Hot-melt extrusion process for preparing indometacin quick release preparation from multi-element auxiliary materials

A technology of hot-melt extrusion and indomethacin, which can be applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and devices that make medicines into special physical or ingestible forms, which can solve the disadvantages Hot-melt extrusion process, unfavorable drug highly dispersed, difficult drug mixing and other problems, to achieve the effect of short heating time, low cost, and no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

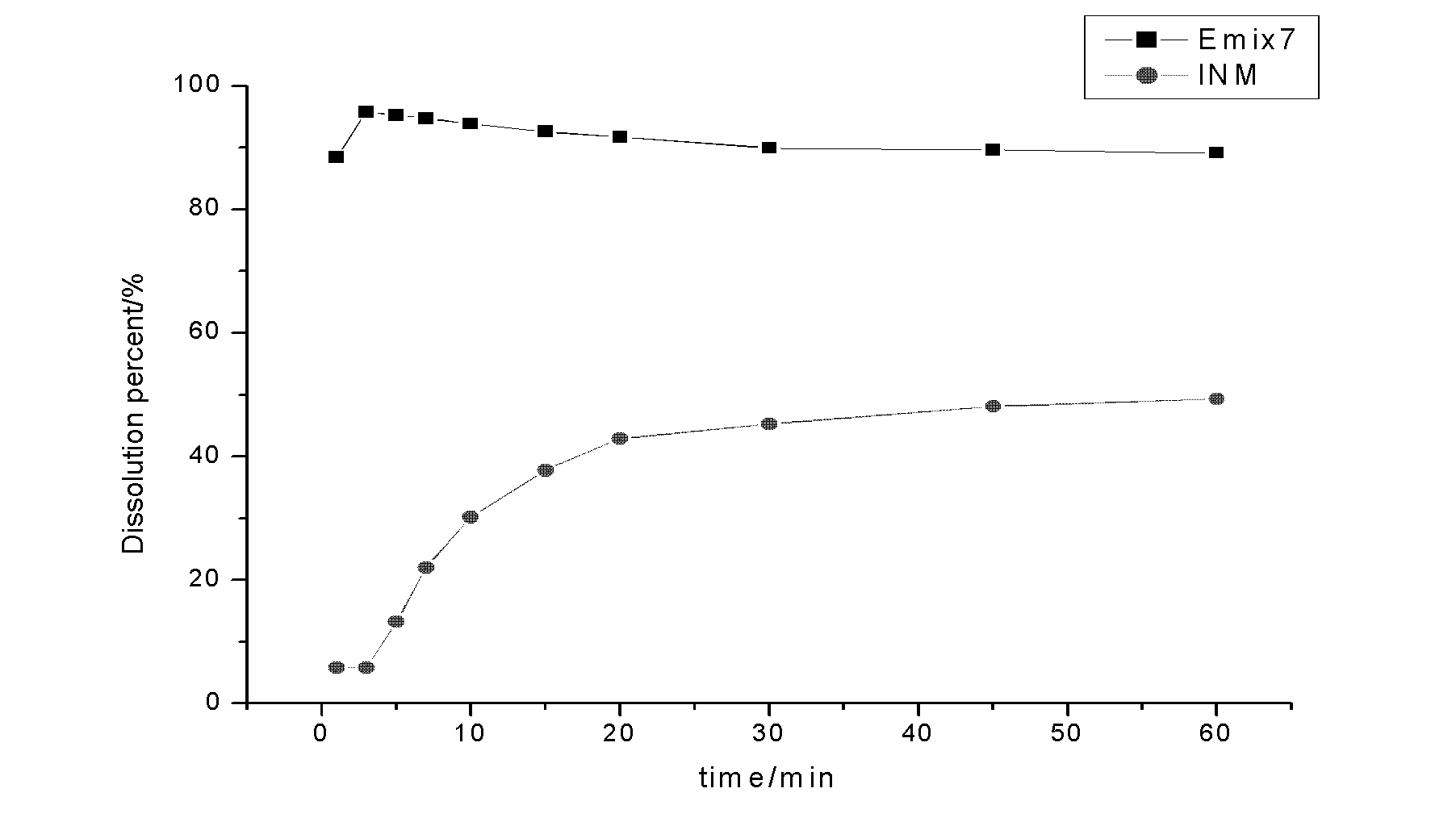

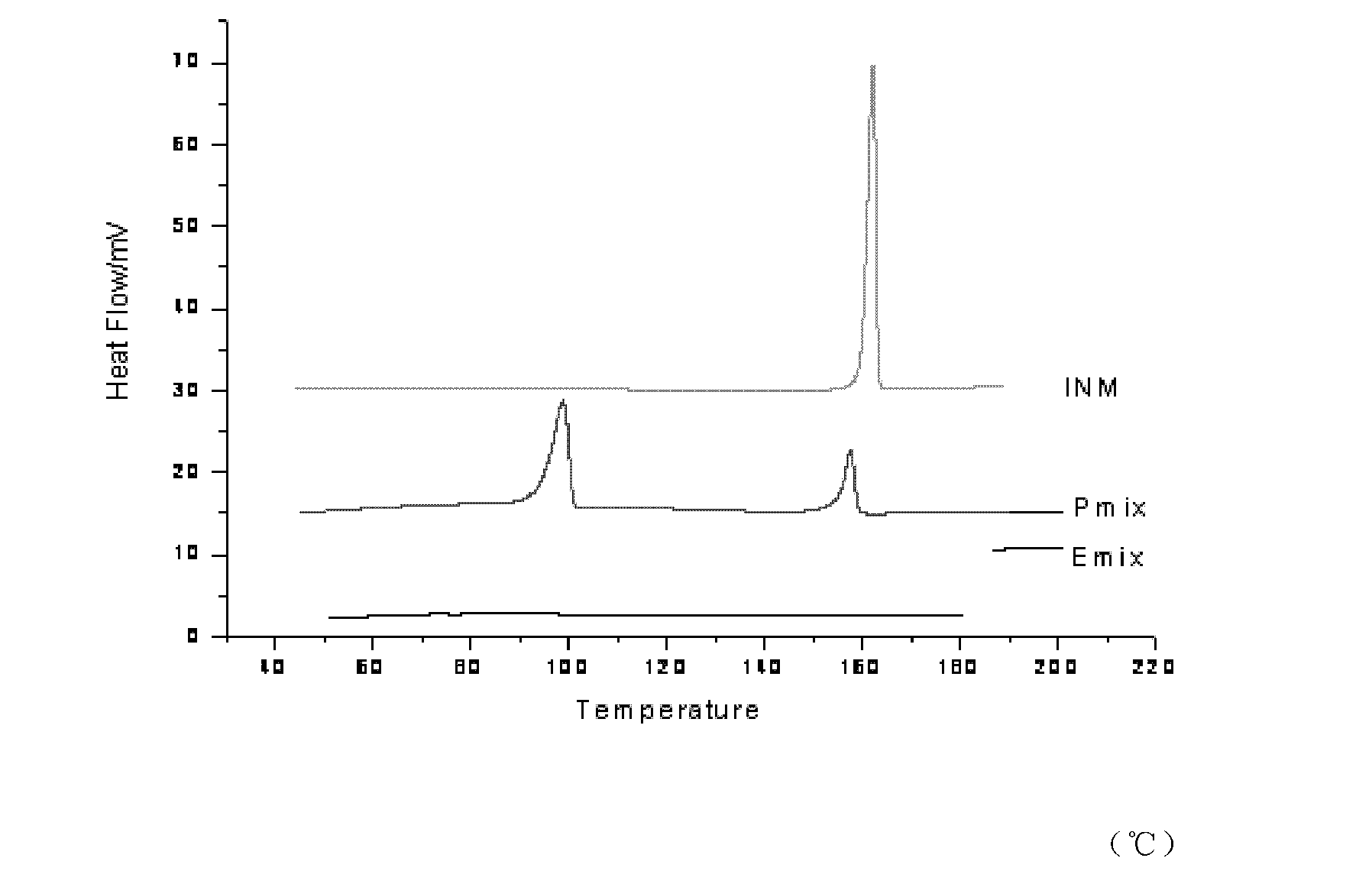

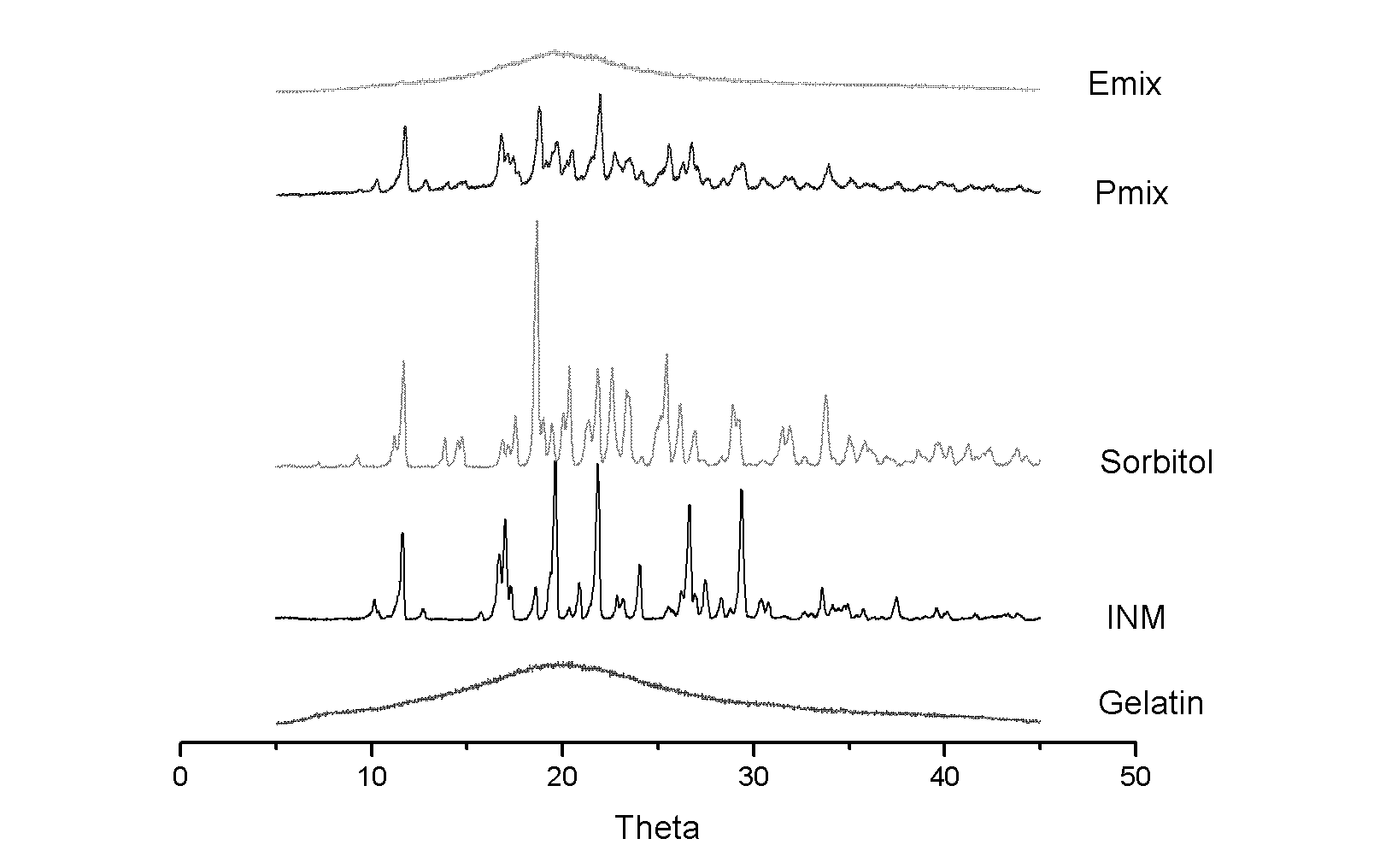

Embodiment 1

