Indometacin sustained release tablet, preparation method thereof, as well as release controlling method and standard

A technology of indomethacin sustained-release tablets and indomethacin, which is applied in the field of medicine, can solve problems such as the direct preparation process of indomethacin sustained-release tablet powder and the method and standard of controlled release, and achieve production The process is simple and controllable, the standard method is accurate, and the effect of improving clinical efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0203] Preparation:

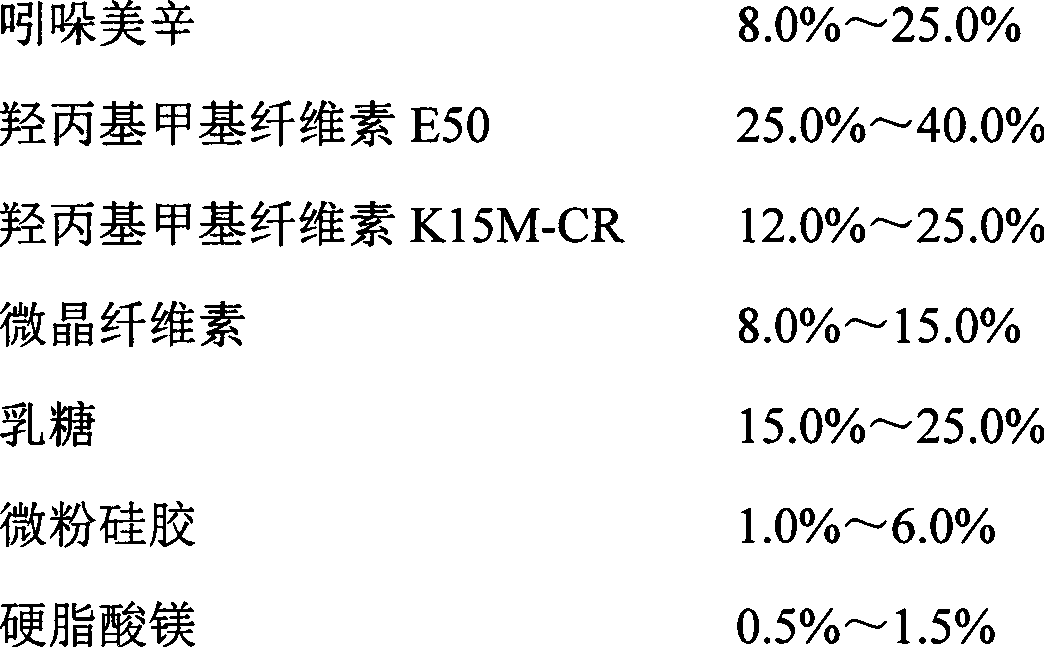

[0204] (1) Take the following components by weight:

[0205] components

unit (g)

Indomethacin

198

Hydroxypropyl Methyl Cellulose E50

660

Hydroxypropyl Methyl Cellulose K15M-CR

550

217.8

541.2

Micropowder silica gel

22

11

production

10000 pieces

[0206] (2) Pass the prescribed amount of indomethacin, hydroxypropyl methylcellulose K15M-CR and micropowdered silica gel through a 100-mesh sieve for 3 times, mix for 10 minutes, and set aside;

[0207] (3) Pass the hydroxypropyl methylcellulose E50 of the prescribed amount through an 80-mesh sieve once, add the materials in the above (2), mix for 9 minutes, and set aside;

[0208] (4) Pass the prescribed amount of microcrystalline cellulose and lactose through an 80-mesh sieve once, add the materials in the above (3), mix for 6 minutes, and s...

Embodiment 2

[0213] Preparation:

