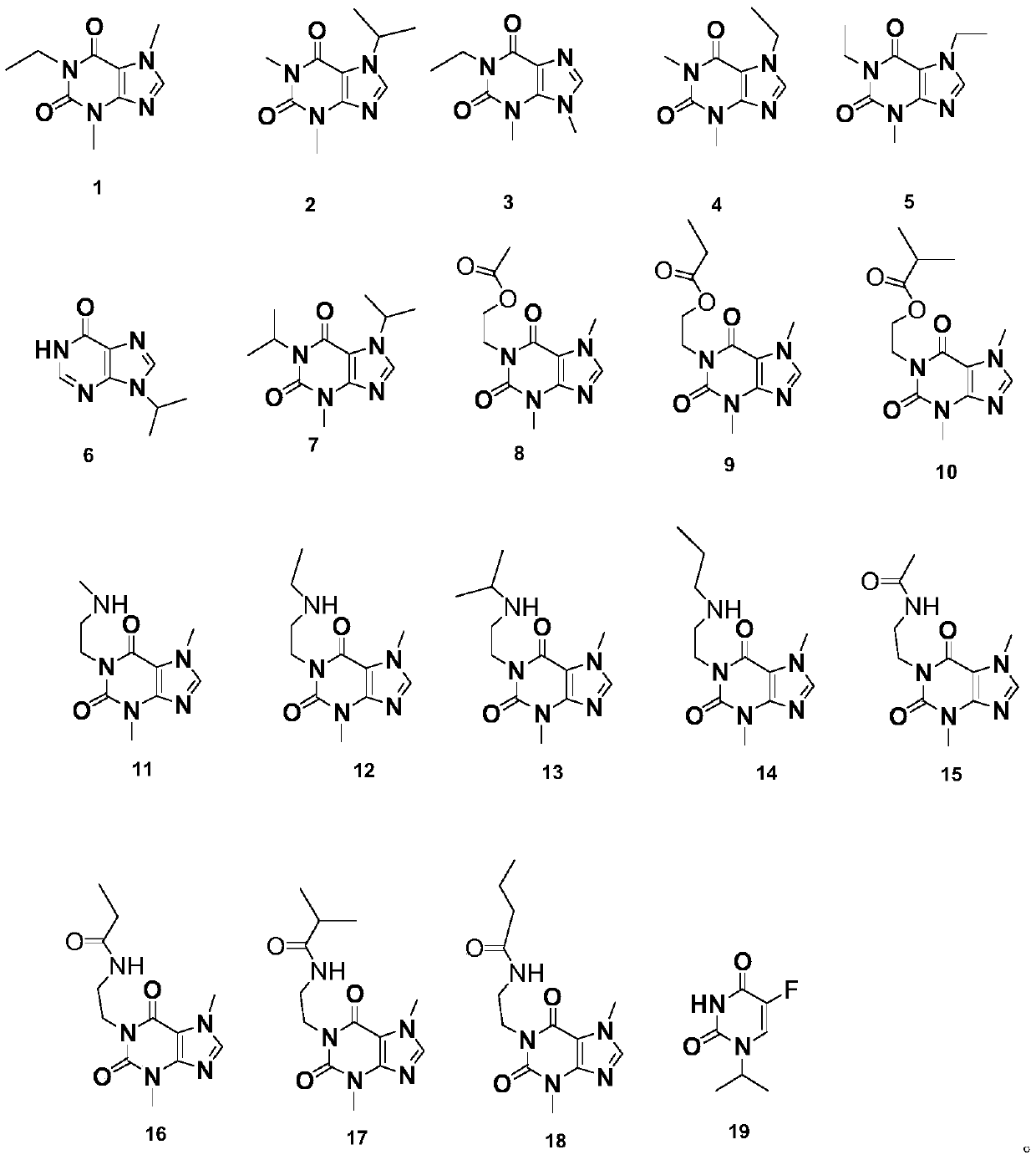

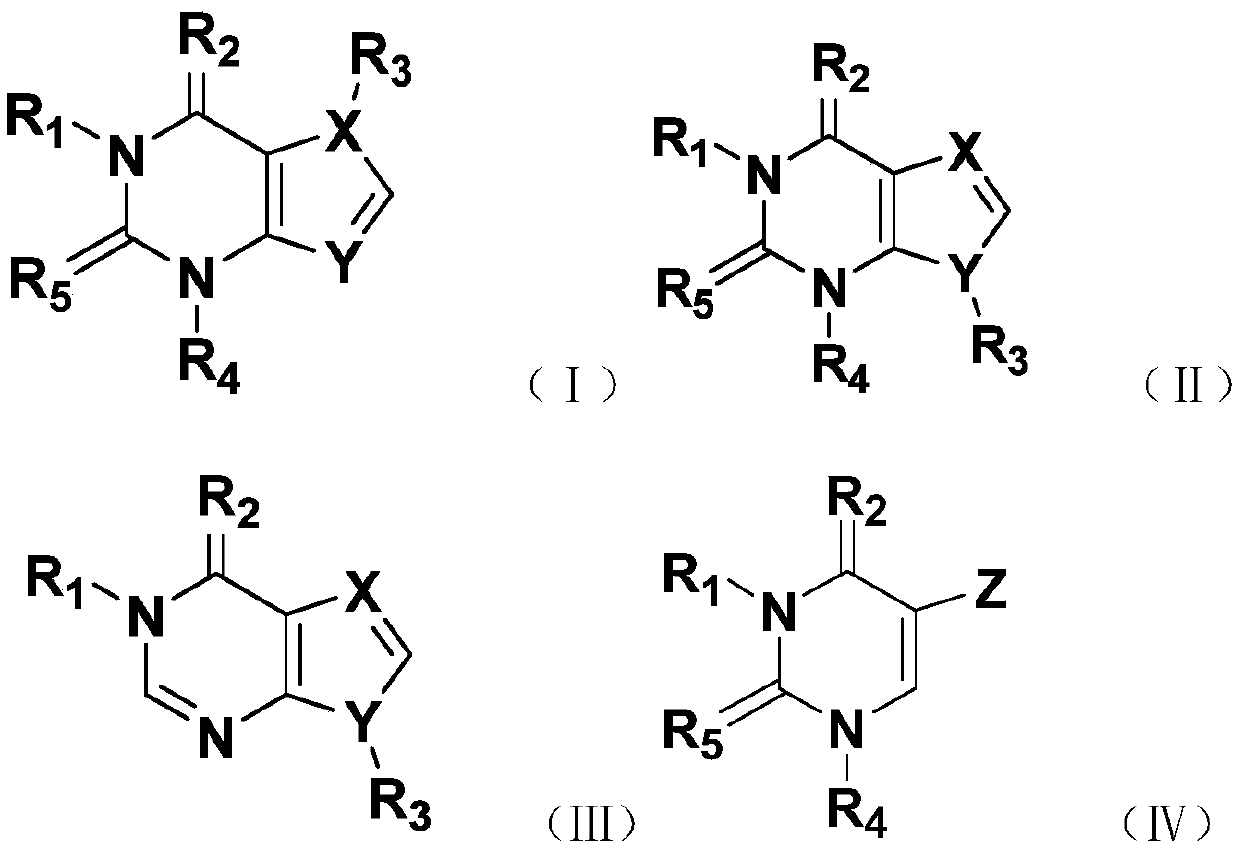

Converting cox inhibition compounds that are not COX-2 selective inhibitors to derivatives that are COX-2 selective inhibitors

InactiveUS6762182B1Generate efficientlyMinimizes and obviates GI irritationBiocideAnimal repellantsIndometacinCyclooxygenase

A method of altering specificity of cyclooxygenase-inhibiting compounds that have a COOH moiety by changing the various COOH containing compounds, such as indomethacin, into ester derivatives or into secondary amide derivatives.

Owner:VANDERBILT UNIV

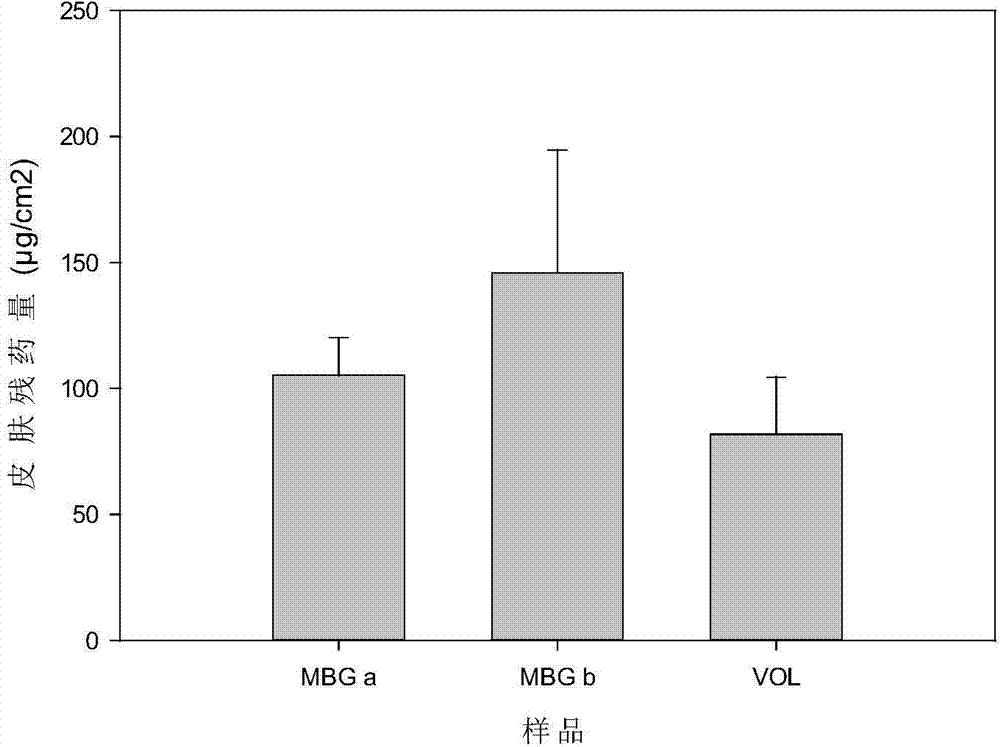

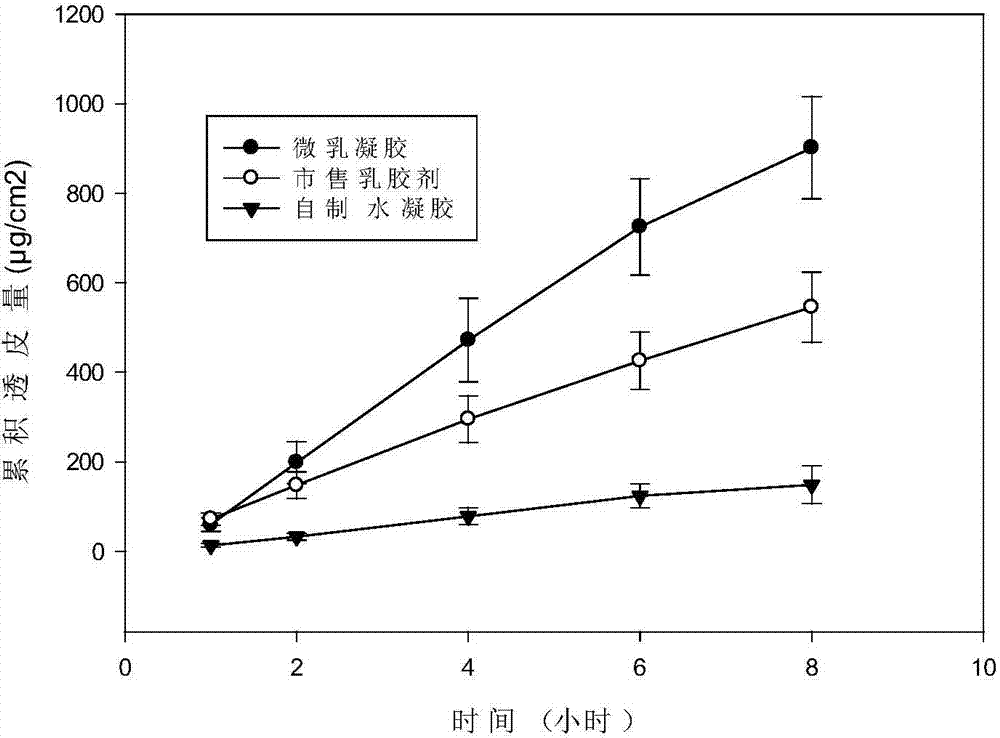

Multifunctional microemlusion gel preparation and preparation process thereof

InactiveCN103655459AImprove skin penetrationImprove performanceAntimycoticsAntipyreticIndometacinActive agent

The invention discloses a multifunctional microemlusion gel preparation and a preparation process thereof, and belongs to the technical field of medicines. The preparation mainly comprises bulk pharmaceutical chemicals (such as non-steroidal anti-inflammatory drugs-diclofenac sodium, ibuprofen, indometacin, antifungal drugs-ornidazole, antiviral drugs-ganciclovir, hormone drugs-dexamethasone, local anesthesia drugs-lidocaine and irritants-menthol), a cationic polymer and a microemlusion, can further comprise gel or a thickener, and can be used for transdermal drug delivery and local drug delivery. The preparation process is simple, convenient, good in stability and pollution-free. Compared with existing cream and gel, the preparation has the advantages that a novel action mechanism is adopted, the accumulative penetration amount of unit area of drugs is remarkably increased, a certain slow-release effect is achieved, and the drug delivery frequency and the drug delivery amount can be reduced; a chemical penetration enhancer and a conventional preservative are not added, a certain bacterial inhibition effect is achieved, the skin irritation is avoided, and the use safety of the drugs is improved.

