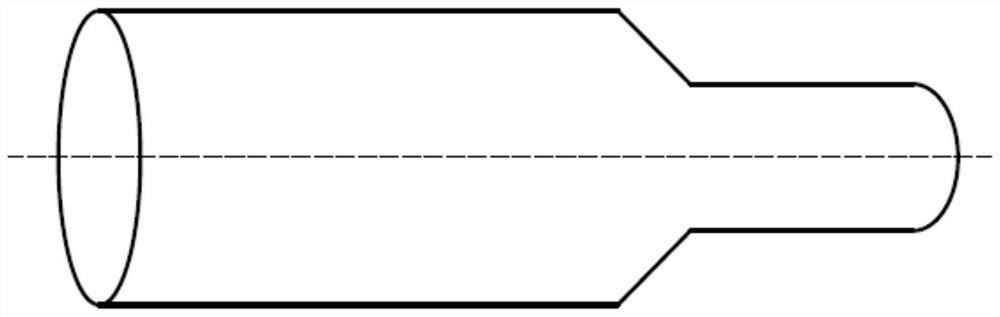

Formula, preparation method and application of heat-shrinkable sleeve

A heat-shrinkable sleeve and formula technology, applied in the directions of application, chemical instruments and methods, tubular articles, etc., can solve the problems of difficult control of glue output and stretching, high price of double-walled tubes, unfavorable production and processing, etc., and achieve good results. The effect of sealing performance, low cost, and low by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

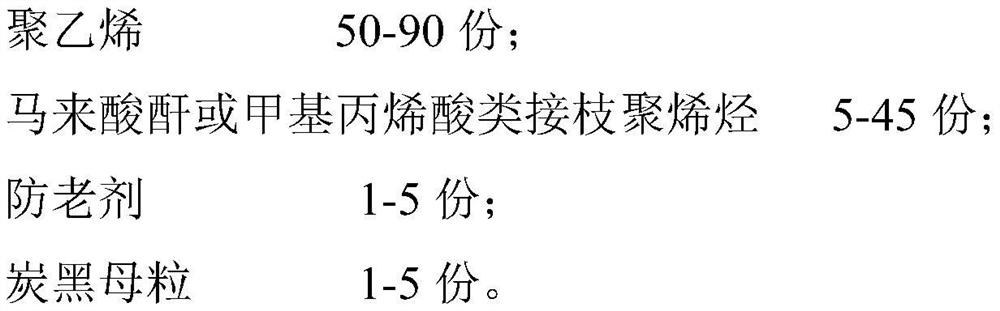

[0035] According to another embodiment provided by the present invention, it is a method for preparing a heat-shrinkable sleeve, comprising the following steps:

[0036] According to 50-90 parts of polyethylene, 5-45 parts of maleic anhydride or methacrylic grafted polyolefin, 1-5 parts of antioxidant, and 1-5 parts of carbon black masterbatch are blended and extruded through an extruder Granules, and then obtained by irradiation expansion. Preferably, the temperature of the extruder is 130-160°C. More preferably, the temperature of the extruder is 135°C.

[0037] In this preparation method, by mixing maleic anhydride or methacrylic grafted polyolefin into polyethylene, since maleic anhydride or methacrylic grafted polyolefin has both polar groups and olefin nonpolar The chain segment can have a better bonding effect with the surface of the metal pipe after heating, and it is difficult to tear off, and the temperature of the extruder only needs to be 130-160°C, which is low ...

Embodiment 1

[0041] According to 88 parts of linear low density polyethylene (melt index 4g / 10min), 10 parts of maleic anhydride graft modified polyethylene (maleic anhydride monomer content is 4%wt), 2 parts of antioxidant, 3 parts of carbon black masterbatch The parts are blended and granulated by an extruder at 135 ° C, extruded, cross-linked by irradiation, baked in an oven to soften, expanded by air expansion equipment, cooled and shaped to make a heat-shrinkable sleeve.

[0042] The performance test was carried out on the prepared heat-shrinkable sleeve, and the results are shown in Table 1 below:

[0043] Table 1. The mechanical performance test result of the heat-shrinkable sleeve prepared in embodiment 1

[0044]

[0045] The prepared heat-shrinkable sleeve shrinks on the aluminum tube after being baked at 200°C / 3min, and cannot be completely torn off by external force.

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the only difference is:

[0048] According to 50 parts of linear low density polyethylene (melt index 2g / 10min), 45 parts of maleic anhydride graft modified polyethylene (maleic anhydride monomer content is 1%wt), 4 parts of anti-aging agent, 1 part of carbon black masterbatch Parts were blended and extruded into granules through an extruder at 125°C.

[0049] The performance test was carried out on the prepared heat-shrinkable sleeve, and the results are shown in Table 2 below:

[0050] Table 2. The mechanical performance test result of the heat-shrinkable sleeve prepared in embodiment 2

[0051]

[0052] The prepared heat-shrinkable sleeve shrinks on the aluminum tube after being baked at 200°C / 4min, and cannot be completely torn off by external force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com