[0029] Indomethacin (25%), gelatin (37.5%), and sorbitol (37.5%) were mixed with a mixer to prepare a physical mixture, and then a twin-screw hot-melt extruder (KEYA TE-20 twin-screw extruder, Nanjing Keya Industrial Co., Ltd., the following 4 examples are the same) Set the temperature at 70°C in the first zone, 140°C in the second zone, and 130°C in the third zone. After the solid is cooled, it is pulverized and passed through a 60-mesh sieve to obtain a solid dispersion of indomethacin. Drug dissolution was 88.5% at 1 minute and 95.8% at 3 minutes. And the bulk drug reaches the highest value only 49% after one hour.

Embodiment 2

[0031] Mix indomethacin (25%), F68 (10%), sorbitol (32.5%), and gelatin (32.5%) with a mixer to prepare a physical mixture, and then set the temperature of the extruder at 110°C in the first zone, The second zone is 110°C, and the third zone is 80°C. After the temperature is stabilized, the physical mixture is added for hot-melt extrusion. The extruded strips are cooled and crushed to pass through a 60-mesh sieve to obtain a solid dispersion of indomethacin. Drug dissolution reached 93% at 1 minute and 95% at 3 minutes.

Embodiment 3

[0033] Mix indomethacin (25%), F68 (5%), IR (12.5%), sorbitol (28.75%), and gelatin (28.75%) with a mixer to prepare a physical mixture, and then set the temperature of the extruder The first zone is 120°C, the second zone is 130°C, and the third zone is 110°C. After the temperature is stabilized, the physical mixture is added for hot-melt extrusion. The extruded strips are cooled and crushed to pass through a 60-mesh sieve to obtain a solid dispersion of indomethacin. Drug dissolution reached 96% at 1 minute and 98% at 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com