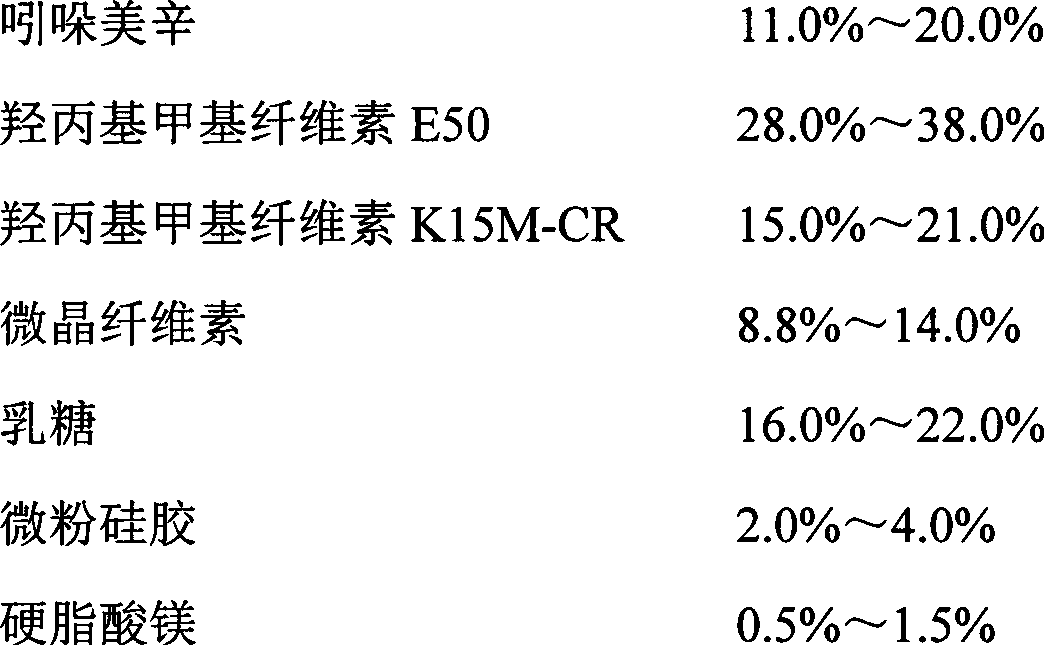

[0214] (1) Take the following components by weight:

[0215] components

unit (g)

Indomethacin

528

Hydroxypropyl Methyl Cellulose E50

550

Hydroxypropyl Methyl Cellulose K15M-CR

286

242

440

Micropowder silica gel

121

33

production

10000 pieces

[0216] (2) Pass the prescribed amount of indomethacin, hydroxypropyl methylcellulose K15M-CR and micropowdered silica gel through a 100-mesh sieve for 3 times, mix for 6 minutes, and set aside;

[0217] (3) Pass the hydroxypropyl methylcellulose E50 of the prescription amount through an 80-mesh sieve once, add the materials in the above (2), mix for 6 minutes, and set aside;

[0218] (4) Pass the prescribed amount of microcrystalline cellulose and lactose through an 80-mesh sieve once, add the materials in the above (3), mix for 10 minutes, and se...

Embodiment 3

[0223] Preparation:

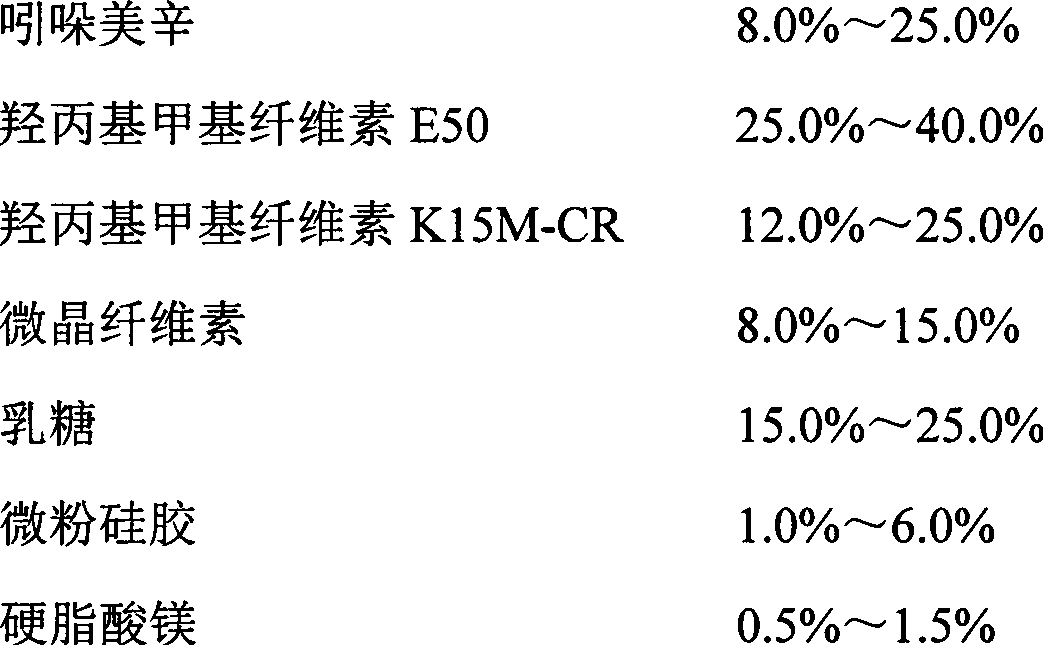

[0224] (1) Take the following components by weight:

[0225] components

unit (g)

Indomethacin

396

Hydroxypropyl Methyl Cellulose E50

660

Hydroxypropyl Methyl Cellulose K15M-CR

462

microcrystalline cellulose

242

lactose

330

Micropowder silica gel

77

Magnesium stearate

33

production

10000 pieces

[0226] (2) Pass the prescribed amount of indomethacin, hydroxypropyl methylcellulose K15M-CR and micropowdered silica gel through a 100-mesh sieve for 3 times, mix for 15 minutes, and set aside;

[0227] (3) Pass the hydroxypropyl methylcellulose E50 of the prescription amount through an 80-mesh sieve once, add the materials in the above (2), mix for 8 minutes, and set aside;

[0228] (4) Pass the prescribed amount of microcrystalline cellulose and lactose through an 80-mesh sieve once, add the materials in the above (3), mix for 8 minutes, and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com