Preparation method for surface enhanced Raman scattering substrate based on cationic resin

A surface-enhanced Raman and cationic resin technology, which is applied in the fields of biochemical analysis and detection and laser Raman spectroscopy detection, can solve problems such as pollution, complex preparation process, and difficult control of substrate uniformity, achieving obvious enhancement effect and simple preparation method , The effect that the production process is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Add 2g of silver nitrate to 30mL of pure water, and stir to dissolve it completely;

[0043] (2) take by weighing 5g cationic resin and join in the silver nitrate solution that step (1) obtains, stir 2 hours with the rotating speed of 200rpm;

[0044] (3) filter the solution obtained in step (2), and wash the filtered cationic resin with pure water 5 times;

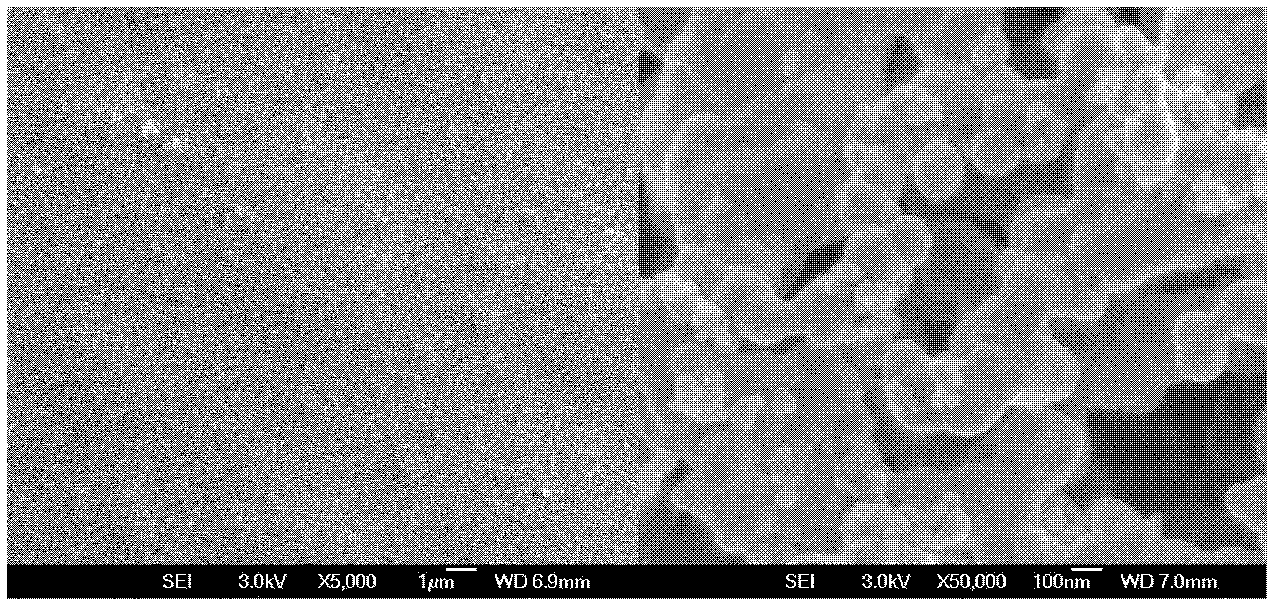

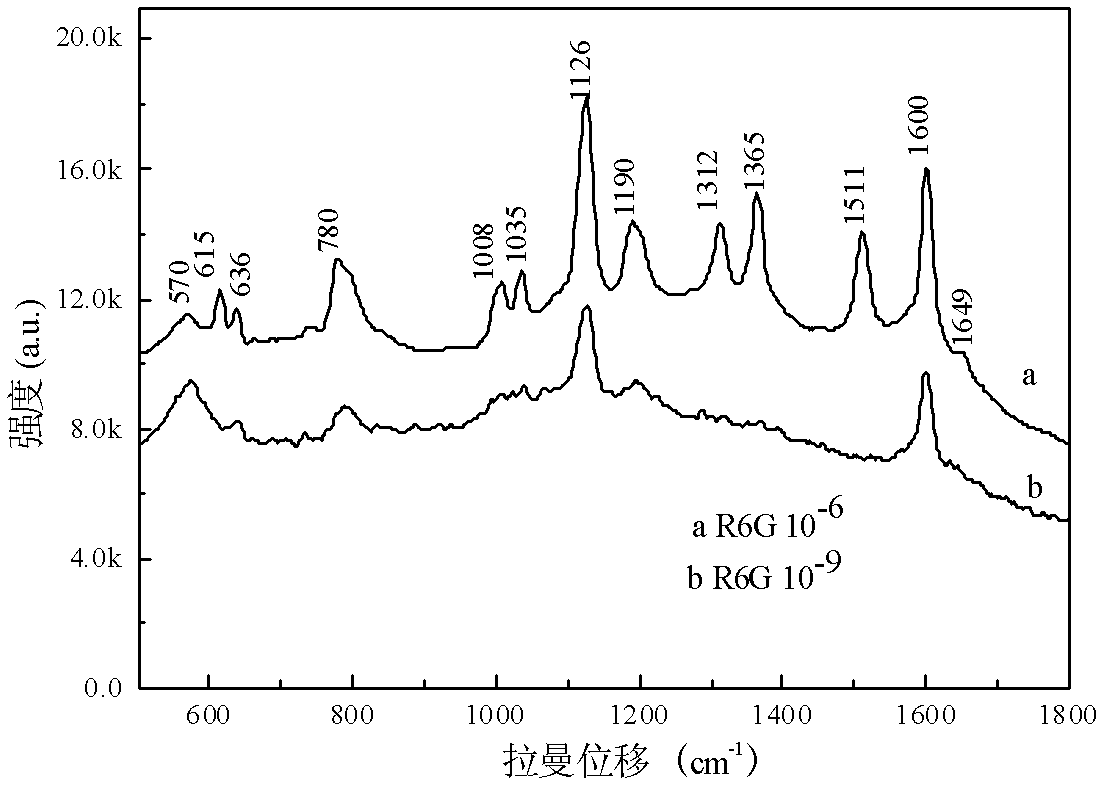

[0045] (4) Add 20mL of pure water to the resin after the cleaning of step (3) gained and place in 10 ℃ of water baths, stir with the rotating speed of 200rpm; Then add the sodium borohydride solution 6mL that mass percent concentration is 10%, continue with the same Stir at a rotating speed, react for 30 seconds, and the surface of the resin is covered with a layer of nano-silver particles; figure 1 shown in the figure on the right.