Owner:CHINA PHARM UNIV

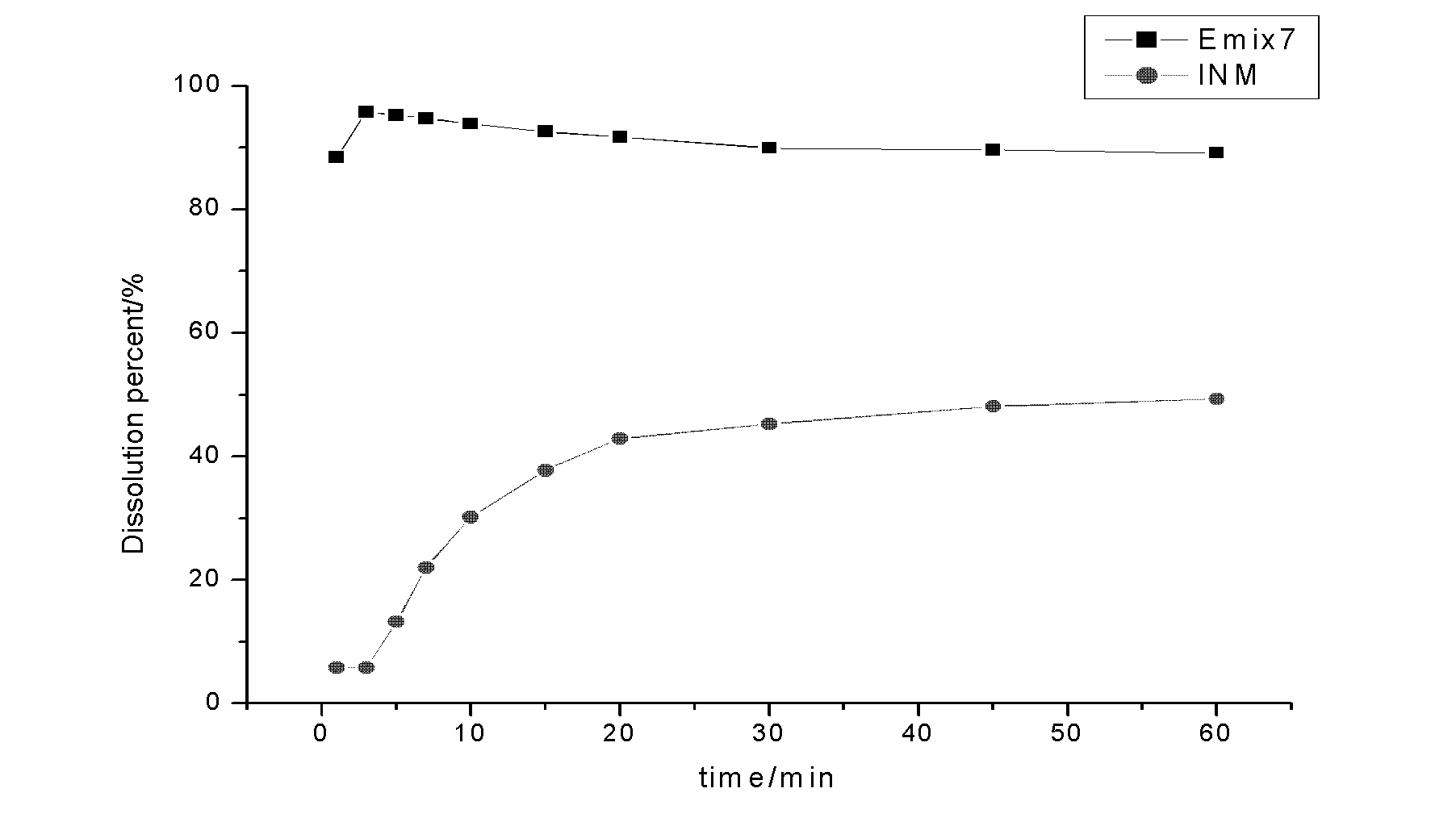

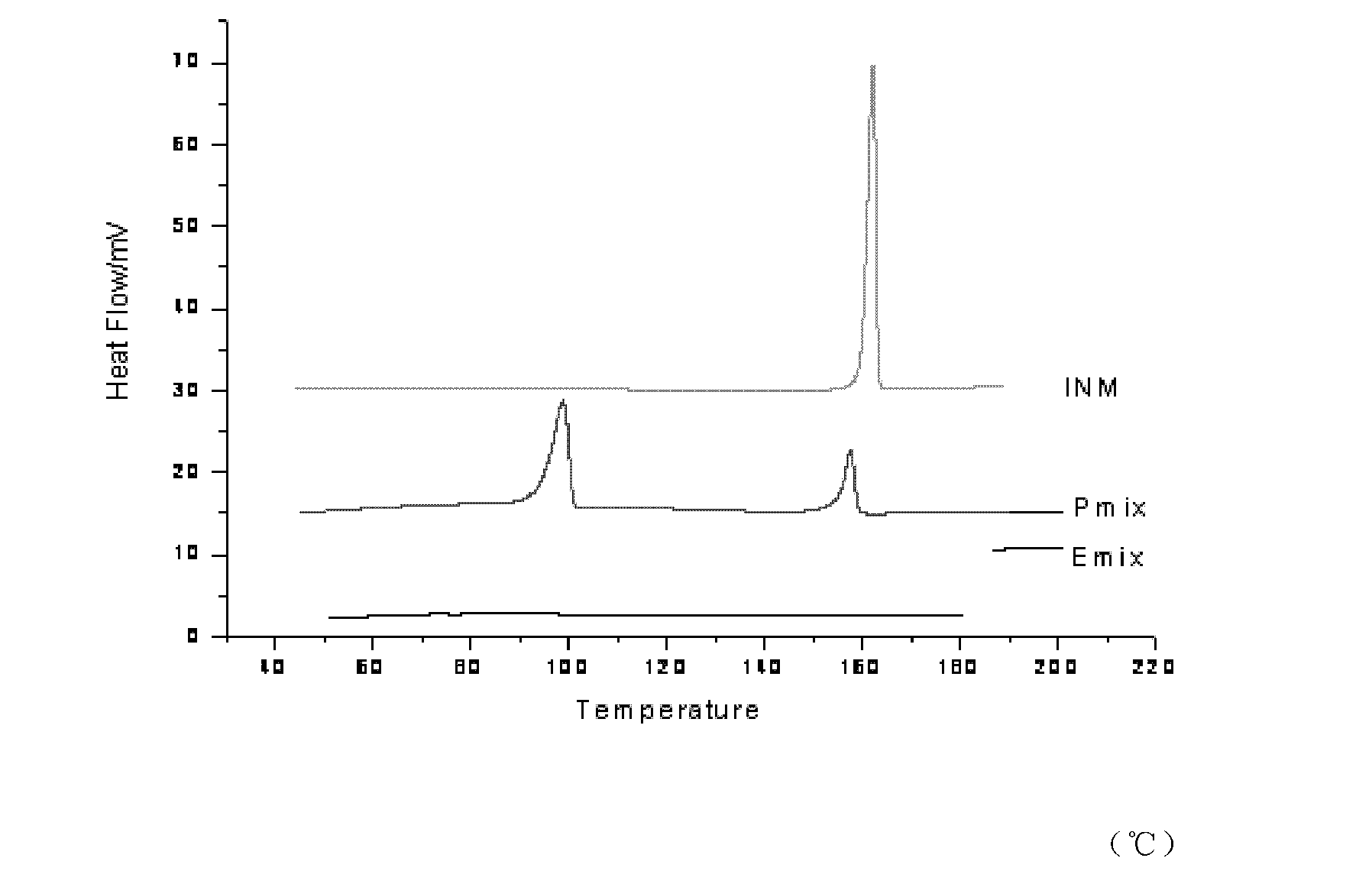

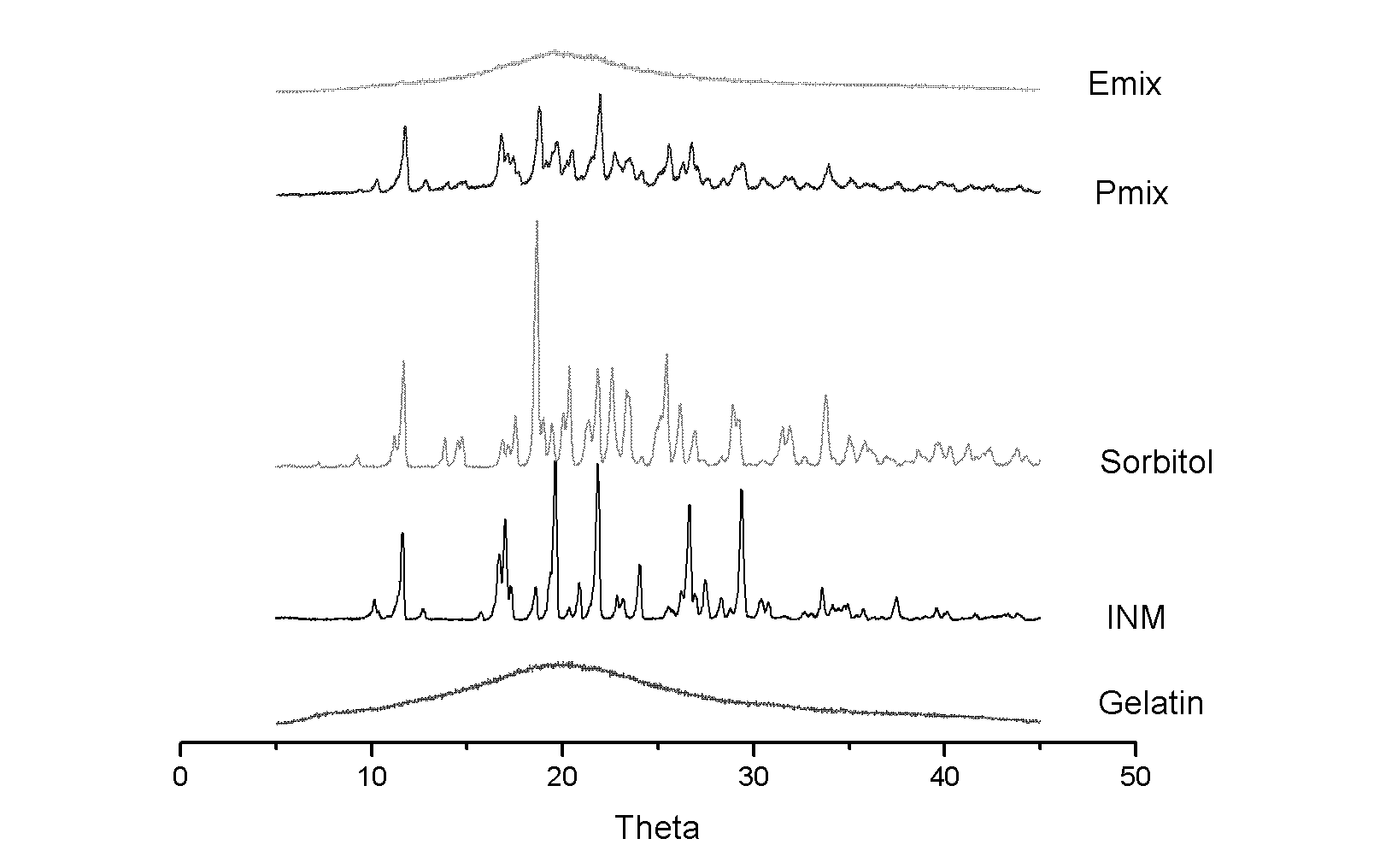

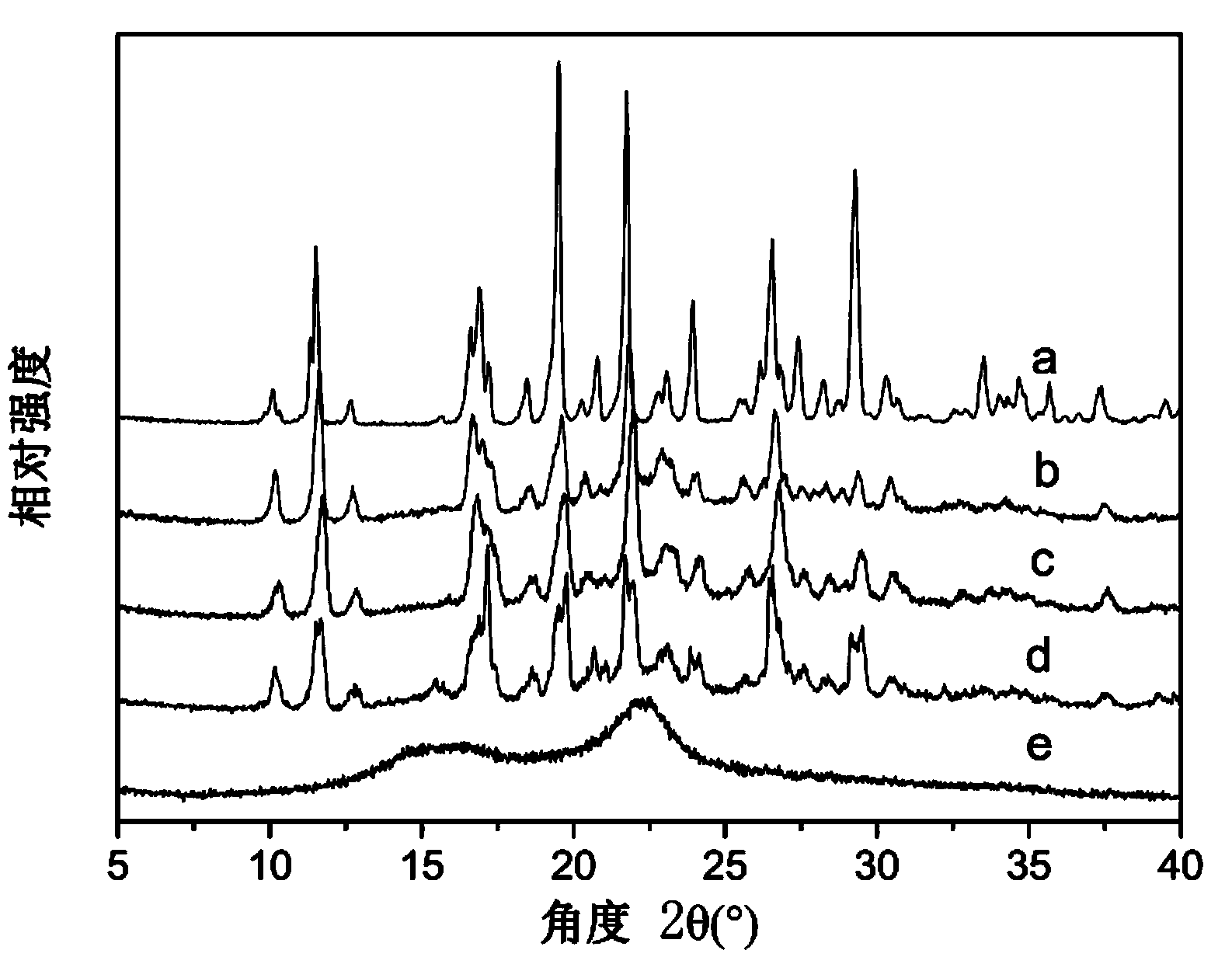

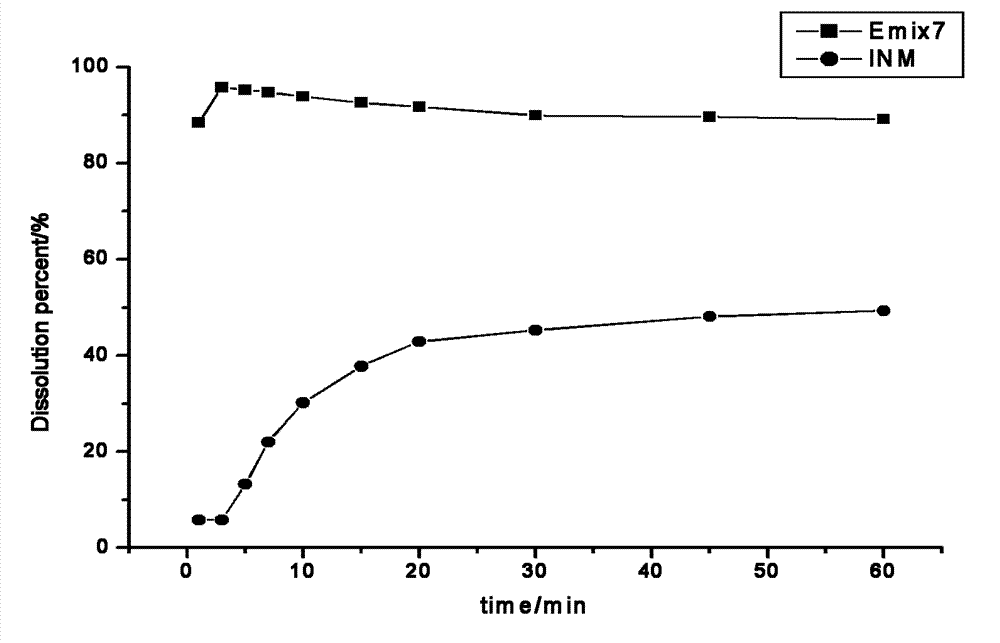

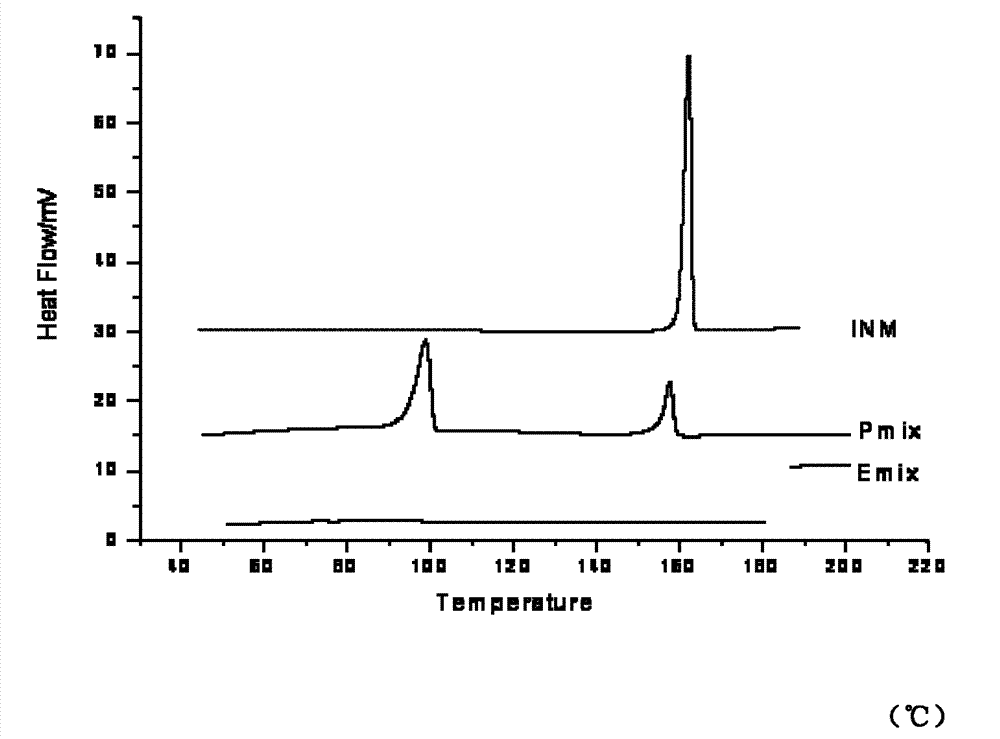

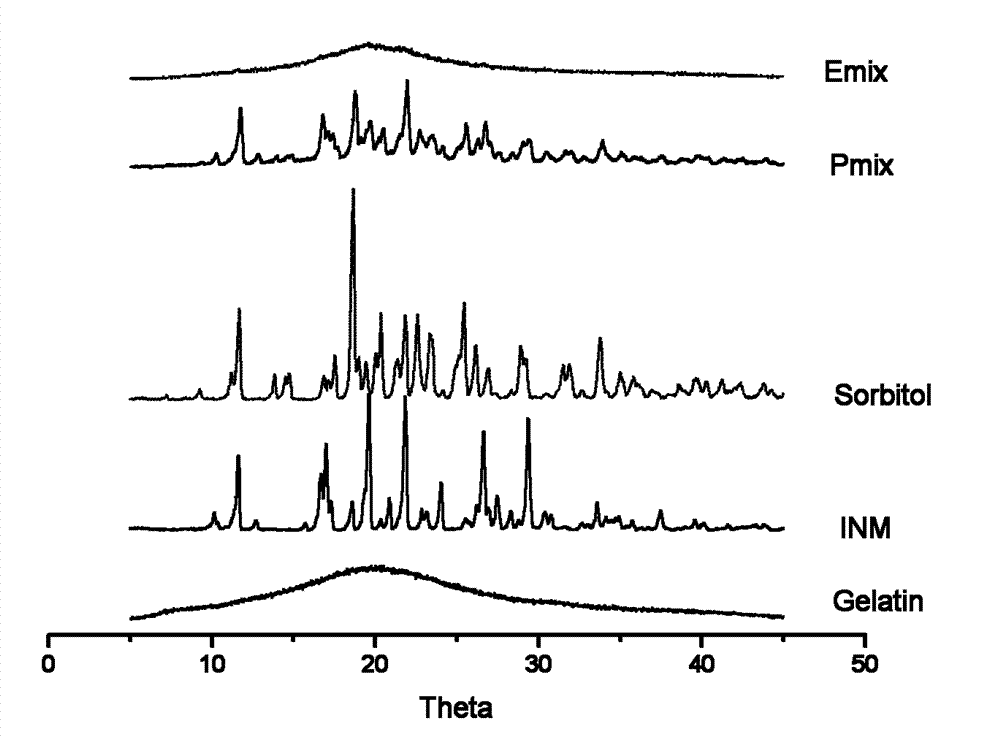

Hot-melt extrusion process for preparing indometacin quick release preparation from multi-element auxiliary materials

InactiveCN102204868ALower extrusion temperatureFacilitate the extrusion processOrganic active ingredientsPowder deliveryIndometacinPolymer science

The invention discloses a hot-melt extrusion process for preparing an indometacin quick release preparation from multi-element auxiliary materials and belongs to the field of pharmacy. The method comprises the following steps of: crushing indometacin and medicinal auxiliary materials, and after screening the powder with a 60 to 120-mesh sieve, uniformly mixing the powder into a physical mixture; according to the melting points or the glass transition temperatures of the medicament and the auxiliary materials, setting the extrusion temperature of a double-screw hot melt extruder to be between 50 and 150 DEG C, after the extrusion temperature reaches the preset temperature, starting a screw, adding the prepared physical mixture into the extruder, and extruding the physical mixture into strips through the screw; and after crushing the strips, screening the powder with a 20 to 80-mesh sieve to obtain medicinal solid dispersoid particles or powder. The auxiliary materials comprise the following components in percentage by weight: 10 to 90 percent of polymer, 5 to 50 percent of plasticizer, 0 to 10 percent of lubricant, 0 to 5 percent of surfactant and 0 to 20 percent of disintegrant. A sugar alcohol with a relatively low softening point or melting point, and the like, serving as the plasticizer, is added into the polymer with a relatively high softening point or melting point so as to reduce the extrusion temperature and make the extrusion process easy. The prepared indometacin solid dispersoid has the characteristic of quickly dissolving out.

Owner:BEIJING UNIV OF CHEM TECH

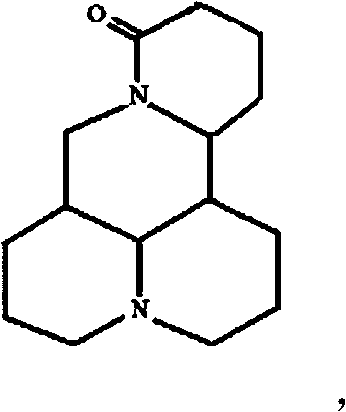

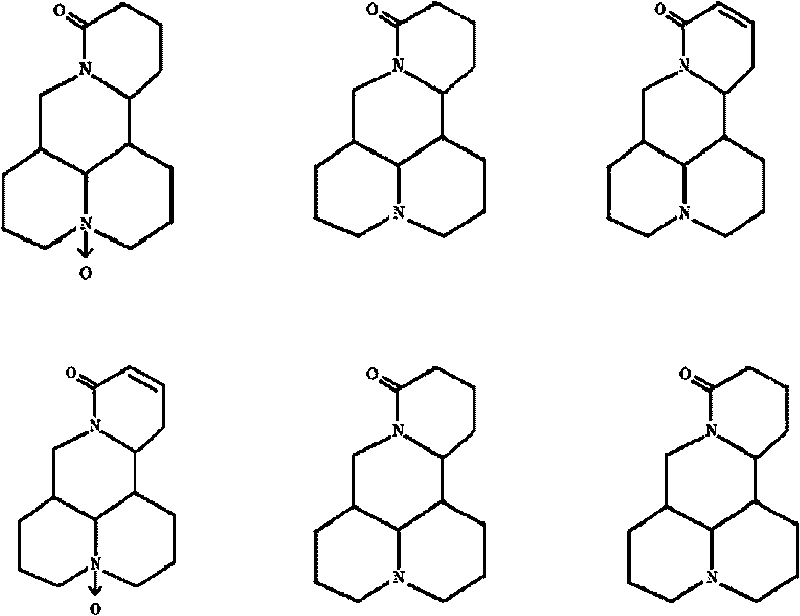

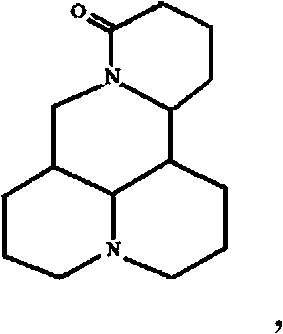

Applications of koumine in preparing medicament for treating chronic ache

ActiveCN101322705AAnalgesic effect is effectiveLittle side effectsOrganic active ingredientsNervous disorderIndometacinTolerability

The invention discloses the application of koumine to the preparation of medicines for treating chronic pains and belongs to the application of gelsemium alkaloid monomer. The analgesic experiments of the koumine on chronic pains of animals prove that the koumine has potent dose-dependent analgesic effect, the analgesic potency is superior to that of the classical antipyretic-analgesic and anti-inflammatory drugs which are aspirin and indomethacin, the therapeutic index of the koumine is much higher than that of the total alkaloids of gelsemium, the koumine possibly has no tolerance, no addiction and little side effect, which indicates that the koumine has potent and low-toxicity analgesic effect, the mechanism of action of the koumine is possibly different from those of clinically common opium analgesics or aspirin analgesics, the koumine and the pharmaceutically acceptable salt thereof have the application of preparing of the medicines for treating chronic pains and have no serious disadvantages of the clinically common analgesics and can be developed into a novel analgesic which has potent analgesic effect in treating chronic pains such as inflammatory pain, neuropathic pain, cancer pain and the like, has no tolerance and addiction and little side effect, thus the koumine has bright industrialization prospect.

