Barrier strip having reinforced rib and method for making the same

A manufacturing method and reinforcing rib technology, which can be used in construction, protective equipment, etc., can solve problems such as affecting traffic safety, short service life, and easy damage, and achieve the effects of ensuring engineering and traffic safety, improving service life, and reducing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

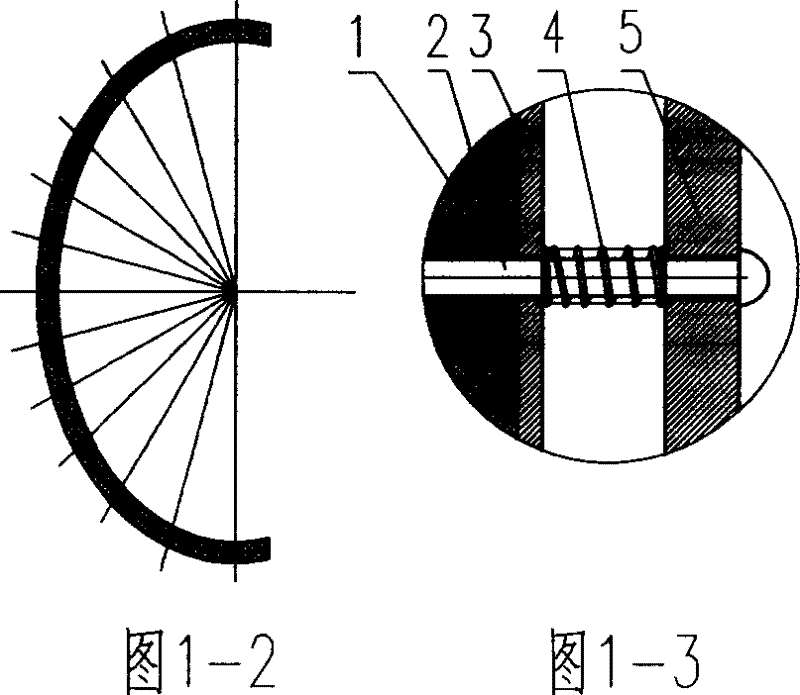

[0044] A barrier strip with stiffeners made of PC engineering plastic material, including a long strip of barrier strip 1 made of PC material and N stiffeners distributed axially in the barrier strip 1, on the axis of the barrier strip N straight holes are reserved in the direction, and N reinforcing ribs 2 are respectively installed in each reserved hole. Each reinforcing rib can be axially expanded and contracted in the reserved hole. Both ends of the reinforcing rib 2 are equipped with springs 4, which are connected with each other. The barrier plate 1 is cushioned with a backing plate 3, the other end of the spring 4 is equipped with an anchor plate 5, and the two ends of the stiffener 2 are anchored on the anchor plate 5 by upsetting (see Picture 1-1 , Figure 1-2 , Figure 1-3 ).

Embodiment 2

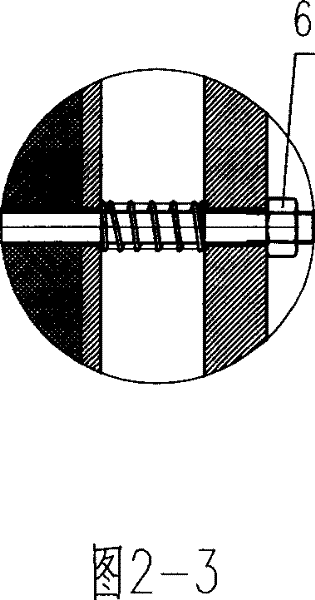

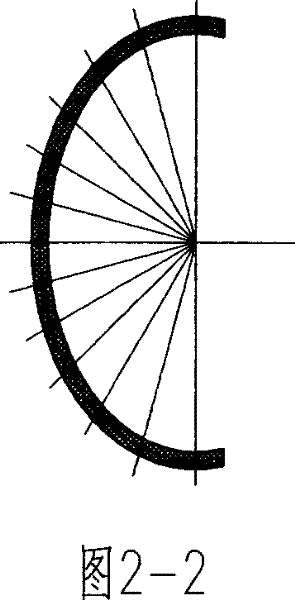

[0046] A barrier strip with reinforcing ribs made of PC engineering plastics. The basic structure is the same as that of the first embodiment. The difference is that: the two ends of the reinforcing ribs 2 are provided with external threads, and they are fixed on the anchor plate 5 by means of nuts (see diagram 2-1 , Figure 2-2 , Figure 2-3 ).

Embodiment 3

[0048] A barrier strip with reinforcing ribs made of PC engineering plastics. The basic structure is the same as that of the first embodiment. The difference is: the anchoring plate 5 is provided with tapered holes, and the two ends of each reinforcing rib 2 pass through the tapered holes, and are anchored by clamping and wedging by the clip 7 On the anchor plate 5 (see Figure 3-1 , Figure 3-2 , Figure 3-3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com