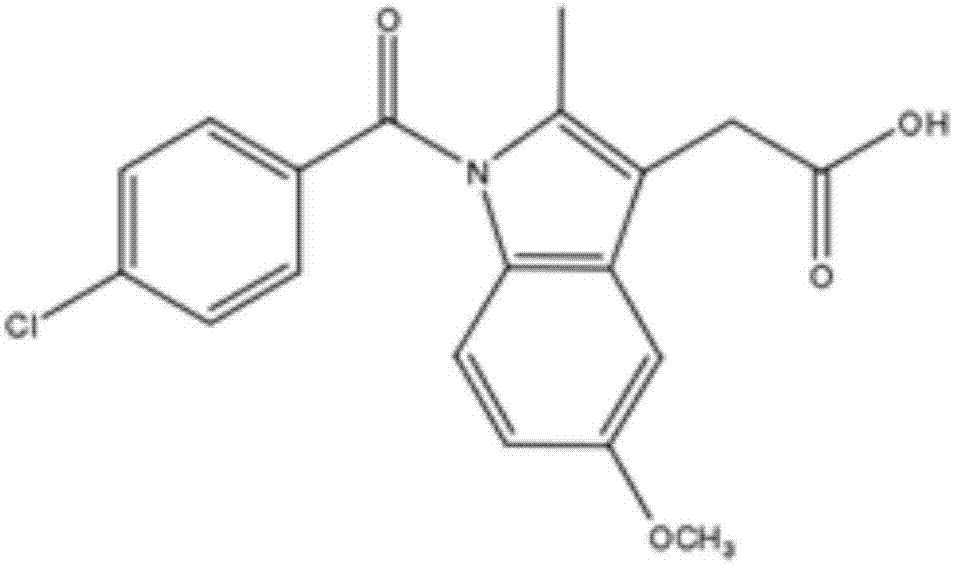

Slow-release aerogel and indomethacin-loaded slow-release aerogel

A technology of indomethacin and airgel, which is applied in the direction of medical preparations containing non-active ingredients, medical preparations containing active ingredients, organic active ingredients, etc., to achieve the effect of mild conditions, high loading efficiency, and easy volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