Owner:FUJIAN MEDICAL UNIV

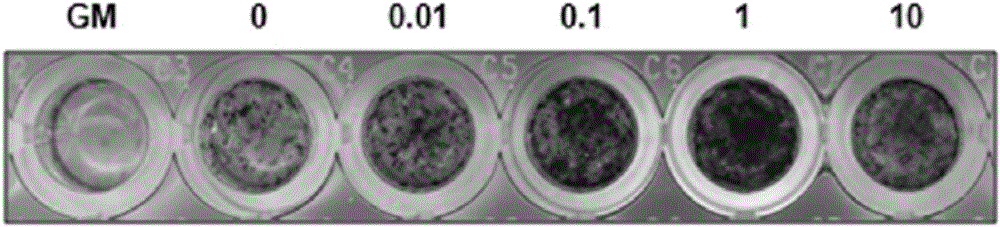

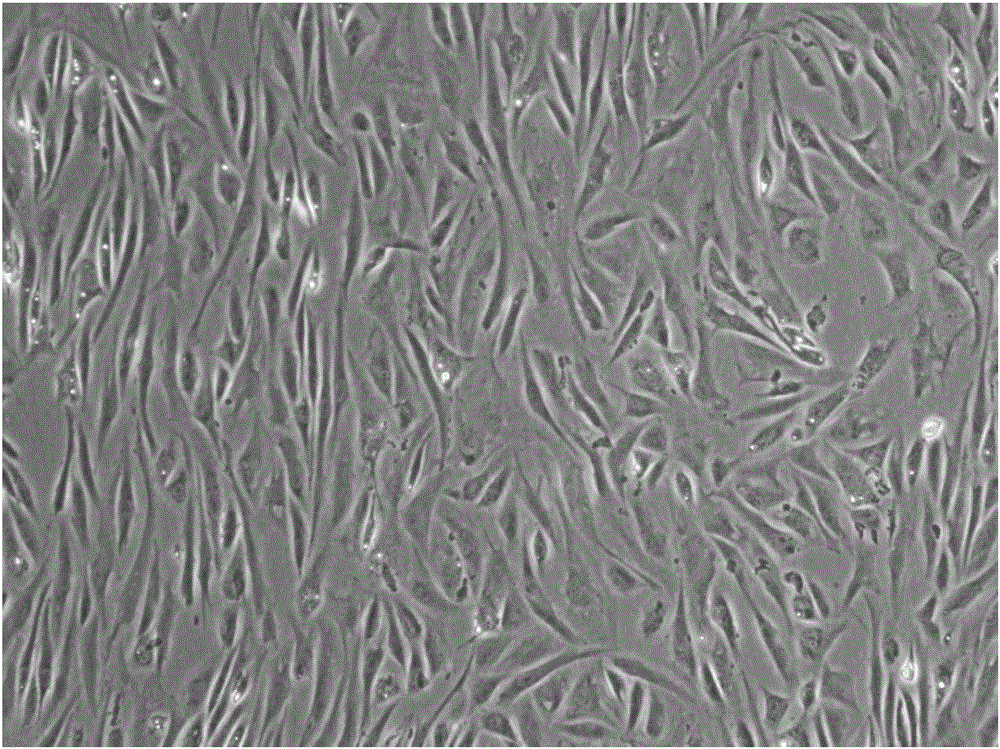

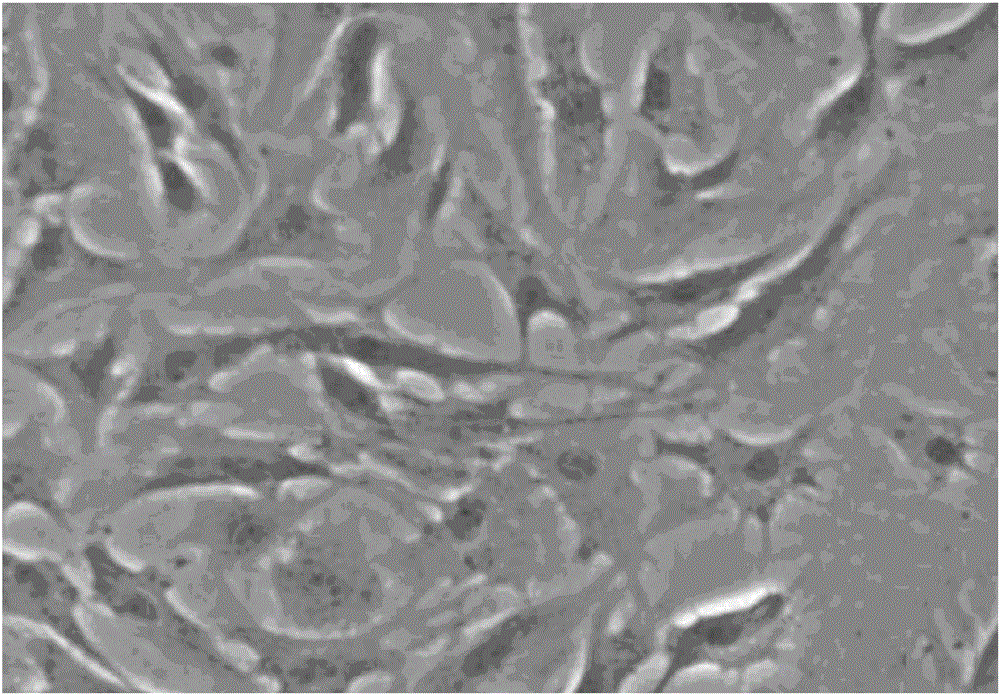

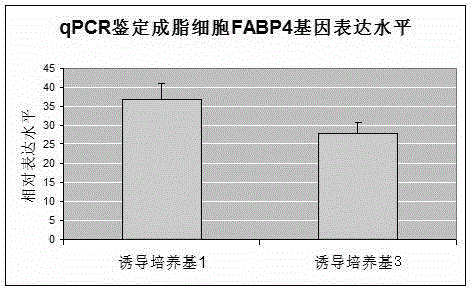

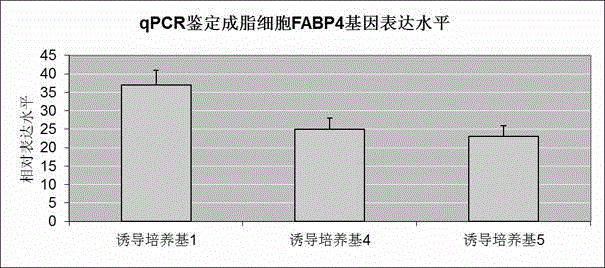

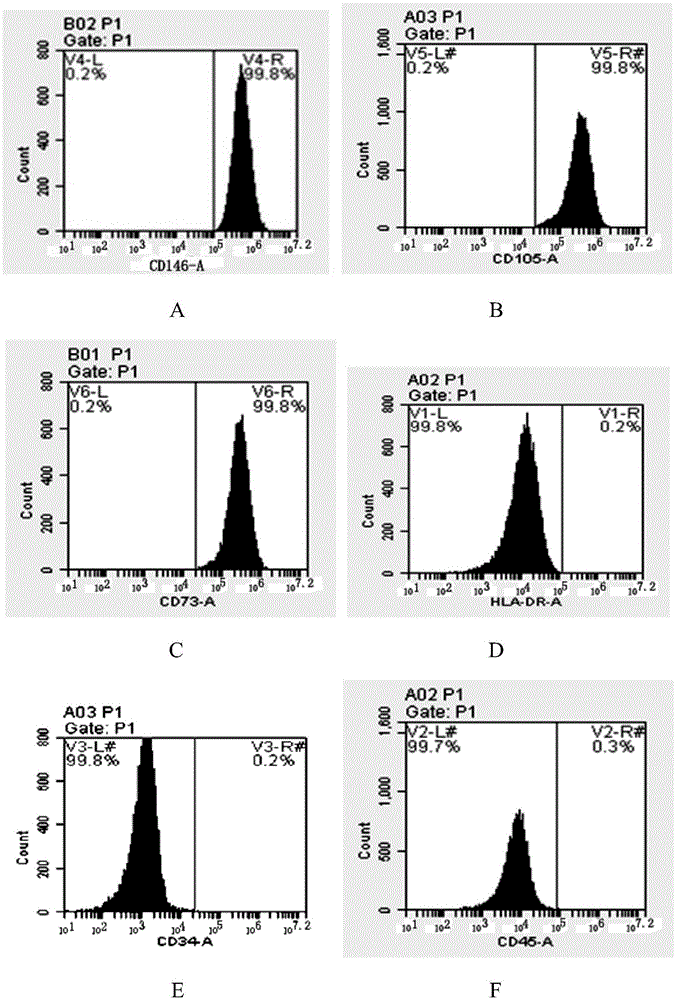

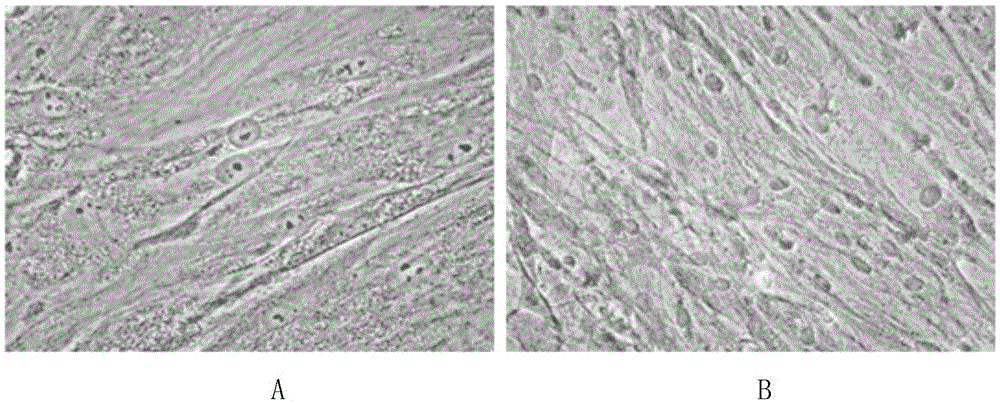

Mesenchymal stem cell adipogenic differentiation culture medium and preparation method thereof

InactiveCN104830757AImprove expression levelStrong specificitySkeletal/connective tissue cellsIndometacinMethyl xanthine

The present invention provides a mesenchymal stem cell adipogenic differentiation culture medium, and belongs to the technical field of stem cells. The mesenchymal stem cell adipogenic differentiation culture medium comprises a DMEM / F12 culture medium, and further comprises FBS with a volume percentage of 5-50%, glutamine with a volume percentage of 0.5-5%, antibiotic with a volume percentage of 0.5-5%, 50-500 [mu]M indometacin, 50-500 nM insulin, 5-50 nM dexamethasone, 0.5-5 [mu]M 3-isobutyl-1-methylxanthine, and 0.05-0.5 [mu]M fasudil hydrochloride. The mesenchymal stem cell adipogenic differentiation culture medium of the present invention has advantages of high inducing efficiency and the like.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

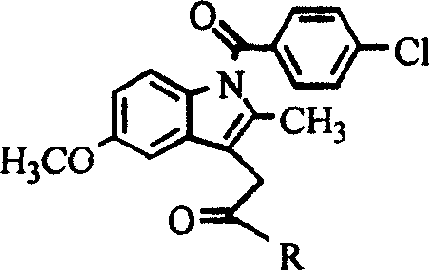

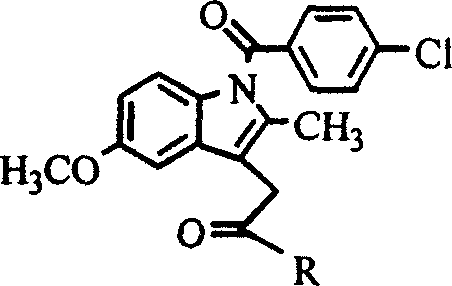

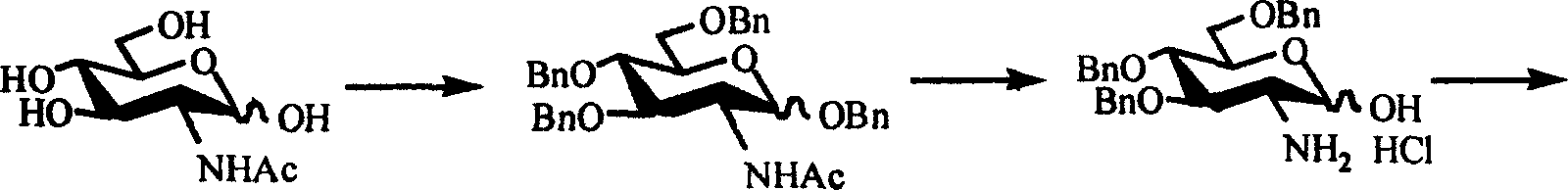

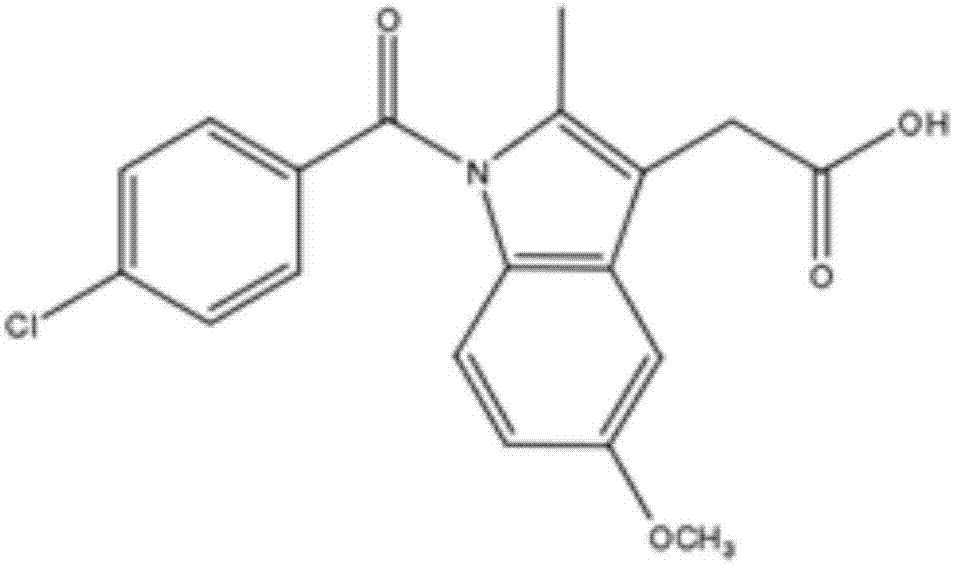

Acetamido glucose devicative of indomethacin and its synthetic method and use

InactiveCN1616474AAvoid disadvantagesOrganic active ingredientsSugar derivativesGlucose polymersD-Glucose

The present invention relates to acetamido glucose derivatives of indomethacin and their synthesis process and use. The kinds of acetamido glucose derivatives of indomethacin prepared with indomethacin and acetamido glucose are 1-O-[1-(4-chloro-benzoyl)-5 -methoxy-2-methyl-3-indolyl-acetoxy]-2-acetylamino-2-deoxy-alpha-D-glucose and 6-O-[1-(4-chloro-benzoyl)-5-methoxy-2-methyl-3-indolyl-acetoxy]-2-acetylamino-2-deoxy-alpha-D-glucose. The derivatives of the present invention has the activity of inhibiting mouse ear dropsy caused by croton oil and may be used in preparing antiphlogistic medicine.

Owner:OCEAN UNIV OF CHINA

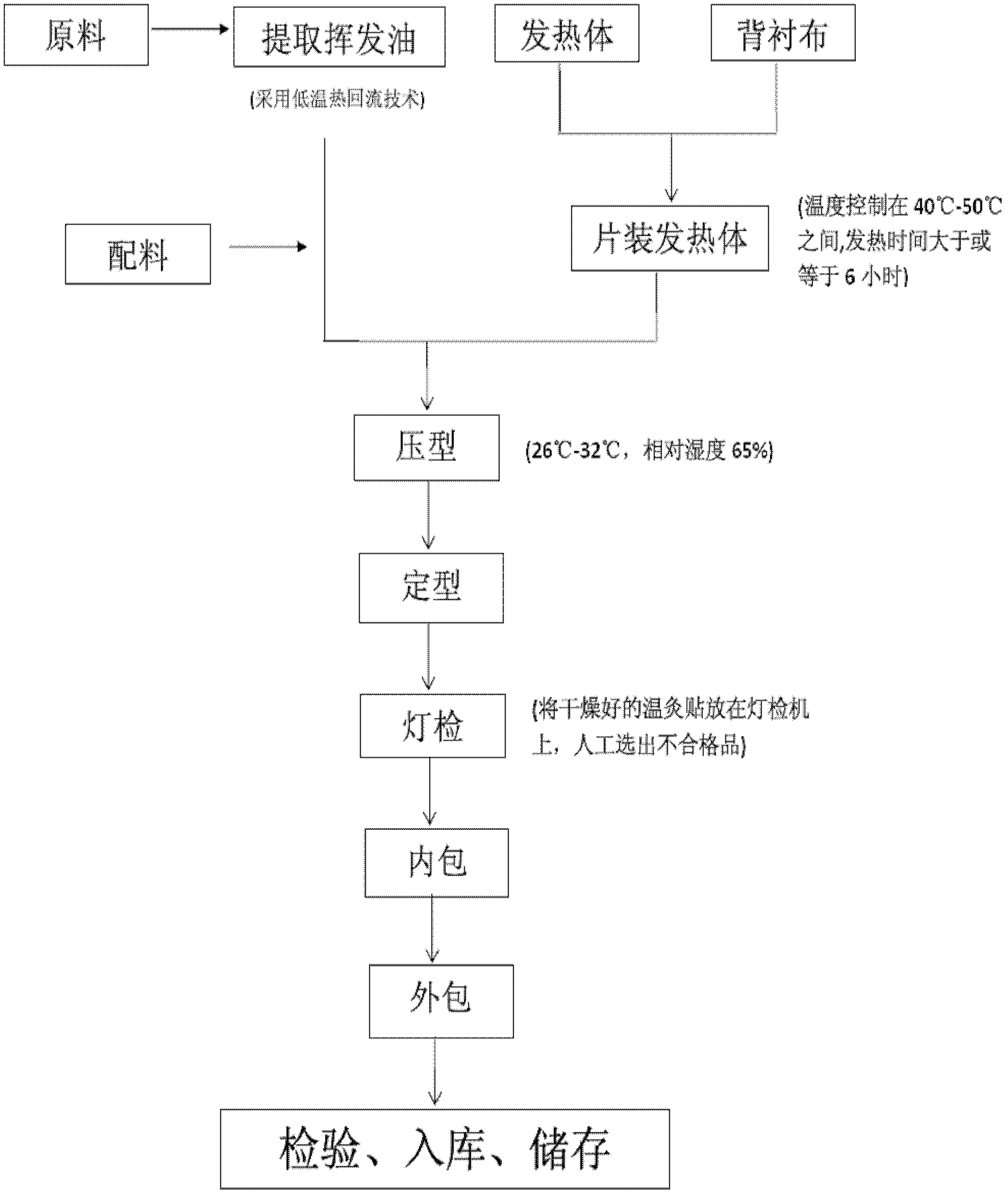

Mild moxibustion plaster added with heating element and application thereof

ActiveCN102357111AHas an expectorant effectCounter cardiotonicDevices for heating/cooling reflex pointsOrganic active ingredientsIndometacinSaline water

The invention belongs to the medicine category, and in particular discloses a mild moxibustion plaster. The mild moxibustion plaster comprises the following components in parts by weight: 40-50 parts of blumea oil, 20-30 parts of indometacin, 30-45 parts of heating element, 5-10 parts of medical rubber and 2-5 parts of back lining cloth, wherein the heating element comprises reduced iron powder, active carbon, saline water and far infrared ceramic powder on a ratio by weight of reduced iron powder to active carbon to saline water to far infrared ceramic powder as (8-14):(3-6):1:(5-8). According to the mild moxibustion plaster disclosed by the invention, the moxibustion method is combined with plasters, so that a mild moxibustion plaster is developed; and the mild moxibustion plaster is used for moxibustion treatment, therefore the disadvantages of inconsistent moxibustion time, less human body absorption and large raw material waste and the like in the conventional moxibustion method are completely overcome.