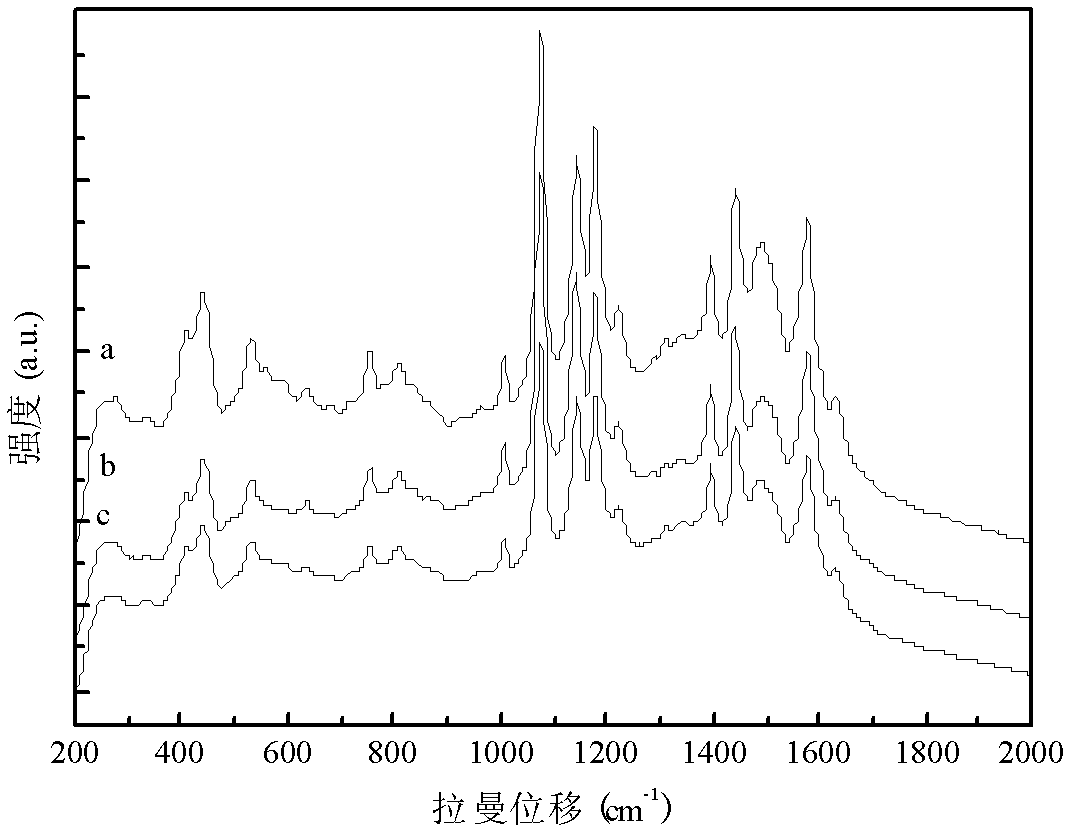

[0046] (5) Wash the silver-coated resin obtained in step (4) several times, and dry it in a constant temperature oven to obtain a surface-enhanced Raman scattering substrate wit...

Embodiment 2

[0049] (1) Add 1.5g of silver nitrate to 30mL of pure water and stir to dissolve it completely;

[0050] (2) Take by weighing 4g cationic resin and join in the silver nitrate solution that step (1) obtains, stir about 2 hours with the rotating speed of 200rpm;

[0051] (3) filter the solution obtained in step (2), and wash the filtered cationic resin with pure water 5 times;

[0052] (4) add 20mL pure water to the resin after step (3) gained cleaning and place in 10 ℃ of water baths, stir with the rotating speed of 200rpm; Then add the sodium borohydride solution 6mL that the mass percent concentration is 10%, continue with the same Stir at high speed, react for 30 seconds, and the surface of the resin is covered with a layer of nano-silver particles;

[0053] (5) Wash the silver-coated resin obtained in step (4) several times, and dry it in a constant temperature oven to obtain a surface-enhanced Raman scattering substrate with stable detection signals.

[0054] Dissolve p-...

Embodiment 3

[0057] (1) Add 3g of silver nitrate to 50mL of pure water and stir to dissolve it completely;

[0058] (2) Take 8g cationic resin and join in the silver nitrate solution that step (1) obtains, stir about 2 hours with the rotating speed of 200rpm;

[0059] (3) filter the solution obtained in step (2), and wash the filtered cationic resin with pure water for 4 times;

[0060] (4) add 20mL pure water to the resin after step (3) gained cleaning and be placed in 10 ℃ of water baths, stir with the rotating speed of 200rpm; Add the sodium borohydride solution 8mL that mass percent concentration is 10% then, continue with the same Stir at high speed, react for 40 seconds, and the surface of the resin is covered with a layer of nano-silver particles;

[0061] (5) Wash the silver-coated resin obtained in step (4) several times, and dry it in a constant temperature oven to obtain a surface-enhanced Raman scattering substrate with stable detection signals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com