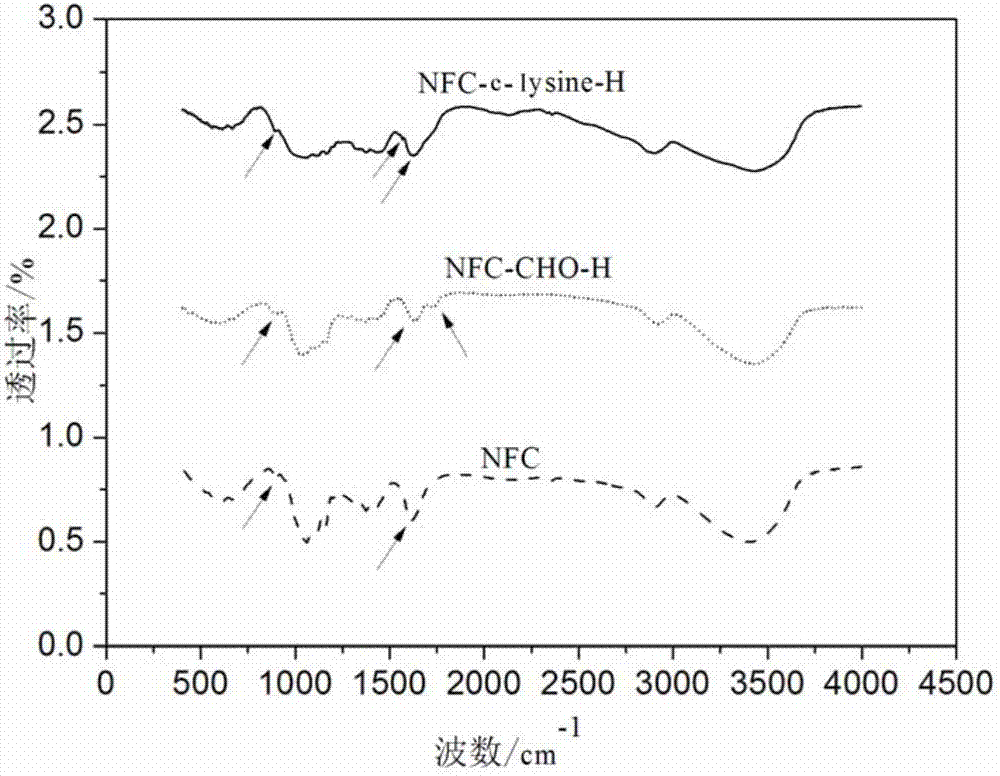

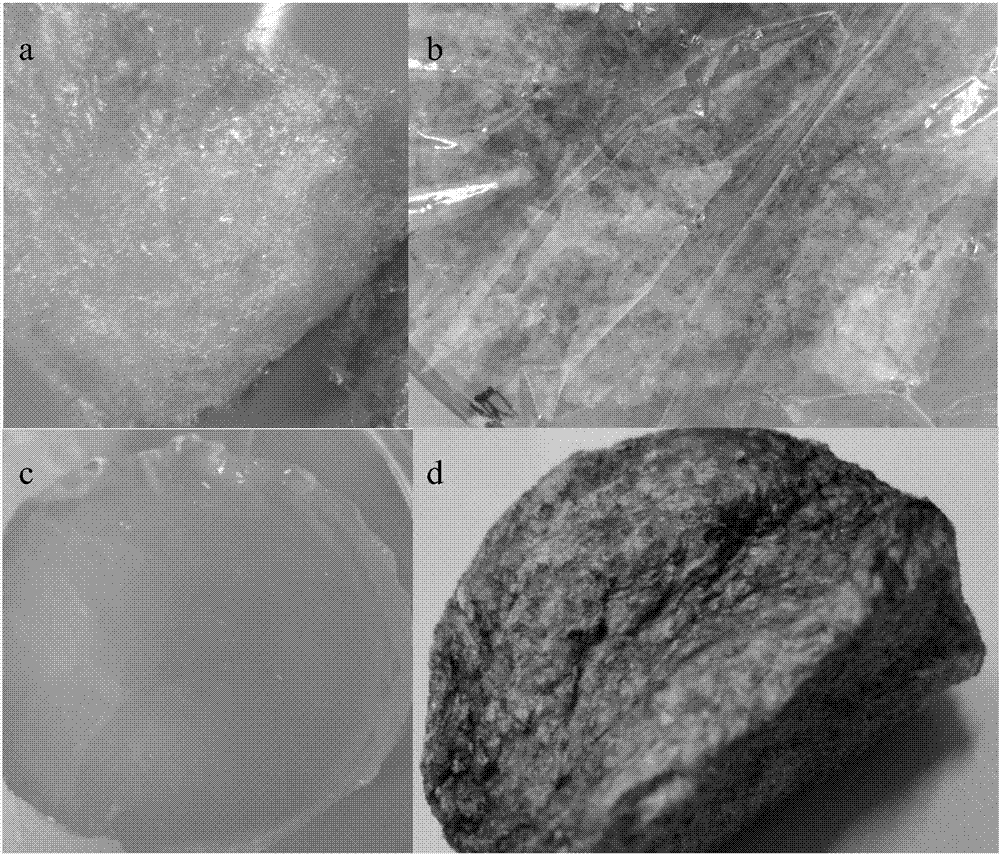

[0034] (1) Disperse 1g of nanocellulose raw material in 0.1M acetic acid buffer solution (pH=4.5) to obtain a 1% viscous solution, add 0.8g of sodium periodate, stir well, react at 40°C for 10h, add ethyl alcohol The reaction was terminated with 2 ml of diol, and then subjected to a large amount of water dialysis treatment for 2 days to obtain purified aldylated nanocellulose. After freeze-drying treatment, white formylated nano-cellulose is obtained. The whole reaction was carried out in a three-neck flask, which was wrapped with black paper to avoid light.

[0035] (2) Add the aldylated nanocellulose (0.5 g dry weight) of step (1) into a mixed solvent composed of 9 mL DMSO and 1 mL water, soak to make the material fully swell, and then add 0.5 mL of lysine solid g, reacted at 50°C for 4 hours, the color of the material changed from colorless to brown. After the reaction material dropped to room temperature, 0.5g of sodium borohydride alcohol solution was added, and a large ...

Embodiment 2

[0043] Step (1) is with embodiment 1.

[0044] (2) Add the aldylated nanocellulose (0.5 g dry weight) of step (1) into a mixed solvent composed of 9 mL DMSO and 1 mL water, soak to make the material fully swell, and add 1.0 g of lysine solid , reacted at 60°C for 8 hours, the color of the material changed from colorless to brown. After the reaction material dropped to room temperature, 0.5g of sodium borohydride alcohol solution was added, and a large amount of hydrogen gas could be seen. The purpose of sodium borohydride is to make the imine group The group (C=N) is reduced to an amino group. Finally, the product solution was dialyzed with a large amount of deionized water to obtain lysine-modified nanocellulose.

[0045] (3) disperse the lysine-modified nanocellulose (0.4g of dry weight) of step (2) in the aqueous solution containing 1.6g cationic guar gum and 0.2g polyvinyl alcohol, stir at high speed, obtain viscous White solution, add aqueous solution of sodium hydroxid...

Embodiment 3

[0050] Step (1) is with embodiment 1.

[0051] (2) Add the aldylated nanocellulose (0.5 g dry weight) of step (1) into a mixed solvent composed of 9 mL DMSO and 1 mL water, soak to make the material fully swell, and add 0.25 g of lysine white solid g, reacted at 30°C for 4 hours, the color of the material changed from colorless to brown. After the reaction material dropped to room temperature, 0.5g of sodium borohydride alcohol solution was added, and a large amount of hydrogen gas could be seen. The purpose of sodium borohydride was to make the imine produced The group (C=N) is reduced to an amino group. Finally, the product solution was dialyzed with a large amount of deionized water to obtain lysine-modified nanocellulose.

[0052] (3) disperse the lysine-modified nanocellulose (0.2g of dry weight) of step (2) in the aqueous solution containing 2g cationic guar gum and 0.2g polyvinyl alcohol, stir at high speed, obtain viscous white solution, add an aqueous solution of so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com