Owner:HUNAN JINLIUGU PHARMA

Medicine composition containing matrine class alkaloid, preparation method and pharmaceutical application

The invention provides a medicine composition containing matrine class alkaloid, a preparation method and pharmaceutical applications. The medicine composition is the combination of the matrine class alkaloid and inflammation-resisting pain-relieving class medicines. The inflammation-resisting pain-relieving medicine comprises the non-steroidal inflammation-resisting medicines of aspirin, acetaminophen, indometacin, ibuprofen, oxyphenbutazone, naproxen, mefenamic acid, diclofenac sodium, celecoxib, rofecoxib, valdecoxib and the like and also comprises the vegetable inflammation-resisting pain-relieving class medicines of escin, ferulic acid, berberine, wilfordine, ephedrine and the like and the pain-relieving class medicines of morphia, demerol and the like. The matrine class alkaloid and one or various of the inflammation-resisting pain-relieving class medicines can form a medicine composition used for the pharmaceutical applications of resisting cold, allaying a fever and treating the swelling and pain of the bone joint and the muscle, rheumatic diseases, cardiovascular diseases, arteriosclerotic diseases, tumors, anaphylactic diseases, senile dementia, mosquito bite, insect bite and the like.

Owner:QINGDAO QIYUAN BIO TECH CO LTD

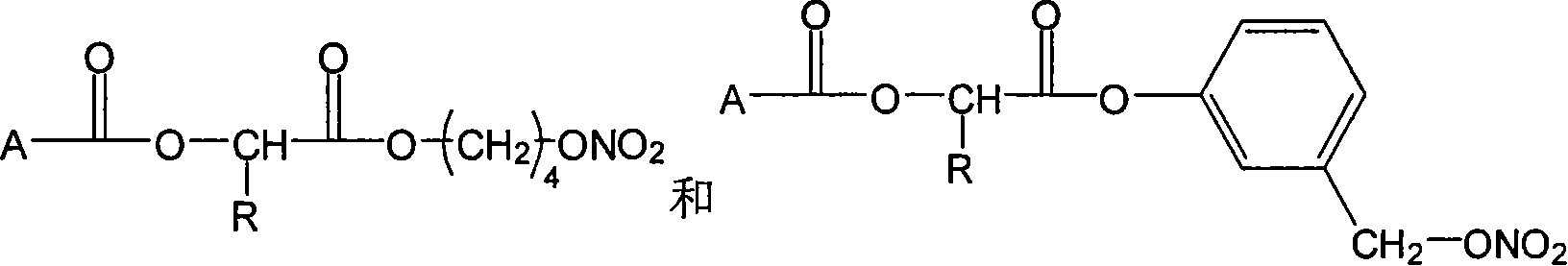

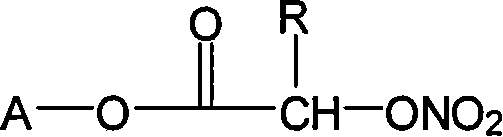

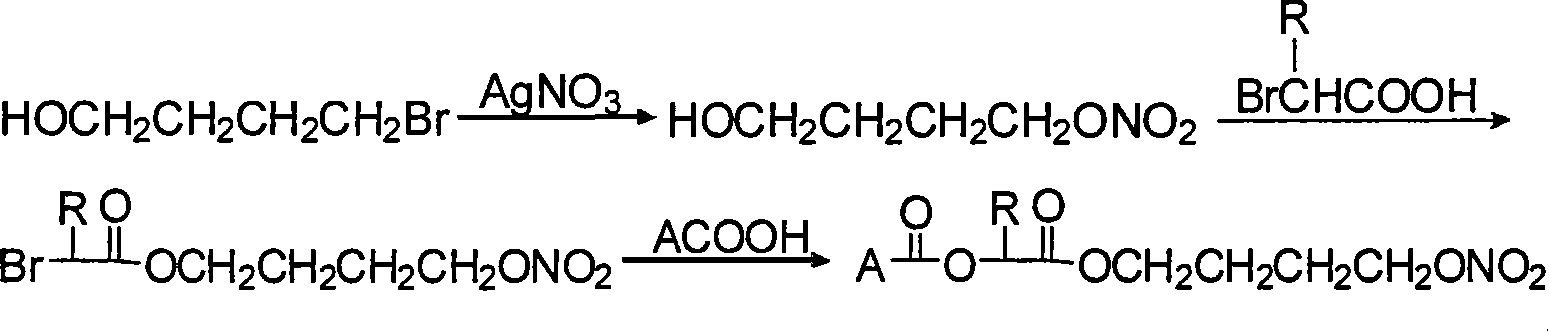

Nonsteroidal antiinflammatories with nitric oxide donors and its preparation method

InactiveCN101053662ALittle side effectsMild reaction conditionsAntipyreticAnalgesicsIndometacinSide effect

The invention relates to a non-steroidal anti-inflammatory drug with nitrogen oxide donor and a method for preparing same, which can be used to eliminate inflammation, relieve fever and stop pain, and can decrease the frequently seen side effect thereof on the gastrointestinal tract. The structure of which is A-O(X)-CO-O(y)-B-ONO2,wherein, A is the non-steroidal anti-inflammatory group; B is the connection group, when x=0, y=1; when x=1 then y=0. The the non-steroidal anti-inflammatory groups includes aspirin, diclofenac, indometacin, lumiracoxib, brufen, ketoprofen, naproxen, piroxicam, and meloxicam. The preparation process are that the bromhydrin (or hydroxybenzene) reacts with silver nitrate into hydroxy nitrate, then reacts with bromo acid into the connection group of nitrogen oxide donor, then connects with the non-steroidal anti-inflammatory drug; or the non-steroidal anti-inflammatory drug condensates with bromo acid into a bromide intermediate, then reacts with silver nitrate into the non-steroidal anti-inflammatory drug with nitrogen oxide donor.

Owner:江苏吴中苏药医药开发有限责任公司

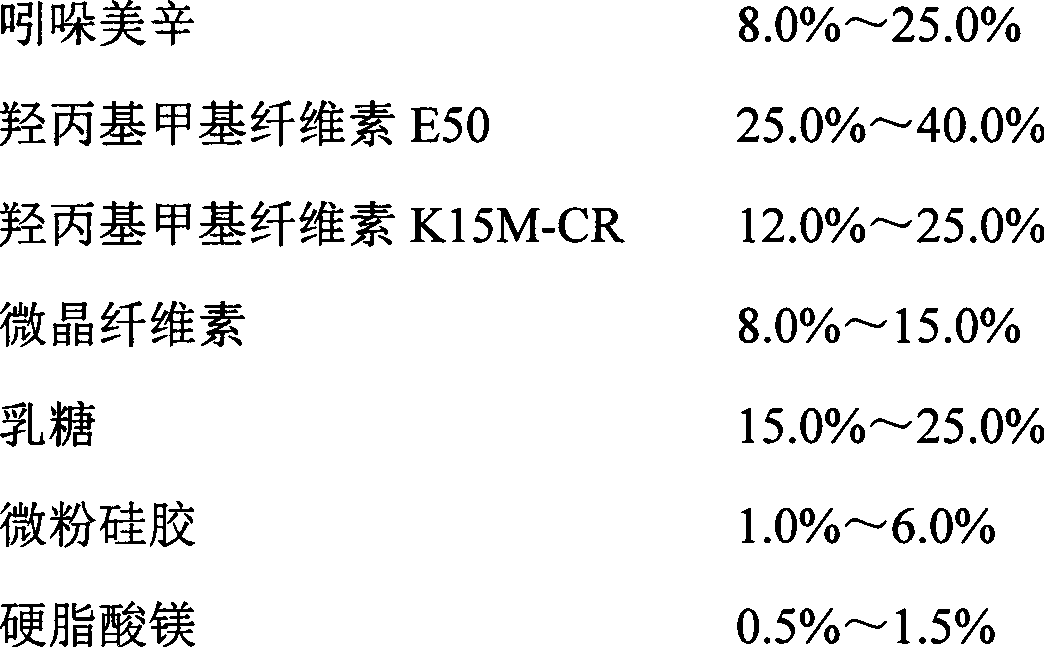

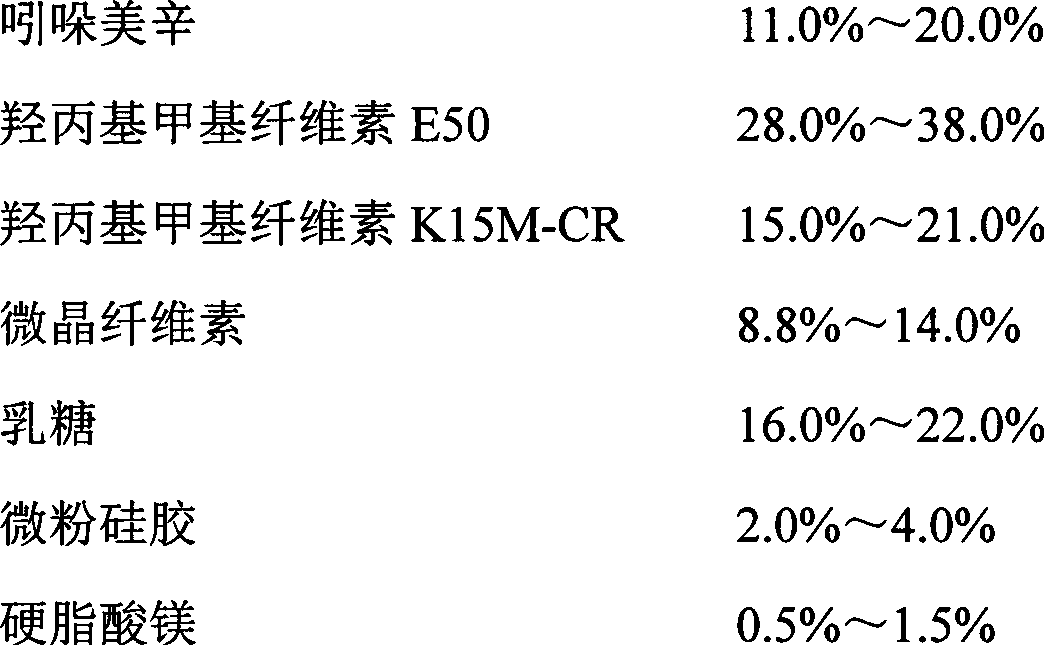

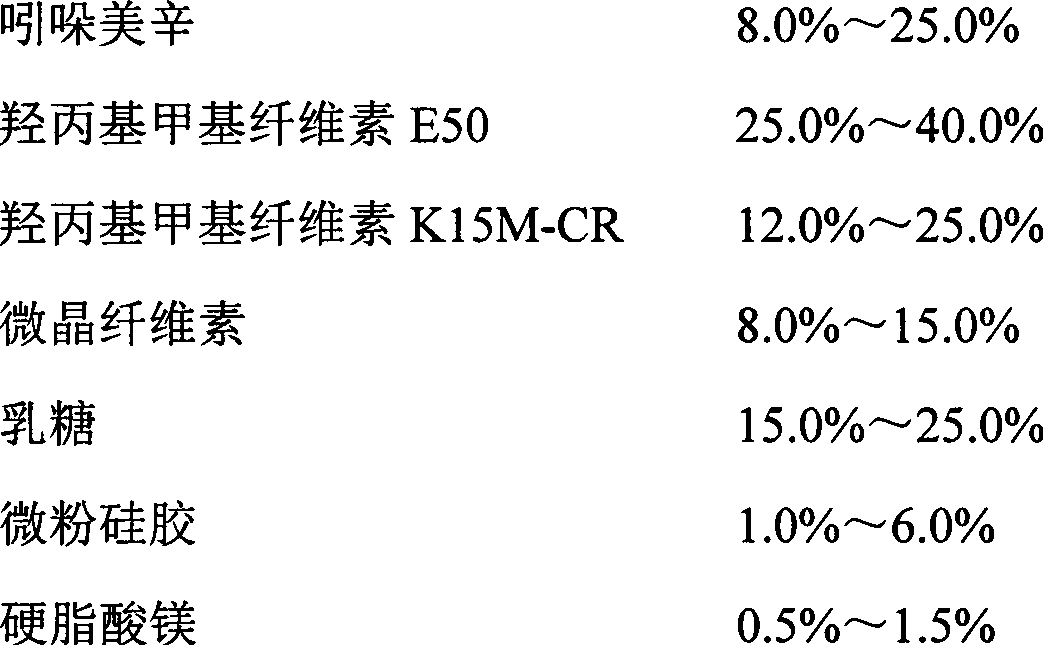

Indometacin sustained release tablet, preparation method thereof, as well as release controlling method and standard

InactiveCN103099795AThe production process is simple and controllableReduce the amount requiredOrganic active ingredientsAntipyreticIndometacinReference product

The invention relates to an indometacin sustained release tablet, a preparation method thereof, as well as a release controlling method and standard. The indometacin sustained release tablet is prepared from the following components in percentage by weight: 8.0-25.0% of indometacin, 25.0-40.0% of hydroxypropyl methyl cellulose, 12.0-25.0% of microcrystalline cellulose K15M-CR, 8.0-15.0% of microcrystalline cellulose, 15.0-25.0% of lactin, 1.0-6.0% of gum acacia and 0.5-1.5% of magnesium stearate. A full-powder direct compression process is adopted; the production process is simplified; the methoxyl content of prepared mid-product methoxyl is 8.2-18%; and the propoxyl content is 2.6-7.8%. The quality of the indometacin sustained release tablet disclosed by the invention reaches the standard; a reference product has release similarity; mass control is carried out before production; rework can be reduced; the production cost is saved; the energy consumption is reduced; and the production efficiency is improved.

Owner:深圳国源国药有限公司

Nucleoside derivative for preventing and treating inflammatory reaction as well as application thereof

ActiveCN109912598ALittle side effectsSimple structure and processOrganic chemistryAntipyreticIndometacinDisease

The invention provides a nucleoside derivative for preventing and treating inflammatory reaction as well as application of the derivative to preparation of medicines for preventing and treating inflammatory diseases. The nucleoside derivative for preventing and treating inflammatory reaction, which is provided by the invention, can obviously improve the disease conditions of pancreatitis, hepatitis, arthritis and the like, can improve the damaged and inflammatory indexes of organs and has the effect better than that of a positive control medicine indometacin. Compared with the traditional anti-inflammatory medicines aspirin, ibuprofen, indometacin, butazodine, diclofenac, piroxicam and glucocorticoid, the nucleoside derivative for preventing and treating inflammatory reaction, which is provided by the invention, has the advantage that the side effect is obviously smaller.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

