A kind of non-oriented silicon steel for high power factor motor and its production method

A high power factor, oriented silicon steel technology, applied in the field of non-oriented silicon steel for high power factor motors and production, can solve unthinkable problems and achieve excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is described in detail below:

[0062] Table 1 is the composition value list of each embodiment of the present invention and comparative example;

[0063] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

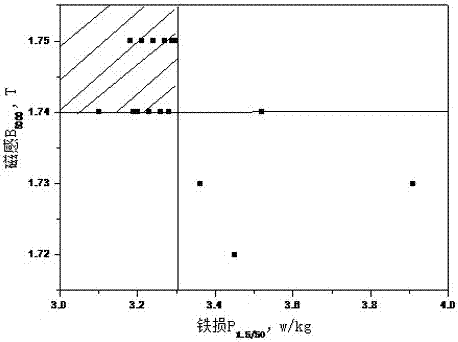

[0064] Table 3 is a list of performance detection and motor performance simulation of each embodiment of the present invention and comparative examples.

[0065] Each embodiment of the present invention carries out according to the following steps:

[0066] 1) Smelting and continuous casting into blanks by using pure steel mode;

[0067] 2) Heating the slab, controlling its heating rate to 6-10°C / min, soaking temperature at 1100-1160°C, soaking time at 30-60min;

[0068] 3) Carry out hot rolling, control the rough rolling temperature at 1000-1050°C; control the finish rolling entrance temperature at 950-1000°C, control the final rolling temperature at 750-850°C, and control the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com