Instant whole-wheat crisp chips and making method thereof

A technology of chips and noodles, which is applied in the field of preparing ready-to-eat whole-wheat chips, can solve the problems of nutrient damage, wheat nutrient loss, etc., and achieve the effects of eating convenience, reducing processing costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

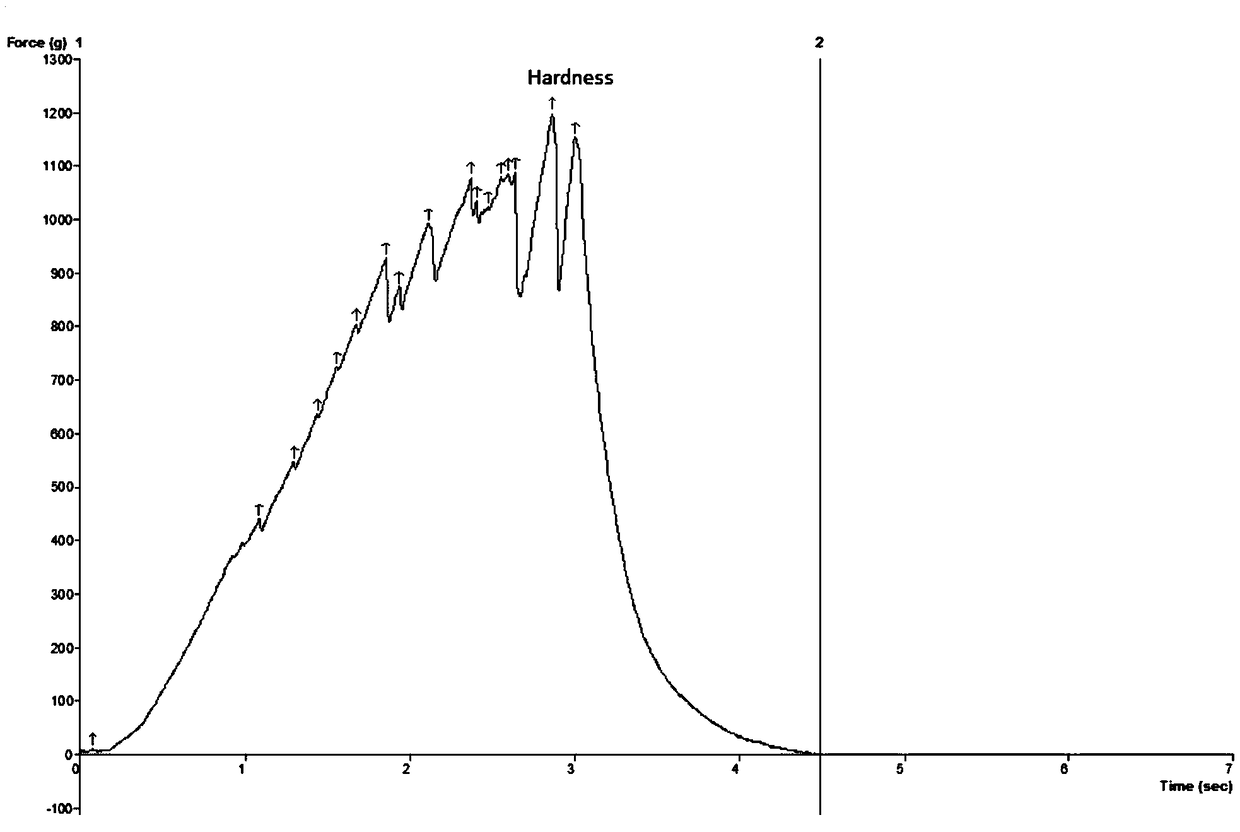

Image

Examples

Embodiment 1

[0028] A kind of ready-to-eat wholemeal crisp, its preparation method comprises the steps:

[0029] (1) Soaking, the complete wheat grains are completely submerged in water at a room temperature of 24°C until the water content of the wheat grains is 35wt%;

[0030] (2) Cooking, the wheat grains processed in step (1) are boiled in water for 10min;

[0031] (3) extruding, adding the wheat grains cooked through step (2) while hot into a twin-screw extruder (feed speed 11kg / h, the outer diameter of the die head is 1.5mm, and the screw speed is 70r / min; twin-screw extruder The temperature settings of the four zones in the press sleeve are: 65°C, 90°C, 90°C, 60°C, 60°C) for extrusion treatment to obtain strip-shaped extrudates;

[0032] (4) tablet pressing, the strip extrudate obtained in step (3) is pressed into a thickness of 1mm, a dough sheet with a width of 14.5cm, and further cut into a square dough sheet with a side length of 1.8cm;

[0033] (5) Drying, spread the square no...

Embodiment 2

[0036] A kind of ready-to-eat wholemeal crisp, its preparation method comprises the steps:

[0037] (1) Soaking, completely submerging the whole wheat grains in water at a room temperature of 24°C until the water content of the wheat grains is 40wt%;

[0038] (2) Cooking, the wheat grains processed in step (1) are boiled in water for 5min;

[0039] (3) extruding, adding the wheat grains cooked through step (2) while hot into a twin-screw extruder (feed speed 11kg / h, the outer diameter of the die head is 1.5mm, and the screw speed is 60r / min; twin-screw extruder The temperature settings of the four zones in the press sleeve are: 65°C, 70°C, 70°C, 60°C, 60°C) for extrusion treatment to obtain strip-shaped extrudates;

[0040] (4) tablet pressing, the strip extrudate obtained in step (3) is pressed into a thickness of 1mm, a dough sheet with a width of 14.5cm, and further cut into a square dough sheet with a side length of 3.0cm;

[0041] (5) Drying, spread the square noodles p...

Embodiment 3

[0044] A kind of ready-to-eat wholemeal crisp, its preparation method comprises the steps:

[0045] (1) Soaking, the complete wheat grains are completely submerged in water at a room temperature of 24°C until the water content of the wheat grains is 37wt%;

[0046] (2) cooking, the wheat grains that step (1) is processed is boiled in water for 25min;

[0047] (3) extruding, adding the wheat grains cooked through step (2) while hot into a twin-screw extruder (feed speed 11kg / h, the outer diameter of the die head is 1.5mm, and the screw speed is 100r / min; twin-screw extruder The temperature settings of the four zones in the press sleeve are: 65°C, 110°C, 110°C, 60°C, 60°C) for extrusion treatment to obtain strip-shaped extrudates;

[0048] (4) tablet pressing, the strip extrudate obtained in step (3) is pressed into a thickness of 1mm, a dough sheet with a width of 14.5cm, and further cut into square dough sheets with a side length of 3.0cm;

[0049] (5) Drying, evenly spread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com