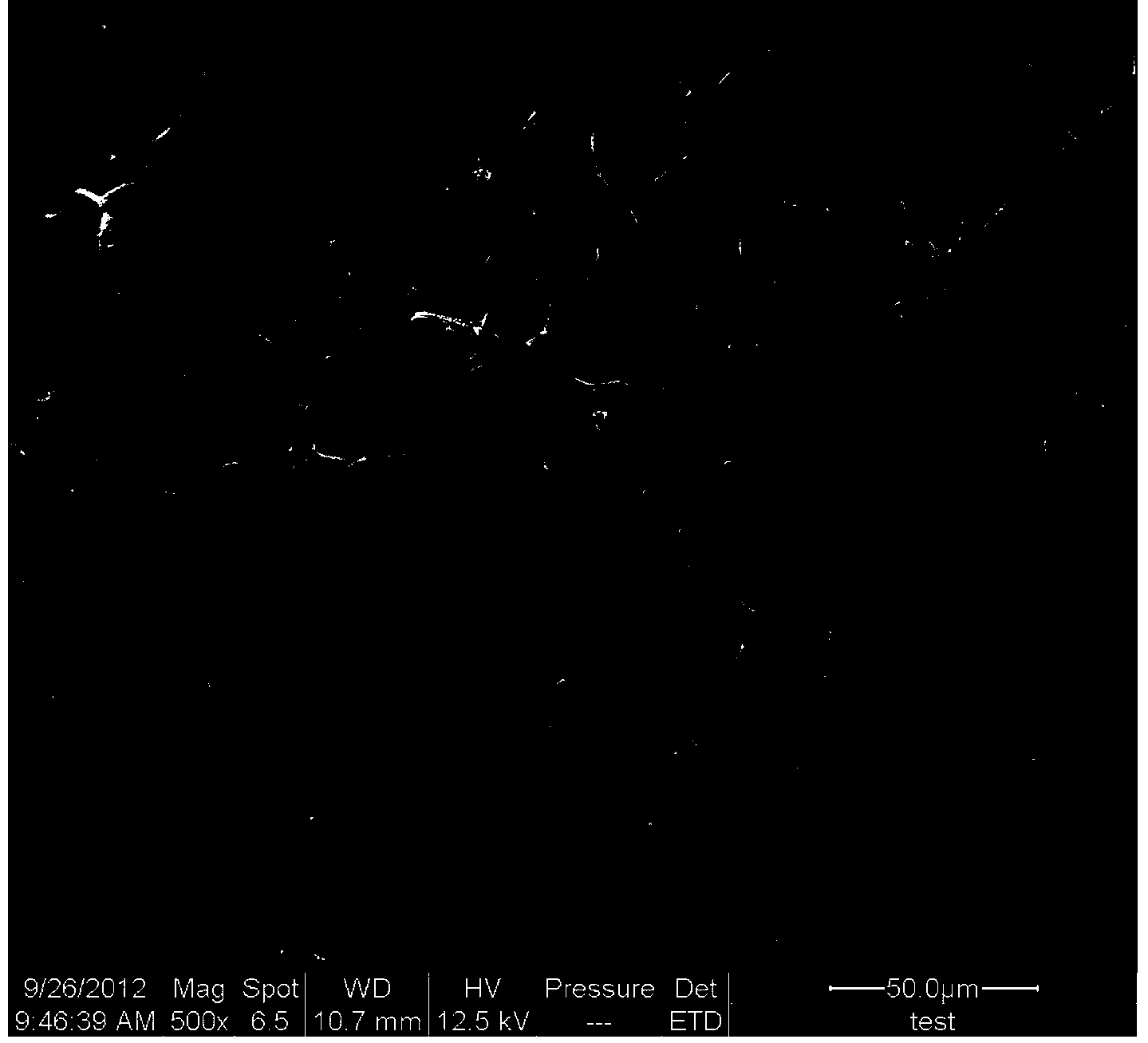

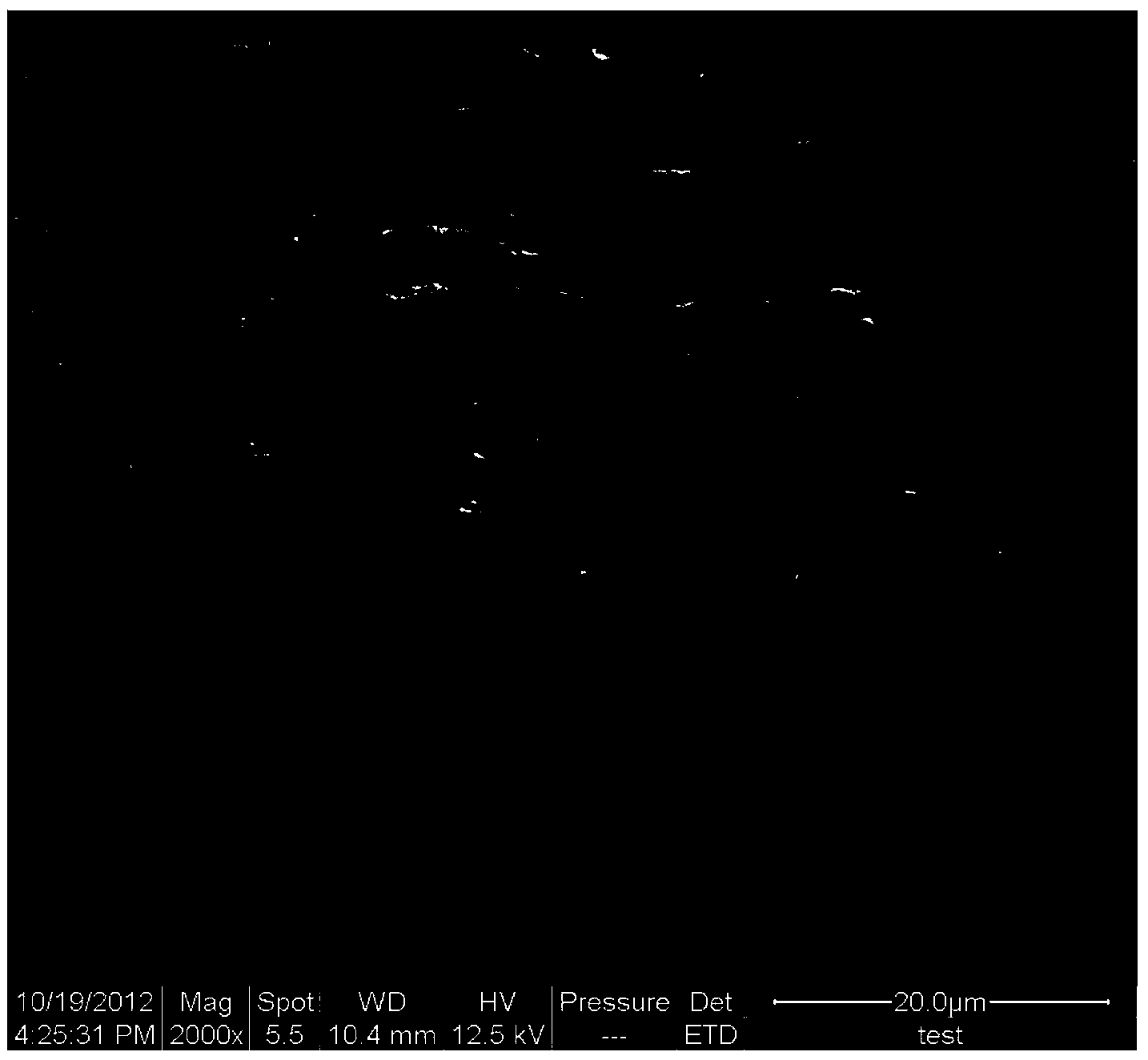

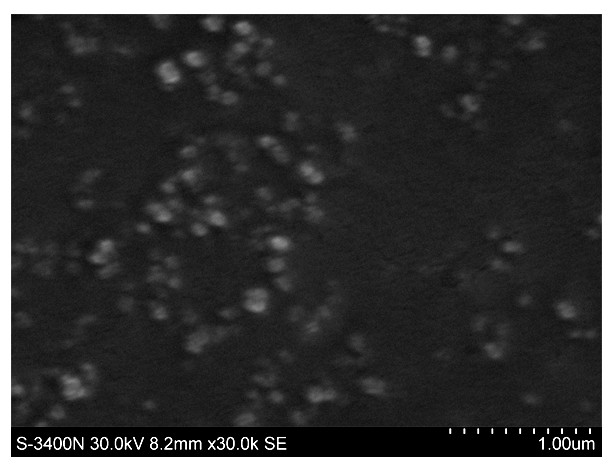

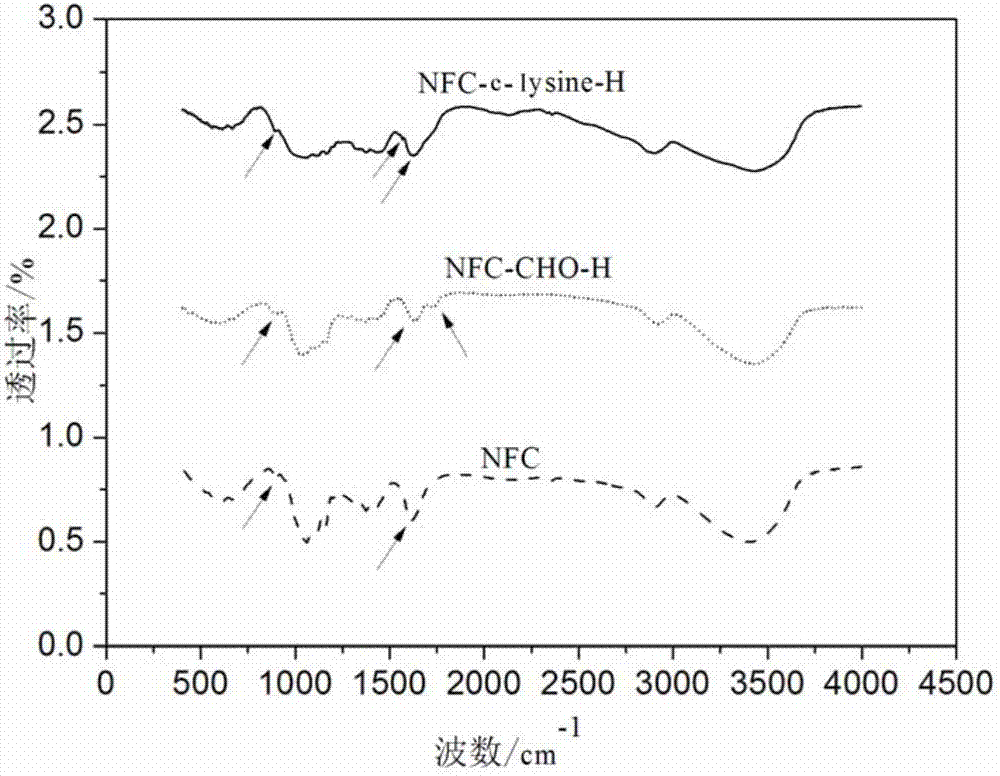

Self-assembly compound system of cellulose nanometer fibril and indometacin and preparation method of self-assembly compound system

The invention provides a preparation method of the self-assembly compound system of cellulose nanometer fibril and indometacin, relating to a preparation method of a novel drug delivery system and solving the problem that an existing drug delivery system has low drug loading capacity, short action time of the drug and frequent dosing. The preparation method of the self-assembly compound system of cellulose nanometer fibril and indometacin comprises the following steps of firstly, preparing the water solution of the cellulose nanometer fibril; secondly, preparing the solution of indometacin; thirdly, preparing the mixed liquor of cellulose nanometer fibril and indometacin; fourthly, ultrasonic processing or ultrasonic processing and high pressure homogeneity processing; fifthly, vacuum filtering; and sixthly, drying so as to obtain the self-assembly compound system of cellulose nanometer fibril and indometacin. The self-assembly compound system of cellulose nanometer fibril and indometacin prepared by the method has the advantages of high drug loading capacity, long action time of the drug, and less dosing time, and is mainly used in a novel drug delivery system.

Owner:NORTHEAST FORESTRY UNIVERSITY

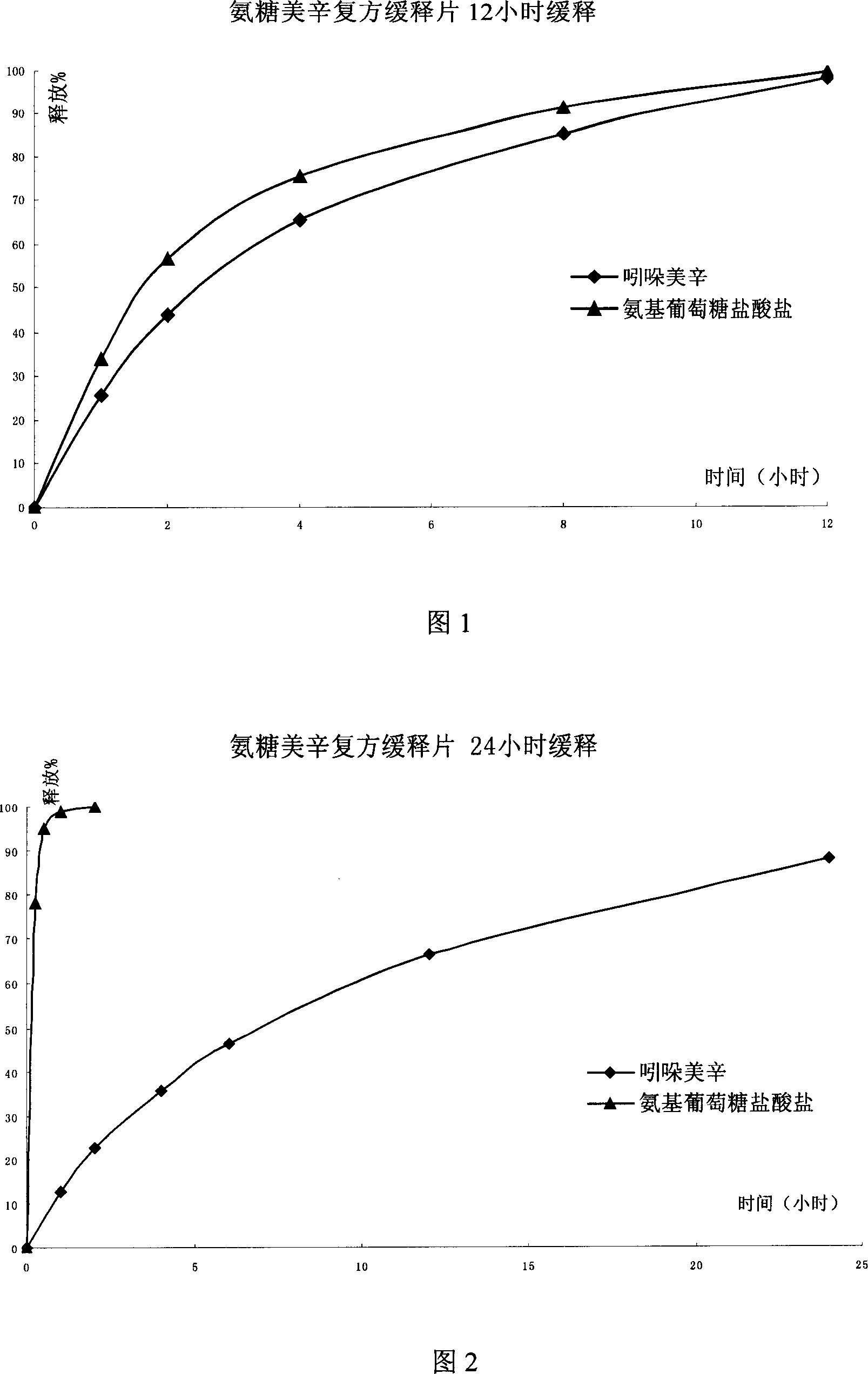

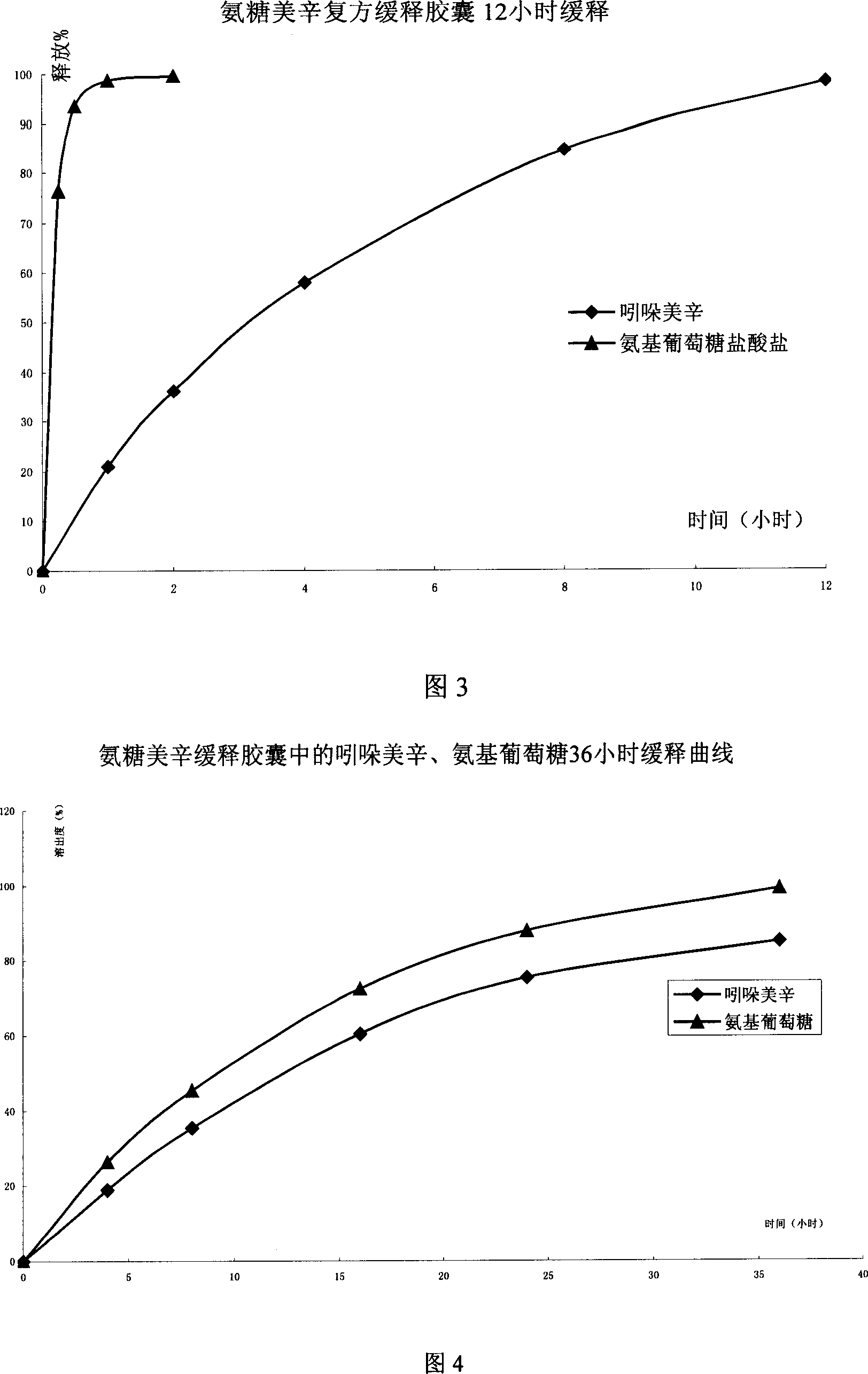

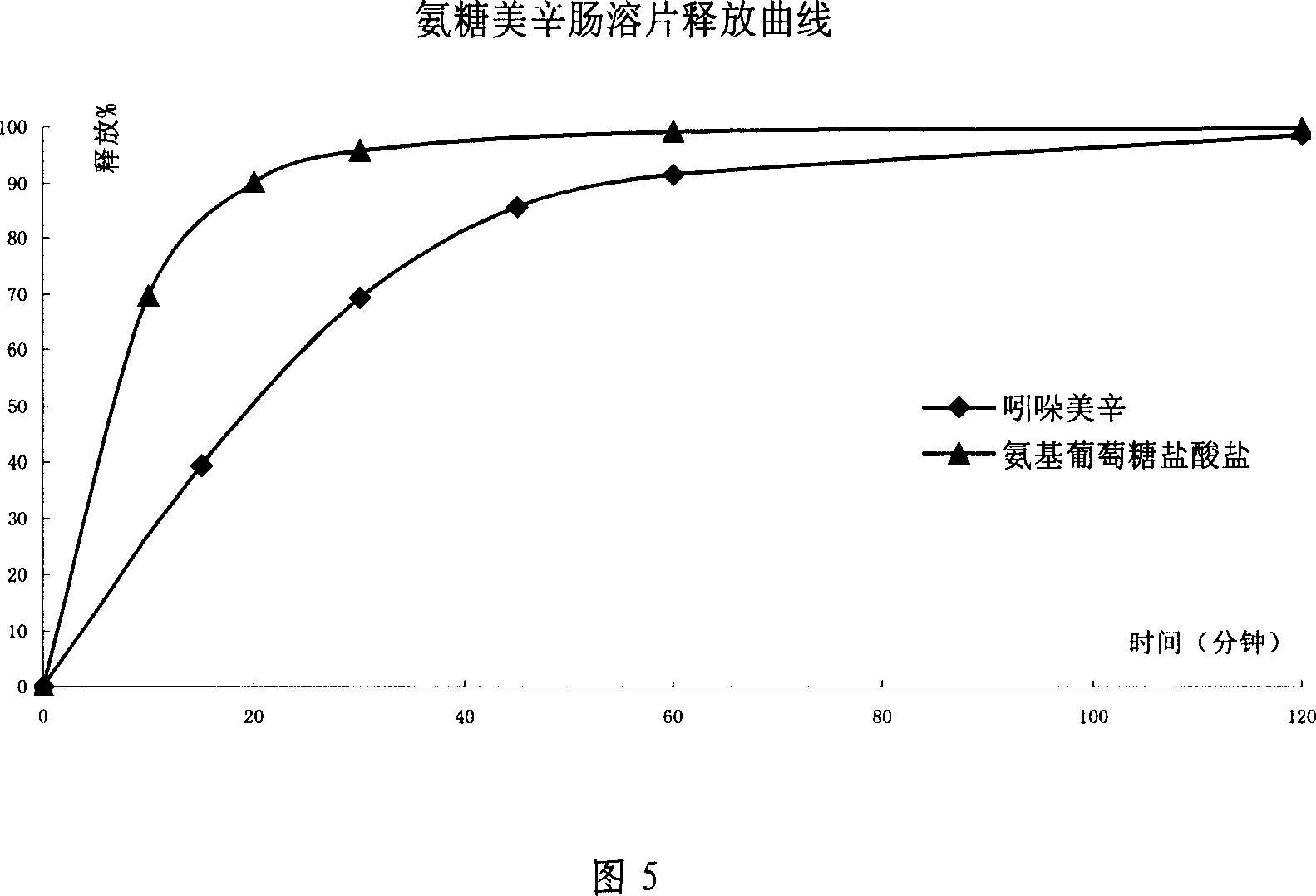

Sustained releasing formulation of compound glucosamine, preparation process and application thereof

InactiveCN1961887ASafe releaseSmooth releaseOrganic active ingredientsAntipyreticSide effectVolumetric Mass Density

The invention relates to a composite slow-release agent, wherein it contains indomethacin, aminoglucose salt, slow-release material and other findings, while their ratios are 5-45%, 20-80%, 1-75%, and the left is findings. Its preparation comprises that mixing indomethacin and / or aminoglucose salt, and slow-release material and / or packs, then adding other findings, using general slow-release technique to obtain one or several skeleton or mould-contoro slow-release agent. The invention can be made into particle, oral, tablet or capsule. The invention can keep stable blood drug density in 8-36h, reduce side effect.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

Indometacin and albuterol suppository, preparation method, detection method and application thereof

ActiveCN102670593ASolve solubilitySolving Dispersion ProblemsOrganic active ingredientsComponent separationIndometacinSalbutamol

The invention provides an indometacin and albuterol suppository and a preparation method of the suppository; the suppository comprises effective dose of indometacin, effective dose of albuterol, a dispersing agent, emulsifier and a molding agent. The preparation method comprises the steps of dissolving the indometacin and the albuterol in the dispersing agent, then mixing with the molten molding agent and the emulsifier, and homogenizing to obtain the suppository. The suppository provided by the invention is featured with smooth production and uniform quality; and auxiliary materials do not influence content detection; wherein content detection recovery rate of the albuterol reaches 97%, and content uniformity A+1.8S is less than 10, and is superior to a requirement that content uniformity A+1.8S of a suppository is less than 25 (Department 2 of Chinese Pharmacopoeia 2005 edition, Page 75 of Appendix XE); and layering and precipitation do not appear after the suppository is subjected to a challenge test at 45 degrees centigrade for 72 hr.

