Preparation method and application of biocompatible nano composite hydrogel

A biocompatible and nanocomposite technology, which is applied in the field of preparation of biocompatible nanocomposite hydrogels, can solve the problems of limiting the application of hydrogels, low cross-linking density, and weak strength, and achieve excellent mechanical properties, Low production cost, reduced release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

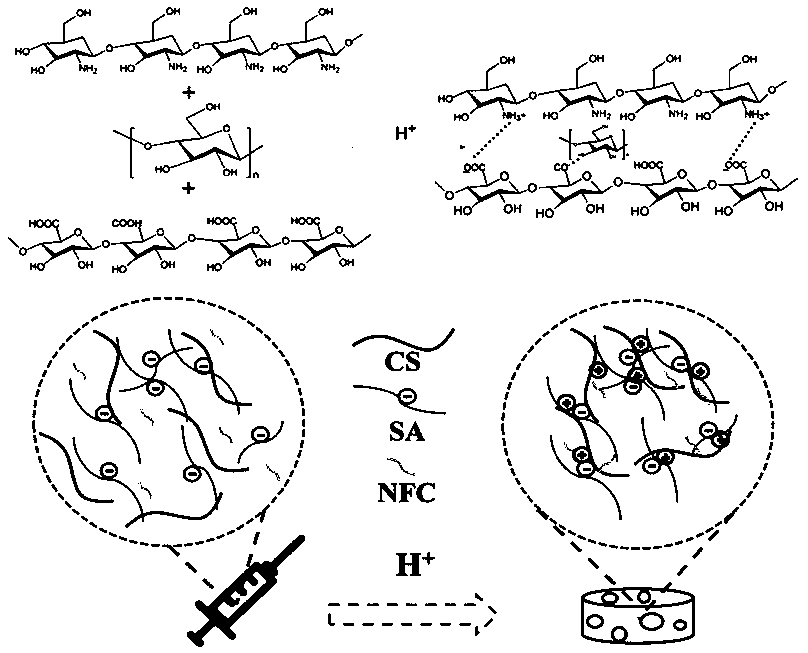

Method used

Image

Examples

Embodiment 1

[0027] (1) First, weigh choline chloride and oxalic acid with a molar ratio of 1:2 and place them in a three-necked flask, and heat and stir in an oil bath at 90° C. for half an hour to obtain a clear and transparent eutectic solvent; Add the above deep eutectic solvent, the solid-liquid ratio is 1:20, and carry out purification pretreatment at 110 ° C for 3 hours; then, use deionized water and absolute ethanol to wash to remove the residual deep eutectic solvent to obtain purified cellulose. Next, the purified cellulose was directly added to the ball milling tank for wet ball milling for 16 h, and then centrifuged at 8000 r / min for 8 min for 5 times. Finally, the nanofibrillated cellulose colloid with a concentration of 2% was obtained by rotary evaporation.

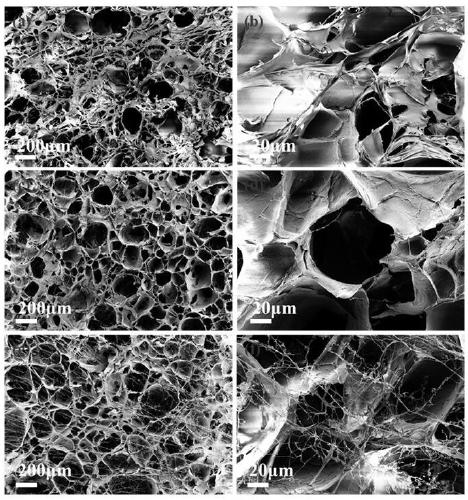

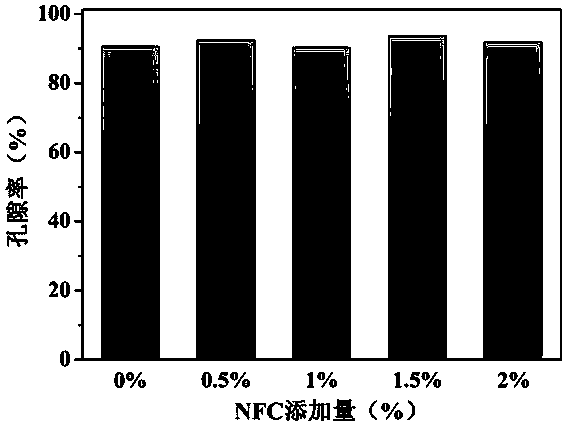

[0028] (2) First, take a certain volume (the content of nanofibrillated cellulose is 0.5% of sodium alginate / chitosan) of nanofibrillated cellulose colloid and disperse it in deionized water, and ultrasonically disperse ...

Embodiment 2

[0031] (1) First, weigh choline chloride and oxalic acid with a molar ratio of 1:2 and place them in a three-necked flask, and heat and stir in an oil bath at 90° C. for half an hour to obtain a clear and transparent eutectic solvent; Add the above deep eutectic solvent, the solid-liquid ratio is 1:20, and carry out purification pretreatment at 120 ° C for 1 hour; then, use deionized water and absolute ethanol to wash to remove the residual deep eutectic solvent to obtain purified cellulose. Next, the purified cellulose was directly added to the ball milling tank for wet ball milling for 20 h, then centrifuged at 8000 r / min for 8 min, centrifuged for 5 times, and finally the nanofibrillated cellulose colloid with a concentration of 2% was obtained by rotary evaporation.

[0032] (2) First, take a certain volume (the content of nanofibrillated cellulose is 1% of sodium alginate / chitosan) of nanofibrillated cellulose colloid and disperse it in deionized water, and ultrasonically di...

Embodiment 3

[0035] (1) First, weigh choline chloride and oxalic acid with a molar ratio of 1:2 and place them in a three-necked flask, and heat and stir in an oil bath at 90° C. for half an hour to obtain a clear and transparent eutectic solvent; Add the above deep eutectic solvent, the solid-liquid ratio is 1:20, and carry out purification pretreatment at 100 ° C for 5 hours; then, use deionized water and absolute ethanol to wash to remove the residual deep eutectic solvent to obtain purified cellulose. Next, the purified cellulose was directly added to the ball milling tank for wet ball milling for 12 h, and then centrifuged at 8000 r / min for 8 min for 5 times. Finally, the nanofibrillated cellulose colloid with a concentration of 2% was obtained by rotary evaporation.

[0036] (2) First, take a certain volume (the content of nanofibrillated cellulose is 1.5% of sodium alginate / chitosan) of nanofibrillated cellulose colloid and disperse it in deionized water, and ultrasonically disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com