Owner:LIVZON GROUP LIVZON PHARMA FACTORY +1

Chinese herbal medicine compound preparation for treating swine fever high fever and preparation method thereof

ActiveCN105233253AWith detoxificationEnhance immune functionOrganic active ingredientsPeptide/protein ingredientsIndometacinPatrinia

The invention relates to a Chinese herbal medicine compound preparation for treating swine fever high fever and a preparation method thereof. The Chinese herbal medicine compound preparation is prepared from, by weight, 30-50 parts of isatis roots, 20-40 parts of folium isatidis, 40-60 parts of astragalus membranaceus, 10-30 parts of scutellaria baicalensis, 20-40 parts of fructus forsythiae, 10-30 parts of licorice roots, 20-40 parts of dahurian patrinia herbs, 10-20 parts of prunella vulgaris, 5-10 parts of sodium indometacin, 5-15 parts of mannatide, 0.5-1 part of polysorbate and 0.1-0.3 part of sodium hydrogen sulfite. The Chinese herbal medicine compound preparation is prepared from pure natural traditional Chinese medicinal materials and appropriate anti-virus ingredients, no antibacterial or antibiotic drug residue exists, and the curative effect is more thorough.

Owner:ZHENGZHOU HOUYI PHARMA

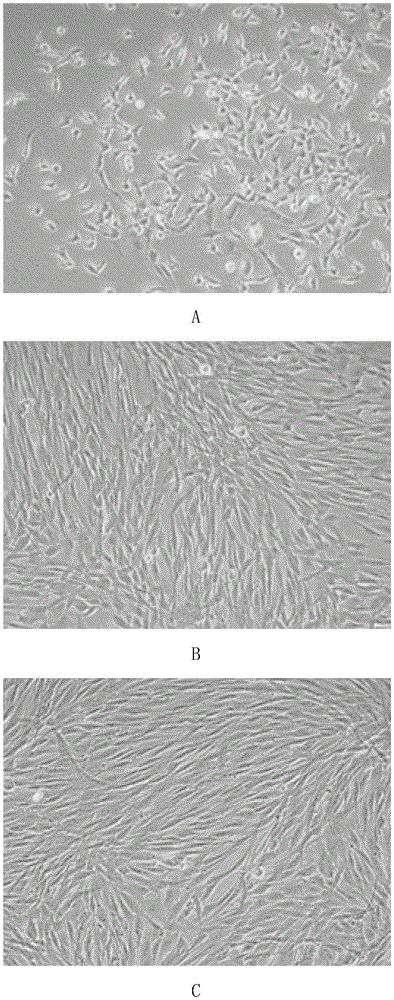

Periodontal ligament stem cell adipogenic differentiation inducing liquid and periodontal ligament stem cell adipogenic differentiation inducing method

ActiveCN105462917AImprove fat conversion efficiencySuccessfully achieved adipogenic inductionSkeletal/connective tissue cellsArtificially induced pluripotent cellsDexamethasoneIndometacin

The invention relates to periodontal ligament stem cell adipogenic differentiation inducing liquid and a periodontal ligament stem cell adipogenic differentiation inducing method. The adipogenic differentiation inducing liquid is prepared from a basic culture medium, IBMX, insulin, indometacin, dexamethasone, PRP and FBS; preferentially, the adipogenic differentiation inducing liquid is prepared from, 0.1 mmoL / L of IBMX, 10 mg / L of insulin, 0.1 mmoL / L of indometacin, 1 micromoL / L of dexamethasone, 5 v / v% of PRP, 10 v / v% of FBS and the balance basic culture medium, wherein the basic culture medium is a DMEM / F12 culture medium. The adipogenic differentiation inducing method comprises the step of performing inducing through the adipogenic differentiation inducing liquid. On the basis of common inducing culture liquid, PRP is added; in this way, the pimelosis efficiency of PDLSCs is effectively improved, and adipogenic inducing of PDLSCs can be achieved successfully.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

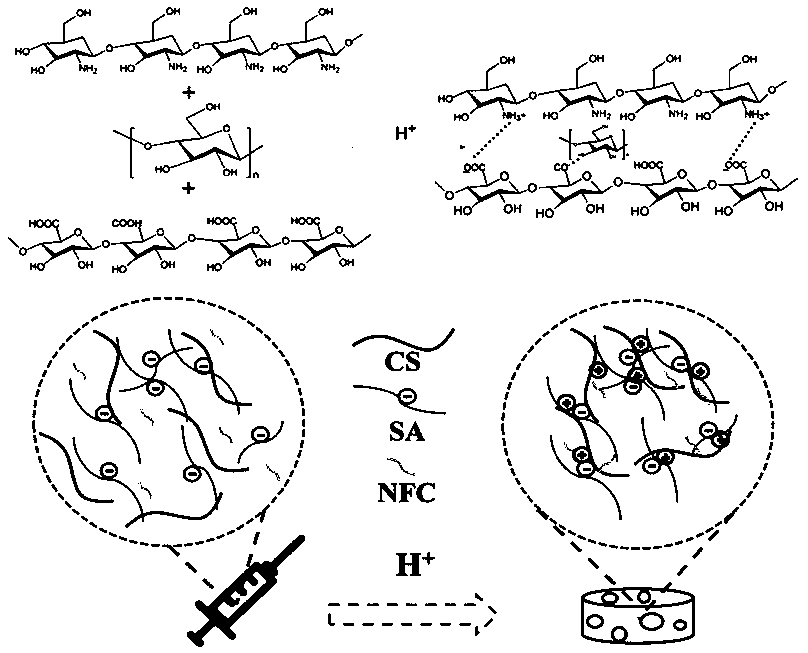

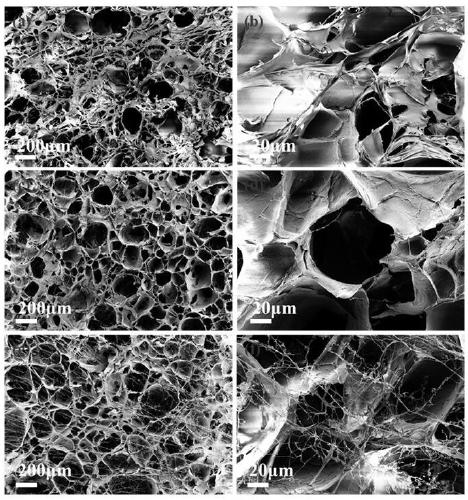

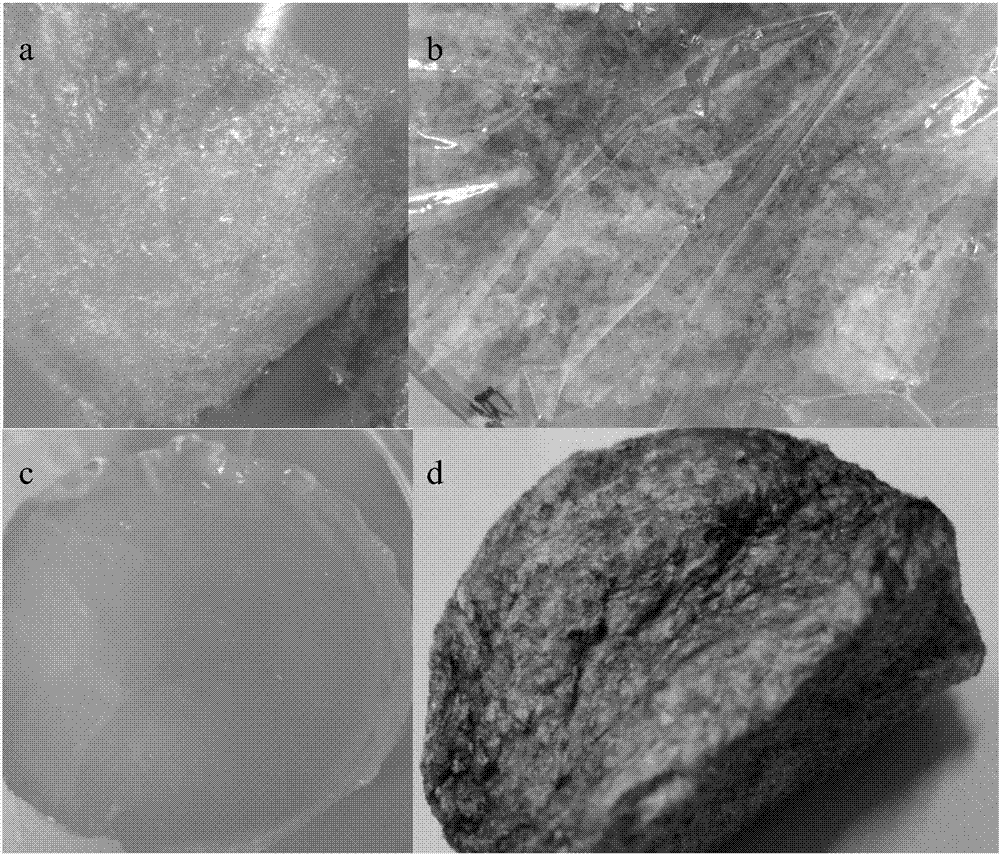

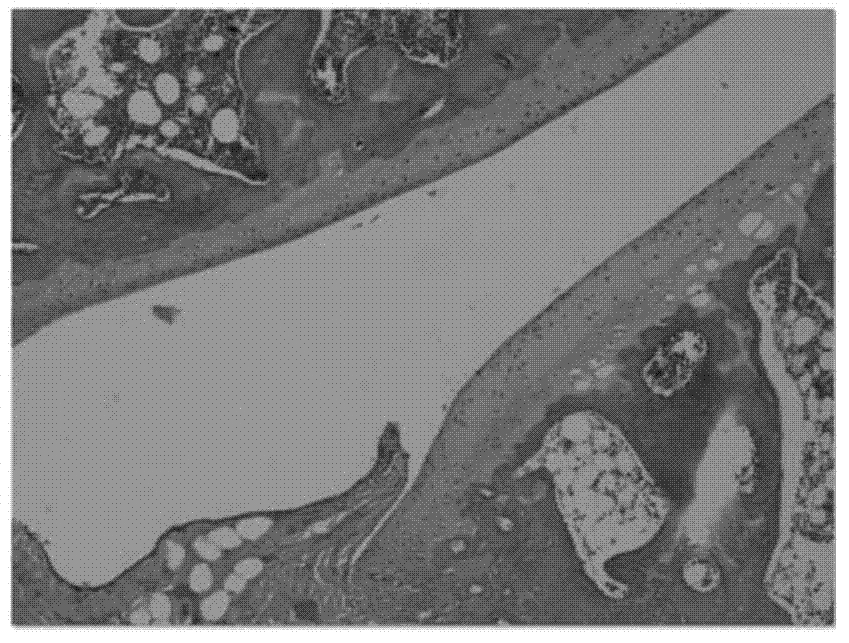

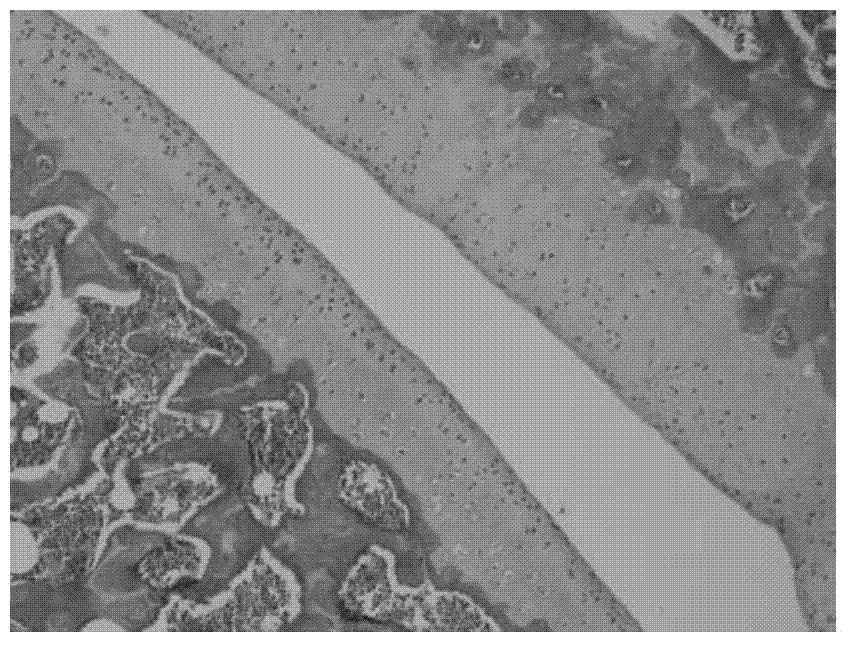

Preparation method and application of biocompatible nano composite hydrogel

InactiveCN111228213AImprove mechanical propertiesHas pH responsivenessOrganic active ingredientsAerosol deliveryCelluloseIndometacin

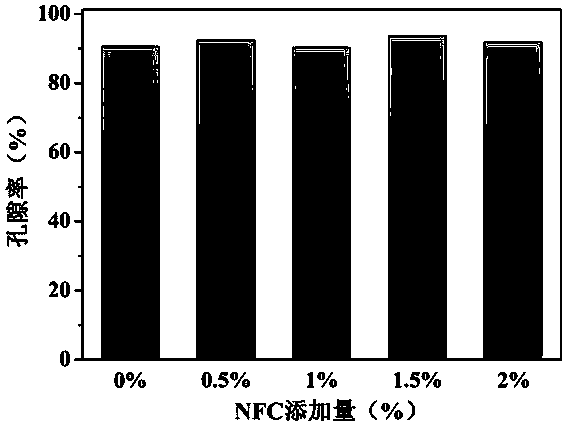

The invention discloses a preparation method and application of a biocompatible nano composite hydrogel. The preparation method comprises the following steps: firstly, extracting nano fibrillation cellulose from cotton fiber powder by using a process with the combination of a eutecticevaporate solvent and wet-process ball milling; and secondly, by taking sodium alginate and chitosan as raw materials and the nano fibrillation cellulose as a reinforcing phase, preparing the nano composite hydrogel on the basis of an electrostatic function, a hydrogen-bond interaction and a biomass nano effect. In addition, an indometacin medicine is carried by the sodium alginate / chitosan / nano fibrillation cellulose composite hydrogel, and a slow release effect of the indometacin medicine can be achieved. not only is the preparation method simple in preparation process and rice in material source, but also the prepared composite hydrogel is of a porous three-dimensional network structure, the porosity ismaintained at 90% or greater, the swelling ratio is up to 1321%, and good mechanical properties are achieved; and meanwhile, the hydrogel has pH value sensitivity upon release of an indometacin modelmedicine, and shows a property of slow release.

Owner:ZHEJIANG SCI-TECH UNIV

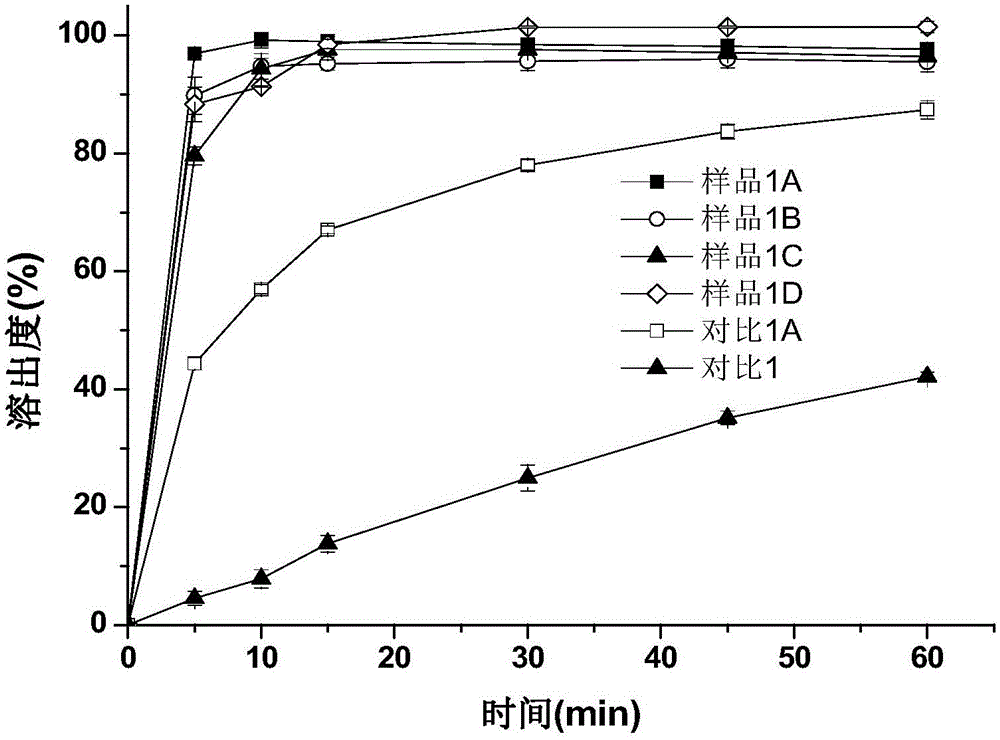

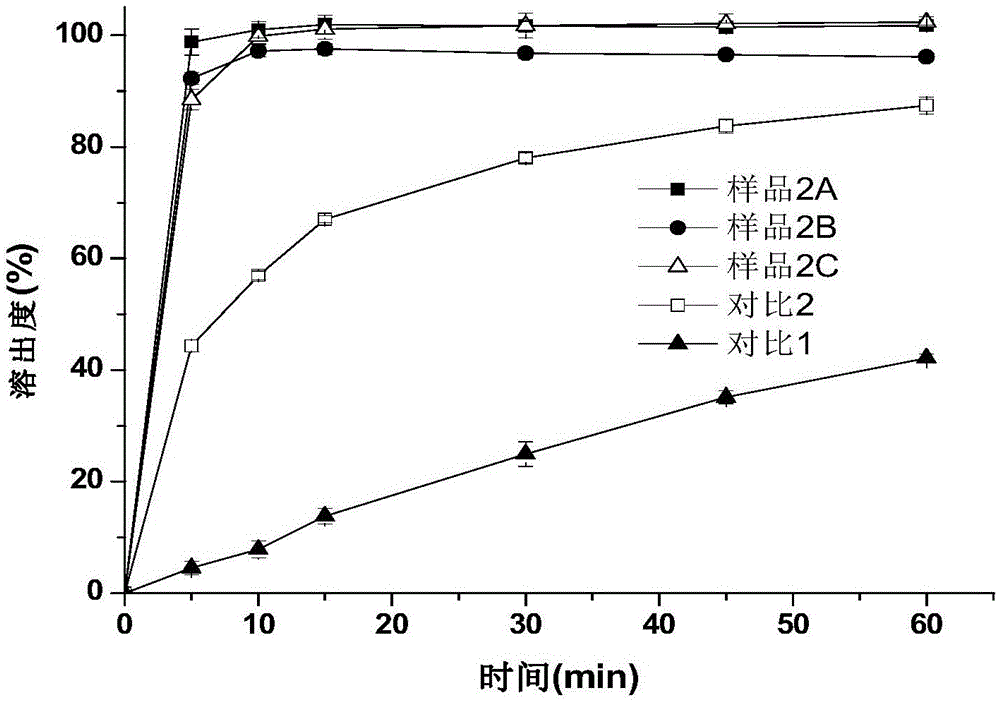

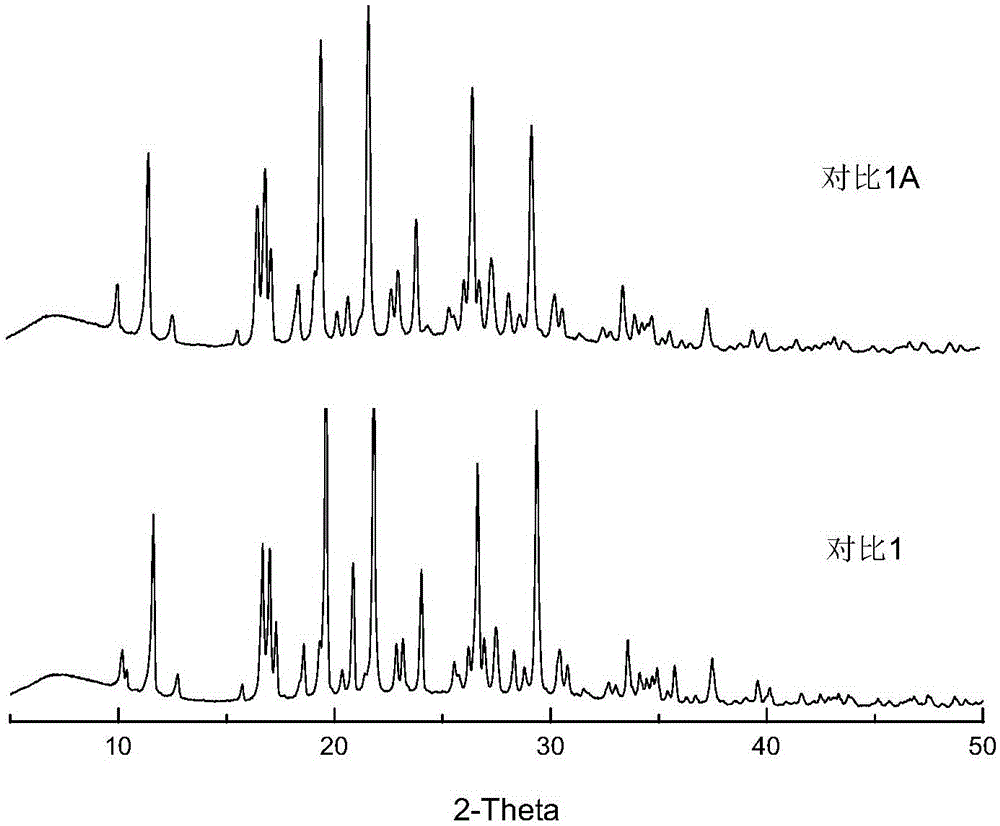

Indometacin amorphous particle, particle drug preparation, preparation method and application

InactiveCN105125503AHigh dissolution rateImprove bioavailabilityOrganic active ingredientsNervous disorderIndometacinAlcohol

The invention discloses an indometacin amorphous particle, a particle drug preparation, a preparation method and application. The preparation method includes the following steps: dissolving indometacin in water containing hydrophilic polymer and alkalizer or low-concentration alcohol water solution; controlling pH of the solution to be 7.5-9; under a mixing condition, adding acidifier until pH of the solution is 2.5-4.5 to form mixed liquid containing the indometacin amorphous particle, and performing separation to obtain the indometacin amorphous particle. Dissolution performance of the indometacin amorphous particle and the particle drug preparation is improved obviously, the indometacin amorphous particle and the particle drug preparation are high in bioavailability if being taken orally, high in stability, simple in preparation method, free of toxic solvent residue, safe, reliable and good in market prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing externally-used medicine gel for treating perianal ulcer

InactiveCN105147675APromote healingEliminates ulcer exudateOrganic active ingredientsAerosol deliveryIndometacinTetrahydropalmatine

The invention discloses a method for preparing externally-used medicine gel for treating perianal ulcer. The method comprises the following steps of weighing raw materials, preparing a gel substrate, dissolving L-tetrahydropalmatine and indomethacin in ethanol, then adding the solution into the substrate, performing even stirring, adding propylene glycol, glycerin and purified water to reach total amount and regulating a pH value of triethanolamine to be neutral to obtain the externally-used medicine gel. The externally-used medicine gel prepared by means of the method contains the tetrahydropatine and indomethacin, can remove ulcerative exudate and accelerate healing of ulcerative surface and accordingly achieves the purpose of curing the perianal ulcer.

Owner:崔新明

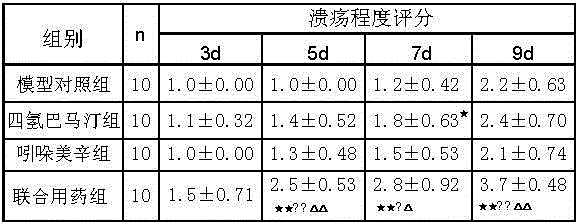

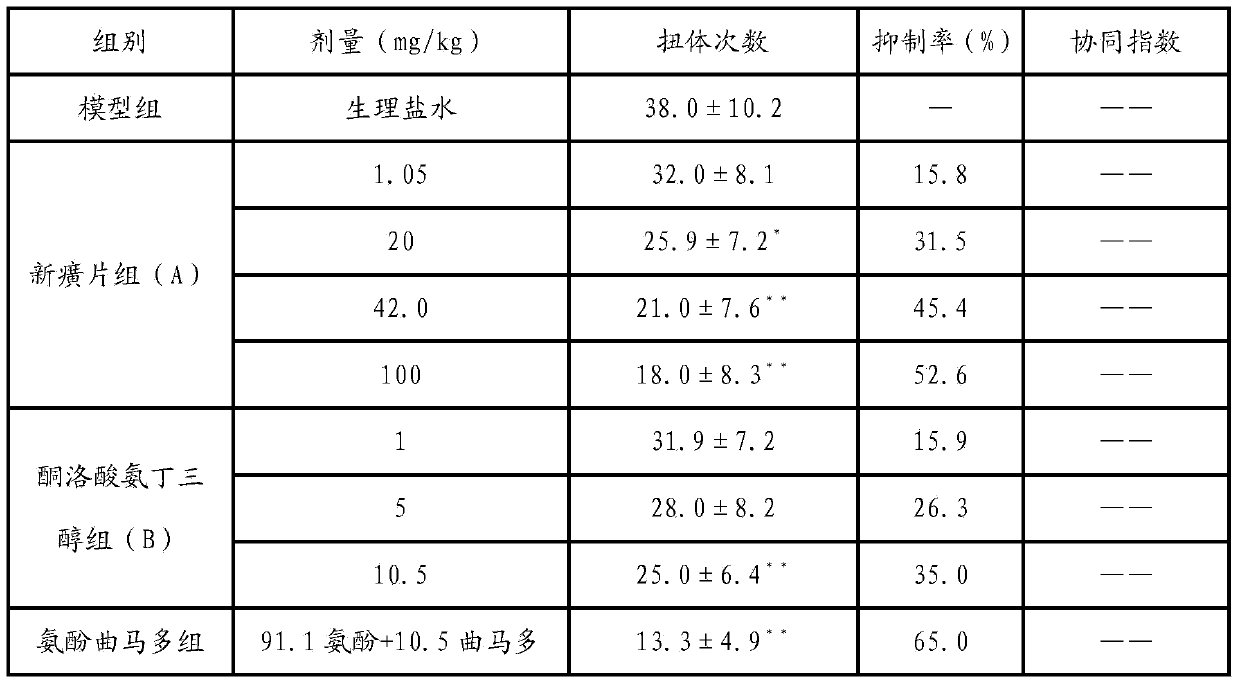

Method for researching abirritation mechanism of Chinese herbal medicinal ingredients of Xinhuang tablets

ActiveCN103432596APain BenefitsGood treatment effectOrganic active ingredientsNervous disorderIndometacinTreatment effect

The invention discloses a method for researching an abirritation mechanism of Chinese herbal medicinal ingredients of Xinhuang tablets and a pharmaceutical composition comprising the Xinhuang tablets. The method for researching the abirritation mechanism comprises the following steps of preparing a Xinhuang tablet sample and an indometacin sample in a weight ratio of 95:2, establishing a living acetic acid writhing reaction model and a living planta reaction model to evaluate the drug treatment effects and the synergic index of the Chinese herbal medicinal ingredients of the Xinhuang tablets and indometacin, and establishing a naloxone occlusion reaction model to evaluate the influence of occlusion on the analgesic effect. Based on the research on the mechanism of action, and in order to improve the treatment effect for analgesia, the invention also provides an analgesic composition which is composed of the Xinhuang tablets and ketorolac tromethamine. The method is used for measuring the abirritation mechanism of the Chinese herbal medicinal ingredients of the Xinhuang tablets, is simple and clear; applicable effective drugs can be selected from the known compound medicines by the pharmacological research method.

Owner:XIAMEN TRADITIONAL CHINESE MEDICINE

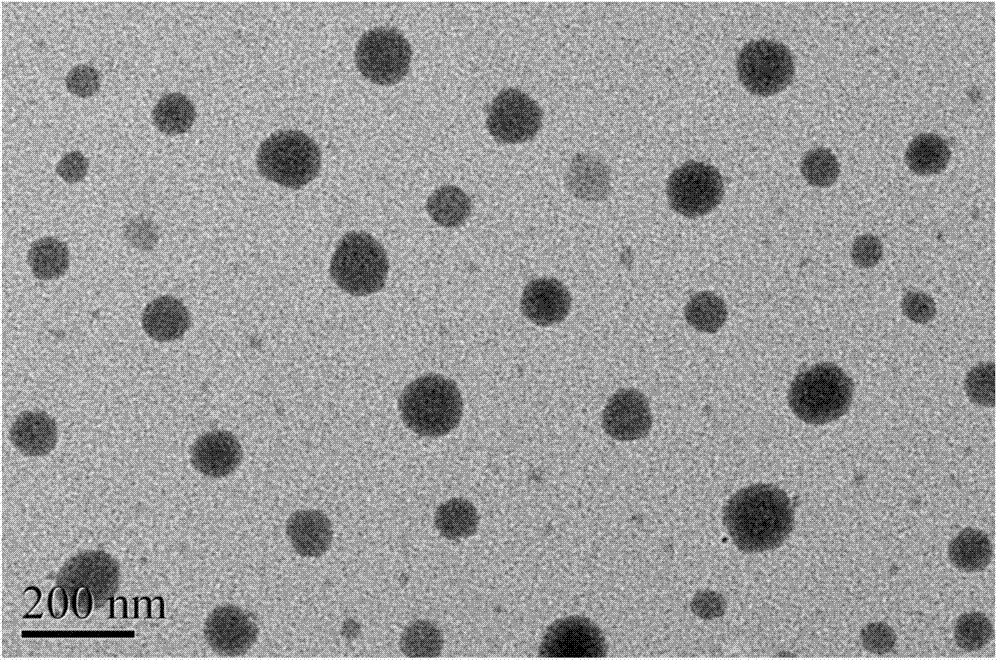

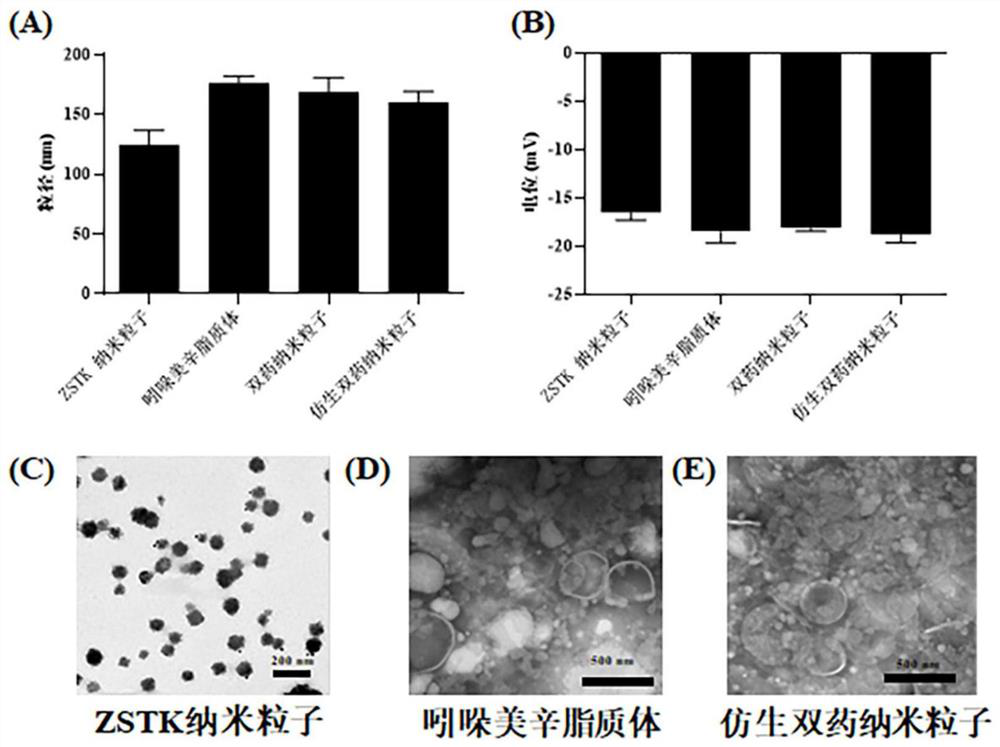

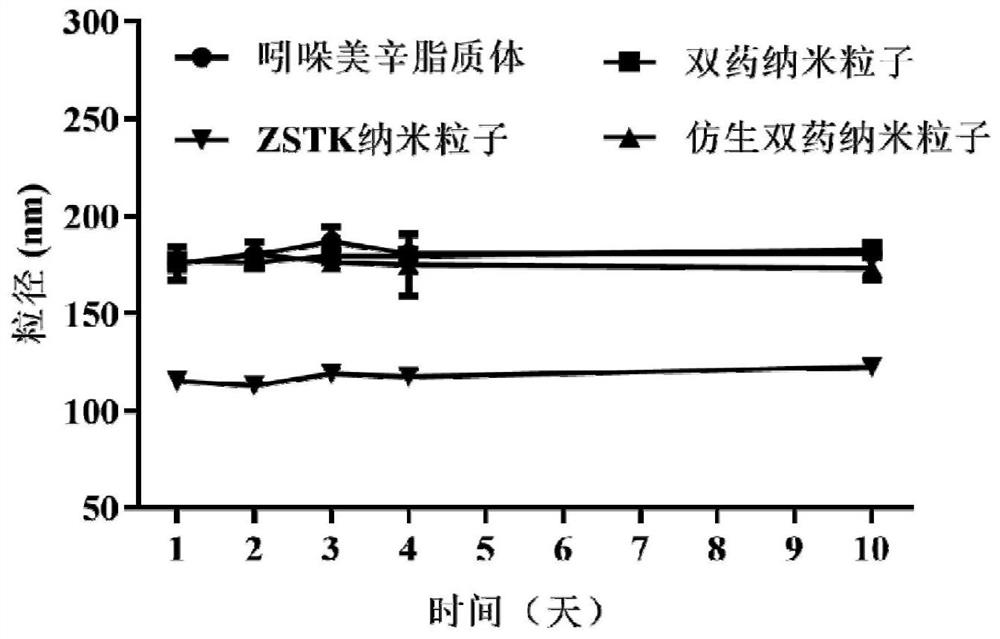

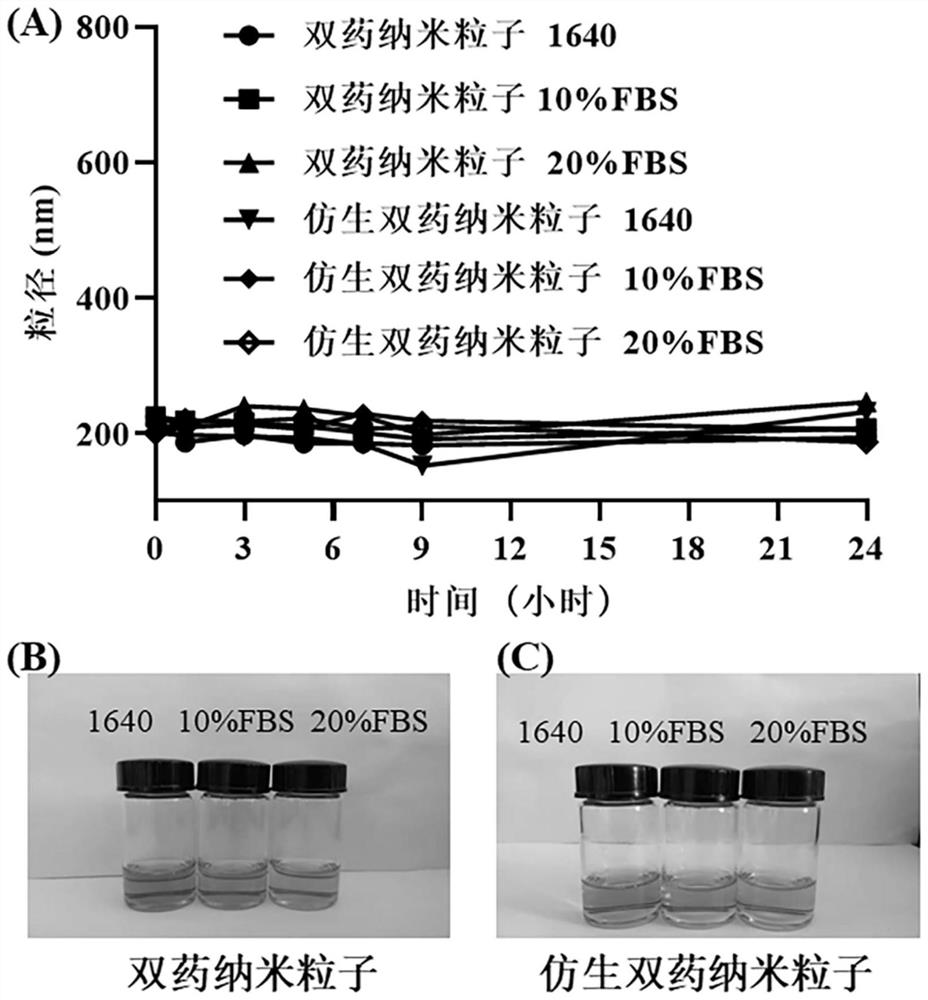

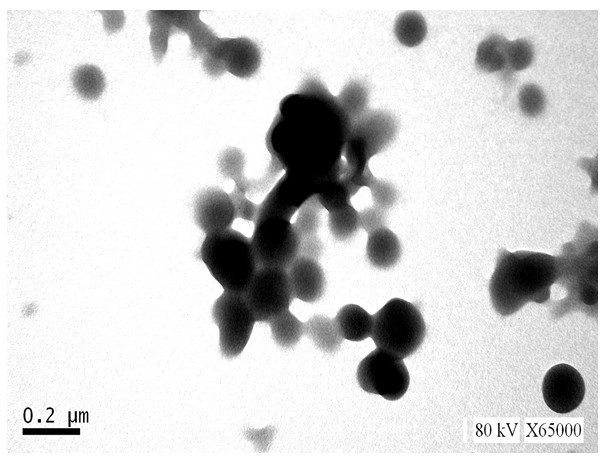

Preparation method of cancer cell membrane chimeric liposome nano drug delivery system

ActiveCN112494495AReduce dosageAdd active targetingOrganic active ingredientsPowder deliveryIndometacinCancer cell

The invention provides a preparation method of a cancer cell membrane chimeric liposome nano drug delivery system. The preparation method comprises the following steps of: dissolving high-purity cholesterol, hydrogenated soybean phospholipid, distearoyl phosphatidyl ethanolamine-polyethylene glycol 2000 and indometacin in absolute ethyl alcohol under a dark condition to prepare an ethanol solution; carrying out rotary evaporation on the obtained ethanol solution to form a thin film; hydrating the thin film to obtain a hydrated thin film; adding a cancer cell membrane suspension solution into the hydrated thin film and extruding to obtain chimeric indometacin liposome; mixing the chimeric indometacin liposome and ZSTK474 carrier-free nanoparticles; and extruding to obtain the cancer cell membrane chimeric liposome nano drug delivery system. By adopting the preparation method of the cancer cell membrane chimeric liposome nano drug delivery system, provided by the invention, an active targeting function on tumor tissues is increased, the anti-tumor efficiency of a drug is easy to improve and the dosage of a tumor cell membrane is extremely saved; and the preparation method is convenient for clinical application.

Owner:TIANJIN MEDICAL UNIV +1

Self-assembly system based on hydrophilic polymer and medicine and preparation method thereof

ActiveCN102091332AEasy to realize industrializationEasy to makeMacromolecular non-active ingredientsIndometacinPolymer science

The invention relates to a self-assembly system based on hydrophilic polymer and medicine and a preparation method thereof. The system consists of a hydrophilic polymer and a carboxyl-containing medicine, wherein the hydrophilic polymer is polymine or beta-cyclodextrin modified polymine; and the carboxyl-containing medicine is selected from ibuprofen, ketoprofen, fenoprofen, flurbiprofene, oxaprozin, naproxen, indometacin, sulindac, etodolac, diclofenac, pontal, meclofenamic acid, flufenamic acid, tolfenamic acid, lumiracoxib, licofelone, diflunisal and aspirin. The system is prepared by dissolving the hydrophilic polymer in a certain amount of water, dissolving the medicine in a water soluble solvent, slowly adding the organic solution of the medicine into the aqueous solution of the polymer under the action of ultrasound, placing the mixed solution in a dialysis bag, dialyzing in deionized water with magnetic stirring, replacing the deionized water at certain time interval, filtering dislysate after 5 to 48 hours, cooling and drying.

Owner:ARMY MEDICAL UNIV

Indomethacin liposome eye drops

InactiveCN1206987CReduce burning sensationLess tinglingOrganic active ingredientsSenses disorderIndometacinLipid formation

The invention relates to an ophthalmic pharmaceutical preparation, especially a liposome eye drop preparation containing indomethacin. The composition of the indomethacin liposome eye drop of the invention is: indomethacin, prepared lipid Body fat, buffer solution.

Owner:珠海丽波医药科技有限公司 +1

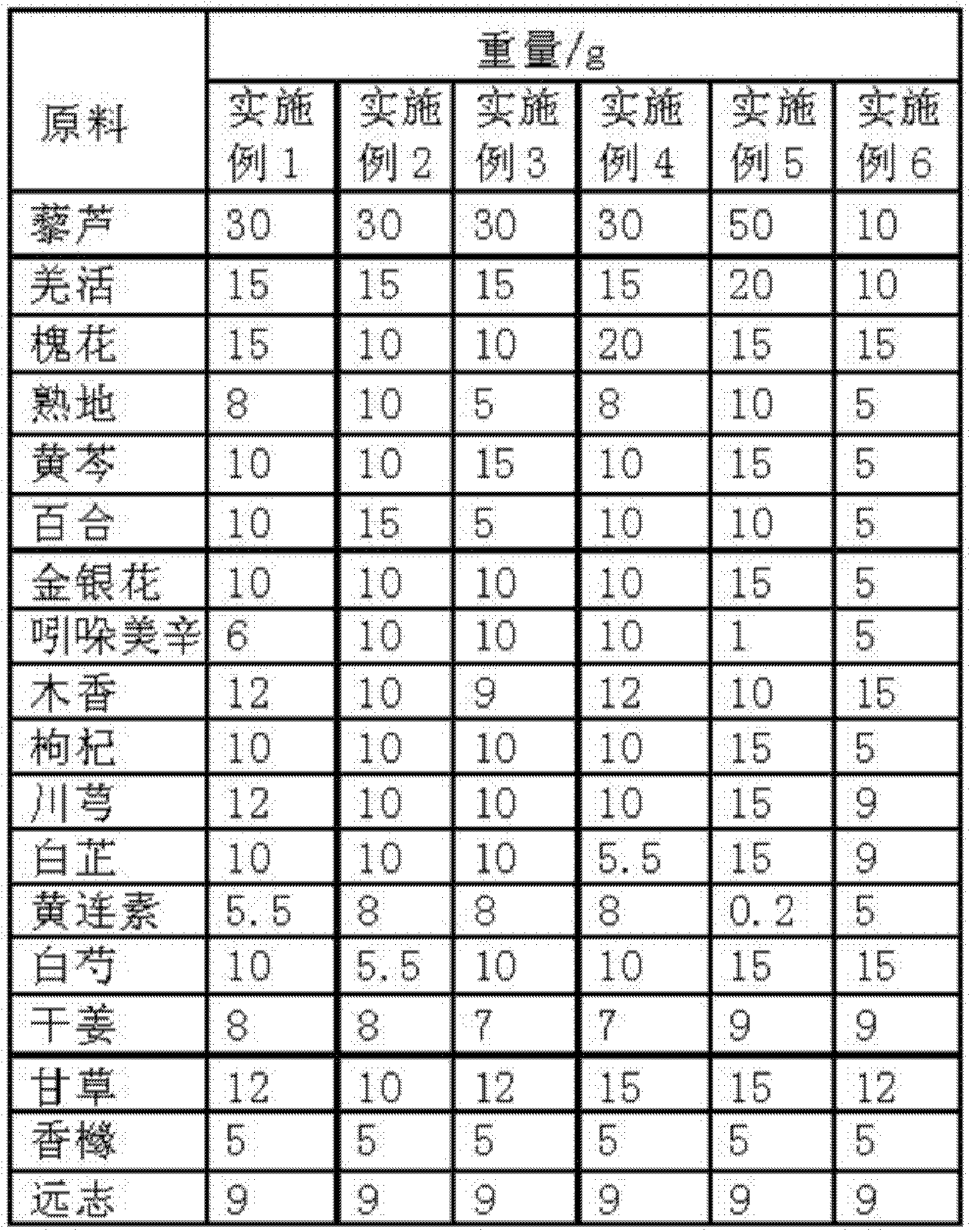

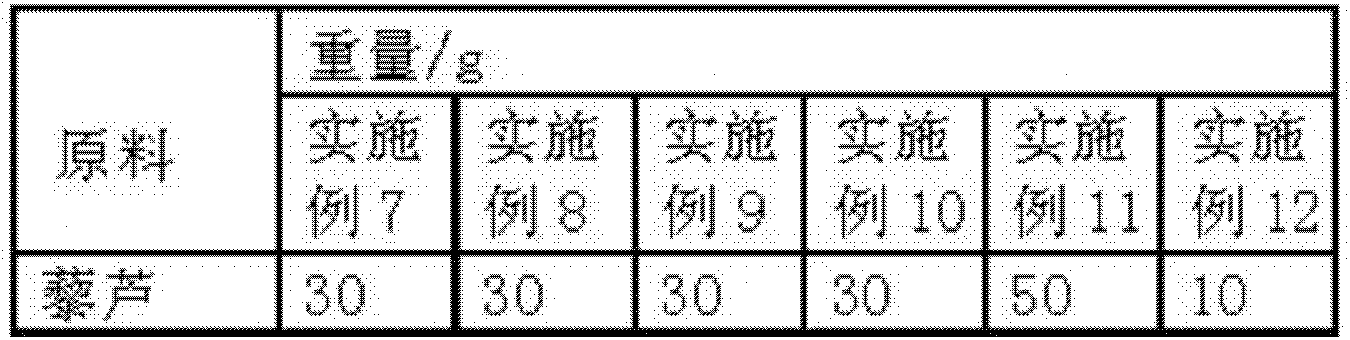

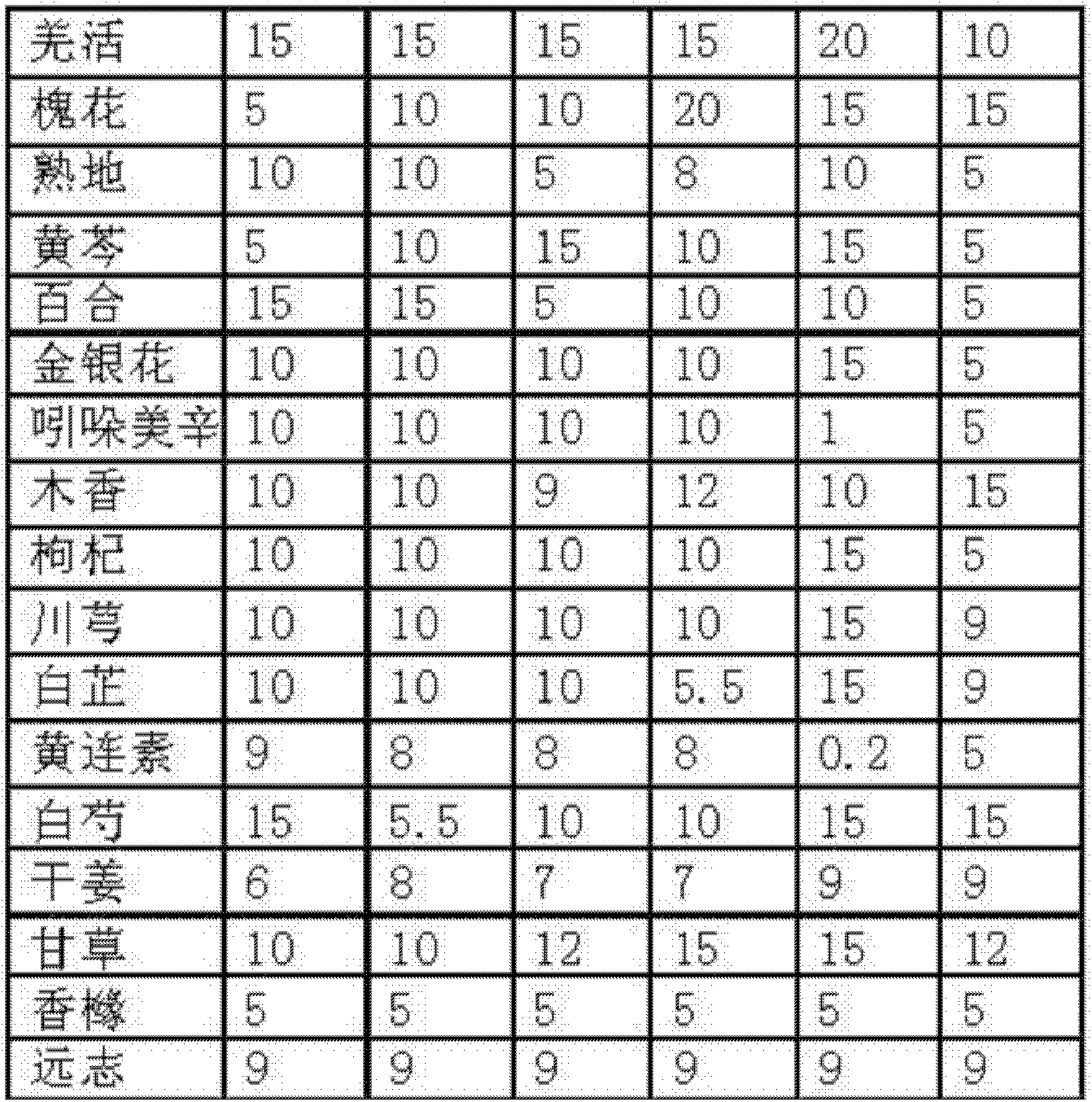

Traditional Chinese and western medicinal compound preparation for treating acute gastroenteritis and preparation method thereof

InactiveCN103800877APromoting blood circulation and removing stasisGood synergyOrganic active ingredientsDigestive systemIndometacinSide effect

The invention belongs to the technical field of medicines, and in particular relates to a traditional Chinese and western medicinal compound preparation for treating acute gastroenteritis and a preparation method thereof. Currently, a chemotherapeutic medicine for treating acute gastroenteritis has the defects of high liver toxicity and poor curative effect in the prior art. The traditional Chinese and western medicinal compound preparation for treating acute gastroenteritis comprises the following components in parts by weight: 10-15 parts of veratrum nigrum, 10-20 parts of notopterygium root, 5-20 parts of sophora japonica, 5-15 parts of scutellaria baicalensis, 5-10 parts of prepared rehmannia, 5-15 parts of lily, 5-15 parts of honeysuckle, 1-10 parts of indometacin, 5-15 parts of medlar, 9-15 parts of costustoot, 9-15 parts of Ligusticum wallichii, 5-15 parts of angelica root, 0.2-9 parts of berberine, 5.5-15 parts of radix paeoniae alba, 6-9 parts of dried ginger, and 10-15 parts of liquorice. The traditional Chinese and western medicinal compound preparation has a good treatment effect on treating or preventing acute gastroenteritis, is low in side effect, and has remarkable clinical application values.

Owner:王雪雁

Hot-melt extrusion process for preparing indometacin quick release preparation from multi-element auxiliary materials

InactiveCN102204868BLower extrusion temperatureFacilitate the extrusion processPowder deliveryOrganic active ingredientsIndometacinPolymer science

The invention discloses a hot-melt extrusion process for preparing an indometacin quick release preparation from multi-element auxiliary materials and belongs to the field of pharmacy. The method comprises the following steps of: crushing indometacin and medicinal auxiliary materials, and after screening the powder with a 60 to 120-mesh sieve, uniformly mixing the powder into a physical mixture; according to the melting points or the glass transition temperatures of the medicament and the auxiliary materials, setting the extrusion temperature of a double-screw hot melt extruder to be between 50 and 150 DEG C, after the extrusion temperature reaches the preset temperature, starting a screw, adding the prepared physical mixture into the extruder, and extruding the physical mixture into strips through the screw; and after crushing the strips, screening the powder with a 20 to 80-mesh sieve to obtain medicinal solid dispersoid particles or powder. The auxiliary materials comprise the following components in percentage by weight: 10 to 90 percent of polymer, 5 to 50 percent of plasticizer, 0 to 10 percent of lubricant, 0 to 5 percent of surfactant and 0 to 20 percent of disintegrant. A sugar alcohol with a relatively low softening point or melting point, and the like, serving as the plasticizer, is added into the polymer with a relatively high softening point or melting point so as to reduce the extrusion temperature and make the extrusion process easy. The prepared indometacin solid dispersoid has the characteristic of quickly dissolving out.

Owner:BEIJING UNIV OF CHEM TECH

Compound radix angelicae pubescentis transdermal patch used for treating rheumatism and preparation method thereof

InactiveCN105288023AHigh content of active ingredientsImprove bioavailabilityHydroxy compound active ingredientsAntipyreticIndometacinTransdermal patch

The invention discloses a compound radix angelicae pubescentis transdermal patch used for treating rheumatism and a preparation method thereof. The Chinese herb compound is prepared from radix angelicae pubescentis, angelica sinensis, cassia twigs, ash bark and cyperus rotundus. A volatile oil mixture of the Chinese herb compound is extracted, then a transdermal patch matrix is prepared, the volatile oil extract of the Chinese herb compound, indometacin and borneol are dissolved with 75% ethyl alcohol and then evenly mixed with the matrix, the medicine is evenly applied on a back layer, a polyacrylic resin pressure-sensitive adhesive is smeared around the medicine, the product is covered with release paper and cut to have a regulated area, and the transdermal patch is obtained after sealed packaging. The patch can stop pain rapidly and prevent stimulation to the gastrointestinal tract, the liver and the kidneys from indometacin.

Owner:周菊香

Slow-release aerogel and indomethacin-loaded slow-release aerogel

ActiveCN107987323AHigh dissolution rateImprove bioavailabilityOrganic active ingredientsAntipyreticPolyvinyl alcoholMolecular materials

The invention belongs to the technical field of medicine slow release and high molecular materials and discloses slow-release aerogel and indomethacin-loaded slow-release aerogel. The slow-release aerogel is prepared by the following steps: taking nanocellulose and sodium periodate to be subjected to oxidization reaction to obtain aldehyde nanocellulose; then dispersing the aldehyde nanocelluloseinto a solvent and adding lysine to react to obtain lysine modified nanocellulose; dispersing the obtained product into a water solution of cationic guar gum and polyvinyl alcohol; then adding an alkaline catalyst and a macromolecular crosslinking agent in sequence; standing and crosslinking at 25 to 70 DEG C and carrying out polymerization reaction for 6 to 24h to obtain aerogel; neutralizing theaerogel, immersing and washing, freezing and drying to obtain the slow-release aerogel. The slow-release aerogel is immersed into an ammonia water solution of indomethacin and is subjected to swelling and adsorption; after the adsorption is balanced, a product is taken out and dried to obtain the indomethacin-loaded slow-release aerogel. According to the slow-release aerogel and the indomethacin-loaded slow-release aerogel, the lysine modified nanocellulose is added and the loading rate and the slow release speed of the prepared aerogel on the indomethacin are adjustable.

Owner:SOUTH CHINA UNIV OF TECH

Application of traditional Chinese medicine composition in preparation of drug for treating osteoarthritis

InactiveCN103655871ARelieve superficial symptomsGood inhibitory effectAntipyreticAnalgesicsIndometacinInflammatory factors

The invention discloses an application of traditional Chinese medicine composition in preparation of a drug for treating osteoarthritis. The traditional Chinese medicine composition comprises traditional Chinese medicines in parts by weight as follows: 600 parts of rhizoma cibotii, 192 parts of fructus rosae fruit, 360 parts of caulis spatholobi, 144 parts of philippine flemingia roots, 360 parts of kadsura coccinea, 240 parts of beautiful millettia roots, 30 parts of glossy privet fruit, 180 parts of mistletoe, 30 parts of semen cuscutae, 26 parts of rhizoma corydalis, 26 parts of radix zanthoxyli, 12 parts of mastic and 20 parts of myrrh. Research demonstrates that the traditional Chinese medicine composition has anti-inflammatory and analgesic effects, has a good inhibiting effect on inflammatory factors causing the osteoarthritis, and is definite in curative effect compared with indometacin and diacerein used clinically. The traditional Chinese medicine composition is used as a traditional Chinese patent medicine and has no adverse effect during decades of clinical use, so that the high-efficiency and low-toxicity treatment drug is provided for patients with the osteoarthritis, and the significant progress is achieved.

Owner:GUANGZHOU CHEN LI JI PHARMA FACTORY

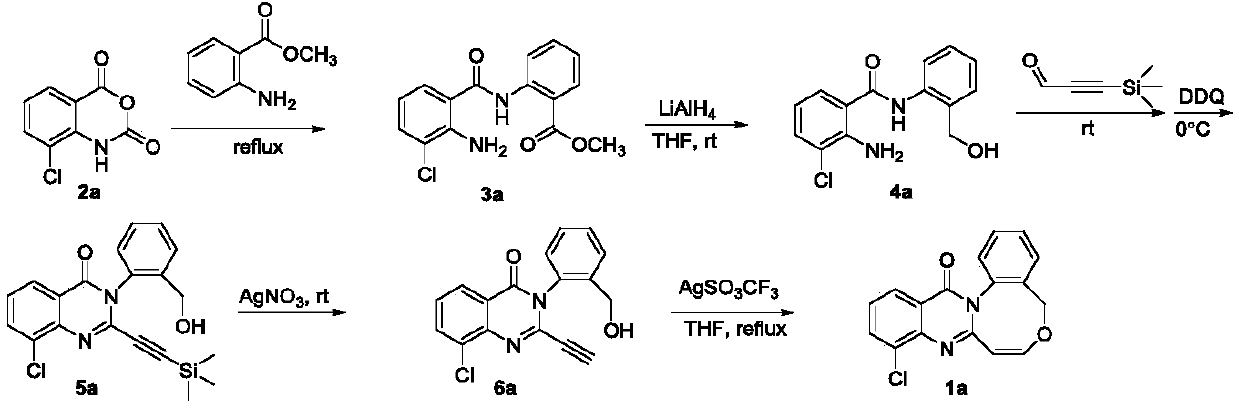

Quinazolinone derivatives and production method and application thereof

ActiveCN110724153AHigh yieldReduce manufacturing costOrganic chemistryAntipyreticIndometacinChemical compound

The invention discloses quinazolinone derivatives and a production method and application thereof. The quinazolinone derivatives are synthesized by means of the simple and convenient method, the yields are high, the production cost is low, with a concentration of 50 mM and an LPS concentration of 1 <mu>g / mL, the capability of compounds 1a, 1i, 1l and 1n of inhibiting release of NO is superior to that of an anti-inflammatory medicine indometacin, while the capability of 1b, 1e and 1j of inhibiting release of NO is equivalent to that of indometacin; and the cytotoxic effects of the compounds 1a,1i, 1l, 1n, 1b and 1j, with high capability of inhibiting release of NO, on RAW264.7 cells are all lower than that of the anti-inflammatory medicine indometacin. The quinazolinone derivatives have obvious anti-inflammatory effects and very low toxicity, can be made into anti-inflammatory medicines in various dosage forms, and have very high medical values and wide market prospects.

Owner:GUANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com